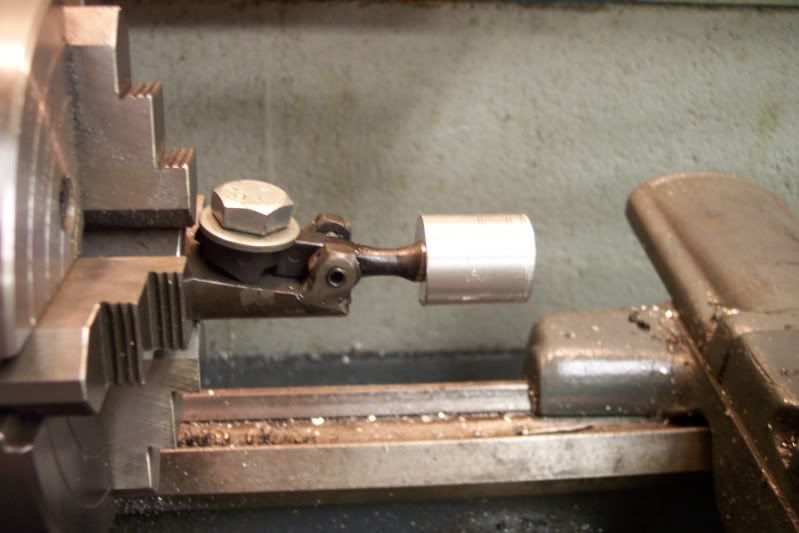

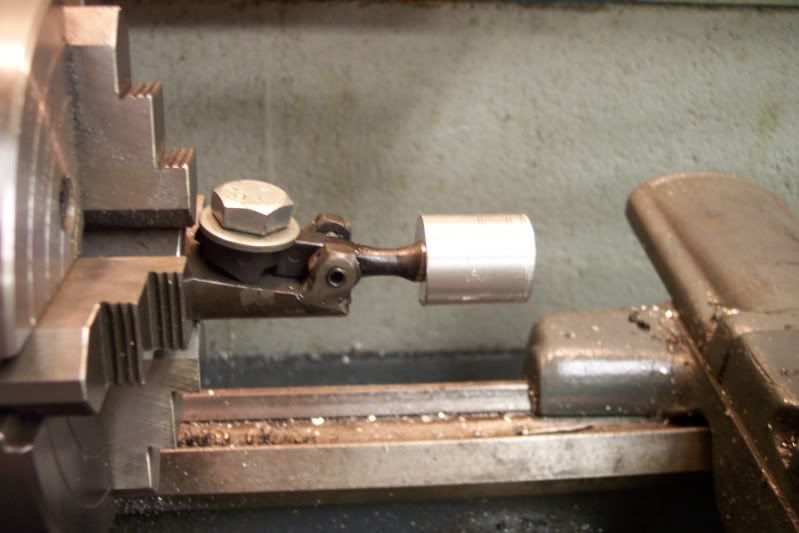

I'm not sure what happened to the old thread, but it sounded like a problem with a pic in another member's signature. Anyway, here is my little Savage bolt knob jig for Savage handles. It's not fancy, but works pretty well. With the combination of the 4 jaw chuck and set screws it's pretty easy to set a handle up for threading. I've been threading them 3/8-24 since nearly every handle has has an air pocket inside and I don't want to run out of material.

This post is simply a how-to kind of deal to show how easy it can be. It's not an advertisement as I am not in business. There are plenty of 'Hide vendors here to take care of that.

jig

turned down the knob

threaded

knob blank

done

This post is simply a how-to kind of deal to show how easy it can be. It's not an advertisement as I am not in business. There are plenty of 'Hide vendors here to take care of that.

jig

turned down the knob

threaded

knob blank

done