Reloaded some 8.6 for the first time and tested them out yesterday. Just cooked up 4 rounds of each and they were shot using my 8.6 BLK gas gun, with 8" barrel through my Dead Air Primal can. Velocities captured with Magneto Speed v3.

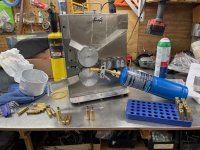

Reloading Setup:

Q/Gorilla once fired brass, Hornady Custom Grade dies, sized to specs using Sheridan gauge, brass was right around 1.790" after sizing.

First load:

Barnes 210 gr TSX

2.650" COAL

29.5 grains, Accurate 1680

Unknown large rifle primer

1694 fps average MV

I was not out shooting for accuracy as I was mostly just seeing if this was going to blow up my gun or not, so no comments there. I believe this round was way over pressure even though Faxon/Q chart said the MV on this should be more like 1750 fps, believe I saw some unburnt powder as well sitting on the bench after shooting. Attached a picture of the brass after shooting, which was already pretty beat up from the original firing, but more for showing the primer came back and flattened fairly significantly.

Second load:

Gorilla 285gr Subsonic Fracturing Projectile

2.750" COAL(had nothing to base on, so went with this)

14.5 grains, Accurate 1680

Random large rifle primer

980 fps average MV

Again, I was not out testing for accuracy, but was much more pleased with this round than the other one as far as performance goes. Faxon/Q chart for a 300 gr Sierra SMK was at 860 fps with 14.7 gr of powder with an 8 " barrel, so clearly there's some disconnect here as well. I was well above the final circumferential cut on the bullet, so maybe I was a bit too deep which drove up the pressure and velocity? Gun functioned well and locked back after each shot, ejection wasn't much to speak of as far as distance goes, but was at least coming out around 3-4 o'clock.

Reloading Setup:

Q/Gorilla once fired brass, Hornady Custom Grade dies, sized to specs using Sheridan gauge, brass was right around 1.790" after sizing.

First load:

Barnes 210 gr TSX

2.650" COAL

29.5 grains, Accurate 1680

Unknown large rifle primer

1694 fps average MV

I was not out shooting for accuracy as I was mostly just seeing if this was going to blow up my gun or not, so no comments there. I believe this round was way over pressure even though Faxon/Q chart said the MV on this should be more like 1750 fps, believe I saw some unburnt powder as well sitting on the bench after shooting. Attached a picture of the brass after shooting, which was already pretty beat up from the original firing, but more for showing the primer came back and flattened fairly significantly.

Second load:

Gorilla 285gr Subsonic Fracturing Projectile

2.750" COAL(had nothing to base on, so went with this)

14.5 grains, Accurate 1680

Random large rifle primer

980 fps average MV

Again, I was not out testing for accuracy, but was much more pleased with this round than the other one as far as performance goes. Faxon/Q chart for a 300 gr Sierra SMK was at 860 fps with 14.7 gr of powder with an 8 " barrel, so clearly there's some disconnect here as well. I was well above the final circumferential cut on the bullet, so maybe I was a bit too deep which drove up the pressure and velocity? Gun functioned well and locked back after each shot, ejection wasn't much to speak of as far as distance goes, but was at least coming out around 3-4 o'clock.