So I've had the rifle for about two months now, first few times I brought her to the range the rifle performed flawlessly. I then, out of curiosity, disassembled the rifle (not anything over 10 level, just dropped the floorplate and removed the action from the stock). Ever since, the rifle has been having trouble feeding the last round in the magazine.

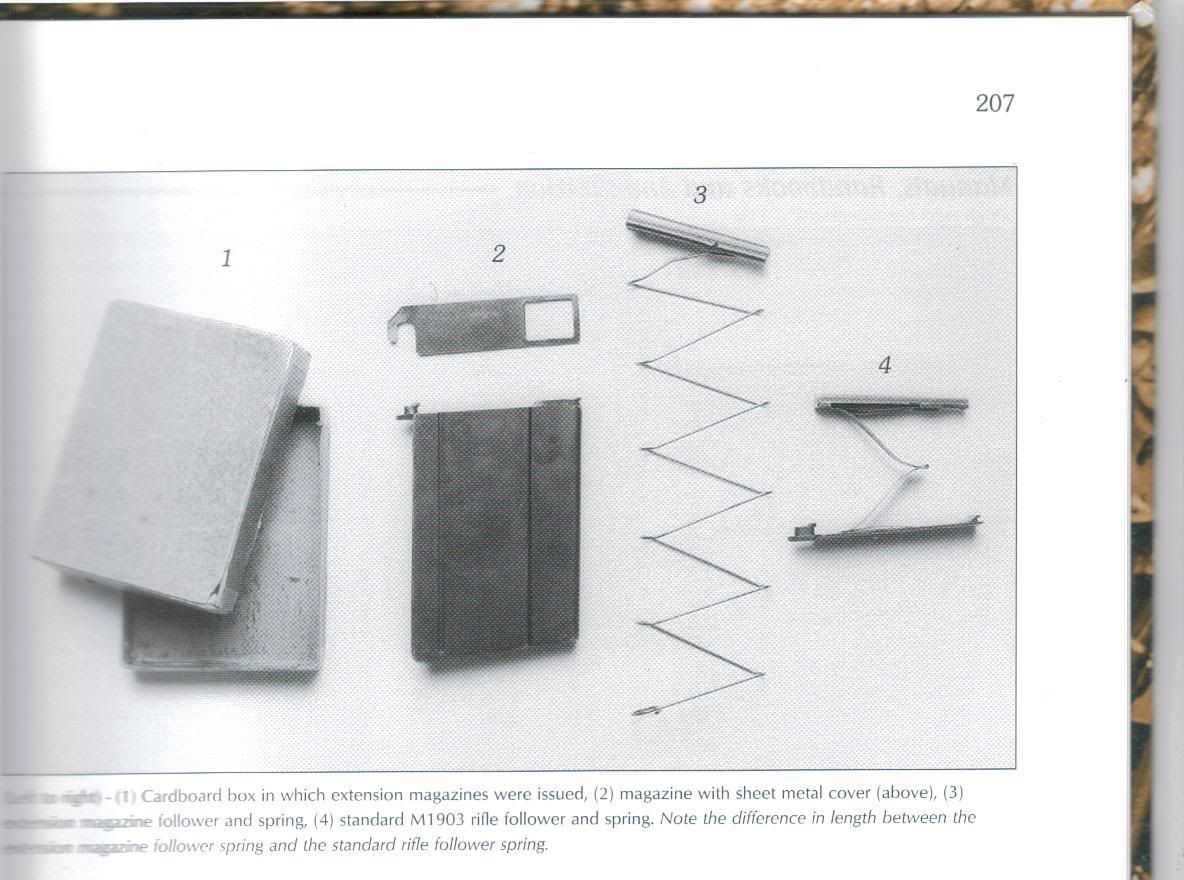

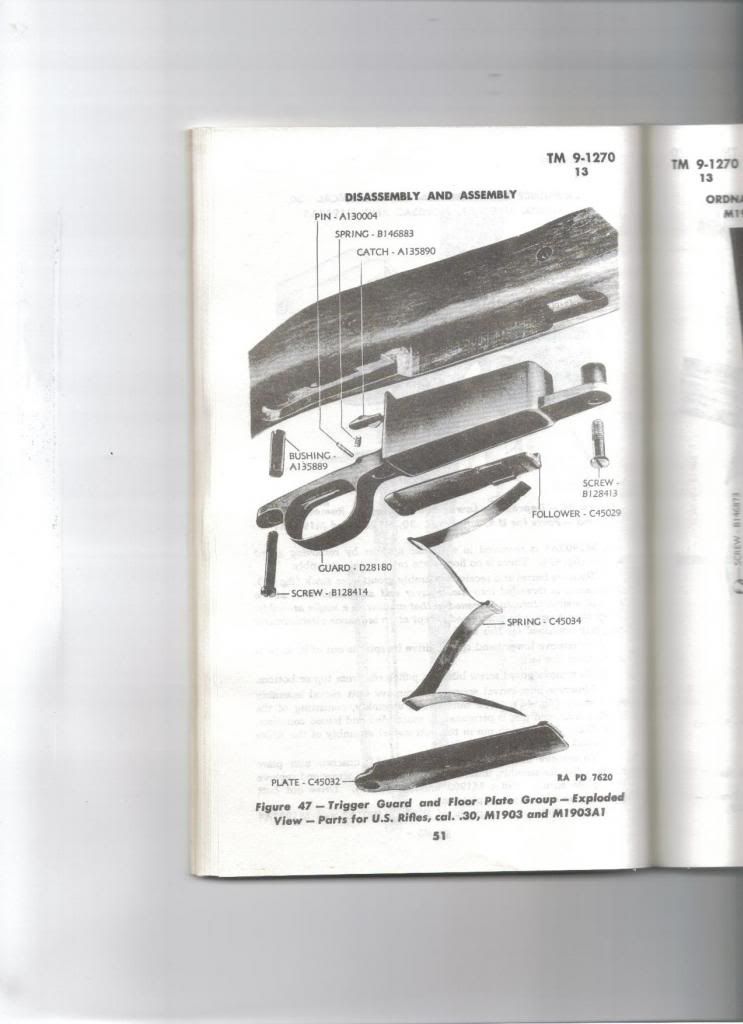

Now with the 03-a3, the magazine spring and the follower are just loose inside the magazine well, which has a stamped channel in which the bottom of the spring rests.

So initially, I figured that the spring was not resting in the channel. after multiple repositionings, the problem still isn't solved.

here's whats going on mechanically to cause the jam-

as the rifle is emptied, the magazine follower ascends. once it reaches the last bullet, the diagonal pressure being applied by the one remaining round(sitting on the right side of the follower) is pushing the follower to the left. this is fine when it is feeding the other four rounds, but unfortunately as the follower goes to feed the last round, the left side of the follower hangs up on the bottom of the action, pinning the last round in place.

my range fix-it has been to just open the action after the fourth round, and depress the last round with my thumb, allowing the follower to slide back into proper position.

I've been thinking of redneck ways of solving the problem, but this is a classic rifle, and I'm not in the mood to have my stupidity ruin it.

And so I seek your wisdom.

Thanks ahead of time for your input

Now with the 03-a3, the magazine spring and the follower are just loose inside the magazine well, which has a stamped channel in which the bottom of the spring rests.

So initially, I figured that the spring was not resting in the channel. after multiple repositionings, the problem still isn't solved.

here's whats going on mechanically to cause the jam-

as the rifle is emptied, the magazine follower ascends. once it reaches the last bullet, the diagonal pressure being applied by the one remaining round(sitting on the right side of the follower) is pushing the follower to the left. this is fine when it is feeding the other four rounds, but unfortunately as the follower goes to feed the last round, the left side of the follower hangs up on the bottom of the action, pinning the last round in place.

my range fix-it has been to just open the action after the fourth round, and depress the last round with my thumb, allowing the follower to slide back into proper position.

I've been thinking of redneck ways of solving the problem, but this is a classic rifle, and I'm not in the mood to have my stupidity ruin it.

And so I seek your wisdom.

Thanks ahead of time for your input