So I've wanted an excuse to buy a 3D printer for a while simply to make this. Finally took the plunge and picked one up. Coming into this, I knew zero about CAD design or 3D printing...so it's been alot of YouTube but I finally made a thing. Be gentle...I had no idea what I was doing and had to teach myself.

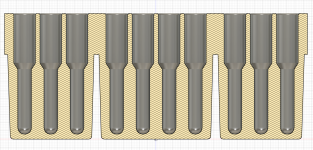

This is a replacement for the black insert that comes with the MTM H50-XL Deluxe Ammo Box ( https://mtmcase-gard.com/products/deluxe-ammo-box-50-round-handle-300-wsm-300-rem-ultra-mag ).

It is designed to more securely hold loaded 300 PRC ammo for transport. The insert that comes with the box holds the ammo near the bullet tip. I've never liked this design...especially as someone who often flies with loaded reloads. Ammo often arrives having banged around in the case. I've even seen this change my COAL and (I would assume) concentricity of loaded rounds. So this was designed to hold the body tighter and index off the shoulder and not the bullet. The bullet floats freely with the only "pressure" being on the shoulder of the case. In addition, I also increased the height of the insert to securely hold more of the body of the case. In theory, I feel this should be a better solution.

The cartridge cuts for the case were made from SAAMI spec 300 PRC dimensions. The COAL should be plenty long for 99.9% of 300 PRC reloads, even those that go beyond standard mag length. Of course this will also work for similar cartridges beyond the 300 PRC, but YMMV depending on what you use.

So why not design a whole new ammo box with this integrated? Well that was my original intent, but I like this solution better. I don't think you're going to print a more secure or better box than the injection molded plastic that MTM makes. I think this is the best of both worlds.

Next step will be making more insert for my other cartridges I commonly travel with.

You can download it here if you want to give it a try: https://www.thingiverse.com/thing:5810858

This is a replacement for the black insert that comes with the MTM H50-XL Deluxe Ammo Box ( https://mtmcase-gard.com/products/deluxe-ammo-box-50-round-handle-300-wsm-300-rem-ultra-mag ).

It is designed to more securely hold loaded 300 PRC ammo for transport. The insert that comes with the box holds the ammo near the bullet tip. I've never liked this design...especially as someone who often flies with loaded reloads. Ammo often arrives having banged around in the case. I've even seen this change my COAL and (I would assume) concentricity of loaded rounds. So this was designed to hold the body tighter and index off the shoulder and not the bullet. The bullet floats freely with the only "pressure" being on the shoulder of the case. In addition, I also increased the height of the insert to securely hold more of the body of the case. In theory, I feel this should be a better solution.

The cartridge cuts for the case were made from SAAMI spec 300 PRC dimensions. The COAL should be plenty long for 99.9% of 300 PRC reloads, even those that go beyond standard mag length. Of course this will also work for similar cartridges beyond the 300 PRC, but YMMV depending on what you use.

So why not design a whole new ammo box with this integrated? Well that was my original intent, but I like this solution better. I don't think you're going to print a more secure or better box than the injection molded plastic that MTM makes. I think this is the best of both worlds.

Next step will be making more insert for my other cartridges I commonly travel with.

You can download it here if you want to give it a try: https://www.thingiverse.com/thing:5810858