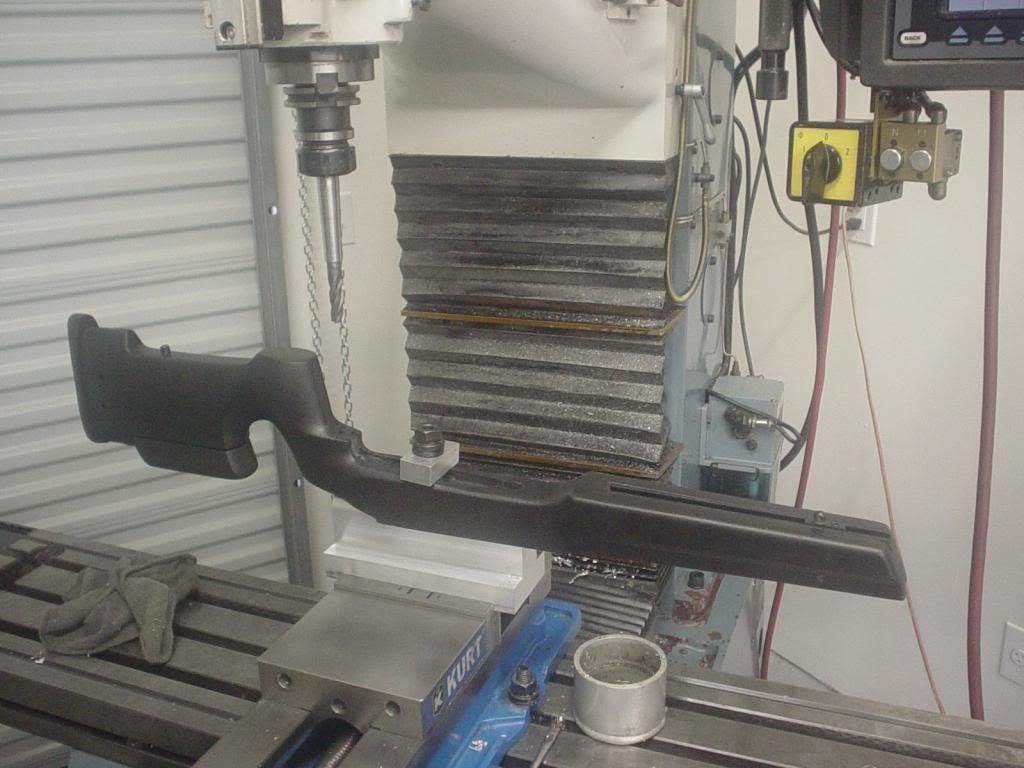

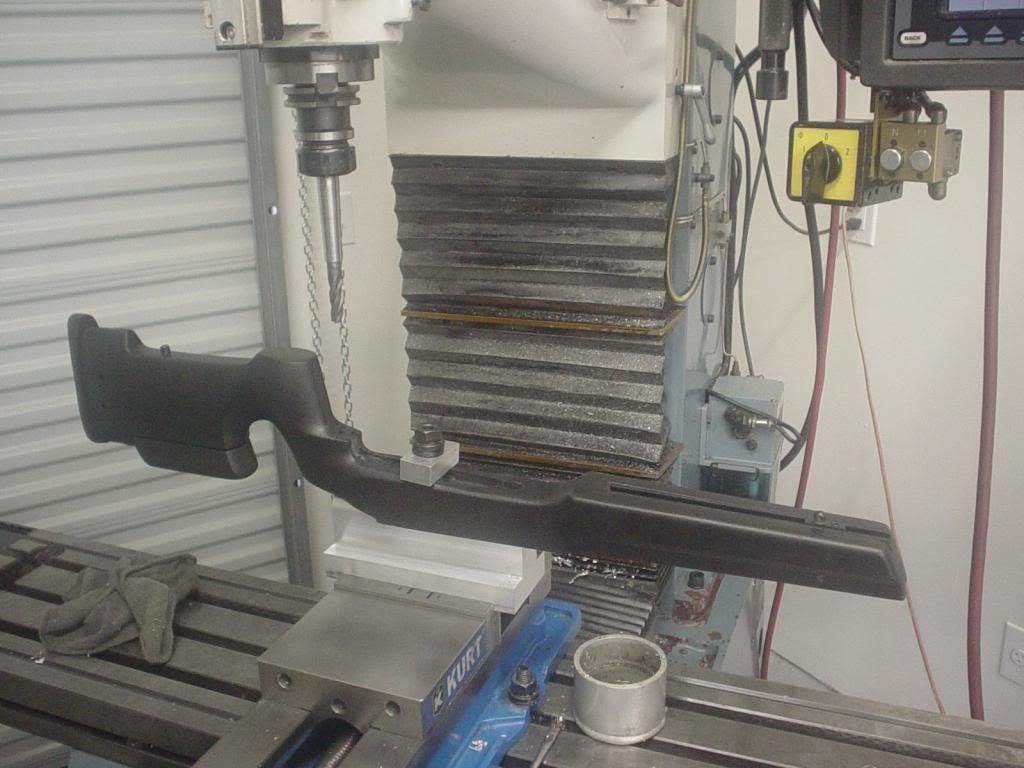

Thanks to a forum member for posting an install print for bottom metal. Saved alot of time. I was just getting ready to toss it up on the CMM and reverse engineer it. So then I needed a nice fixture to hold the stock. I made a block with full radius that duplicates the action. To get the stock aligned I have two 5/16" holes that are 3/4" deep on location of the action bolts and then 1/4-28 thread below that another 1" deep. I put 5/16" drill rods in the holes and set the stock overthem. The 5/16" holes in the bedding block get the stock straight and located. The 1/2-13 stud in the middle is useing a sperical washer and nut set up to compensate for the angle of the top surface of the stock. I cut the ends over the action screw and then use them to hold it down and then remove the middle stud and cut the middle section. The mill is a 3 axis Prototrak and works great for this job. Hope you guys enjoy things I post and just want to be helpfull to any other hobbiest guys out there.