I measured the depth of the throat in my .308 chambered 700 SA and found that the approximate max length of cartridges using the Hornady 168 HPBTs I have boxes of is around 2.925" to stay .010" off the lands; I made a gage to measure to the ogive (actually where the bullet is .300 diameter, not sure if I'm using the term correctly) so that is where I'm really measuring the cartridges for fitting my chamber/barrel, but nonetheless, the OAL ends up .025" longer than what I can fit in the AICS mags and .035" longer than what will reliably move through the mag (2.890"). I'm sure this is nothing unusual.

Problem is, even 2.890" long cartridges won't feed (except the first one) as stripping the round on top off pushes the next round against the strip in the front of the mag, which is a few thousandths too far to clear the mag opening in the action. Again, I'm sure this has been seen before.

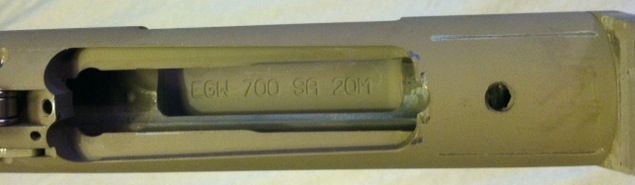

Sooooo I need to modify my feed ramp, and although I have a pretty good idea what I want it to look like, I remember seeing a thread here with a picture of one done by an honest-to-goodness professional smith, and I'd like to see it again to confirm if I'm on the right track.

If anybody has pictures like this, I'd appreciate seeing them.

I am going to cut it deep enough to allow for the longest cartridges the mags will accomadate, including removal of the limiter plates spot wleded in the mags, should I become brave enough to remove them.

Don't want to be doing this twice.

Joe

Problem is, even 2.890" long cartridges won't feed (except the first one) as stripping the round on top off pushes the next round against the strip in the front of the mag, which is a few thousandths too far to clear the mag opening in the action. Again, I'm sure this has been seen before.

Sooooo I need to modify my feed ramp, and although I have a pretty good idea what I want it to look like, I remember seeing a thread here with a picture of one done by an honest-to-goodness professional smith, and I'd like to see it again to confirm if I'm on the right track.

If anybody has pictures like this, I'd appreciate seeing them.

I am going to cut it deep enough to allow for the longest cartridges the mags will accomadate, including removal of the limiter plates spot wleded in the mags, should I become brave enough to remove them.

Don't want to be doing this twice.

Joe