Hey guys,

Im a noob here trying to figure out what my headspace measurements are on my 1x fired brass.

I have an LMT Mws 7.62x51 with 20" stainless barrel.

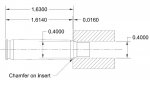

I use the Hornady headspace bushing insert (.400) on a digital caliper. My fired brass measures 1.623 headspace, this seems way too small

compared to some of the other LMT's out there. I even thought it was the bushing that was out of spec and went and bought a new one only to

find it was the same measurement. I measure new factory ammo (168g FGMM) and it is 1.624 with the Hornady gauge.

Could my chamber be that small?

A good member here (Elfster1234) has been helping me figure this one out. Does anyone have any ideas? Am I doing something wrong?

Thanks,

Dacam

Im a noob here trying to figure out what my headspace measurements are on my 1x fired brass.

I have an LMT Mws 7.62x51 with 20" stainless barrel.

I use the Hornady headspace bushing insert (.400) on a digital caliper. My fired brass measures 1.623 headspace, this seems way too small

compared to some of the other LMT's out there. I even thought it was the bushing that was out of spec and went and bought a new one only to

find it was the same measurement. I measure new factory ammo (168g FGMM) and it is 1.624 with the Hornady gauge.

Could my chamber be that small?

A good member here (Elfster1234) has been helping me figure this one out. Does anyone have any ideas? Am I doing something wrong?

Thanks,

Dacam