I am slowly accumulating what is needed to start reloading for the first time and will be doing so on a 260 Remington that should be arriving at the end of this year. Without having experience yet in reloading and still in the stage of reading all I can I noticed a box of Berger Hybrid 140gr 6.5mm bullets have some creases, or possibly stress cracks at the forward end of the ogive. I compared them against some new Scenar-L 136gr and notice the Lapua has some very slight lines as well, but nothing as pronounced as the Bergers. Are these lines typical in target style bullets at this level and do they present any issues with accuracy or anything else?

Berger's only

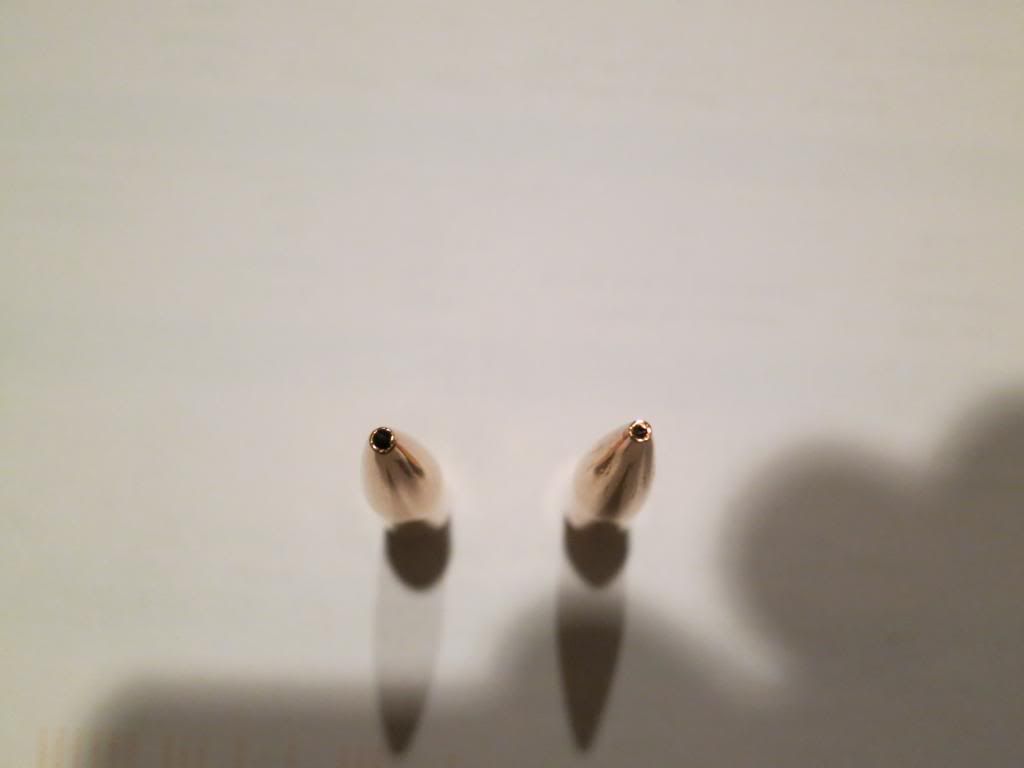

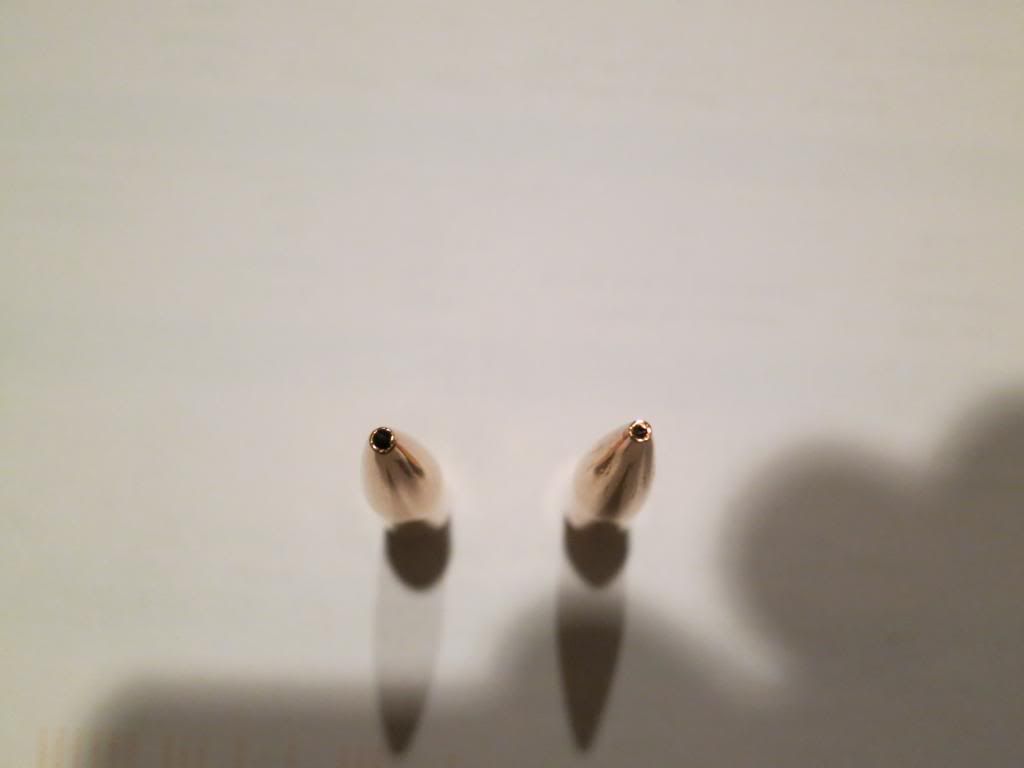

Below are some photos just for shits and grins that show some comparisons against the Lapua Scenar-L's which are on the left in the photos and the 140gr Berger Target Hybrid

Berger's only

Below are some photos just for shits and grins that show some comparisons against the Lapua Scenar-L's which are on the left in the photos and the 140gr Berger Target Hybrid