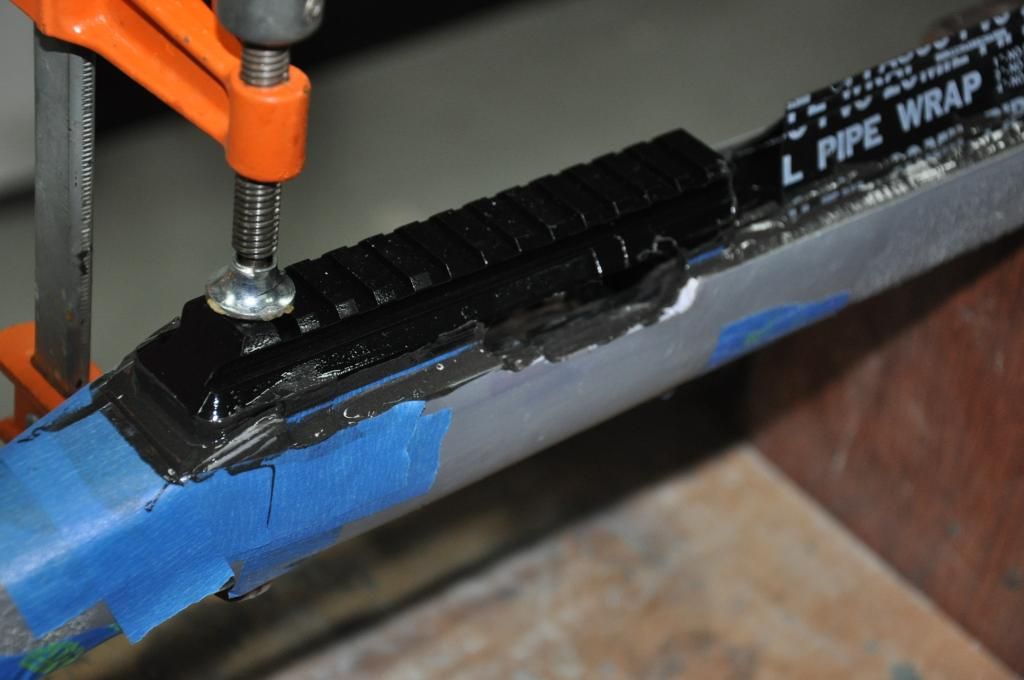

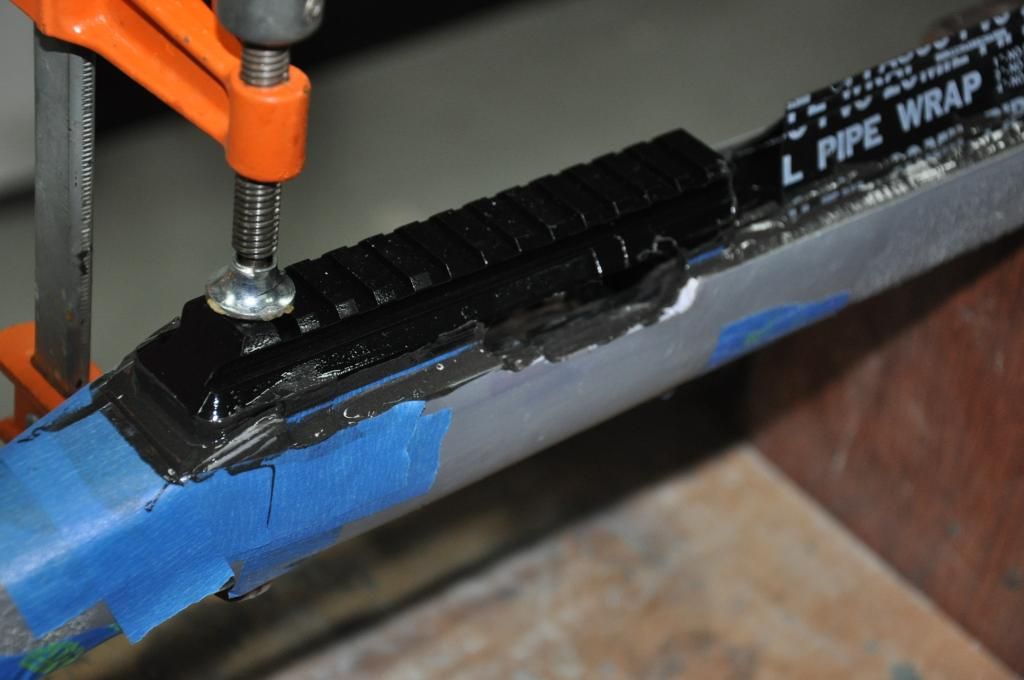

I bought this little rifle about 8 months ago because I always wanted a nice .22. While I'm happy with the rifle, I don't care for the little Houge stock they put it in. It is more for a 9 year old than a full grown man. I looked around for a better stock, but just didn't care for the looks of most, plus I wanted quality without spending much money. Sound familiar? I have never worked with .22s, so don't laugh too hard ok. I pulled a McMillan HTG stock out of my stash that was already inletted for a Remington action, and Badger bottom metal. I took some measurements, and stuck it in the mill. After inletting all material that was in the way, I tried the action, and I thought it would work. There were a lot of voids, but nothing some Marine Tex couldn't fill. After taping, clay filling, and applying release agent, I mixed up some Marine Tex and made a big mess. This is going to be a post as I go, so I really don't know how it will turn out. The idea is to have a full size feeling rifle in a mini me package for training.