Does anyone have any experience with extended bolt knobs, as far as installation. My though was grinding bolt handle down, slipping knob on, and securing it with Devcon.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gunsmithing Bolt Knobs Remington 700

- Thread starter Jim Buck

- Start date

Re: Bolt Knobs Remington 700

The knobs I have appear to be a slip on type. Thats why I was thinking Devcon.

The knobs I have appear to be a slip on type. Thats why I was thinking Devcon.

Re: Bolt Knobs Remington 700

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: excaliber</div><div class="ubbcode-body">Don`t go big, big bolt knobs look stupid. </div></div>

+1

I wouldn't go any larger than the Badger Ordnance bolt knob.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: excaliber</div><div class="ubbcode-body">Don`t go big, big bolt knobs look stupid. </div></div>

+1

I wouldn't go any larger than the Badger Ordnance bolt knob.

Re: Bolt Knobs Remington 700

Why do you need a different bolt knob, the factory one works just fine?

Why do you need a different bolt knob, the factory one works just fine?

Re: Bolt Knobs Remington 700

Watched a buddy install a Badger bolt knob on my son's R700 bolt a few days ago. It is really simple with the right jigs and tools. He did the job in about 30 minutes total.

Watched a buddy install a Badger bolt knob on my son's R700 bolt a few days ago. It is really simple with the right jigs and tools. He did the job in about 30 minutes total.

Re: Bolt Knobs Remington 700

I agree its a nice knob but it doesn't really transition well into the handle.

I agree its a nice knob but it doesn't really transition well into the handle.

Re: Bolt Knobs Remington 700

Yeah, we sure wouldn't want anything to look stupid. Dosn't matter how well it works, as long as it looks tacticool.

okie

Yeah, we sure wouldn't want anything to look stupid. Dosn't matter how well it works, as long as it looks tacticool.

okie

Re: Bolt Knobs Remington 700

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Jim Buck</div><div class="ubbcode-body">Does anyone have any experience with extended bolt knobs, as far as installation. My though was grinding bolt handle down, slipping knob on, and securing it with Devcon. </div></div>

They make a plastic bolt-on model that requires no alterations at all. And it is inexpensive.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Jim Buck</div><div class="ubbcode-body">Does anyone have any experience with extended bolt knobs, as far as installation. My though was grinding bolt handle down, slipping knob on, and securing it with Devcon. </div></div>

They make a plastic bolt-on model that requires no alterations at all. And it is inexpensive.

Re: Bolt Knobs Remington 700

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Jim Buck</div><div class="ubbcode-body">Does anyone have any experience with extended bolt knobs, as far as installation. My though was grinding bolt handle down, slipping knob on, and securing it with Devcon. </div></div>

Here is how I do them:

I start out by cutting off the existing knob:

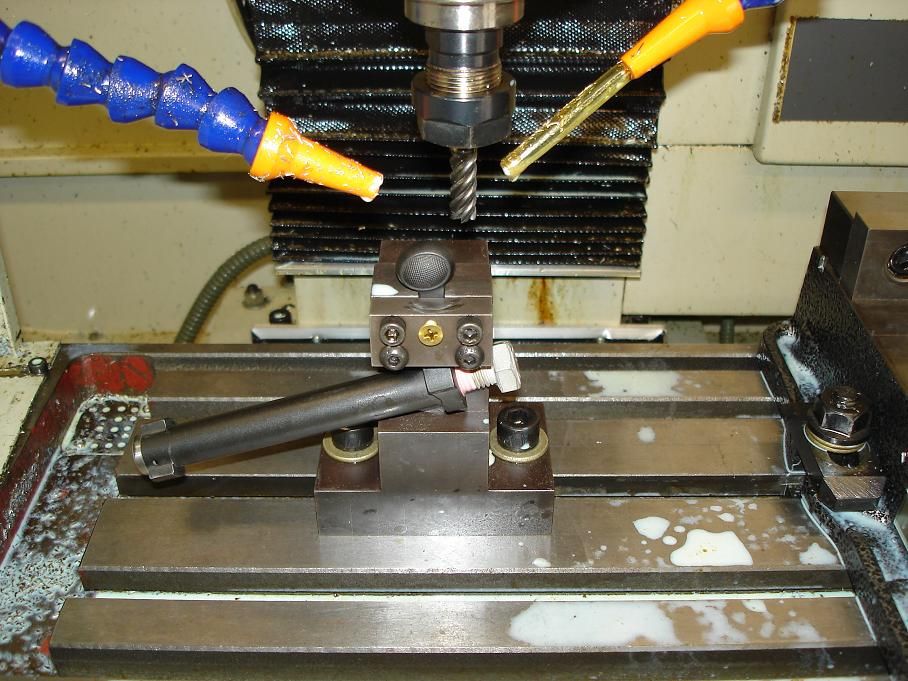

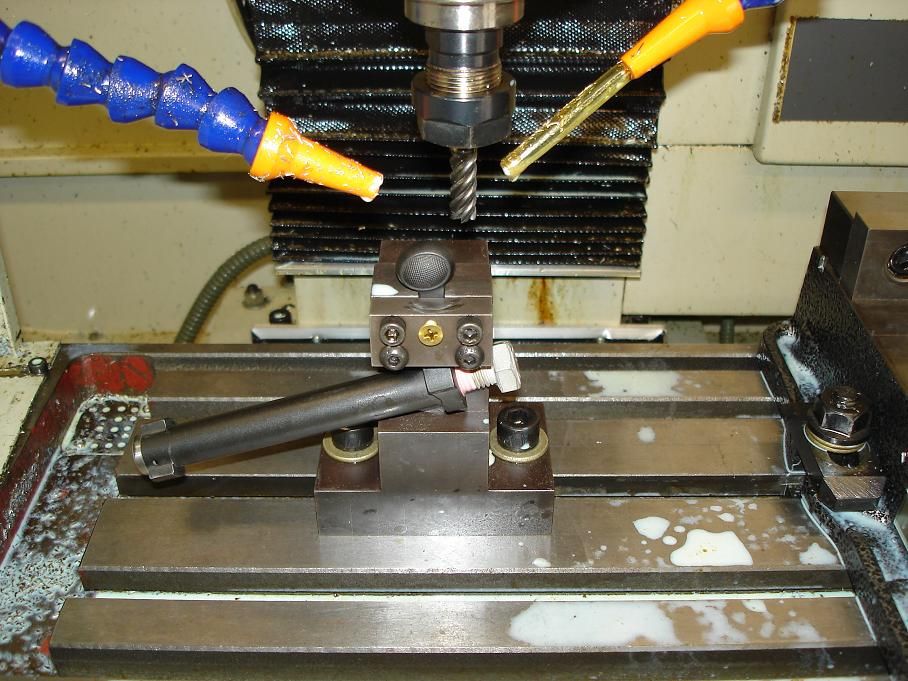

The bolt goes into the vise in a fixture that sets the angle and then it's milled perpendicular:

A hole is driled down into the shank:

A setscrew is turned down into a pin that will lightly press into the hole:

The setscrew is pressed into the bolt handle shank:

The setscrew is tig welded to the bolt handle shank:

The bolt knob threads on to the setscrew:

Finished results:

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Jim Buck</div><div class="ubbcode-body">Does anyone have any experience with extended bolt knobs, as far as installation. My though was grinding bolt handle down, slipping knob on, and securing it with Devcon. </div></div>

Here is how I do them:

I start out by cutting off the existing knob:

The bolt goes into the vise in a fixture that sets the angle and then it's milled perpendicular:

A hole is driled down into the shank:

A setscrew is turned down into a pin that will lightly press into the hole:

The setscrew is pressed into the bolt handle shank:

The setscrew is tig welded to the bolt handle shank:

The bolt knob threads on to the setscrew:

Finished results:

Re: Bolt Knobs Remington 700

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: 2156SMK</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Jim Buck</div><div class="ubbcode-body">Does anyone have any experience with extended bolt knobs, as far as installation. My though was grinding bolt handle down, slipping knob on, and securing it with Devcon. </div></div>

Here is how I do them:

I start out by cutting off the existing knob:

The bolt goes into the vise in a fixture that sets the angle and then it's milled perpendicular:

A hole is driled down into the shank:

A setscrew is turned down into a pin that will lightly press into the hole:

The setscrew is pressed into the bolt handle shank:

The setscrew is tig welded to the bolt handle shank:

The bolt knob threads on to the setscrew:

Finished results:

</div></div>

</div></div>

+1

This is the best way. There are other ways such as turning down the old knob and threading it but sometimes you run into void areas of metal (holes). It works in most cases but this is by far the best approach.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: 2156SMK</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Jim Buck</div><div class="ubbcode-body">Does anyone have any experience with extended bolt knobs, as far as installation. My though was grinding bolt handle down, slipping knob on, and securing it with Devcon. </div></div>

Here is how I do them:

I start out by cutting off the existing knob:

The bolt goes into the vise in a fixture that sets the angle and then it's milled perpendicular:

A hole is driled down into the shank:

A setscrew is turned down into a pin that will lightly press into the hole:

The setscrew is pressed into the bolt handle shank:

The setscrew is tig welded to the bolt handle shank:

The bolt knob threads on to the setscrew:

Finished results:

+1

This is the best way. There are other ways such as turning down the old knob and threading it but sometimes you run into void areas of metal (holes). It works in most cases but this is by far the best approach.

Re: Bolt Knobs Remington 700

There are quite a few people here on the HIDE that do GREAT work on REM 700 bolt knobs.

<object width="425" height="350"> <param name="movie" value="http://www.youtube.com/v/64dNubJcyPM"></param> <param name="wmode" value="transparent"></param> <embed src="http://www.youtube.com/v/64dNubJcyPM" type="application/x-shockwave-flash" wmode="transparent" width="425" height="350"> </embed></object>

<object width="425" height="350"> <param name="movie" value="http://www.youtube.com/v/3i2lCg8MHXQ"></param> <param name="wmode" value="transparent"></param> <embed src="http://www.youtube.com/v/3i2lCg8MHXQ" type="application/x-shockwave-flash" wmode="transparent" width="425" height="350"> </embed></object>

There are quite a few people here on the HIDE that do GREAT work on REM 700 bolt knobs.

<object width="425" height="350"> <param name="movie" value="http://www.youtube.com/v/64dNubJcyPM"></param> <param name="wmode" value="transparent"></param> <embed src="http://www.youtube.com/v/64dNubJcyPM" type="application/x-shockwave-flash" wmode="transparent" width="425" height="350"> </embed></object>

<object width="425" height="350"> <param name="movie" value="http://www.youtube.com/v/3i2lCg8MHXQ"></param> <param name="wmode" value="transparent"></param> <embed src="http://www.youtube.com/v/3i2lCg8MHXQ" type="application/x-shockwave-flash" wmode="transparent" width="425" height="350"> </embed></object>

Re: Bolt Knobs Remington 700

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: red6actual</div><div class="ubbcode-body">Why do you need a different bolt knob, the factory one works just fine? </div></div>

for a hunting rifle, sure. i'm sure plenty of people get away with the oem remington knob on a tac match rifle but being able to grab the handle like second gear at 7200 rpm is nice.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: red6actual</div><div class="ubbcode-body">Why do you need a different bolt knob, the factory one works just fine? </div></div>

for a hunting rifle, sure. i'm sure plenty of people get away with the oem remington knob on a tac match rifle but being able to grab the handle like second gear at 7200 rpm is nice.

Re: Bolt Knobs Remington 700

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: TRAAV</div><div class="ubbcode-body">

+1

This is the best way. There are other ways such as turning down the old knob and threading it but sometimes you run into void areas of metal (holes). It works in most cases but this is by far the best approach. </div></div>

i'm not convinced it's the "best" way.

i have machined just a <span style="font-style: italic">few</span> remington handles and have never found porosity in a place i feel would affect the integrity of the handle/knob once the knob is epoxied on.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: TRAAV</div><div class="ubbcode-body">

+1

This is the best way. There are other ways such as turning down the old knob and threading it but sometimes you run into void areas of metal (holes). It works in most cases but this is by far the best approach. </div></div>

i'm not convinced it's the "best" way.

i have machined just a <span style="font-style: italic">few</span> remington handles and have never found porosity in a place i feel would affect the integrity of the handle/knob once the knob is epoxied on.

Re: Bolt Knobs Remington 700

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: 300sniper</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: TRAAV</div><div class="ubbcode-body">

+1

This is the best way. There are other ways such as turning down the old knob and threading it but sometimes you run into void areas of metal (holes). It works in most cases but this is by far the best approach. </div></div>

i'm not convinced it's the "best" way.

i have machined just a <span style="font-style: italic">few</span> remington handles and have never found porosity in a place i feel would affect the integrity of the handle/knob once the knob is epoxied on. </div></div>

I've only done about a dozen myself, by hand. And to date haven't found any handles that had any porosity. Of coarse that may change with the very next one.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: 300sniper</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: TRAAV</div><div class="ubbcode-body">

+1

This is the best way. There are other ways such as turning down the old knob and threading it but sometimes you run into void areas of metal (holes). It works in most cases but this is by far the best approach. </div></div>

i'm not convinced it's the "best" way.

i have machined just a <span style="font-style: italic">few</span> remington handles and have never found porosity in a place i feel would affect the integrity of the handle/knob once the knob is epoxied on. </div></div>

I've only done about a dozen myself, by hand. And to date haven't found any handles that had any porosity. Of coarse that may change with the very next one.

Re: Bolt Knobs Remington 700

plenty of them do have casting porosity in them. it is usually in the center of the oem knob. i just don't see that area having much stress on it, especially if the knob is epoxied on. i leave an unthreaded shank on my handles to keep the minor diameter larger near the shoulder. i don't like the idea of threading the handle all the way to the shoulder concentrating all the stress in one place. once i start seeing porosity near the shoulder, then i'll start looking at other options. as of now, i haven't seen anything close to where the shoulder ends up.

i cnc machine and thread mill my handles.

to the op, if you are crafty with a grinder/sanding disc and you have an unthreaded knob, i think sanding down the oem knob to a close fitting round shank, getting completely clean/degreaser and epoxying the knob on would be just fine. i have other means at my disposal so i get more advanced than that but at the end of the day, it's just a freaking bolt knob.

plenty of them do have casting porosity in them. it is usually in the center of the oem knob. i just don't see that area having much stress on it, especially if the knob is epoxied on. i leave an unthreaded shank on my handles to keep the minor diameter larger near the shoulder. i don't like the idea of threading the handle all the way to the shoulder concentrating all the stress in one place. once i start seeing porosity near the shoulder, then i'll start looking at other options. as of now, i haven't seen anything close to where the shoulder ends up.

i cnc machine and thread mill my handles.

to the op, if you are crafty with a grinder/sanding disc and you have an unthreaded knob, i think sanding down the oem knob to a close fitting round shank, getting completely clean/degreaser and epoxying the knob on would be just fine. i have other means at my disposal so i get more advanced than that but at the end of the day, it's just a freaking bolt knob.

Re: Bolt Knobs Remington 700

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: 300sniper</div><div class="ubbcode-body">i have machined just a <span style="font-style: italic">few</span> remington handles and have never found porosity in a place i feel would affect the integrity of the handle/knob once the knob is epoxied on. </div></div>

I have only done about 70-80 of them and I still have most of those knobs sitting in my scrap pile.

On about 1/4-1/3 of them, the void extends into the area where I am cutting the knob off of the casting.

So, on the vast majority, you are correct that there is not a void there.

A void further up inside the middle of where the original knob was cast would certainly not matter after the new knob is epoxied on to the threads.

However, I still go to the trouble of cutting them off and welding the setscrew in there so that I KNOW there is no void where it matters.

You are not seeing the void with your machining method because you are staying outside of it.

Rest assured though, it's in there...

If you started cutting some bolt knobs off, you would certainly see what I am talking about.

One thing about the cut-weld method is that you can always repair the bolts that come into the shop after breaking from the machine-then-thread method.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: 300sniper</div><div class="ubbcode-body">i have machined just a <span style="font-style: italic">few</span> remington handles and have never found porosity in a place i feel would affect the integrity of the handle/knob once the knob is epoxied on. </div></div>

I have only done about 70-80 of them and I still have most of those knobs sitting in my scrap pile.

On about 1/4-1/3 of them, the void extends into the area where I am cutting the knob off of the casting.

So, on the vast majority, you are correct that there is not a void there.

A void further up inside the middle of where the original knob was cast would certainly not matter after the new knob is epoxied on to the threads.

However, I still go to the trouble of cutting them off and welding the setscrew in there so that I KNOW there is no void where it matters.

You are not seeing the void with your machining method because you are staying outside of it.

Rest assured though, it's in there...

If you started cutting some bolt knobs off, you would certainly see what I am talking about.

One thing about the cut-weld method is that you can always repair the bolts that come into the shop after breaking from the machine-then-thread method.

Re: Bolt Knobs Remington 700

How much strain is transferred to the inside of a bolt handle during use? My guess is nearly zero with my method. I've done a bunch of them and if anyone has broken one off, I haven't heard about.

How much strain is transferred to the inside of a bolt handle during use? My guess is nearly zero with my method. I've done a bunch of them and if anyone has broken one off, I haven't heard about.

Re: Bolt Knobs Remington 700

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: 300sniper</div><div class="ubbcode-body">How much strain is transferred to the inside of a bolt handle during use?</div></div>

I could not tell you that.

I think the main reason ANY of them break off is the judicius use of a 2x4 to open the bolt when a case is stuck.

Any method that works without any breaking off is certainly a good enough method.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: 300sniper</div><div class="ubbcode-body">How much strain is transferred to the inside of a bolt handle during use?</div></div>

I could not tell you that.

I think the main reason ANY of them break off is the judicius use of a 2x4 to open the bolt when a case is stuck.

Any method that works without any breaking off is certainly a good enough method.

Re: Bolt Knobs Remington 700

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: 2156SMK</div><div class="ubbcode-body">

Any method that works without any breaking off is certainly a good enough method. </div></div>

ayup.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: 2156SMK</div><div class="ubbcode-body">

Any method that works without any breaking off is certainly a good enough method. </div></div>

ayup.

Re: Bolt Knobs Remington 700

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: 2156SMK</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: 300sniper</div><div class="ubbcode-body">How much strain is transferred to the inside of a bolt handle during use?</div></div>

I could not tell you that.

I think the main reason ANY of them break off is the <span style="color: #FF0000">judicius use of a 2x4 to open the bolt when a case is stuck</span>.

Any method that works without any breaking off is certainly a good enough method. </div></div>

I've a friend that has broke one knob off at the threads and tore off two handles using the 2x4 method of extraction. You'd think he'd learn from the first one. I guess I'd better school him on the art of resizing brass.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: 2156SMK</div><div class="ubbcode-body"><div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: 300sniper</div><div class="ubbcode-body">How much strain is transferred to the inside of a bolt handle during use?</div></div>

I could not tell you that.

I think the main reason ANY of them break off is the <span style="color: #FF0000">judicius use of a 2x4 to open the bolt when a case is stuck</span>.

Any method that works without any breaking off is certainly a good enough method. </div></div>

I've a friend that has broke one knob off at the threads and tore off two handles using the 2x4 method of extraction. You'd think he'd learn from the first one. I guess I'd better school him on the art of resizing brass.

Re: Bolt Knobs Remington 700

Ive personally done about 1500 Remingtons.

Many times the handle will have hollow voids. I wouldn't ever use the method that threads the factory knob OD 5/16x24. <span style="text-decoration: underline">Even if it works over 99% of the time.</span>

I'd use either Randalls method of tig welding a stud to the handle, or our method of doing basically what he did, but our studs screw into the handle, and knob. Very simple, very strong. Never had any problems. The method we use was taught to me by a other smith on here. Its used by several companies with zero problems that Ive seen.

I've repaired broken off Badgers that were installed by threading the existing knob.

And in all honesty I've never seen one done at "home" that looked as good as one done professionally.

I personally think our installs have the nicest transition...

All just my opinion though

Ive personally done about 1500 Remingtons.

Many times the handle will have hollow voids. I wouldn't ever use the method that threads the factory knob OD 5/16x24. <span style="text-decoration: underline">Even if it works over 99% of the time.</span>

I'd use either Randalls method of tig welding a stud to the handle, or our method of doing basically what he did, but our studs screw into the handle, and knob. Very simple, very strong. Never had any problems. The method we use was taught to me by a other smith on here. Its used by several companies with zero problems that Ive seen.

I've repaired broken off Badgers that were installed by threading the existing knob.

And in all honesty I've never seen one done at "home" that looked as good as one done professionally.

I personally think our installs have the nicest transition...

All just my opinion though

Re: Bolt Knobs Remington 700

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Jim Buck</div><div class="ubbcode-body">The knobs I have appear to be a slip on type. Thats why I was thinking Devcon. </div></div>

It wont hold if you simply epoxy it. It needs to screw onto something solid.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Jim Buck</div><div class="ubbcode-body">The knobs I have appear to be a slip on type. Thats why I was thinking Devcon. </div></div>

It wont hold if you simply epoxy it. It needs to screw onto something solid.

Similar threads

- Replies

- 6

- Views

- 2K