I'll be rebarreling my Remmy 700 action in .260 Remington soon.

I have an ample supply of .308 brass.

How difficult is it to make .260 cases from .308?

Is it just a matter of FL resizing them in a .260 die, turning the neck and trimming the length?

If buying .260 brass is the way to go, is there any to stay away from?

Where can I get .260 dies?

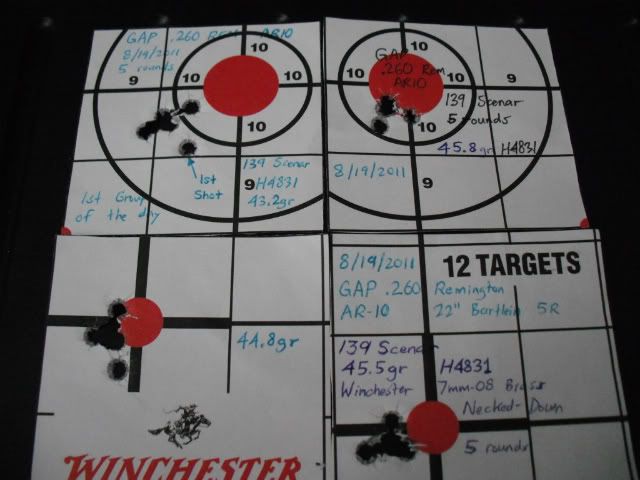

Anybody ever used IMR 4895 in .260 Remington cartridges? Powder is tough to come by these days, at least the popular powders, but I have 12 pounds or more of I4895 and a bunch of bullets on the way (some 139 scenars, 140 SMKs, Nosler competitions, etc.) so I hope I can at least get started with what I have.

Thanks in advance.

Joe

I have an ample supply of .308 brass.

How difficult is it to make .260 cases from .308?

Is it just a matter of FL resizing them in a .260 die, turning the neck and trimming the length?

If buying .260 brass is the way to go, is there any to stay away from?

Where can I get .260 dies?

Anybody ever used IMR 4895 in .260 Remington cartridges? Powder is tough to come by these days, at least the popular powders, but I have 12 pounds or more of I4895 and a bunch of bullets on the way (some 139 scenars, 140 SMKs, Nosler competitions, etc.) so I hope I can at least get started with what I have.

Thanks in advance.

Joe