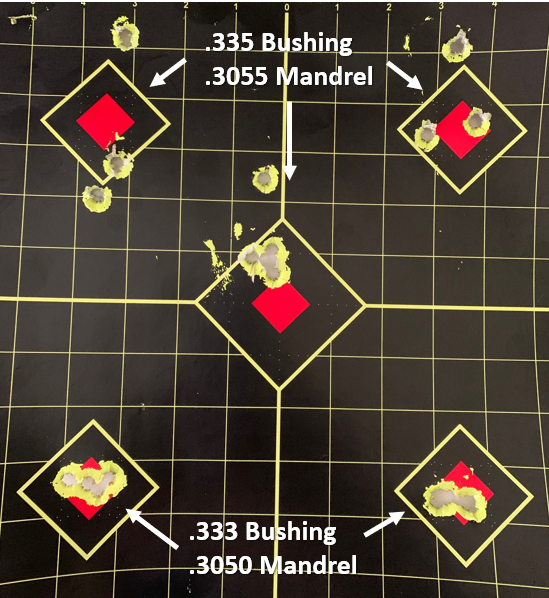

Been screwing around lately with different things that impact neck tension, specifically "Bushing" and "Mandrel" combinations. Took a test out to the range today, and was surprised by the results. This was with a MPA 300-WMBA rifle with maybe 1500 rounds down the barrel. Common elements between the test groups were Lapua 2x brass (annealed), Federal 215 Magnum primers, Berger 200.2x bullets, Retumbo 74.7gn of powder, and seating depth the same (obviously). The ONLY difference between test groups was the Bushing and the Mandrel.

The top-left, center, and top-right of this target is with .335 bushing and .3055 mandrel. Average velocity was 2989 with SD of 8.83 ... and crappy groups.

The bottom-left and bottom-right are 5-shots each with .333 bushing and .3050 mandrel. Average velocity was 2944 (a full 45 ft/sec less) with SD of 7.46 ... and nice tight groups.

The "pull" on the ram for the larger bushing/mandrel combination was consistent, but very light resistance. The "pull" on the ram for the smaller bushing/mandrel combination was still smooth, but with slightly more pressure to seat the bullet.

The small surprise here was that a small change to increase neck tension provided much smaller group sizes at 100 yards.

The big surprise here was that slightly more neck tension actually reduced my velocity by a significant number, all other things being equal.

Any other surprises or observations from you "Neck Tension Mavens" out there.

The top-left, center, and top-right of this target is with .335 bushing and .3055 mandrel. Average velocity was 2989 with SD of 8.83 ... and crappy groups.

The bottom-left and bottom-right are 5-shots each with .333 bushing and .3050 mandrel. Average velocity was 2944 (a full 45 ft/sec less) with SD of 7.46 ... and nice tight groups.

The "pull" on the ram for the larger bushing/mandrel combination was consistent, but very light resistance. The "pull" on the ram for the smaller bushing/mandrel combination was still smooth, but with slightly more pressure to seat the bullet.

The small surprise here was that a small change to increase neck tension provided much smaller group sizes at 100 yards.

The big surprise here was that slightly more neck tension actually reduced my velocity by a significant number, all other things being equal.

Any other surprises or observations from you "Neck Tension Mavens" out there.