I had an old 24" bull barrel left over from when I build an AR-15 Space gun for NRA across the course matches. The barrel shot decent but I got into other types of matches and the upper has sat unfired now for 4-5 years. Now I have a sickness, I cant leave things be, and I own a lathe. So I decided to make that old upper into a 3-Gun upper.

First thing I did was chop it off to ~18".

I got to use my new front spider chuck for the first time for this project, wow those 20tpi adjustment bolts make it easy to indicate a bore.

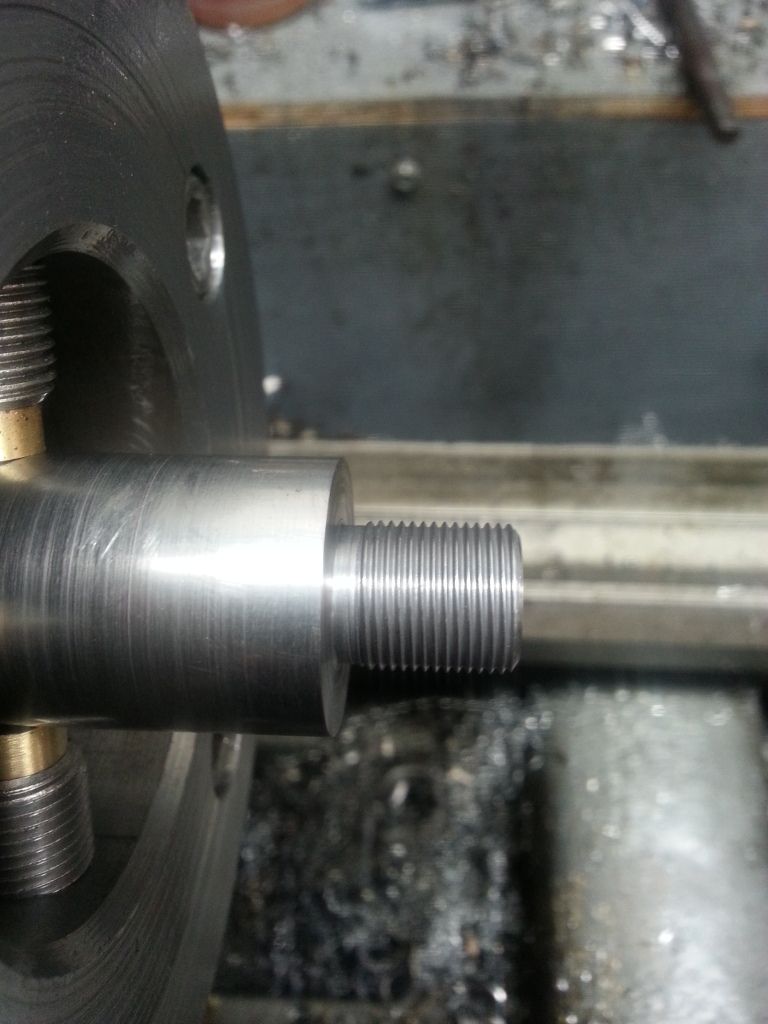

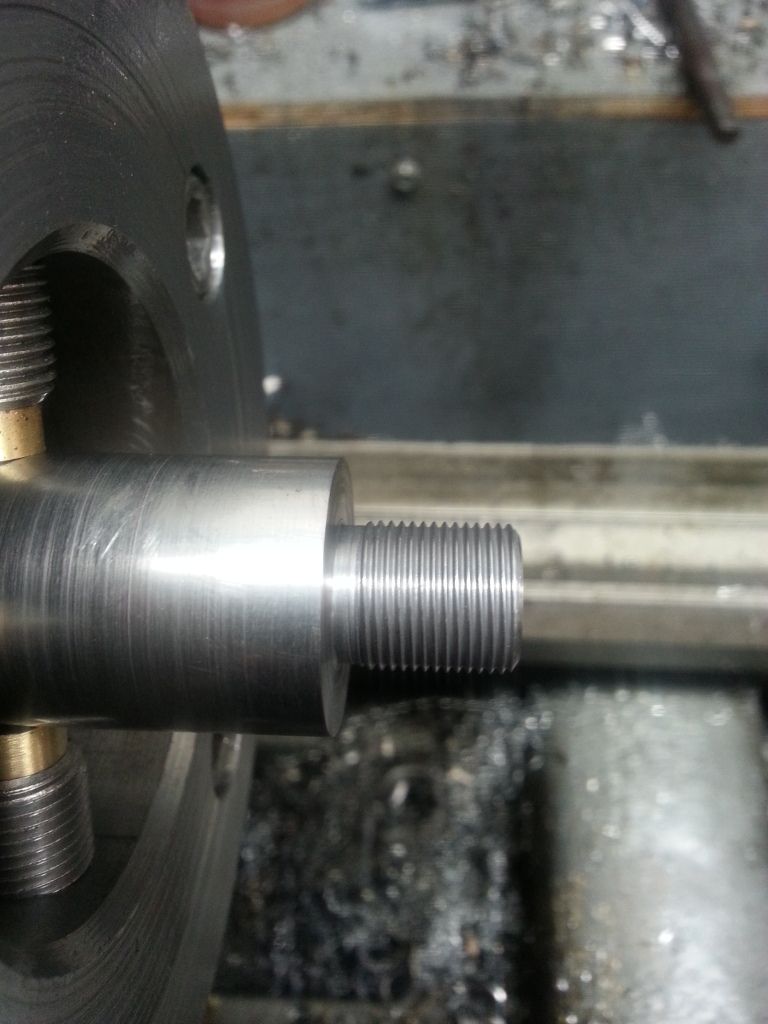

So after indication I turned the muzzle down for the 1/2x28 threads.

Now I stared to reprofile the rest of the barrel. For this I moved it out over the bed and used my 3-Jaw on the barrel extension and the muzzle in the live center. I turned the entire barrel to 0.750" with a small piece for the gas block to seat against at 0.875" That was a massive amount of material to remove. Thank God for power feeds.

After profiling I moved back to the spider and re-indicated and turned a crisp crown with a razor shard tool I ground just for this.

And here is what she looked like after all was said and done.

I didnt weigh the barrel before and after but I easily took half the weight off of it. Next project is a muzzle brake from the cut off barrel stub.

First thing I did was chop it off to ~18".

I got to use my new front spider chuck for the first time for this project, wow those 20tpi adjustment bolts make it easy to indicate a bore.

So after indication I turned the muzzle down for the 1/2x28 threads.

Now I stared to reprofile the rest of the barrel. For this I moved it out over the bed and used my 3-Jaw on the barrel extension and the muzzle in the live center. I turned the entire barrel to 0.750" with a small piece for the gas block to seat against at 0.875" That was a massive amount of material to remove. Thank God for power feeds.

After profiling I moved back to the spider and re-indicated and turned a crisp crown with a razor shard tool I ground just for this.

And here is what she looked like after all was said and done.

I didnt weigh the barrel before and after but I easily took half the weight off of it. Next project is a muzzle brake from the cut off barrel stub.