I have a savage 280 ackley that I'm trying to work up a load for. When I close the bolt on the brass there is a lot of resistance. I have bumped the shoulders back as far as the dies will allow and the bolt is still hard to close. I'm using redding fl dies. Any other suggestions?

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bolt hard to close

- Thread starter kdw52

- Start date

you probably don't have the die screwed down far enough to set the shoulder back enough...

When you set up the die, you typically raise the ram, and screw the die down till it touches the shell holder. That would seem like you're all set to push the case as far into the die as it will go.

The thing is, once the press linkage is under a load (the pressure of sizing the case), it does not push the shell holder against the die base any longer, due to the springing of the press linkage; there is some gap between the shell holder and the base of the die when you have the case inserted. You can check this by taking a flashlight and back-lighting the die base/shell holder junction... you'll probably see a gap when you've pressed the case all the way up.

The solution is to turn the die in an extra 1/8th turn, and re-check the die base/shell holder junction... turn it in another 1/8th turn if you're still seeing a gap.

You've got a tight chamber, that's for sure.

Dan

When you set up the die, you typically raise the ram, and screw the die down till it touches the shell holder. That would seem like you're all set to push the case as far into the die as it will go.

The thing is, once the press linkage is under a load (the pressure of sizing the case), it does not push the shell holder against the die base any longer, due to the springing of the press linkage; there is some gap between the shell holder and the base of the die when you have the case inserted. You can check this by taking a flashlight and back-lighting the die base/shell holder junction... you'll probably see a gap when you've pressed the case all the way up.

The solution is to turn the die in an extra 1/8th turn, and re-check the die base/shell holder junction... turn it in another 1/8th turn if you're still seeing a gap.

You've got a tight chamber, that's for sure.

Dan

Assuming you are "camming over" the press and you still can't bump the shoulder back enough, you can simply grind a few .001"s off the bottom of your die, so the case will be deeper in the die once the shellholder contacts the die.

Another thought, assuming you're still rocking a barrel nut on your rifle, would be to re-headspace the rifle slightly looser...as in .001" to .002" looser. It would still be inside the spec, but would allow your die in it's current form to bump the shoulder back far enough for easy chambering.

Another thought, assuming you're still rocking a barrel nut on your rifle, would be to re-headspace the rifle slightly looser...as in .001" to .002" looser. It would still be inside the spec, but would allow your die in it's current form to bump the shoulder back far enough for easy chambering.

Since you are forming custom brass to fit your rifle, resetting the headspace is the easiest and best (IMHO) way to correct the situation. Whoever headspaced your new barrel (or chamber) probably used a Standard .280 headspace gauge.Loosen the nut, screw out the barrel a tad, chamber your tight brass and re-headspace off of it. Check that with a few other cases to ensure you have a "touch" of feeling resistance whtn they chamber. Tighten the nut...frequently that will stretch the threads just a bit and you need to re-headspace so that you have more feel when you chamber the brass. Might take 5 minutes or so to get it right. If you got rid of the nut...take a little off the shell holder.

Did you measure your cases before and after you sized them? That's a quick way to tell if you are actually moving anything. In a pinch, I've used a spent .40 shell casing to measure the shoulder - not the most perfect tool for the job but it works. That will tell you if it's a sizing issue or something else.

Probably not an issue with an aftermarket barrel, but try chambering your sized but not loaded brass. Eliminates the possibility of you jamming into the lands. You may have to reduce your coal.

Probably not an issue with an aftermarket barrel, but try chambering your sized but not loaded brass. Eliminates the possibility of you jamming into the lands. You may have to reduce your coal.

And if your rifle is like mine and the brass is too long, once you close the bolt it will be just as difficult to open it.

Have you blackened a case to find out where exactly it is making contact in your chamber? A Sharpy works fine.

OFG

OFG

It can be addressed by the previous posts, but, did you start with new brass for this rifle or are you using brass that was fired numerous times in a different barrel? I always use new brass in a new barrel. I had some issues with IMI brass one time, similar to your problem. I went back to Lapua brass and never had another problem. I'm guessing the IMI "hardened" quickly as I do not anneal.

I've had that same exact problem when I first started reloading rifle rounds. My issue is as suggested before - not screwing the sizing down far enough. You do have to screw it down past hitting the base so that it "cams over" when you size. The other obvious thing to check is if your brass OAL is too long. You might have to trim the neck back to spec.

I don't have a benchrest .308 rifle, but a precision one regardless built by GAP. I've found that some new factory loads chambers very tight, especially PRIVI. My own handloads using Lapua brass are smooth as butter though. So, brand of brass could be part of the problem.

I don't have a benchrest .308 rifle, but a precision one regardless built by GAP. I've found that some new factory loads chambers very tight, especially PRIVI. My own handloads using Lapua brass are smooth as butter though. So, brand of brass could be part of the problem.

I have not tried any loaded rounds. Having this problem with new nosler brass. The press is camming over and the ram and dies are touching.

If you've properly adjusted your dies all the way down, one other thing to check is to be sure the decapping spindle isn't set too far down into the case. If it's too far down, the sizing button can bottom out and you won't be fully sizing the case. It doesn't happen too often, but it can.

You'd be surprised that just another 1/12th-1/24th turn of the die into the press could cure your problem. Many new reloaders fail to set their dies up properly. It may do you good to get a headspace/shoulder bump gauge and take some measurements to see what your numbers are.

You'd be surprised that just another 1/12th-1/24th turn of the die into the press could cure your problem. Many new reloaders fail to set their dies up properly. It may do you good to get a headspace/shoulder bump gauge and take some measurements to see what your numbers are.

M

milo 2.0

Guest

I have not tried any loaded rounds. Having this problem with new nosler brass. The press is camming over and the ram and dies are touching.

Why are you sizing brass that you're going to blow the shoulders forward on? Will unsized cases fit?

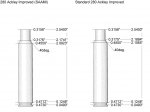

FYI, there are 2 ( prob more) different 280 AI chambers. One being SAAMI (spec By Nosler) and the original Ackley. The SAMMI shoulder is approx .0143 shorter than the original and can cause headspace issues. Fire formed brass from the original used in a SAMMI chamber will make it hard to close the bolt.

Also this memo from the Redding site spells it out better.

280 Ackley Improved vs. 280 Rem. Improved 40 Degree | Redding Reloading Equipment: reloading equipment for rifles, handguns, pistols, revolvers and SAECO bullet casting equipment

280 Ackley Improved vs. 280 Rem. Improved 40 Degree | Redding Reloading Equipment: reloading equipment for rifles, handguns, pistols, revolvers and SAECO bullet casting equipment

The brass is new nosler 280ai. I was unaware of the bolt tension with an ackley. I'm new at this and it's my first one.

I shoot the same brass (SAMMI spec) but my Cooper is also a SAMMI spec chamber so I've never had an issue. Savages are good guns. I would think the chamber would be spot on. Maybe check tha the case over all length is not too long and your jamming the bullets into the lands of the rifling.

I've had this happen when I shot my 308 with the factory barrel, than put a rock creek match barrel on it and I could never get the brass to fit. This was because the FL for doesnt get the bell around the head of the case. Sort of how glock brass needs to be fed through a push through die before the work in other guns.

Similar threads

- Replies

- 6

- Views

- 425

- Replies

- 10

- Views

- 559

- Replies

- 15

- Views

- 557