Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

300 wsm - 212 or 241 seneca

- Thread starter Schw15

- Start date

Now that is a good looking round wow!!! I have a arc nucleus with cip mags most I think is 3.760ishView attachment 7690769

I guess it really depends on the magazine. Here's my .300NM load with 3.91" COAL and it fits just fine in an SRS mag.

What powder are you using with the 230? I have imr 8133 might be to slow......View attachment 7690947

300 WSM, 230 Berger Hybrid, 3.200” OAL to put BT / bearing junction @ N / S junction.

You could do 241 fairly easily, just determine needed freebore and have a reamer ground.

What powder are you using with the 230? I have imr 8133 might be to slow......

8133 works fine for me in the 220-250 grain range, but 300 RUM and >4" COAL.

Yes great powder for 300 win mag. 7 mag 28 nosler and I use it in a 7mm-300 win mag. Was thinking something different 300 wsm but powder shortage for got I can't just buy what we want when we want now.8133 works fine for me in the 220-250 grain range, but 300 RUM and >4" COAL.

I could see N560 or N565 and R26 being awesome in 300WSM with heaviesYes great powder for 300 win mag. 7 mag 28 nosler and I use it in a 7mm-300 win mag. Was thinking something different 300 wsm but powder shortage for got I can't just buy what we want when we want now.

High density and energy

T

According to the product page the optimal freebore is 0.090"-0.165" I'd suggest getting in contact with PVA and ask them about the specs you need.

What would be a suitable freebore for the 212 in a 300 Norma.

According to the product page the optimal freebore is 0.090"-0.165" I'd suggest getting in contact with PVA and ask them about the specs you need.

My 7 twist barrel is 0.160” freebore, based on a recommendation from Josh K. It works correctly with both the 212 and 241 Seneca, and i can load both bullets to a small jump.

The bullet is not full diameter until it gets to the first bore rider/pressure ring which is way to the back of the bullet. The full .308” diameter bearing surface is quite short, with a pressure relief gap in the middle. So the super short freebore works just fine.

The bullet is not full diameter until it gets to the first bore rider/pressure ring which is way to the back of the bullet. The full .308” diameter bearing surface is quite short, with a pressure relief gap in the middle. So the super short freebore works just fine.

Btw due to the severe powder shortage, i ended up using 4000MR, because i could not find Reloder-26 or N570/N565 anywhere.

It is a little more temperature sensitive than i would like, but i get good speed from it. Almost on par with RL-26. During cold winter days (40-45 deg F), speed drops 10-20 fps. When the barrel gets hot (140 deg F), speed goes up 20 fps. ES ended up at 35 fps, 2x more than i would like.

Will develop a new load when i get my hands on a better powder.

It is a little more temperature sensitive than i would like, but i get good speed from it. Almost on par with RL-26. During cold winter days (40-45 deg F), speed drops 10-20 fps. When the barrel gets hot (140 deg F), speed goes up 20 fps. ES ended up at 35 fps, 2x more than i would like.

Will develop a new load when i get my hands on a better powder.

Minor update:

1) The 212 Seneca bullets had an average weight of 210.6 grain, and the PVA folks explained that this is normal. The shape the CNC machine is programmed to cut stays exactly the same, but the density of the bar stock changes slightly from batch to batch. All mono bullets have this issue, but the weight change is too small to really matter. Very consistent weight range (0.3 gn), and base to ogive are all within vernier measurement error.

2) SG for the 212 Seneca is 1.7 at a twist rate of 7.0, and all the bullets flew well, always stable with nice round holes in paper. Good!

3) With 4000MR, i could get the as-measured 210.6 gn bullets to 2,960 fps before i got a very hard bolt lift. But the soft Norma brass starts to open up its primer pockets around 2,900 fps (no HBN used). Planning to buy ADG brass later in 2022 when the second batch is hopefully released.

4) Found a 1.0 grain wide speed node at 2,870 fps. The secondary/lower node is at 2,755 fps and is also 1 grain wide: These super wide nodes are apparently a feature of the 300 WSM. Very useful.

5) Optimized seating depth from a 40 thou jump down to a 3 thou jump. Got a window of 6 thou where group size was under 0.3”, with very tight groups, and often two bullets in one round hole. Quite impressive, actually!

6) For long jumps it is entirely possible to take the load completely out of tune, and get a 2” plus group. It went from a 2.5” groups to a tiny 0.19” in just a 12 thou change in jump. Bullet is easy to tune, but in my application, it does need to be tuned.

Very happy with group size. My ES is just too high, 4000MR powder is somewhat temp sensitive. According to the Lee load manual, it gives nearly the same velocity as RL-26, for the heavies.

1) The 212 Seneca bullets had an average weight of 210.6 grain, and the PVA folks explained that this is normal. The shape the CNC machine is programmed to cut stays exactly the same, but the density of the bar stock changes slightly from batch to batch. All mono bullets have this issue, but the weight change is too small to really matter. Very consistent weight range (0.3 gn), and base to ogive are all within vernier measurement error.

2) SG for the 212 Seneca is 1.7 at a twist rate of 7.0, and all the bullets flew well, always stable with nice round holes in paper. Good!

3) With 4000MR, i could get the as-measured 210.6 gn bullets to 2,960 fps before i got a very hard bolt lift. But the soft Norma brass starts to open up its primer pockets around 2,900 fps (no HBN used). Planning to buy ADG brass later in 2022 when the second batch is hopefully released.

4) Found a 1.0 grain wide speed node at 2,870 fps. The secondary/lower node is at 2,755 fps and is also 1 grain wide: These super wide nodes are apparently a feature of the 300 WSM. Very useful.

5) Optimized seating depth from a 40 thou jump down to a 3 thou jump. Got a window of 6 thou where group size was under 0.3”, with very tight groups, and often two bullets in one round hole. Quite impressive, actually!

6) For long jumps it is entirely possible to take the load completely out of tune, and get a 2” plus group. It went from a 2.5” groups to a tiny 0.19” in just a 12 thou change in jump. Bullet is easy to tune, but in my application, it does need to be tuned.

Very happy with group size. My ES is just too high, 4000MR powder is somewhat temp sensitive. According to the Lee load manual, it gives nearly the same velocity as RL-26, for the heavies.

Last edited:

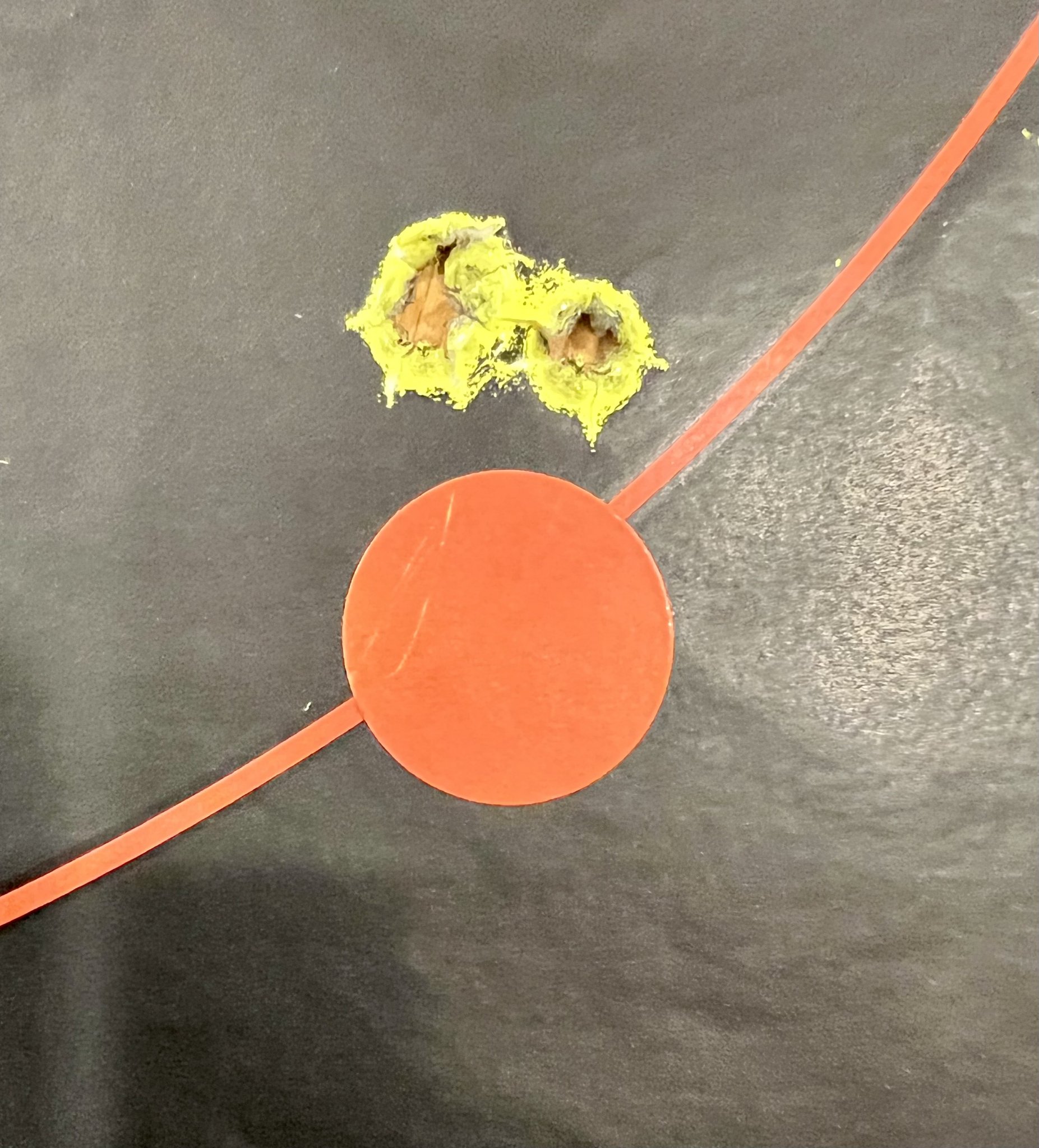

After optimizing seating depth for the 212 gn Seneca, i got these 0.2-0.3” groups.

These are all three shot groups at 100, just too expensive to shoot 5 shot groups.

Just outside of the 6 thou seating window where groups are optimal, my groups opened up to 0.5” to 0.7”, often with two or three in one hole and another 0.5” or more away. Pretty tolerant to changes in jump. But seating depth optimization was needed in my rifle. No barrel tuner on this rifle (yet).

It was very easy to tune this load.

These are all three shot groups at 100, just too expensive to shoot 5 shot groups.

Just outside of the 6 thou seating window where groups are optimal, my groups opened up to 0.5” to 0.7”, often with two or three in one hole and another 0.5” or more away. Pretty tolerant to changes in jump. But seating depth optimization was needed in my rifle. No barrel tuner on this rifle (yet).

It was very easy to tune this load.

Attachments

Last edited:

I’m having trouble with these in my 300wm. 198’s and 212’s. Last batch I loaded up for testing I had set a round down on my bench to reach for my ammo box. It started to role towards the edge and I figured out why things were so erratic. Get 2 in the same hole and one an inch away. Concentricity was .017” out  . Going to have to get a different seating stem for these. Normally I check a few in each batch but seamed like a waste of time when everything else is like .002-3” out when measured on the bullet of a loaded round. Good news is my brass is very concentric. With the short bearing surface and long nose that seater is just pushing them any which way they want to go

. Going to have to get a different seating stem for these. Normally I check a few in each batch but seamed like a waste of time when everything else is like .002-3” out when measured on the bullet of a loaded round. Good news is my brass is very concentric. With the short bearing surface and long nose that seater is just pushing them any which way they want to go

Several times I thought I had my load shooting a tiny little group. Go to confirm and boom 2” group.

Wasted a bunch of components and barrel life chasing my tail. Lesson learned like normal… the hard way

Several times I thought I had my load shooting a tiny little group. Go to confirm and boom 2” group.

Wasted a bunch of components and barrel life chasing my tail. Lesson learned like normal… the hard way

Is the seating stem messing the bullets up anywhere? Or hard to seat? I know I had a stem that was denting the sharp point of the 120 version.I’m having trouble with these in my 300wm. 198’s and 212’s. Last batch I loaded up for testing I had set a round down on my bench to reach for my ammo box. It started to role towards the edge and I figured out why things were so erratic. Get 2 in the same hole and one an inch away. Concentricity was .017” out. Going to have to get a different seating stem for these. Normally I check a few in each batch but seamed like a waste of time when everything else is like .002-3” out when measured on the bullet of a loaded round. Good news is my brass is very concentric. With the short bearing surface and long nose that seater is just pushing them any which way they want to go

Several times I thought I had my load shooting a tiny little group. Go to confirm and boom 2” group.

Wasted a bunch of components and barrel life chasing my tail. Lesson learned like normal… the hard way

I pulled the stem. Bullet just flops around in it. Doesn’t hit the tip but definitely needs a sharper angle to it. Seats vlds fine but these are sharper angled meaplates than vld Checking on options

What dies?I pulled the stem. Bullet just flops around in it. Doesn’t hit the tip but definitely needs a sharper angle to it. Seats vlds fine but these are sharper angled meaplates than vld Checking on options

I had to hone my whidden die for the badlands bullets

Maybe this weekend l will make a custom bullet stem for it.

Maybe this weekend l will make a custom bullet stem for it.

^Same here but with the Sherman Hornady dies for the 6.5 Max. Just drilled out the stem a bit - it was crushing the LHRT tips. Badlands were fine because aluminum tips, and I don't run much neck tension, but clearly better if the force on the projectile is distributed.

I wanna see how that turns out, then I’ll send ya mineI had to hone my whidden die for the badlands bullets

Maybe this weekend l will make a custom bullet stem for it.

I have a rcbs set and a lee custom set. Neither one will work for these needles lol

Pretty easy part to make really.I wanna see how that turns out, then I’ll send ya mine

I have a rcbs set and a lee custom set. Neither one will work for these needles lol

I’ll probably be cutting a new 338 barrel this weekend so probably do it then.

Green with envyPretty easy part to make really.

I’ll probably be cutting a new 338 barrel this weekend so probably do it then.

[Did not see the similar post from Chickentoast in time, apologies!]I’m having trouble with these in my 300wm. 198’s and 212’s. Last batch I loaded up for testing I had set a round down on my bench to reach for my ammo box. It started to role towards the edge and I figured out why things were so erratic. Get 2 in the same hole and one an inch away. Concentricity was .017” out. Going to have to get a different seating stem for these. Normally I check a few in each batch but seamed like a waste of time when everything else is like .002-3” out when measured on the bullet of a loaded round. Good news is my brass is very concentric. With the short bearing surface and long nose that seater is just pushing them any which way they want to go

Several times I thought I had my load shooting a tiny little group. Go to confirm and boom 2” group.

Wasted a bunch of components and barrel life chasing my tail. Lesson learned like normal… the hard way

I had a similar issue: The Seneca bullet is so long the very sharp point touches the inside (top) of the seating stem hole, and the Hornady seating stem (for their Custom Grade two die set) which is meant for the 230 grain Atip was not contacting the ogive of the bullet. Tip got damaged and concentricity was poor. So i drilled a hole inside the seating stem to avoid contact with the tip. That worked better.

Also had to reduce neck tension as the seating force was way too high - even though i was annealing every time (16 thou necks on the Norma 300 WSM brass). Seating stem left deep indentations on the bullet nose.

I now ‘paint’ the inside of the necks with Neolube nr 2, a suspended (liquid) carbon lubricant that dries quickly, and that seems to help. [The Keith Glasscock F-class trick.]

For various reasons (better feel), i switched to the LE Wilson seater and a small arbor press, and concentricity improved further.

Btw: Had to readjust the Wilson seating stem way down to make the seater work correctly with the long bullet. Also drilled a hole inside the Wilson seating stem, but not sure if it really needed it. Just wanted to be sure. See pics below.

Last edited:

Bullet tips are not making contact in either of my dies. But the only spot it does contact the bullet is a bout 1/8” from the tip and it does make a ring on the nose. Like a free tubb ring. I polished it a bit and that helped with the ring marks a little but still such a floppy fit. Been thinking about getting a set of whidden dies

I like the forester seater dies and easy to polish out to work well. Used them with the 230 a-tip no solids thoughBullet tips are not making contact in either of my dies. But the only spot it does contact the bullet is a bout 1/8” from the tip and it does make a ring on the nose. Like a free tubb ring. I polished it a bit and that helped with the ring marks a little but still such a floppy fit. Been thinking about getting a set of whidden dies

Hmmm this gives me an idea. I’ll see if I can swap out one of my seater stems. Thanks hadn’t thought about thatI had a 25 prc and shot the 120 but while loading them I had hornady dies and used a 6mm stem and worked great

Bullet tips are not making contact in either of my dies. But the only spot it does contact the bullet is a bout 1/8” from the tip and it does make a ring on the nose. Like a free tubb ring. I polished it a bit and that helped with the ring marks a little but still such a floppy fit. Been thinking about getting a set of whidden dies

Both Wilson and Hornady Custom Grade dies make contact about 0.54” from the tip, and it is a fairly snug fit now (not exactly perfect, but workable).

241 Seneca on the left.

212 Seneca on the right.

Glad you found a solution let us know how it goesSwapped out the seating stem for one from my extra 243 set. Bingo. Every single time I’m getting.002-3” run out measured on the bullet Was getting .015-20”. Time for a short test

Nice 1/2” group with a flyer 1” to the right. I don’t feel I pulled it.

Then shot my 205gr sbd2 load and it shot one hole bout 1/4”

Then shot my 205gr sbd2 load and it shot one hole bout 1/4”

I’m done trying with this barrel. The badlands are doing great. I’ll finish this barrel off with those.

Plus my hunting load will also be my play load

Plus my hunting load will also be my play load

That's always nice have the same load for both. Those badlands are still impressive g7 .405. Have you tried any warner flatline 198?I’m done trying with this barrel. The badlands are doing great. I’ll finish this barrel off with those.

Plus my hunting load will also be my play load

300 win mag? What do you usually get 1200 to 1500 rds?Haven’t tried those but I’m at 600 rounds on this barrel.

Had the same experience initially: Two or three shots in one tiny round little hole (often below 0.2”) and then one off 0.7” to the side. Redid seating optimization in smaller increments of 3 thou, and got that particular problem tuned out. We shall see if the tune holds….Nice 1/2” group with a flyer 1” to the right. I don’t feel I pulled it.

Then shot my 205gr sbd2 load and it shot one hole bout 1/4”

Powder is a little temp sensitive, which is not going to help. The load seems to do better if i keep the rounds in my shirt pocket, under a warm jacket, but pucture injuries are very likely! Those are very long and very sharp tips.

Btw, when you receive your bullets, check the tips under a magnifying glass: A few will be bent over, 90 degrees, thanks to Fedex dropping the box too many times. I used those for pressure testing.

Would be nice if the bullets could be packed individually, like other mono bullets e.g. Peregrine.

Also: These bullets might do better (more consistent) with blunter tips, like Hornady did with the 230 and 250 A-tips. Give up some BC but gain BC consistency post Fedex handling mishaps. Hornady could have machined a sharp aluminum tip, but they made it flat. I think for a reason (probably more robust that way, especially in a magazine under heavy recoil).

Results with 212 Seneca and 4000MR in a 28” 7 twist 300 WSM (not the ideal powder, good speed, similar to RL-26, but a little temp sensitive):

Hard bolt lift at 2910 fps. Brass had an ejector mark and primer pocket opened up 1.0 thou.

Higher node at 2870 fps. Mid sixties powder charge. Node was 1.0 wide. Brass is ok but expected life would be below 10 reloads.

Lower node at 2750 fps. Lower sixties in terms of powder charge. Node was also about 1.0 gn wide. Long brass life, but giving up some performance.

Next time i will probably build a 300 PRC.

Hard bolt lift at 2910 fps. Brass had an ejector mark and primer pocket opened up 1.0 thou.

Higher node at 2870 fps. Mid sixties powder charge. Node was 1.0 wide. Brass is ok but expected life would be below 10 reloads.

Lower node at 2750 fps. Lower sixties in terms of powder charge. Node was also about 1.0 gn wide. Long brass life, but giving up some performance.

Next time i will probably build a 300 PRC.

Last edited:

I did a huge seating depth test in increments of .003”. Went through 90 of the 198’s and 58 of the 212’s. Tips would definitely be in better shape if they didn’t ship them in a plastic bag!!!!! Many tips where curled a hair and oal was .003” es on the bullets.

Those tips are fragile. Wouldn’t even want to run them in a mag even if they would fit lol.

Now I check, it was 140 of the 198’s.

Next barrel will be a 1:7 so we’ll see how that one does

Those tips are fragile. Wouldn’t even want to run them in a mag even if they would fit lol.

Now I check, it was 140 of the 198’s.

Next barrel will be a 1:7 so we’ll see how that one does

Last edited:

ADG brass has arrived, very consistent weight range (3 grains), more case capacity than either Norma or Nosler (234 grain average weight, 81.4 gn of water capacity), and shot well during fire forming.

Looks like the higher node will be achievable.

Has anybody been able to confirm the BC of the 30 cal Badlands bullets via drop data?

Looks like the higher node will be achievable.

Has anybody been able to confirm the BC of the 30 cal Badlands bullets via drop data?

I have confirmed bc of the 205’s out to half mile. Tried at 1 mile but conditions were horrible for spotting and winds were all over the place! Hopefully soon I can get back out to 1 mile and use my GoPro to help spot

At half mile my vertical dispersion was 3.5” for 8 rounds on steel.

At half mile my vertical dispersion was 3.5” for 8 rounds on steel.

Similar threads

- Replies

- 0

- Views

- 208

- Replies

- 6

- Views

- 347

- Replies

- 6

- Views

- 552