Made up a handful (40) rounds to really start wringing out the Structure Barrel .300 WM next month when I go down to Oklahoma for a hog hunt.

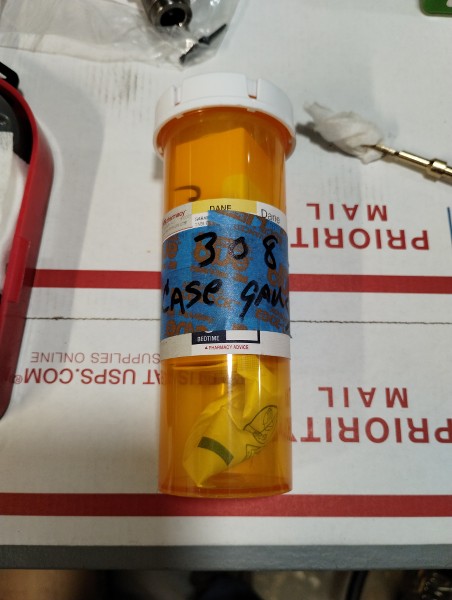

Started wtih full-up case prep. FL resized, neck turned, primer pockets trued and swaged.

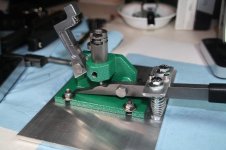

And I used my Auto-Trickler for the first time and it is awesome!

Slow and steady on these rounds. Nothing bulk loading about today.

Was going to do some shooting with the Hinson Rifle but snow all over everything. Next weekend looks better.

So back to the Autotrickler... ordered that in 2021 at PRE. Arrived summer 2022, but I had too much farm work and stuff to use it. Got it set up one day. But had not used it with loading live ammo. Holy crap do I love that tool! Not going to use it for bulk .38's or .300 BLK. But for the big stuff that I want accurate within a tenth or less... this rig is fantastic. I will say that if your loading room is in a frame building or on a wood floor, it 'is' sensitive to movement. But only during the last little trickle stage. It's such a cool bit of equipment and now I wondered how I lived without it! Wow, does it speed things up!

Cheers,

Sirhr

Still have to dye it yet.