I'm hoping you guys can give me some advice on what you think may be going on here. Although I've been an avid shooter and reloader for many years, this is my first rifle set up for 1000+ yards. It is a stock Savage 110FCP .338LM. Load is 89.9gr Retumbo, WLRM primer, 300gr SMK, Lapua brass. I'd rather not mention the scope brand at this point until I rule it out as a possible cause, but suffice to say it is one that enjoys one of the better reputations here on the forum.

So the problem: at 100 yards, with this load the rifle will put three rounds into .30 MOA every time. At 500 yards, I was still getting a solid .50 MOA. However, on the three attempts I've made to shoot at 1000, the rifle starts out shooting at least sub-MOA where it should, but after a few shots, they begin to climb successively higher - up to a couple feet or more. I can then return the scope to zero, go back to 100 yards, and put another three rounds into .30 MOA, dead-on zero.

Now, I know that having a high ES can cause a load that shoots tight at 100 yds to break down at 1000, and I wasn't running a chrono when I was shooting at 1000, but on my earlier tests with this load I got an ES around 33 (avg - 2711). Not great, I know, but this load grouped much better than the same load with a CCI 250 at 500 yards, despite the CCI giving an ES of 21 - so I succumbed to the lure of the tighter groups at 500. Even so, if I plug in loads with an ES of 50 into the Shooter app, it only shows a difference in drop of about 12 in. from highest to lowest. PLUS, half of those would be ABOVE the aim point, and half would fall BELOW. With my current problem, the rifle starts out hitting where it would be expected for the avg. MV, then begins to climb higher and higher, but never lower - and WAY more than the extreme calculation of 12 inches.

Winds have been very light in each of these sessions, and are not a factor. The only three causes I can think of are 1) A high ES causing vertical stringing, but this is more severe than predicted; 2) A scope problem that drifts POI at the higher elevation (8.1 mil), but not at the lower, 100 yd. zero (Geez, is that even possible??), or 3) A problem with shooting technique. My ability to shoot consistently at 100 and 500, plus my first few shots of each session at 1000 would seem to indicate I'm doing my part, but I'm open to suggestions.

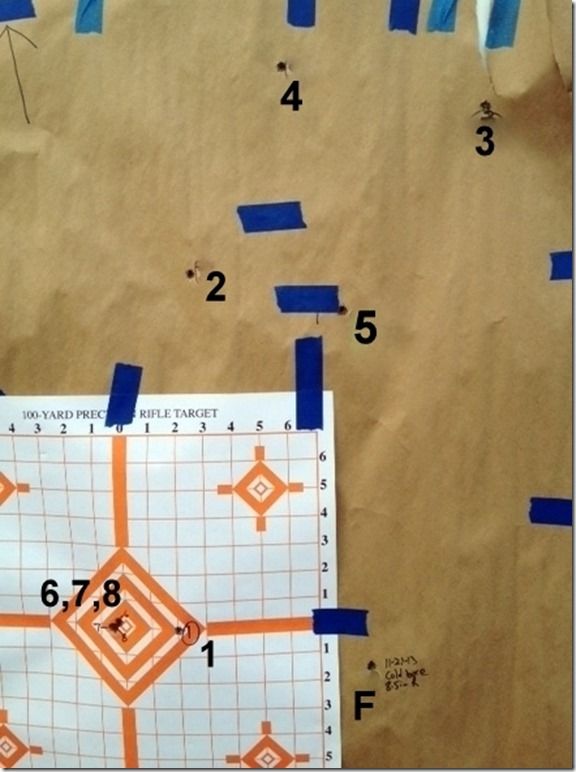

In the pic below, you can see my first shot (labeled "F" = clean/cold bore fouler) just to the right of the edge of the white paper, and close to the proper elevation (I over-compensated for a 4 mph wind from 90 deg.). I reduced my windage adjustment by half, and fired my next shot (labeled "1"). I felt pretty good about hitting dead-on elevation and only two inches right at 1000 yds on the first shot after the fouler. However, shot numbered 2-5 all did as in previous sessions, and climbed up, up, up. Having seen this happen twice before, I moved up to 100 yards, set the turrets to Zeros, and fired shots 6,7, and 8 into a 0.278 in. group (typical for this load), essentially dead-on zero.

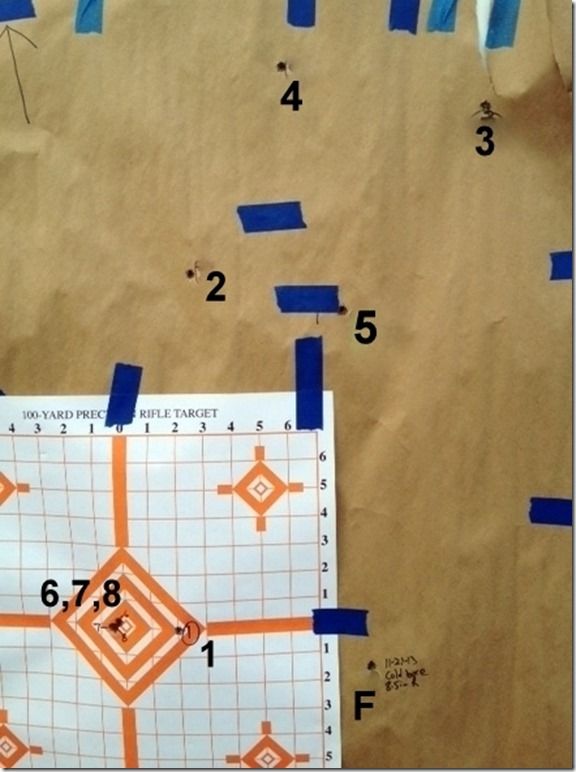

Here's a close-up of the 100 yd. group (shots 6,7, and 8).

So what do you guys think? Can ES of 30, or even 50 make THAT much difference between 100 and 1000?

So the problem: at 100 yards, with this load the rifle will put three rounds into .30 MOA every time. At 500 yards, I was still getting a solid .50 MOA. However, on the three attempts I've made to shoot at 1000, the rifle starts out shooting at least sub-MOA where it should, but after a few shots, they begin to climb successively higher - up to a couple feet or more. I can then return the scope to zero, go back to 100 yards, and put another three rounds into .30 MOA, dead-on zero.

Now, I know that having a high ES can cause a load that shoots tight at 100 yds to break down at 1000, and I wasn't running a chrono when I was shooting at 1000, but on my earlier tests with this load I got an ES around 33 (avg - 2711). Not great, I know, but this load grouped much better than the same load with a CCI 250 at 500 yards, despite the CCI giving an ES of 21 - so I succumbed to the lure of the tighter groups at 500. Even so, if I plug in loads with an ES of 50 into the Shooter app, it only shows a difference in drop of about 12 in. from highest to lowest. PLUS, half of those would be ABOVE the aim point, and half would fall BELOW. With my current problem, the rifle starts out hitting where it would be expected for the avg. MV, then begins to climb higher and higher, but never lower - and WAY more than the extreme calculation of 12 inches.

Winds have been very light in each of these sessions, and are not a factor. The only three causes I can think of are 1) A high ES causing vertical stringing, but this is more severe than predicted; 2) A scope problem that drifts POI at the higher elevation (8.1 mil), but not at the lower, 100 yd. zero (Geez, is that even possible??), or 3) A problem with shooting technique. My ability to shoot consistently at 100 and 500, plus my first few shots of each session at 1000 would seem to indicate I'm doing my part, but I'm open to suggestions.

In the pic below, you can see my first shot (labeled "F" = clean/cold bore fouler) just to the right of the edge of the white paper, and close to the proper elevation (I over-compensated for a 4 mph wind from 90 deg.). I reduced my windage adjustment by half, and fired my next shot (labeled "1"). I felt pretty good about hitting dead-on elevation and only two inches right at 1000 yds on the first shot after the fouler. However, shot numbered 2-5 all did as in previous sessions, and climbed up, up, up. Having seen this happen twice before, I moved up to 100 yards, set the turrets to Zeros, and fired shots 6,7, and 8 into a 0.278 in. group (typical for this load), essentially dead-on zero.

Here's a close-up of the 100 yd. group (shots 6,7, and 8).

So what do you guys think? Can ES of 30, or even 50 make THAT much difference between 100 and 1000?

Last edited: