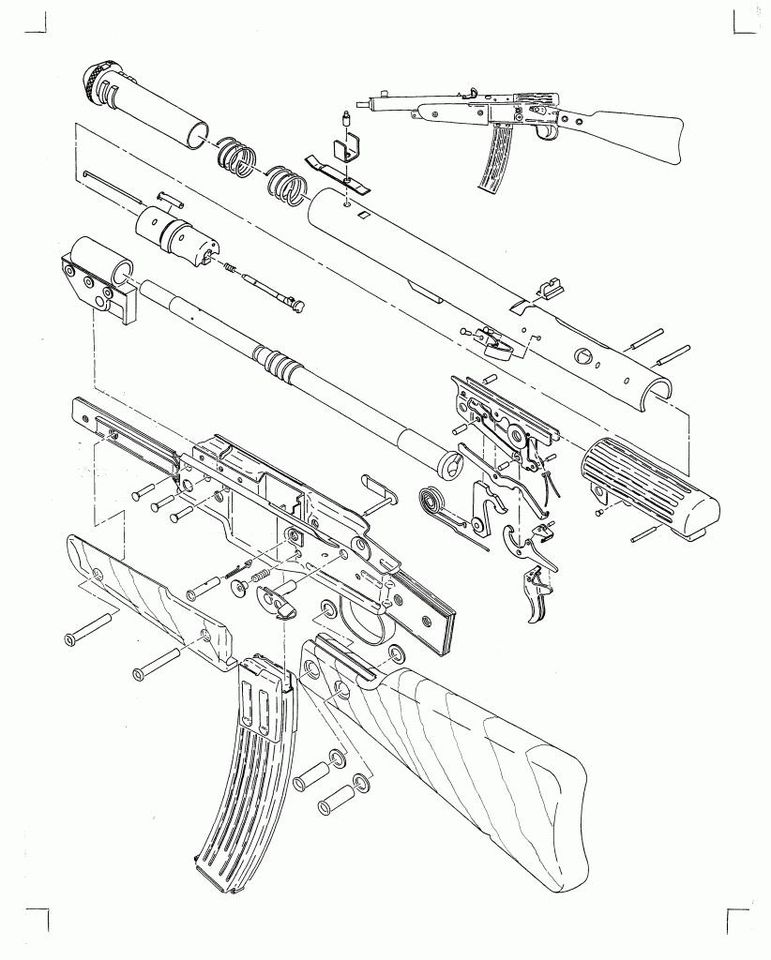

And by Anti-Sniper I mean the antithesis of a sniper rifle. The Gewehr VG1-5 was one of Hitler's last ditch weapons intended for distribution to the Volksswehr...or people's army, made up of men over 60 and boys 16 and under...all other men already being required for national service. The VG1-5 was a semi-auto only rifle in 7,92x33 Kurz, using the same magazine and cartridge as the MP44.

Allegheny Arsenal makes a copy of this for $4500. I tried to get on the waiting list for one but was told they aren't really taking any more people for the waiting list. So I'll have to make my own. I'm not going to make a clone...that would be far too complicated. Allegheny Arsenal/Gun Lab has been working on theirs for the past several years and only finished the first five last year. I will make something visually similar. I have decided to base it around the Sten MKII due to the availability of parts.

The VG1-5 is pretty much a straight blow back operated rifle. There are four holes in the forward part of the barrel that vent gas into a barrel shroud to retard blow back. These four holes aren't really necessary. At first i was going to use the 7.92x33 cartridge but I would have had to open up the bolt face and change the extractor. Since I'm not making an exact clone...or even a close clone...I decided to make it in 9mm. Way cheaper, way easier. To aid in the visual deception i purchased an Airsoft Mp44 to serve as a parts donor. The airsoft gun is made of pot metal, but I was mainly interested in the magazine housing. The magazine is made of steel and appears to be a replacement mag for the MP44 rifle that has had the follower removed. I could interchange my real MP44 mag with the airsoft mag with no problem.

I also decided to use Sterling magazines, which are superior to the ordinary Sten mags. They have a double roller follower which makes for smooth loading. I cut the base plate of the Sterling and welded it so it would fit inside the Airsoft Mp44 mag.

I welded a Sterling mag assembly to the Sten tube. I'll cut the mag well off the Airsoft MP44 and will weld it to the Sten tube. When finished, the mp44 mage will have the upper most portion of the Sten mag slide into the Sten mag well which sits inside the Mp44 mag well. The Mp44 mag well will hold the mag in place and utilize the Mp44 mag release. The Sten mag well will be cut down from what is shown in the photo. It will not be visible when done, shrouded by the Mp44 mag well.

I made a stock out of Birch, like the original, and fabricated a close copy of the front sight.

Now I am waiting on my tubing to fabricate the reciprocating barrel shroud which also serves as the charging handle.

Allegheny Arsenal makes a copy of this for $4500. I tried to get on the waiting list for one but was told they aren't really taking any more people for the waiting list. So I'll have to make my own. I'm not going to make a clone...that would be far too complicated. Allegheny Arsenal/Gun Lab has been working on theirs for the past several years and only finished the first five last year. I will make something visually similar. I have decided to base it around the Sten MKII due to the availability of parts.

The VG1-5 is pretty much a straight blow back operated rifle. There are four holes in the forward part of the barrel that vent gas into a barrel shroud to retard blow back. These four holes aren't really necessary. At first i was going to use the 7.92x33 cartridge but I would have had to open up the bolt face and change the extractor. Since I'm not making an exact clone...or even a close clone...I decided to make it in 9mm. Way cheaper, way easier. To aid in the visual deception i purchased an Airsoft Mp44 to serve as a parts donor. The airsoft gun is made of pot metal, but I was mainly interested in the magazine housing. The magazine is made of steel and appears to be a replacement mag for the MP44 rifle that has had the follower removed. I could interchange my real MP44 mag with the airsoft mag with no problem.

I also decided to use Sterling magazines, which are superior to the ordinary Sten mags. They have a double roller follower which makes for smooth loading. I cut the base plate of the Sterling and welded it so it would fit inside the Airsoft Mp44 mag.

I welded a Sterling mag assembly to the Sten tube. I'll cut the mag well off the Airsoft MP44 and will weld it to the Sten tube. When finished, the mp44 mage will have the upper most portion of the Sten mag slide into the Sten mag well which sits inside the Mp44 mag well. The Mp44 mag well will hold the mag in place and utilize the Mp44 mag release. The Sten mag well will be cut down from what is shown in the photo. It will not be visible when done, shrouded by the Mp44 mag well.

I made a stock out of Birch, like the original, and fabricated a close copy of the front sight.

Now I am waiting on my tubing to fabricate the reciprocating barrel shroud which also serves as the charging handle.

Last edited: