So I'm considering a Mausingfield build with the following ideas. This'll be a long one sorry as I have a few ideas swirling around. Let us know what you think.

- Firstly; I at minimum want to use a long action. If the .585" (Lapua) action is the same footprint as the standard long action, I'll use it and buy two spare bolts in .540" and .470". Can anyone confirm that? Is the Lapua Mag bolt face M5 even available yet?

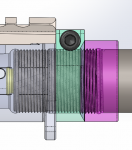

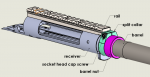

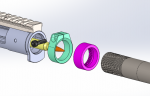

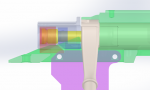

- Secondly; I'm wanting to set it up as a switch barrel using the West Texas Ordnance SwitchLug. To do so, I'll need to pin it to the integral lug of the Mausingfield. Can anyone foresee any issues securing the switch lug to the ARC M5? Furthermore, does the Long action (.540" and .585") have the same .185" thick recoil lug as the short action M5?

- Thirdly; I want to use a KRG Xray stock. Will the long action M5 have any fitment issues? KRG states that the Xray has a .400" lug pocket. Has anyone ever milled one larger? I'll need to mill it an extra .135" to accommodate the M5 integral lug AND SwitchLug sandwiched together. KRG have been very helpful providing pictures on how much larger the pocket can go. Seems like it's doable.

- Fourthly; I want to use the Bix n Andy Tacsport Two stage trigger. Anyone know of any fitment issues with either the Xray or ARC M5?

Let me know what you think.

- Firstly; I at minimum want to use a long action. If the .585" (Lapua) action is the same footprint as the standard long action, I'll use it and buy two spare bolts in .540" and .470". Can anyone confirm that? Is the Lapua Mag bolt face M5 even available yet?

- Secondly; I'm wanting to set it up as a switch barrel using the West Texas Ordnance SwitchLug. To do so, I'll need to pin it to the integral lug of the Mausingfield. Can anyone foresee any issues securing the switch lug to the ARC M5? Furthermore, does the Long action (.540" and .585") have the same .185" thick recoil lug as the short action M5?

- Thirdly; I want to use a KRG Xray stock. Will the long action M5 have any fitment issues? KRG states that the Xray has a .400" lug pocket. Has anyone ever milled one larger? I'll need to mill it an extra .135" to accommodate the M5 integral lug AND SwitchLug sandwiched together. KRG have been very helpful providing pictures on how much larger the pocket can go. Seems like it's doable.

- Fourthly; I want to use the Bix n Andy Tacsport Two stage trigger. Anyone know of any fitment issues with either the Xray or ARC M5?

Let me know what you think.