So I started off with a goal of building a 77 grain 5.56 load capable of 1moa for my new project. It’s an 18” Noveske SPR Suppressed.

Well, that’s where I started and it seems I am still there…

In a perfect world, or rather normal world, I would have a number of choices for components. Spending the past eight months I collected:

-1K once fired mixed brass

-1K FGMM SM Rifle Primers

-1K Nosler 77 Grain CC Match Bullets

-8lbs of Ramshot Tac

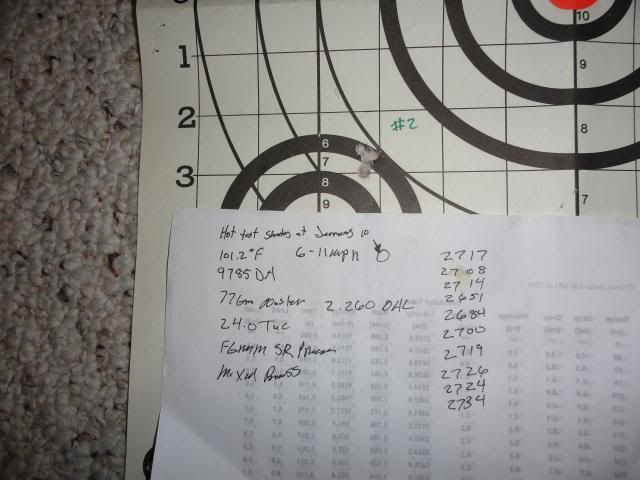

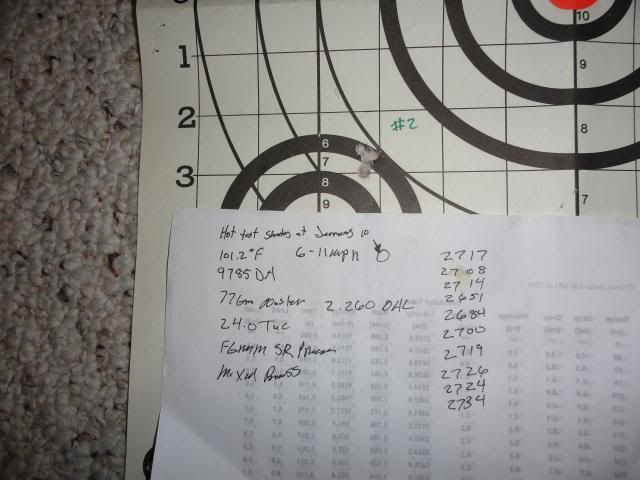

After some research I started my loads at standard length with 24.0 Tac. The first 10 rounds of this showed promise, which followed with another 10 rounds. This load was shot at around 40 degrees initially so I was concerned about loading up a bunch until further testing could commence. Pressure signs were there with a slightly flattened primer. No obvious swipes were found. My concerns were that higher ambient temps would cause pressures to rise.

The best 5 shot group came in with a Average MV at 2682 FPS.

Mid Spring I tested 10 rounds loaded at 24.4 Grains of Tac. Pressure signs were expectedly more pronounced and the accuracy dropped off. Compared side by side with 24.0 the choice seemed obvious. While I netted another 40-50 FPS it didn’t matter because it didn’t shoot.

I loaded 50 Rounds for further testing with 24.0 Tac.

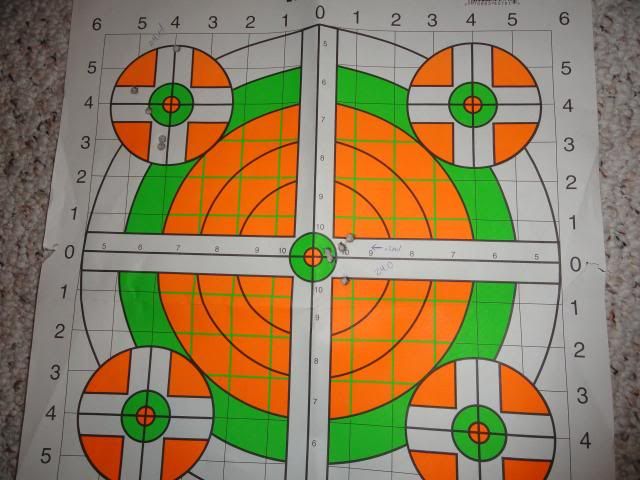

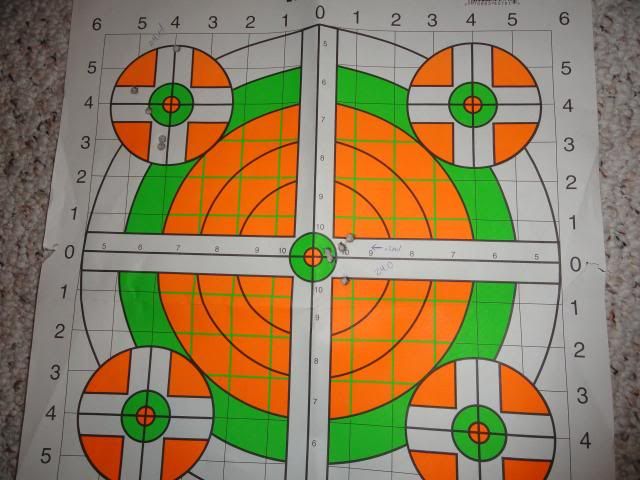

This brings us to several weeks ago where on a hell of hot day I had a chance to put that 24.0 load to test. 101 Degrees, and I let it bake in the sun for a while. This was shot under much different conditions and POI changed about a 1” high 1” right. 10 rounds fired, 3 X 3 shot groups with a single cold clean bore starting it off. It didn’t set the world on fire but met my goals with one of the groups falling right in well under ½ MOA. Pressures were similar to that seen before, velocities were also very close to before.

So a few days ago I decided to take out the steel and shoot 2 X 5 shot groups at 200 yards. Here’s the results…………. Basically a overgrown 4” group netting 2MOA. It was windy 10-15mph, with .4 mil held for wind, but even at that this sucks.

Where do you think I should go from here? I still have another 30 or so loaded up at 24.0. Going back through the targets so far the load has produced some good groups but not very consistently. This is mixed brass, I understood that going into this venture. I just don’t know how much there is to be gained separating the brass out by head stamp. There is a good portion of WC, FC, LC and Nato.

The reality is I can’t develop a load for each head stamp, I just don’t have the resources for that. If I did, well I would have bought a single lot of LC but they just cant be had.

I accept some variations from mixed brass but I feel like I am back at square one

Well, that’s where I started and it seems I am still there…

In a perfect world, or rather normal world, I would have a number of choices for components. Spending the past eight months I collected:

-1K once fired mixed brass

-1K FGMM SM Rifle Primers

-1K Nosler 77 Grain CC Match Bullets

-8lbs of Ramshot Tac

After some research I started my loads at standard length with 24.0 Tac. The first 10 rounds of this showed promise, which followed with another 10 rounds. This load was shot at around 40 degrees initially so I was concerned about loading up a bunch until further testing could commence. Pressure signs were there with a slightly flattened primer. No obvious swipes were found. My concerns were that higher ambient temps would cause pressures to rise.

The best 5 shot group came in with a Average MV at 2682 FPS.

Mid Spring I tested 10 rounds loaded at 24.4 Grains of Tac. Pressure signs were expectedly more pronounced and the accuracy dropped off. Compared side by side with 24.0 the choice seemed obvious. While I netted another 40-50 FPS it didn’t matter because it didn’t shoot.

I loaded 50 Rounds for further testing with 24.0 Tac.

This brings us to several weeks ago where on a hell of hot day I had a chance to put that 24.0 load to test. 101 Degrees, and I let it bake in the sun for a while. This was shot under much different conditions and POI changed about a 1” high 1” right. 10 rounds fired, 3 X 3 shot groups with a single cold clean bore starting it off. It didn’t set the world on fire but met my goals with one of the groups falling right in well under ½ MOA. Pressures were similar to that seen before, velocities were also very close to before.

So a few days ago I decided to take out the steel and shoot 2 X 5 shot groups at 200 yards. Here’s the results…………. Basically a overgrown 4” group netting 2MOA. It was windy 10-15mph, with .4 mil held for wind, but even at that this sucks.

Where do you think I should go from here? I still have another 30 or so loaded up at 24.0. Going back through the targets so far the load has produced some good groups but not very consistently. This is mixed brass, I understood that going into this venture. I just don’t know how much there is to be gained separating the brass out by head stamp. There is a good portion of WC, FC, LC and Nato.

The reality is I can’t develop a load for each head stamp, I just don’t have the resources for that. If I did, well I would have bought a single lot of LC but they just cant be had.

I accept some variations from mixed brass but I feel like I am back at square one

Last edited: