I've been having a issue with my Aero Solus bolt dragging on my Magpul Pro700 chassis. The issue is that as I'm running my bolt the firing pin will rotate into the "fire" position protruding my firing pin and preventing a round to chamber. So far this has caused me a minimum of 4 stages between my last two matches. I am then forced to pull my bolt out on the clock and physically rotate my firing pin back into the proper position. I can never recreate the malfunction though and it only happens in the middle of a stage which is driving me nuts. Tried calling Aero but they only have the "chat with customer service" option which is another headache lol. Just seeing if anyone else is experiencing similar issues?

- Thread starter Chato308

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Good luck. I would just file or dremel the chassis where dragging and hit it with some krylon. Done.

Is your firing pin screwed in all the way to the cocking piece ?

If you have to deal with aero customer service good luck , I just went through a multi month back and forth with them about my Solus action and chassis , be patient they will ask you one question at a time and only respond once a day if your lucky , they eventually offerd to sell me another action at dealer cost and then ghosted me when I said yes , love the Solus products but so frustrated with the company

If you have to deal with aero customer service good luck , I just went through a multi month back and forth with them about my Solus action and chassis , be patient they will ask you one question at a time and only respond once a day if your lucky , they eventually offerd to sell me another action at dealer cost and then ghosted me when I said yes , love the Solus products but so frustrated with the company

Yes, I make sure to verify before each stage and it still happens lol. But when I try to recreate the problem on purpose I can never do it. I'll try beveling my chassis where it drags and see if it helps. Worst case I'll make the detent notch a little deeper and see if that helps.Is your firing pin screwed in all the way to the cocking piece ?

If you have to deal with aero customer service good luck , I just went through a multi month back and forth with them about my Solus action and chassis , be patient they will ask you one question at a time and only respond once a day if your lucky , they eventually offerd to sell me another action at dealer cost and then ghosted me when I said yes , love the Solus products but so frustrated with the company

Sounds like your trigger pull weight is too low and the sear and cocking piece aren't mating up properly.

This would allow your firing pin to move forward as you close the bolt.

This would allow your firing pin to move forward as you close the bolt.

It doesn’t sound like an action or a trigger problem. Once the bolt is lifted, the trigger is out of the picture. The firing pin rubbing on the chassis is not normal. Sounds like the chassis is too high behind the action and it doesn’t like the small amount of vertical play in the bolt when fully extended. I think it’s a great excuse to upgrade your chassis.

That's what I figured but man do I like this chassis lol (mainly the folder) it's insanely rigid. I'll try upping the trigger weight some and see if it helps, then try to bevel the chassis if that doesn't help. Worst case I'll swap to a Grayboe or something similar

If the problem is that the stock is decocking the firing pin when the bolt is at the rear, the trigger has nothing to do with it. Trigger problems usually manifest as the firing pin dropping as you rotate the bolt handle down.

To be honest I'm not sure when it happens as I can't recreate the problem when I try on purpose. I try running the bolt while dragging it againt the chassis. I almost feel like it happens when I have my bolt lifted as I'm transitioning and then it rotates sometime between transition and bolt closing. But unfortunately I'm usually hyper focused on running the stage clean vs looking at my bolt.

This definitely sounds like a chassis clearance issue now that you’ve given more details.

I would venture to say this is not a Solus issue, as I’ve never heard of this happening before. Seems like an isolated incident.

I would venture to say this is not a Solus issue, as I’ve never heard of this happening before. Seems like an isolated incident.

I’d be more willing to bet it’s the trigger tech firing pin/sear handoff not holding than the chassis somehow rotating your bolt with linear movement.

When it happens, are you running the bolt really fast trying to beat the clock?

Every trigger tech I’ve had can have the firing pin override the sear if the bolt is slammed home super hard and fast.

When it happens, are you running the bolt really fast trying to beat the clock?

Every trigger tech I’ve had can have the firing pin override the sear if the bolt is slammed home super hard and fast.

I’d be more willing to bet it’s the trigger tech firing pin/sear handoff not holding than the chassis somehow rotating your bolt with linear movement.

When it happens, are you running the bolt really fast trying to beat the clock?

Every trigger tech I’ve had can have the firing pin override the sear if the bolt is slammed home super hard and fast.

what weight is the TT set at?

this is a hell of a claim that all your triggertech triggers fail basic operational function and safety. if that was true across the board, theres no way triggertech would still be in business.

Oh the joys of a 600$ action.........I have not experienced this. I have roughly 80 rounds and prob 500 dry fires down the barrel on one my solus. I installed a BnA Dakota single stage and it's set as low as possible weight wise. Also had a TT Special in there set at 1#. Never had any decocking happen ever. Im leaning to think that there is an event happening when cycling the bolt that the rear of bolt/cocking piece is making contact with the butt stock, and it's causing the cocking piece to drop off the detent into the valley of the cocking cam, jamming up the firing sequence.

Ensure the rear action screw is short enough to NOT protrude up into the groove the cocking piece rides in. Does the rear of bolt touch the cheek piece at all at rear most path of travel? Impact could cause this. The cocking piece could also be dragging over some part of the folder on the way back or forward causing the fp to rotate. Set up a camera to film you manipulating the bolt as you would in a field setting, play it back in slow mo, you'll find the interference eventually. The action is obviously costing you points. This is a situation where you could literally buy points by upgrading to an origin. However lose the ability to run AW mags.

Ensure the rear action screw is short enough to NOT protrude up into the groove the cocking piece rides in. Does the rear of bolt touch the cheek piece at all at rear most path of travel? Impact could cause this. The cocking piece could also be dragging over some part of the folder on the way back or forward causing the fp to rotate. Set up a camera to film you manipulating the bolt as you would in a field setting, play it back in slow mo, you'll find the interference eventually. The action is obviously costing you points. This is a situation where you could literally buy points by upgrading to an origin. However lose the ability to run AW mags.

Its not failing basically at all, they will just tell you you have the weight too low.what weight is the TT set at?

this is a hell of a claim that all your triggertech triggers fail basic operational function and safety. if that was true across the board, theres no way triggertech would still be in business.

Its happened since day 1 ttrem700 came out up until the new diamond from last year and they are well aware of it. Its not an issue in most every realistic situation but triggers overriding the sear down is far from a new or novel occurrence.

Its not failing basically at all, they will just tell you you have the weight too low.

Its happened since day 1 ttrem700 came out up until the new diamond from last year and they are well aware of it. Its not an issue in most every realistic situation but triggers overriding the sear down is far from a new or novel occurrence.

View attachment 8423423

so its not actually an issue, you just have the sear engagement turned down so much chasing a ridiculously light trigger that its unsafe.

thats not something that is exclusive to TT. I had a timney i bought from a guy that couldnt pass the drop test. completely unsafe. so, it can realistically be done on any adjustable trigger. not just TT.

At what pull weight do they stop working? I’ve got one coming. If it is no better than a factory trigger that will be a lot of $$$ for nothing.so its not actually an issue, you just have the sear engagement turned down so much chasing a ridiculously light trigger that its unsafe.

thats not something that is exclusive to TT. I had a timney i bought from a guy that couldnt pass the drop test. completely unsafe. so, it can realistically be done on any adjustable trigger. not just TT.

You cant adjust sear in a TT.so its not actually an issue, you just have the sear engagement turned down so much chasing a ridiculously light trigger that its unsafe.

thats not something that is exclusive to TT. I had a timney i bought from a guy that couldnt pass the drop test. completely unsafe. so, it can realistically be done on any adjustable trigger. not just TT.

And its not a drop test issue at all. Its a firing pin carrying overriding the top sear at speed issue.

Guys, to my understanding, the issue is NOT the trigger allowing the cocking piece to travel forward and decock. He stated the cocking piece is rotated not allowing a round be chambered. This is happening before it's getting into battery and the cocking piece is near the trigger sear. It's decocking during bolt throw somewhere......by the time the bolts coming forward to near battery, the cocking piece has fallen into the cam valley, preventing the bolt from moving ahead. To me, this doesn't sound trigger related at all.

Last edited:

Not even opening the whole bolt, just pop the handle up, then right back down. Quick and simple.If the trigger is not holding the firing pin back while closing the bolt, wouldn't opening the bolt re-cock the firing pin?

TriggerTechs are designed where you can completely remove the weight screw and the spring is internally captured in the housing, so it will never go any lower than with the screw completely removed, and it’s designed to still function perfectly this way (removed). I have the screws removed on most of mine, and never had any issue.At what pull weight do they stop working? I’ve got one coming. If it is no better than a factory trigger that will be a lot of $$$ for nothing.

If you have to take the bolt out and manually turn the bolt shroud to recock it, then it’s not a trigger issue. Check for stock, rear action screw, cheek piece or hand interference.To be honest I'm not sure when it happens as I can't recreate the problem when I try on purpose. I try running the bolt while dragging it againt the chassis. I almost feel like it happens when I have my bolt lifted as I'm transitioning and then it rotates sometime between transition and bolt closing. But unfortunately I'm usually hyper focused on running the stage clean vs looking at my bolt.

If the firing pin drops as you’re rotting the bolt handle down, then it is a trigger/sear/firing pin issue.

Don't jack with the detent notches or anything else on your bolt.Yes, I make sure to verify before each stage and it still happens lol. But when I try to recreate the problem on purpose I can never do it. I'll try beveling my chassis where it drags and see if it helps. Worst case I'll make the detent notch a little deeper and see if that helps.

Mill/cut a slot in your stock for the bottom of the cocking piece to run unimpeded during the complete bolt cycle.

While pushing forward and pulling bolt to rear (don't need to rotate the bolt handle), apply downward and lateral (pull right and down simultaneously) pressure on the handle to induce heavy drag on the bolt shroud . It's to see if the drag and lateral pressure causes an issue where the bolt shroud rotates counter clockwise (basically decocking) due to the drag while opening, closing, or both.

You want to do it multiple times back and forth to see if it's a instant clockwise rotation on a single pull or push or if it's an incremental thing where the bolt shroud slowly rotates after repeated cycles.

You want to do it multiple times back and forth to see if it's a instant clockwise rotation on a single pull or push or if it's an incremental thing where the bolt shroud slowly rotates after repeated cycles.

I just dont see what there would be on the stock to impede the bolt at all, much less apply any rotational force.

Some pics would help OP.

(admittedly this is the lite version with an impact pictured but its all I could find with the bolt at the rear and the normal version looks effectively the same in that area from what I can tell)

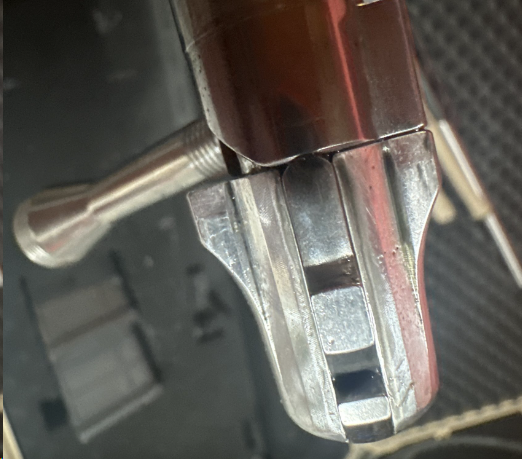

As terry mentioned, I wouldn't file on anything with the detent on the bolt but I would like to see a picture of it like this to ensure that its not teetering directly on the edge and is out of spec etc when compared to someone elses.

I was just jumping to the trigger assuming that he was using the wrong terminology.

If it really is dragging on the chassis, relieving the spring tension on the body and allowing the shroud to rotate out of battery then it should be pretty easy to diagnose, likely scratches on the area that its catching on.

Some pics would help OP.

(admittedly this is the lite version with an impact pictured but its all I could find with the bolt at the rear and the normal version looks effectively the same in that area from what I can tell)

As terry mentioned, I wouldn't file on anything with the detent on the bolt but I would like to see a picture of it like this to ensure that its not teetering directly on the edge and is out of spec etc when compared to someone elses.

I was just jumping to the trigger assuming that he was using the wrong terminology.

If it really is dragging on the chassis, relieving the spring tension on the body and allowing the shroud to rotate out of battery then it should be pretty easy to diagnose, likely scratches on the area that its catching on.

I just dont see what there would be on the stock to impede the bolt at all, much less apply any rotational force.

Some pics would help OP.

(admittedly this is the lite version with an impact pictured but its all I could find with the bolt at the rear and the normal version looks effectively the same in that area from what I can tell)

As terry mentioned, I wouldn't file on anything with the detent on the bolt but I would like to see a picture of it like this to ensure that its not teetering directly on the edge and is out of spec etc when compared to someone elses.

I was just jumping to the trigger assuming that he was using the wrong terminology.

If it really is dragging on the chassis, relieving the spring tension on the body and allowing the shroud to rotate out of battery then it should be pretty easy to diagnose, likely scratches on the area that its catching on.

i guess i just took it for granted that someone saying something is dragging on the stock would have pulled the action out and inspected and identified where exactly it was dragging on the stock. but here we are....

I already stated that above.i guess i just took it for granted that someone saying something is dragging on the stock would have pulled the action out and inspected and identified where exactly it was dragging on the stock. but here we are....

Yeah, that’s a Magpul issue, not a Solus issue…

I’d contact Magpul about it to let them know it’s happening and show them the pictures. They definitely need to redesign that portion of the chassis to avoid that from happening with any other 700 footprint actions.

Most chassis drop right after the tang, even of just 1/4” to 1/2” to avoid things like that. I don’t think Magpul thought that out and tested that design thoroughly before releasing them. And that’s not a shot at Magpul, I use tons of their stuff, but it’s not the first time they’ve managed to barely fuck up tolerances causing an issue…

Example, I can’t use MDT steel .223 AICS mags in my Ruger American Ranch with a Magpul Hunter Stock and their bottom metal. It sits JUST slightly too low (non-adjustable latch design) and won’t feed reliably. If I use Magpul .223 AICS mags, it feeds perfectly.

I’d contact Magpul about it to let them know it’s happening and show them the pictures. They definitely need to redesign that portion of the chassis to avoid that from happening with any other 700 footprint actions.

Most chassis drop right after the tang, even of just 1/4” to 1/2” to avoid things like that. I don’t think Magpul thought that out and tested that design thoroughly before releasing them. And that’s not a shot at Magpul, I use tons of their stuff, but it’s not the first time they’ve managed to barely fuck up tolerances causing an issue…

Example, I can’t use MDT steel .223 AICS mags in my Ruger American Ranch with a Magpul Hunter Stock and their bottom metal. It sits JUST slightly too low (non-adjustable latch design) and won’t feed reliably. If I use Magpul .223 AICS mags, it feeds perfectly.

As much as I would like to believe that, Magpul could care less about redesigning their chassis. I've been complaining about their thin polymer magwell being too flimsy and flexing under load but they think it's a non issue. I'll just try cutting a groove but I feel like the problem might be the folder button as that's where most of the wear is atYeah, that’s a Magpul issue, not a Solus issue…

I’d contact Magpul about it to let them know it’s happening and show them the pictures. They definitely need to redesign that portion of the chassis to avoid that from happening with any other 700 footprint actions.

I own two of the Magpul Chassis, I love them. I'm running actual 700's in mine without issue.

I didn't read every single post, but I did see you were unable to recreate it.

Have you tried loading a mag full of dummy rounds and cycling them as you do during a match?

It might be a combination of things and you need to recreate every part of the cycle.

Good luck, hope you resolve it. Looks like your on the right track with the dragging issue.

I didn't read every single post, but I did see you were unable to recreate it.

Have you tried loading a mag full of dummy rounds and cycling them as you do during a match?

It might be a combination of things and you need to recreate every part of the cycle.

Good luck, hope you resolve it. Looks like your on the right track with the dragging issue.

I had a R700 action in this exact chassis and have ran it for years without issue, I definitely agree with you there. I'll load up some dummy rounds and see how that pans outI own two of the Magpul Chassis, I love them. I'm running actual 700's in mine without issue.

I didn't read every single post, but I did see you were unable to recreate it.

Have you tried loading a mag full of dummy rounds and cycling them as you do during a match?

It might be a combination of things and you need to recreate every part of the cycle.

Good luck, hope you resolve it. Looks like your on the right track with the dragging issue.

I don't think it is so much of a redesign, as your chassis is milled to low. I think there have been other people here on the Hide that hare running Solus actions in the Magpul chassis without issue.As much as I would like to believe that, Magpul could care less about redesigning their chassis.

I would take one of your other Rem 700 actions and see if they have the same issue, that will definitely tell you that there is an issue with the chassis.

If you look at the release button, the bolt is even dragging on that as well, so I do not be leave he could even fix the issue.Have you put some lipstick or colored grease on the bottom of the bolt and run it hard maybe with dummy rounds to see exactly where it is touching (yeah I probably missed it, but if so sorry).

That is from his cocking piece hitting the edge of the slot AFTER it was already rotated out of position when the bolt was as full retraction.This stands out to me more than the Chassis rub marks.

Bolt comes fully to the rear with everything in place. No contact on your circled area.

Cocking piece of bolt gets slapped against the chassis and folder button during the transition from rearward to forward movement. Bolt goes forward but with the firing pin assembly now rotated out of position counter-clockwise which would make that deformity on the edge of the slot.

I don't think his chassis is milled too low.I don't think it is so much of a redesign, as your chassis is milled to low. I think there have been other people here on the Hide that hare running Solus actions in the Magpul chassis without issue.

I would take one of your other Rem 700 actions and see if they have the same issue, that will definitely tell you that there is an issue with the chassis.

If that were the case, he would be having issues with the Z-axis magazine position under the receiver.

The SOLUS receivers are pretty much Rem 700 footprint but the bolts are a completely different animal. Totally different diameter body and different shroud/cocking piece design.

Past experience with Rem 700 actions have no bearing on the OP's issue.

Guys, to my understanding, the issue is NOT the trigger allowing the cocking piece to travel forward and decock. He stated the cocking piece is rotated not allowing a round be chambered. This is happening before it's getting into battery and the cocking piece is near the trigger sear. It's decocking during bolt throw somewhere......by the time the bolts coming forward to near battery, the cocking piece has fallen into the cam valley, preventing the bolt from moving ahead. To me, this doesn't sound trigger related at all.

It can't fall into the cam valley unless the bolt is rotated downward.

The firing pin can go forward as if it were fired, but there's no way for it to rotate into the valley.

The cocking piece/firing control can sure fall into the cam valley its twisted or struck by something. Only time it can't is if the cocking piece is inside the raceway at the rear tang it rides in prior to closing the bolt. I've removed bayonet style fire control groups from bolts many times without actually pulling the bolt. So yes, it can rotate without the bolt being moved.It can't fall into the cam valley unless the bolt is rotated downward.

The firing pin can go forward as if it were fired, but there's no way for it to rotate into the valley.

You can remove the bayonet style with the bolt to the rear, but not with it in battery. It won't rotate because of the flat on the bottom of the shroud.

It won't go into battery with the shroud twisted enough to allow the firing pin to drop.

What I'm seeing is the real possibility of the contact with the chassis, causing damage to the cocking piece and allowing it to override the trigger, preventing hand off.

I just took three pics on my Origin action to show what I'm saying.

Decocked, showing how far the bolt will go into the action.

Decocked, showing the position of the cocking piece, and how it cannot go into the body of the action.

Cocked, but not in battery. Showing the cocking piece groove in the receiver. It needs to be able to ride through this trough to allow it to go into battery and also allow the handoff.

If there is any, even minor damage to the leading edge, the trigger cannot pick up the cocking piece with any certainty.

It won't go into battery with the shroud twisted enough to allow the firing pin to drop.

What I'm seeing is the real possibility of the contact with the chassis, causing damage to the cocking piece and allowing it to override the trigger, preventing hand off.

I just took three pics on my Origin action to show what I'm saying.

Decocked, showing how far the bolt will go into the action.

Decocked, showing the position of the cocking piece, and how it cannot go into the body of the action.

Cocked, but not in battery. Showing the cocking piece groove in the receiver. It needs to be able to ride through this trough to allow it to go into battery and also allow the handoff.

If there is any, even minor damage to the leading edge, the trigger cannot pick up the cocking piece with any certainty.

@Mike Casselton were saying the same exact thing to the OP. That the cocking piece is rotating a ways back before cocking piece is even getting close the to sear.

@Mike Casselton were saying the same exact thing to the OP. That the cocking piece is rotating a ways back before cocking piece is even getting close the to sear.

I was thinking that too, so maybe I'm reading it incorrectly. It has been a very long day.

I didn't see where he said he had to remove the bolt to fix it, just lift it and he was good to go.

Or, did someone else say that?

From the original post:

…I am then forced to pull my bolt out on the clock and physically rotate my firing pin back into the proper position…

"autofire". I know this all to well. Happened to my 6 arc AR build using their Diamond 2 stage. Started happening after 200rds. Had to adjust the trigger up to over 34oz to make sure autofire wouldn't happen. They told me "sorry, here's the faq on this issue and clean it with lighter fluid". Half of the autofires it would continue until mag emptied. Glad it didn't happen during a match.Its not failing basically at all, they will just tell you you have the weight too low.

Its happened since day 1 ttrem700 came out up until the new diamond from last year and they are well aware of it. Its not an issue in most every realistic situation but triggers overriding the sear down is far from a new or novel occurrence.

View attachment 8423423

AgreedThis is not a trigger issue.

Loaded up some dummy rounds today. With a loaded mag the bullets push up on the bolt as expected and then forces the rear of the bolt to touch the folder button when I have the bolt to the rear. Similar to the picture I posted above but I'll go ahead and post again. I still can't recreate the issue though

Attachments

Similar threads

- Replies

- 3

- Views

- 152