I lucked out. Local bass pro got 4lbs of it and assortment of others in a few weeks back, I ended up with 2lbs. And I lucked out big time today at local academy, went in getting some .22lr and sure as hell they had 1LB of H4350 and some others on the shelf.Where the hell are you all getting H4350???

- Thread starter Sportin Wood

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I got some IMR 8431 and IMR 3031 at various times as well. Local mom and pop shop here had 8lb of Win 760 last weekWhere the hell are you all getting H4350???

Hi all,

This is my first attempt to reloading, sorry about the lengthy post and bear with me if something sounds stupid

Tikka T3X TAC A1 6,5 CRMR with original Tikka 24" barrel (486 shots before these)

once shot Sako LRP Brass

- Demprimed and then ultrasonic cleaned

- bumped shoulder back 0.002" to 1.558" (Datum) and FL-sized (Redding Type-S Match dies with 0.289" bushing) trimmed to 1.910".

CCI 200 LRP primers

Hornady ELD-M 147gr

Seated the bullet to 2.265" CBTO, which is also close to my Mag max length

Powder is Vihtavuori N555, as there was no loading data available I shot one shot 38-40 gr in 0.5gr increments to test for pressure and then proceeded to shoot 5 shots in 0.3 gr increments.

Unfortunately my labradar died (battery) after the first five shots of 40.3 gr so I shot one shot each load to test for pressures. That's also the reason why i shot 4 shot strings today. The 40.3 gr gave me AVG=773m/s / 2536fps (powder temp +27C / 80.6F)

First I shot the CB and fouled the barrel with 5 shots of Sako Range.

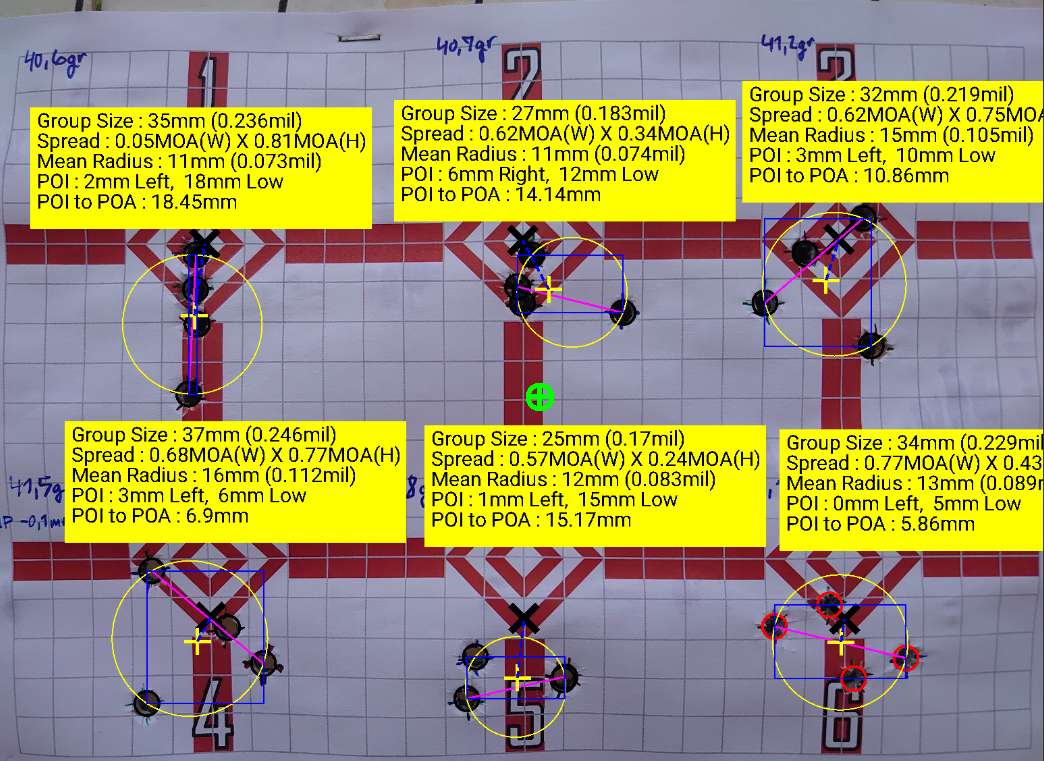

Range was 150m / 164 yards, after 41.2gr i took 0.1 mrad down to avoid aiming at the POI. Waited about 10 min after every 4 shots to let the chamber and barrell cool down a bit.

40.6 gr (Powder temp +18.7C / 65.7F)

AVG=778 m/s (2552fps), ES=6, SD=3.0

1: 780 m/s

2: 776 m/s

3: 781 m/s

4: 774 m/s

40.9 gr

AVG=778 m/s (2552fps), ES=7, SD=2.9

1: 777 m/s

2: 782 m/s

3: 775 m/s

4: 779 m/s

41.2 gr

AVG=786 m/s (2578fps), ES=1, SD=0.3

1: 786 m/s

2: 786 m/s

3: 786 m/s

4: 786 m/s

41.5 gr

AVG=792 m/s (2598fps), ES=3, SD=1.4

1: 793 m/s

2: 792 m/s

3: 793 m/s

4: 790 m/s

41.8 gr

AVG= 798 m/s (2618fps), ES=5, SD=2.1

1: 798 m/s

2: 796 m/s

3: 799 m/s

4: 801 m/s

42.1 gr

AVG= 804 m/s (2637fps), ES=5, SD=2.4

1: 807 m/s

2: 804 m/s

3: 803 m/s

4: 802 m/s

Colours are not that visible in the pic, but:

1st shot = Green

2nd shot = Red

3rd shot = Blue

4th shot = Brown

Didn't get any clear pressure signs and I'm okay happy with the velocities (Tikka barrells are somewhat slow). I'm not happy with groups, but the shooter is a bit rusty here aswell with couple of flyers that were obvious before going to the targets

What do you guys think?

- Do I need to go forward with more powder? I'm somewhat hesitant because the brass is getting quite full already and if I'm going to start bring the bullet seating depth down in the next phase it's just getting more crowded there. Also 2637fps is getting me to over 1.2 km, which is plenty for this caliper and for me.

- I was thinking of selecting one powder measure here and make three groups of different seating depths and go to 300m or 500m to test the groupings, something like:

3 shots of 2.265" (current CBTO)

3 shots of 2.262" (-0.003")

3 shots of 2.259" etc etc.

What recipe should I select going forward?

Cheers, Valtteri

This is my first attempt to reloading, sorry about the lengthy post and bear with me if something sounds stupid

Tikka T3X TAC A1 6,5 CRMR with original Tikka 24" barrel (486 shots before these)

once shot Sako LRP Brass

- Demprimed and then ultrasonic cleaned

- bumped shoulder back 0.002" to 1.558" (Datum) and FL-sized (Redding Type-S Match dies with 0.289" bushing) trimmed to 1.910".

CCI 200 LRP primers

Hornady ELD-M 147gr

Seated the bullet to 2.265" CBTO, which is also close to my Mag max length

Powder is Vihtavuori N555, as there was no loading data available I shot one shot 38-40 gr in 0.5gr increments to test for pressure and then proceeded to shoot 5 shots in 0.3 gr increments.

Unfortunately my labradar died (battery) after the first five shots of 40.3 gr so I shot one shot each load to test for pressures. That's also the reason why i shot 4 shot strings today. The 40.3 gr gave me AVG=773m/s / 2536fps (powder temp +27C / 80.6F)

First I shot the CB and fouled the barrel with 5 shots of Sako Range.

Range was 150m / 164 yards, after 41.2gr i took 0.1 mrad down to avoid aiming at the POI. Waited about 10 min after every 4 shots to let the chamber and barrell cool down a bit.

40.6 gr (Powder temp +18.7C / 65.7F)

AVG=778 m/s (2552fps), ES=6, SD=3.0

1: 780 m/s

2: 776 m/s

3: 781 m/s

4: 774 m/s

40.9 gr

AVG=778 m/s (2552fps), ES=7, SD=2.9

1: 777 m/s

2: 782 m/s

3: 775 m/s

4: 779 m/s

41.2 gr

AVG=786 m/s (2578fps), ES=1, SD=0.3

1: 786 m/s

2: 786 m/s

3: 786 m/s

4: 786 m/s

41.5 gr

AVG=792 m/s (2598fps), ES=3, SD=1.4

1: 793 m/s

2: 792 m/s

3: 793 m/s

4: 790 m/s

41.8 gr

AVG= 798 m/s (2618fps), ES=5, SD=2.1

1: 798 m/s

2: 796 m/s

3: 799 m/s

4: 801 m/s

42.1 gr

AVG= 804 m/s (2637fps), ES=5, SD=2.4

1: 807 m/s

2: 804 m/s

3: 803 m/s

4: 802 m/s

Colours are not that visible in the pic, but:

1st shot = Green

2nd shot = Red

3rd shot = Blue

4th shot = Brown

Didn't get any clear pressure signs and I'm okay happy with the velocities (Tikka barrells are somewhat slow). I'm not happy with groups, but the shooter is a bit rusty here aswell with couple of flyers that were obvious before going to the targets

What do you guys think?

- Do I need to go forward with more powder? I'm somewhat hesitant because the brass is getting quite full already and if I'm going to start bring the bullet seating depth down in the next phase it's just getting more crowded there. Also 2637fps is getting me to over 1.2 km, which is plenty for this caliper and for me.

- I was thinking of selecting one powder measure here and make three groups of different seating depths and go to 300m or 500m to test the groupings, something like:

3 shots of 2.265" (current CBTO)

3 shots of 2.262" (-0.003")

3 shots of 2.259" etc etc.

What recipe should I select going forward?

Cheers, Valtteri

Graph out your distributions, check where the mean of each load looks to be tight as a distribution (low variance) and the groups around each distro looks leveled out. You are looking for a node that is in a stable region that up or down will give little impact and give you the velocities you’ll want to keep the bullet stable at distance. From there fine tune that node up and down to make sure it is in fact stable. After that use that load and begin testing your seating depth. Start long then bump back with the same process above.

I'm not totally sure if I understood you correctly.Graph out your distributions, check where the mean of each load looks to be tight as a distribution (low variance) and the groups around each distro looks leveled out. You are looking for a node that is in a stable region that up or down will give little impact and give you the velocities you’ll want to keep the bullet stable at distance. From there fine tune that node up and down to make sure it is in fact stable. After that use that load and begin testing your seating depth. Start long then bump back with the same process above.

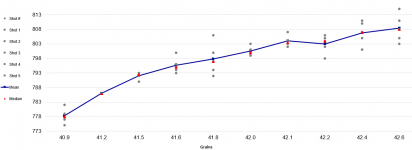

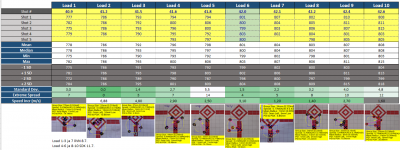

I uploaded the data to the 65 Guys spreadsheet:

From this data I don't see a clear node between two increments 0.3 grains (other than 40.6 and 40.9), the variance between velocities within 41.2 and 41.5 seem to be smallest - Am I getting it?

You’re correct. Outside of the lower node it doesn’t look like you have a significant node yet. If you aren’t getting signs of pressure i would maybe keep going up. You COULD also run a ballistics simulation for the powder, bullet seating depth etc variables on Quick Load OR my new favorite Toy Gordon’s Reloading Tool: LinkI'm not totally sure if I understood you correctly.

I uploaded the data to the 65 Guys spreadsheet:

View attachment 7907949

From this data I don't see a clear node between two increments 0.3 grains (other than 40.6 and 40.9), the variance between velocities within 41.2 and 41.5 seem to be smallest - Am I getting it?

No pressure signs. Had a experienced mentor with me, because of 15 years of shooting government guns I think I wouldn't notice a heavy bolt lift...You’re correct. Outside of the lower node it doesn’t look like you have a significant node yet. If you aren’t getting signs of pressure i would maybe keep going up. You COULD also run a ballistics simulation for the powder, bullet seating depth etc variables on Quick Load OR my new favorite Toy Gordon’s Reloading Tool: Link

My only concern is that if I add more powder, the cases are getting quite full. And if the next step is adjusting the bullet more into the brass, I might get more pressure / inconsistent bullet seating?

On the right side corner in the pic are the 42,1gr - is there enough room for more of the good stuff?

No pressure signs. Had a experienced mentor with me, because of 15 years of shooting government guns I think I wouldn't notice a heavy bolt lift...

My only concern is that if I add more powder, the cases are getting quite full. And if the next step is adjusting the bullet more into the brass, I might get more pressure / inconsistent bullet seating?

On the right side corner in the pic are the 42,1gr - is there enough room for more of the good stuff?

View attachment 7907971

Im not a ballistitian (sp? But I am an engineer) but I’d say you might not have the proper powder and bullet / load combo for your rifle. You may need something that’s faster burning bc you could be “leaving something in the tank” so to speak w h4350 and that short of a barrel or heavy of a bullet. So I’d say maybe try a lighter bullet, 130, 135, 120 and maybe a faster (burning) powder like Varget. You may get better nodes and results….

So i went ahead and loaded 5 rounds 41.6 - 42.6 gr in 0.2 increments.Im not a ballistitian (sp? But I am an engineer) but I’d say you might not have the proper powder and bullet / load combo for your rifle. You may need something that’s faster burning bc you could be “leaving something in the tank” so to speak w h4350 and that short of a barrel or heavy of a bullet. So I’d say maybe try a lighter bullet, 130, 135, 120 and maybe a faster (burning) powder like Varget. You may get better nodes and results….

CB + 4 shot group first and then 5 rounds, waited the barrel to cool down between shot strings.

Different range (still 150m), +18 C.

No pressure marks.

I integrated the results to the previous data sheet (yes I know, increments vary) :

I consulted my mentor and I think I'll be going forward with 42.0 gr.

Going to load 5 rounds current CBTO (2.265") + 5 rds CBTO-0.003" + 5 rds CBTO-0.006" and test for the best group

Am I heading to the right direction?

(Edited and got rid of lots of nonsense)

Last edited:

So i went ahead and loaded 5 rounds 41.6 - 42.6 gr in 0.2 increments.

CB + 4 shot group first and then 5 rounds, waited the barrel to cool down between shot strings.

Different range (still 150m), +18 C.

No pressure marks.

I integrated the results to the previous data sheet (yes I know, increments vary) :

View attachment 7910204View attachment 7910205

I consulted my mentor and I think I'll be going forward with 42.0 gr.

Going to load 5 rounds current CBTO (2.265") + 5 rds CBTO-0.003" + 5 rds CBTO-0.006" and test for the best group

Am I heading to the right direction?

(Edited and got rid of lots of nonsense)

Hell yeah! Nice! My load dev is about that as well for a few a loads I’ve developed for H4350.

Yes, If you change the expander ball or mandrel that you use. The outside will get squeezed a fixed amount, so how far you open it back up controls tension.can you adjust neck tension with full length sizing dies?

and does budlging at the base of the case ie near the primer suggest case wearing out??? have had case start to bulge at the base

After firing, or after sizing?

Off the top of my head with no other info - Either way too hot, chamber issue, or you're running a semi and it's unlocking early/overgassed.

N560….. magical fairy dust….? So I reload both 6.5 cm and 300 PRC. Both of which are listed on VVs load data w decent numbers for both…. Anyone reload 6.5cm with it? Seems a bit slow but the reported numbers look ok…. One powder to rule them all….?

Getting back into a 6.5 CM. I have loads from an old rifle that I will be pulling the bullets and neck sizing to get the neck back.

Hornady virgin brass (from a long time ago...LOL)

H4350

CCI BR-2

Hornady 140 Amax (need to use up probably close to 1k)

Sierra 142 SMK (maybe 400....thought I had another full box of 500, but can't find it)

Once I shoot these, I'll look into heavier bullets (147 ELDM...)

Origin Action

Proof Research 26" Competition (1/8 twist)

I will be running a Dead Air brake until my DA Sandman L gets out of jail. I literally ordered it this afternoon so it'll likely be a birthday present to myself in November.

With the components and rifle above, can I get some suggestions for a range that others have had success? Just trying to narrow down a window rather than trying the full spectrum.

Also, will running suppressed have a huge impact on load? Will I need to create a suppressed load? Once the can is out, I'll likely never run the rifle without it

Hornady virgin brass (from a long time ago...LOL)

H4350

CCI BR-2

Hornady 140 Amax (need to use up probably close to 1k)

Sierra 142 SMK (maybe 400....thought I had another full box of 500, but can't find it)

Once I shoot these, I'll look into heavier bullets (147 ELDM...)

Origin Action

Proof Research 26" Competition (1/8 twist)

I will be running a Dead Air brake until my DA Sandman L gets out of jail. I literally ordered it this afternoon so it'll likely be a birthday present to myself in November.

With the components and rifle above, can I get some suggestions for a range that others have had success? Just trying to narrow down a window rather than trying the full spectrum.

Also, will running suppressed have a huge impact on load? Will I need to create a suppressed load? Once the can is out, I'll likely never run the rifle without it

I do all load development and all shooting with my can so I really don't know how much different it would be in terms if speed but you shouldnt have to do 2 different loads, but as always, shoot it and see. I've shot my 6.5cm out to right at 1400 and 1288 I think it was at night. I shoot a 130 Berger otm though. Great bullet doe 6.5cm imo. 1430 I think is about my limit with my 6.5cm load being super, nor sure how far I could shoot it accurately beyond that since I never have done it.Getting back into a 6.5 CM. I have loads from an old rifle that I will be pulling the bullets and neck sizing to get the neck back.

Hornady virgin brass (from a long time ago...LOL)

H4350

CCI BR-2

Hornady 140 Amax (need to use up probably close to 1k)

Sierra 142 SMK (maybe 400....thought I had another full box of 500, but can't find it)

Once I shoot these, I'll look into heavier bullets (147 ELDM...)

Origin Action

Proof Research 26" Competition (1/8 twist)

I will be running a Dead Air brake until my DA Sandman L gets out of jail. I literally ordered it this afternoon so it'll likely be a birthday present to myself in November.

With the components and rifle above, can I get some suggestions for a range that others have had success? Just trying to narrow down a window rather than trying the full spectrum.

Also, will running suppressed have a huge impact on load? Will I need to create a suppressed load? Once the can is out, I'll likely never run the rifle without it

Do you want to sell your 142 matchkings?Getting back into a 6.5 CM. I have loads from an old rifle that I will be pulling the bullets and neck sizing to get the neck back.

Hornady virgin brass (from a long time ago...LOL)

H4350

CCI BR-2

Hornady 140 Amax (need to use up probably close to 1k)

Sierra 142 SMK (maybe 400....thought I had another full box of 500, but can't find it)

Once I shoot these, I'll look into heavier bullets (147 ELDM...)

Origin Action

Proof Research 26" Competition (1/8 twist)

I will be running a Dead Air brake until my DA Sandman L gets out of jail. I literally ordered it this afternoon so it'll likely be a birthday present to myself in November.

With the components and rifle above, can I get some suggestions for a range that others have had success? Just trying to narrow down a window rather than trying the full spectrum.

Also, will running suppressed have a huge impact on load? Will I need to create a suppressed load? Once the can is out, I'll likely never run the rifle without it

when full length resizing, some of the case, sizes with no problems, but other case is really tight in the neck and hard to press?? and those are the ones that have the bulge near the case head, any thoughts????

Have you measured the head space of your fire formed brass yet and adjusted your shoulder bump? Are you using enough and even lube? Do you have pics of the case bulge? Are you seeing pressure signs on the brass? Swiping, cratering, etc…?

“Brass always looks scratched” is that after firing, or after sizing? Sounds like a lube and die galling problems, but pictures and a full description of your process and loads are needed, otherwise you’re going to get a less than useful back and forth.

ok got it figured out found out one of my die bushings for my sizing die is worn out, which means everytime i resize a case my die is lifting up some. so as the pictures show on a case that is still good the diameter near the case head is .4680 but sizing now with the bushing issue the diameter near the case head is .4725 which means it wont go into battery and gets jammed in the chamber.so most of the case is resized except for near the case head. had to order new bushings for the dies but have figured out the bushings are made of aluminum and keep wearing out. so went out and bought a rcbs rock crusher single stage, and use it for just resizing the case with. but the case with all the problems now wont size and chamber. so lost about 300 case this week!!! oh well live and learn!!

Attachments

I’ve been doing pretty good for a 65cm load work up lately

AI-ATX seems to make it easy but I have been VERY consistent I’m making the rounds.

I’m consistently now getting sub half-MOA groups @100 meters

I know atips are mondo expensive but they are awesome.

Lapua brass

42.9 gr H4350

135 aTIPs

Cci 450 SRPs

7-8 SD

2845 avg muzzle chrono

In my case I have to do virgin loads first to get a decent Ammt of once fired brass

I’ve got a really good slow node also @41.5 gr (2 670 fps)

670 fps)

I’ve proven consistent results with once fired after bumping back 2 thou shoulder and a COL of 2.819 at 3 thou seat pressure

I’m also annealing every time and .262 mandrel. Primer pocket ream depth 0.1270

So, I’ve also saving my atips at this point and loaded up 26 lapua scener-L 136gr OTMs in a 42.6 gr h4350 load of virgins to just use them to get more fired formed

AI-ATX seems to make it easy but I have been VERY consistent I’m making the rounds.

I’m consistently now getting sub half-MOA groups @100 meters

I know atips are mondo expensive but they are awesome.

Lapua brass

42.9 gr H4350

135 aTIPs

Cci 450 SRPs

7-8 SD

2845 avg muzzle chrono

In my case I have to do virgin loads first to get a decent Ammt of once fired brass

I’ve got a really good slow node also @41.5 gr (2

I’ve proven consistent results with once fired after bumping back 2 thou shoulder and a COL of 2.819 at 3 thou seat pressure

I’m also annealing every time and .262 mandrel. Primer pocket ream depth 0.1270

So, I’ve also saving my atips at this point and loaded up 26 lapua scener-L 136gr OTMs in a 42.6 gr h4350 load of virgins to just use them to get more fired formed

Last edited:

I had an 18” proof barrel at one time. 44.4 gr of H4350 and a 127 lrx at sea level going 2780fps. Lapua brass, CCI 450. Hope this helps. Definitely start below that grain weight by a considerable margin.Anyone got any insight for load data using 127 Barnes LRX or Hammer Hunters out of an 18” barrel? Velocities and such

Have you done anything with the 153gr atip? I just got my build back its a 27in bartlein, impact action, christensen arms chasis, shooting factory 140gr eld at 2780fps and .5moa 3 shot groups. But i have 200 153gr atip 300 lapua brass srp cci450 and br4 primers just need to know whats good powder for the atipI’ve been doing pretty good for a 65cm load work up lately

AI-ATX seems to make it easy but I have been VERY consistent I’m making the rounds.

I’m consistently now getting sub half-MOA groups @100 meters

I know atips are mondo expensive but they are awesome.

Lapua brass

42.9 gr H4350

135 aTIPs

Cci 450 SRPs

7-8 SD

2845 avg muzzle chrono

In my case I have to do virgin loads first to get a decent Ammt of once fired brass

I’ve got a really good slow node also @41.5 gr (2View attachment 7913252670 fps)

I’ve proven consistent results with once fired after bumping back 2 thou shoulder and a COL of 2.819 at 3 thou seat pressure

I’m also annealing every time and .262 mandrel. Primer pocket ream depth 0.1270

So, I’ve also saving my atips at this point and loaded up 26 lapua scener-L 136gr OTMs in a 42.6 gr h4350 load of virgins to just use them to get more fired formed

Thanks

I have not used 153s. I can say that I’d go out on a limb and bet they would be great. Still, that a lot heavier than I have shot for Creedmoor in either of my 2 gunsHave you done anything with the 153gr atip? I just got my build back its a 27in bartlein, impact action, christensen arms chasis, shooting factory 140gr eld at 2780fps and .5moa 3 shot groups. But i have 200 153gr atip 300 lapua brass srp cci450 and br4 primers just need to know whats good powder for the atip

Thanks

If you got ‘em already then I’d try ‘em with re16 h4350 n555.

Thanks

So i went ahead and loaded 5 rounds 41.6 - 42.6 gr in 0.2 increments.

CB + 4 shot group first and then 5 rounds, waited the barrel to cool down between shot strings.

Different range (still 150m), +18 C.

No pressure marks.

I integrated the results to the previous data sheet (yes I know, increments vary) :

View attachment 7910204View attachment 7910205

I consulted my mentor and I think I'll be going forward with 42.0 gr.

Going to load 5 rounds current CBTO (2.265") + 5 rds CBTO-0.003" + 5 rds CBTO-0.006" and test for the best group

Am I heading to the right direction?

(Edited and got rid of lots of nonsense)

Yes you are on the right track: Speed graph is rather flat in this area, and SD nrs came way down too, and that is a very good sign.

I would redo 42.0, 42.1, 42.2 and 42.3 gns, using 5 shot groups, and see 1) Does the flat spot repeat in the same area (at different ambient temp), and 2) Is SD still small, and where is the “middle of powder node”? Ignore group size for this step.

Then optimize seating depth in increments of 3 thou, like you proposed, being very careful with your shoulder bump: Errors in shoulder bump changes actual distance to the lands, since the case indexes off the shoulder once inside the chamber. Put aside any cases for now where the case head to shoulder datum line did not come out correct. Around 1.0 to 1.5 thou is about as best you can measure with calipers. Turn the case with your fingers until you get the minimum measurement.

You should be able to shrink your group size a lot via seating depth optimization. A barrel tuner does the same job btw.

When reconfirming your powder node/speed flat spot, wait for a colder or hotter day: If your chosen powder is rather temp sensitive, you may see the powder node move to a different value, but check the speed, it should still correlated well with the speed you saw before (if your crony is top accuracy, so Labradar or Magnetospeed). [Remember that mounting your Labradar at a way different distance from the muzzle every time will cause a speed error, which could confuse your experimental data.]

If the associate speed of the flat spot is consistent, but the required powder charge moves with ambient temp, then you could still figure out a correction in powder charge to compensate for hotter or colder weather. Load more than one batch and pick the most appropriate batch based on the weather prediction.

If the flat spot does not show up this time, then the data from the previous test (or this test) was just blind good luck (or sadly bad luck), and you need to keep looking…

But: Looks like you might be close… Best of luck!

Last edited:

ok got it figured out found out one of my die bushings for my sizing die is worn out, which means everytime i resize a case my die is lifting up some. so as the pictures show on a case that is still good the diameter near the case head is .4680 but sizing now with the bushing issue the diameter near the case head is .4725 which means it wont go into battery and gets jammed in the chamber.so most of the case is resized except for near the case head. had to order new bushings for the dies but have figured out the bushings are made of aluminum and keep wearing out. so went out and bought a rcbs rock crusher single stage, and use it for just resizing the case with. but the case with all the problems now wont size and chamber. so lost about 300 case this week!!! oh well live and learn!!

You could try to rescue your old brass using a small base die. Use lots of lube.

If the web area and primer pockets have expanded, often a sign of over pressure loads, it likely won’t help, but still worth a shot. Brass is expensive, and a small base die will prove to be useful in future (e. g. if a replacement custom barrels has a tight/march chamber), and they are not really expensive.

Best solution: There is a thing called a “ring die”, that is designed to resize the web area. Patriot Valley Arms used to make one, but it seems they stopped. Don’t have one, but would love to have it in reserve…

Last edited:

I got my hands on h4350 so i have staball and h4350 where would you start with that powder i read a lot and that powder was considered to be the best for 6.5creedmoor with the srp brass thanks for your help

Factory works just fine for me, but I prefer my hand loads. These are in large platform AR's.

Mine aren't speed demons as my best groupings are mid range on the powder table. I have used a lot of H4350, but it is hard to find right now. IMR4350 functioned pretty well, i need to get some chrony data on it. In addtion I just got a keg of StaBall 6.5 and plan to ladder this weekend.

My rifle tends to like the heavier projectiles. 147 and 140 ELD Match have worked very well for me. The 120-123 I use in my Grendel.

Use your factory and load the used brass. My 6.5 Creedmoor brass seems to last quite a while.

Think you will like the 6.5 Creedmoor.

Mine aren't speed demons as my best groupings are mid range on the powder table. I have used a lot of H4350, but it is hard to find right now. IMR4350 functioned pretty well, i need to get some chrony data on it. In addtion I just got a keg of StaBall 6.5 and plan to ladder this weekend.

My rifle tends to like the heavier projectiles. 147 and 140 ELD Match have worked very well for me. The 120-123 I use in my Grendel.

Use your factory and load the used brass. My 6.5 Creedmoor brass seems to last quite a while.

Think you will like the 6.5 Creedmoor.

For the 140gr, start at 39gr of H4350 and work up in .3 gr increments. The lower velocity node is around 2,730 fps. That's 41.5gr of H4350 in my gun. Higher velocity nodes are around 2,770 and 2,850. The 2,850 is generally around 42.5gr.

Thank you very much for your helpFor the 140gr, start at 39gr of H4350 and work up in .3 gr increments. The lower velocity node is around 2,730 fps. That's 41.5gr of H4350 in my gun. Higher velocity nodes are around 2,770 and 2,850. The 2,850 is generally around 42.5gr.

I got my hands on h4350 so i have staball and h4350 where would you start with that powder i read a lot and that powder was considered to be the best for 6.5creedmoor with the srp brass thanks for your help

Both are good:

Perhaps use Staball for plinking/practice loads, since it is far easier to get. Also very convenient and fast to load. Of all the ball powders, it is the least temperature sensitive, and it meters very well, so you can use a cheap $30 Lee powder measure to throw the charges, no need to weigh and trickle up each one, as long as you are not super close to a max load. Will be on par or slightly better than factory ammo with an SD of 12-16 fps. Saves a lot of time in the reloading room. I got charges thrown to within 0.2 grain, which is plenty good out to 400 yards. Depends in where you live, but you probably will need a winter and summer load, and that is perfectly fine (if you have access to a crony). Should be a good practice load.

Maybe use H4350 for the 600-1500 yard range, it often produces the best ES, and is very temp insensitive. It beats Staball by about 3x in terms of temp stability. No need for a different winter and summer load. Not hard on the barrel (compared to say double base powders like RL-26), less speed but more barrel life. Generally very accurate in 6.5 Creedmoor. But very hard to find. IMR4350 is similar but not identical, and a viable alternative, but powder charge needed for the same speed will be about 0.6 gn different. I would save H4350 powder for the more serious activities. Very good powder, but can be hard to find.

Enjoy your rifle, and be safe.

Last edited:

Quick note and FYI on 6.5 CM Lapua SRP brass. You know, with the small flash hole. This isn't working with CCI450 primers. I had scored 2000 for 300 BLK and figured I'd give them a try in 6.5 CM, but I'm still seeing pressure signs including pierced primers down to 1.5 grains below book max. So, I'm at 42.2 grains of StaBall 6.5 and getting about 2630 fps with 140 ELD-M's. Compared to Hornady LRP brass with CCI BR2's loaded with 43.7 grains of StaBall 6.5 getting 2693 fps. This is an 18" barrel in my gas gun. COAL is always 2.80 as the gun likes that.

Since my guns a DPMS G2 version I can't get a JP High Pressure Bolt so I scored 1000 CCI BR4's today at Natchez and I'll see how those do.

Anyone else tried magnum SRP primers in the Lapua SRP brass with the small flash holes?

Since my guns a DPMS G2 version I can't get a JP High Pressure Bolt so I scored 1000 CCI BR4's today at Natchez and I'll see how those do.

Anyone else tried magnum SRP primers in the Lapua SRP brass with the small flash holes?

Edit: start wherever you want. Stop at 41.5 and tune with a seating depth test.

That brings up a question I had. The discussions and guides I've seen typically say to start with seating depth, using a charge that will be "close" to where you end up, get the seating depth set, then run your charge ladder. Your method is to get the powder charge settled then fine tune OAL?

Generally speaking my method is charge to the speed I'm looking for then tune group size with seating depth if needed.That brings up a question I had. The discussions and guides I've seen typically say to start with seating depth, using a charge that will be "close" to where you end up, get the seating depth set, then run your charge ladder. Your method is to get the powder charge settled then fine tune OAL?

I'd have to go back through my notes but IIRC, I was running 2700ish on speed with a single digit SD so I stopped playing with powder. Found mag jam or lands, started jumping 30, and jump tested in .020" or so increments and picked a favorable 5 shot group aggregate and ran it from there. I don't get really crazy with depth because it changes case volume, which then changed speed, and you get in this vicious tail chasing exercise. I try and change as few components/variables as possible for easily repeatable results. And in the case of my 6.5CM, I'm loading for PRS, not BR. So if it prints a .500, or 2-ish bullets wide, I'm happy.

Can be done either way. Generally if you are familiar with the powder and bullet and previous good load, you can start with seating depth. This makes load testing a little easier bc the velocity nodes should be easier to spot bc the group " shape" has ready been tuned.

If you are unfamiliar with or testing a new powder or bullet combination, it's best to start with powder charge. The bullet is seated to a best guess depth. Many start at .020 off the lands. This basically gets you going and avoids pressure issues by being seated to close to the lands.

Then you can either use the 3 shot powder charge ladder method, loading 3rounds at .3 gr increments and look for velocity flat spots with low ES and SD numbers or use the 10 single shot method with .3 gr increments and look for flat spots. Then proceed to the 3 shot method to fine tune a narrower range of powder charge. Using a single 10 method first will generally, but not always, identify the velocity node and save components vs just starting with a 3 shot ladder.

Once the powder charge is determined, then you move to seating depth testing to tighten the group up.

Furman has a good video on this on the Long Range Only website.

If you are unfamiliar with or testing a new powder or bullet combination, it's best to start with powder charge. The bullet is seated to a best guess depth. Many start at .020 off the lands. This basically gets you going and avoids pressure issues by being seated to close to the lands.

Then you can either use the 3 shot powder charge ladder method, loading 3rounds at .3 gr increments and look for velocity flat spots with low ES and SD numbers or use the 10 single shot method with .3 gr increments and look for flat spots. Then proceed to the 3 shot method to fine tune a narrower range of powder charge. Using a single 10 method first will generally, but not always, identify the velocity node and save components vs just starting with a 3 shot ladder.

Once the powder charge is determined, then you move to seating depth testing to tighten the group up.

Furman has a good video on this on the Long Range Only website.

I don't get really crazy with depth because it changes case volume, which then changed speed, and you get in this vicious tail chasing exercise.

Exactly! This is what it seemed like to me. Get a charge weight (or seating depth), then get a seating depth (or charge weight) and your numbers change. It could never end.

Thanks for your response!

MG

MG, that is incorrect. Powder charge to determine best velocity, POI, ES and SD. Seating depth to determine group shape/size.

It is not endless.

If your seating depth was jam and you move away from that, pressure will drop and you may have to adjust load. If your seating depth was off the lands and you move to jam, pressure will rise and you may have to adjust load. Other than that, if your seating depth is off the lands and you are moving it in slight increments,.003 increments, that is not going to affect your load.

It is not endless.

If your seating depth was jam and you move away from that, pressure will drop and you may have to adjust load. If your seating depth was off the lands and you move to jam, pressure will rise and you may have to adjust load. Other than that, if your seating depth is off the lands and you are moving it in slight increments,.003 increments, that is not going to affect your load.

Seat to ~Mag length and get a tuner/tuner brake. Then adjust to tighten groups.

Quick note and FYI on 6.5 CM Lapua SRP brass. You know, with the small flash hole. This isn't working with CCI450 primers. I had scored 2000 for 300 BLK and figured I'd give them a try in 6.5 CM, but I'm still seeing pressure signs including pierced primers down to 1.5 grains below book max. So, I'm at 42.2 grains of StaBall 6.5 and getting about 2630 fps with 140 ELD-M's. Compared to Hornady LRP brass with CCI BR2's loaded with 43.7 grains of StaBall 6.5 getting 2693 fps. This is an 18" barrel in my gas gun. COAL is always 2.80 as the gun likes that.

Since my guns a DPMS G2 version I can't get a JP High Pressure Bolt so I scored 1000 CCI BR4's today at Natchez and I'll see how those do.

Anyone else tried magnum SRP primers in the Lapua SRP brass with the small flash holes?

The small flash hole of the (excellent quality) Lapua brass and the magnum primer is almost certainly not the cause of your problems. Many people use CCI450 primers in Lapua brass. I have used that combo for 10 years - and it works really well for me. The magnum primer cup is thicker and stronger than the LRP cup. There are good threads on here discussing this issue.

Short summary: Pierced primers on SRP ammo often have more to do with firing pin geometry than the pressure of your load. Get your firing pin bushed by Greg Tannel (Gretan Rifles), and the problem almost certainly will go away. Not expensive.

I had the same problem with 6.5 CM Berger factory ammo. Firing pin is now bushed - problem solved.

Minor point: This is unlikely to be your issue, but Lapua brass (and almost all “premium” brass) is thicker than cheap Hornady brass, so the max powder load will be 0.5 to 1.0 grain lower. You cannot copy a load recipe developed for say Hornady brass to Norma or Alpha or Lapua brass, just figure out how much to reduce the powder charge to get the same speed and you will be ok. That is the only (minor) side effect of upgrading to premium brass. Upside is that Lapua SRP brass can last 25+ reloads - if you treat them right.

That was a terrific reply with excellent information. Thanks. After some additional load testing I fully agree it's the firing pin and bolt hole issue. I'd resolved the issue on large primers with piercing by going to a very heavy buffer weight and spring but under magnification I can see some erosion on both the pin and the bolt. I'll go about replacing those. No doubt the 450's are under more pressure than the larger BR2's, and no doubt I'd be okay if I had a tighter pin hole match. Gre-Tan web site says no hardened AR bolts, and they're also running > 25 weeks.The small flash hole of the (excellent quality) Lapua brass and the magnum primer is almost certainly not the cause of your problems. Many people use CCI450 primers in Lapua brass. I have used that combo for 10 years - and it works really well for me. The magnum primer cup is thicker and stronger than the LRP cup. There are good threads on here discussing this issue.

Short summary: Pierced primers on SRP ammo often have more to do with firing pin geometry than the pressure of your load. Get your firing pin bushed by Greg Tannel (Gretan Rifles), and the problem almost certainly will go away. Not expensive.

I had the same problem with 6.5 CM Berger factory ammo. Firing pin is now bushed - problem solved.

Minor point: This is unlikely to be your issue, but Lapua brass (and almost all “premium” brass) is thicker than cheap Hornady brass, so the max powder load will be 0.5 to 1.0 grain lower. You cannot copy a load recipe developed for say Hornady brass to Norma or Alpha or Lapua brass, just figure out how much to reduce the powder charge to get the same speed and you will be ok. That is the only (minor) side effect of upgrading to premium brass. Upside is that Lapua SRP brass can last 25+ reloads - if you treat them right.

Has anyone here run 150 SMKs or 153 ELDMs? If so what loads, jumps etc.? Thanks y’all.

Has anyone here run 150 SMKs or 153 ELDMs? If so what loads, jumps etc.? Thanks y’all.

Well I got OK to good results from a 7.0 twist custom barrel (30”) from 41.0 to 41.6 gn of RL-17 using Lapua brass and CCI450 primers. Below 0.5” groups. Start at 39 and work up in 0.3 gn increments. Look at 147 ELDM load data and subtract 0.5 gn.

Best not to mention speed because most guys don’t run such a long barrel. Speed was more than adequate with RL-17.

Btw: This barrel was halfway through it lifespan at that time, so freebore was quote long due to throat erosion, so my load will be too high in a fresh barrel.

Also: Reloder-17 powder is well known for being VERY temperature sensitive, and you WILL FOR SURE need a different winter and summer load! So please be careful. Yes the double base powders give far more speed, but they also erode the barrel at least 2x faster…

Reloder 26 would be a better bet as it is less temp sensitive - if you can find it. 4000MR is close enough to the burn rate of RL-26, and in many calibers give fairly similar velocity. And is more available. It’s temperature sensitivity is rated as “moderate”… [Buddy of mine got one hole groups from a factory 6.5 CM with 4000MR and 140’s.]

I tried H4350 and the speed was slower than desired. The 150 SMK really is better suited to the 6.5 PRC, but with the double base powders, you can get it up to decent speed in a 6.5 CM, perhaps order two barrels instead of one, and have them chambered at the same time with the same reamer.

Btw: When we tried the 150 SMK in an 8 twist custom barrel, some were unstable, and flew sideways through the paper target at 200…. However, a small nr of folks have reported success with the 150 SMK in 8 twist barrels, so try it anyway. The box says minimum recommended twist rate is 7.5.

Last edited:

You might get more and directly related responses if you provided additional information on the specific firearm. Your question is akin to which radial tires should I put on my vehicle?Has anyone here run 150 SMKs or 153 ELDMs? If so what loads, jumps etc.? Thanks y’all.

You might get more and directly related responses if you provided additional information on the specific firearm. Your question is akin to which radial tires should I put on my vehicle?

Fair point: Provide barrel length and twist rate as a minimum. Custom or factory barrel, etc. would also help.

The 150 SMK is a good bullet, and i got good results with a small jump (around 20 thou), but few people are using it, because of the unconventional minimum twist rate of 7.5, most 6.5 Creedmoor off-the-shelf rifles are 8.0 twist. Did not try a long jump.

Sierra apparently acquired Barnes Bullets, and they now make a 140 and a 145 MatchBurner bullet which looks very similar to the Sierra 150 SMK, and both work fine with an 8 twist barrel. The MatchBurner bullets are likely made by Sierra on behalf of their Barnes subsidiary. They are cheap and more easily available, and are basically a shortened version of the 150 SMK, but much more practical. The 145 worked quote well for me with a very long jump (>150 thou) in a factory barrel with 3000 plus rounds on it.

Similar threads

- Replies

- 1

- Views

- 140

- Replies

- 4

- Views

- 1K