Desert Tech? Who the heck is that? Well you all know Desert Tactical Arms (DTA). Apparently they were having trouble with exports and government agencies that did not like the name on the forms they were approving. "Tactical" is apparently one of those "scary words" that send liberals screaming for the hills with fear in their eyes. DTA decided to give in to the continued liberalization of the planet and change their name. So after spending the last 5 years talking about Desert Tactical Arms or DTA... we are suppose to talk about Desert Tech now instead. Same company, same products, new name. Confusing for the end user, and a pain in the ass for everyone else. So, in the future, DTA is now DT or Deserttech, ... or something. Now we've got that out of the way, lets get on with the review!

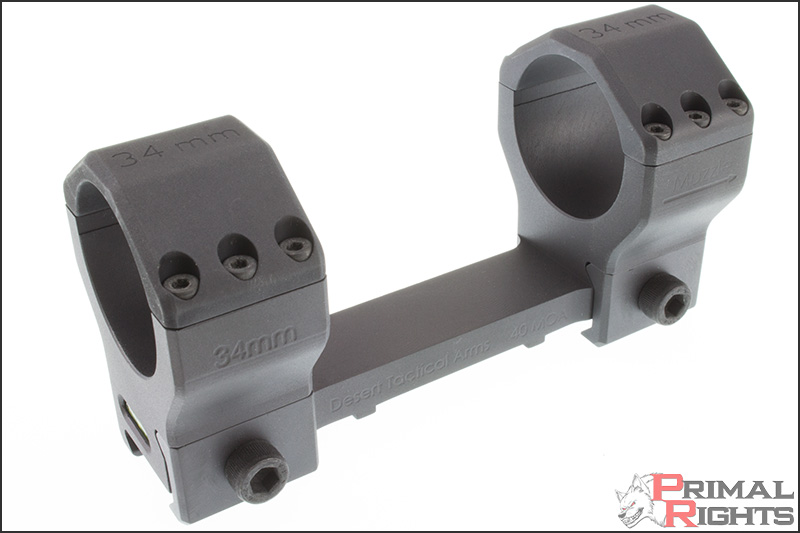

Today we're looking at the 1-piece scope mount from Desert Tech. There have been several revisions of these mounts over the last year. Originally DTA offered two different mounts. One for the SRS, which was a 4-screw ring design, and one for the HTI which was a 6-screw ring design. In an effort to streamline production, they elected to eliminate the SRS design and only offer the HTI version, which is now referred to as the Desert Tech Scope Mount.

Price: $370

Height: 1.5"

Tube Diameter: 34mm (with optional 30mm aluminum inserts)

MOA Slope: 20, 30, or 40 MOA

Material: 7075 T6 Aircraft-Grade Aluminum

As you can see, this mount is very robust. It was designed to tame the most abusive recoil the 50BMG can dish out. The 6-screw ring design has more surface area which ensures a very solid mating between the optic and the mount. The 1.5" height ensures that large optics typically found on long range rifles will clear a monolithic picatinny rail such as is found on DTA rifles. Even with a 40MOA slope, this mount will allow you to run an ARD or sunshade on a Premier 5-25x56 or similarly sized optic, while still maintaining clearance from the pic rail.

Here's a look at the top of the mount. The six cap screws are 2.5mm interface, and provide ample torque to give a good clamp on the scope tube. The ring size is engraved, so you won't forget.

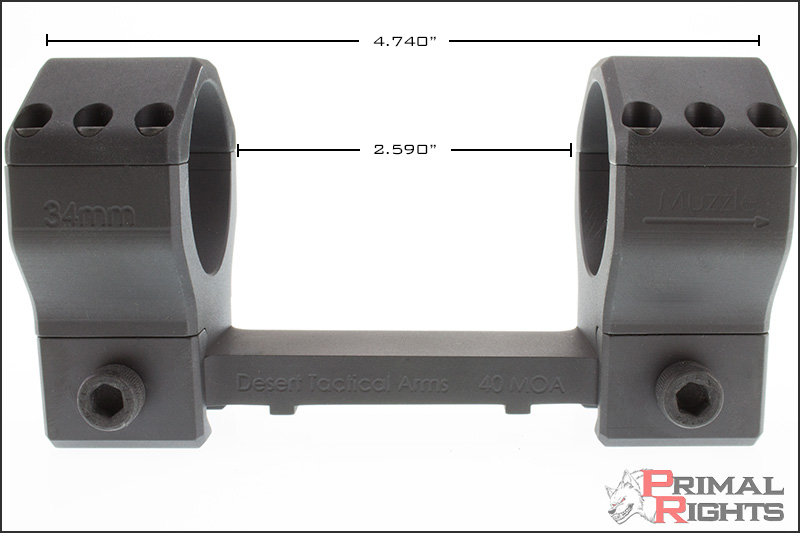

From the side view, you'll see some more indicative engraving to ensure you never forget what size and slope your mount is. The front ring has a directional arrow which indicates the direction of slope, that way you don't put it on backwards. The pic rail clamps are quite large, providing a huge amount of clamping surface. The cap screws use a 5mm interface and can be torqued 70-80in/lbs. Both the SRS and HTI rifle barrel screws are 5mm, and are torqued to 70 and 80in/lbs, respectively. Desert Tech has no published specs that I'm aware of for this mount, so I grabbed a caliper and took some measurements. You'll see those readings in the pictures where applicable.

The rear of the mount has an integral bubble level. This is a very cool feature to help you eliminate canting your rifle. There are bubble levels that clamp onto your scope tube or your picatinny rail, but they generally stick out and get caught on things. The style that clamps on the scope tube almost always gets in the way of your turrets, and can create a knuckle-buster. The integral level is where it's at! If you take a closer look, you can certainly tell the attention to detail that went into the design of the mount.

On the opposite side, they knocked out a couple healthy chunks of material to lighten things up a bit. Notice the foresight to open up the area behind the bubble level. This will let some ambient light through and let you see the level in darker conditions than you would if it were sealed.

On the bottom, two individual lugs to interface with the pic rail. There are also some more areas machined out to save some weight without losing any structural integrity.

Behind the rear pic rail clamp, the bubble level is epoxied in place to ensure that it will not get to wiggling around in there.

These mounts have been working outstandingly well on every application we've used them on thus far. There are a few left in stock, and we'll have a healthy supply of them by the end of January.