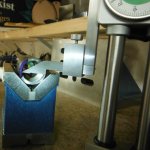

I put a WTB in the PX but with all the smith's looking in here I thought I might better my odds. I am looking to buy one or possibly rent one of the Hollands switch barrel drilling fixtures like this.

http://www.hollandguns.com/DrillFix.jpg

Let me know if you have one to sell or know where I might find one. Thanks!

http://www.hollandguns.com/DrillFix.jpg

Let me know if you have one to sell or know where I might find one. Thanks!

Last edited: