I have a RangeX, and as much as i like it, it has no mount, and no 1/4-20 threaded hole for mounting.

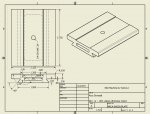

I'm going to fire up my CAD computer today and design a polymer 3d printable rail mount.

If theres any interest, i can upload the files to Thingiverse for use by anyone who would like to 3d print one, have it printed?

My spotter setup would work best with a LRF side rail mount, but it wouldn't take much for me to modify the design and post up a bottom mount version as well.

Or, i suppose i could just design one version with a bottom rail mount and a mount on each side?

I'm going to fire up my CAD computer today and design a polymer 3d printable rail mount.

If theres any interest, i can upload the files to Thingiverse for use by anyone who would like to 3d print one, have it printed?

My spotter setup would work best with a LRF side rail mount, but it wouldn't take much for me to modify the design and post up a bottom mount version as well.

Or, i suppose i could just design one version with a bottom rail mount and a mount on each side?