Hello All

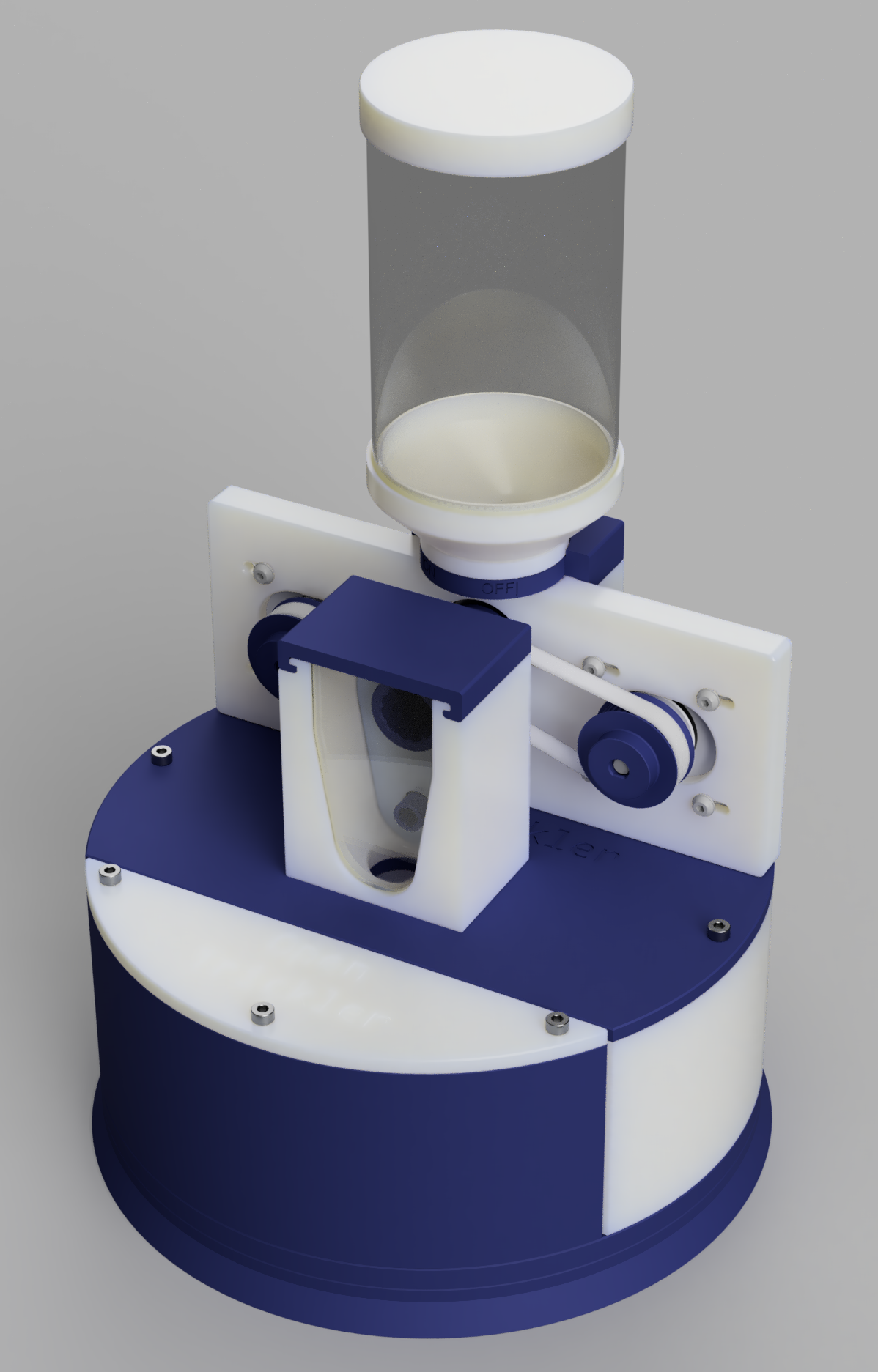

I'd like to share my open source powder trickler system the OpenTrickler

Currently the OpenTrickler supports the following precision scales

Basic function demos

Powder charge

Powder discharge

I'd like to share my open source powder trickler system the OpenTrickler

Inspired by the AutoTrickler v4 and Super Trickler, the OpenTrickler is designed be printed and assembled using garden tools.

Currently the OpenTrickler supports the following precision scales

- A&D FX-120/300 series

- G&G JJ100B series

- A functional 3D printer with minimum 200mm3 build volumn.

- Basic electronics experience and skills, including soldering and identifying basic components.

Basic function demos

Powder charge

Powder discharge

Last edited: