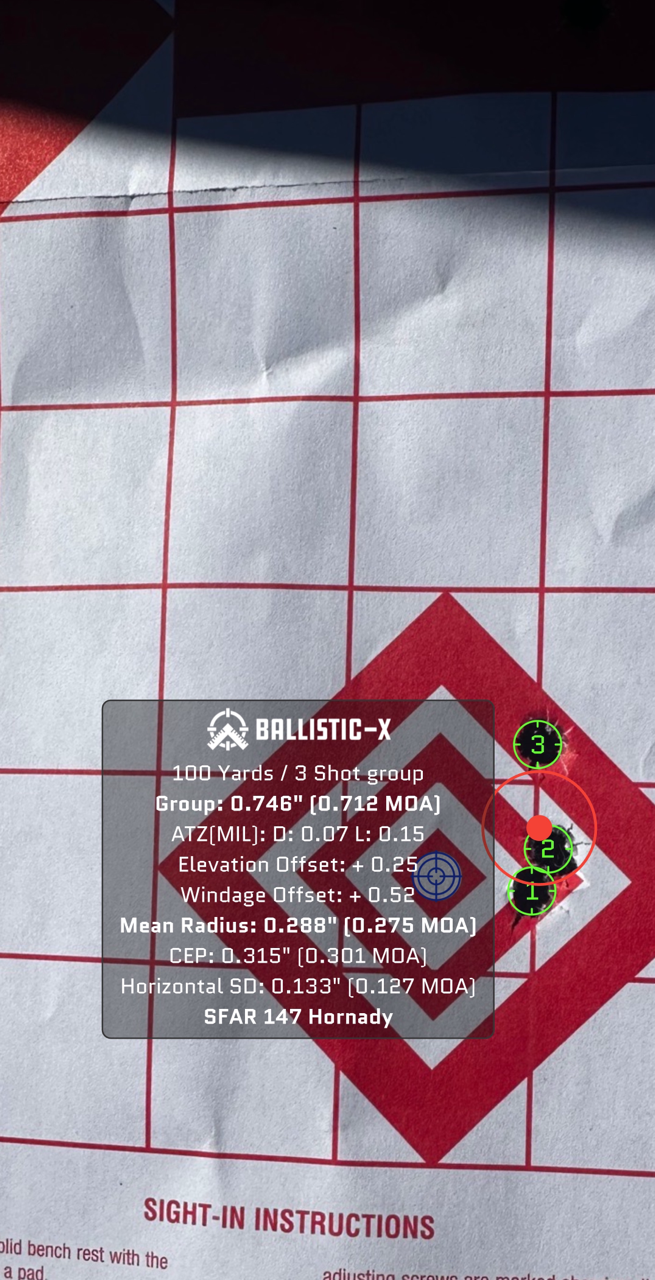

I didn’t get below roughly 1 MOA all day today. But it’s probably because I was paying more attention to the chronograph and documenting the speeds than my actual shooting form. I think most people are better on some days than others - me included for sure! I have not tried any actual “hunting” loads yet.Not a dig, I just happened to be looking for a piece of SFAR information today and some of the results that bubbled up are from other forums (texashuntingforum for one) where some people are experiencing similar issues reportong 1.5-2.5 MOA as "good" accuracy for their SFAR and some saying they get better results with factory ammo than handloads.

- Thread starter Ape_Factory

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

which POF tube is that? Their AR15 6 positon one or something else?

Revolution Buffer Tube - Patriot Store: POF-USA - 6 Position

Mil-Spec 7075-T6 aircraft aluminum Revolution Buffer Tube ensures that the carrier is always supported and eliminates carrier tilt.

Got it and ordered. Smooth inside I hope - not lawnmower cut like the ruger is?

More troubleshooting today.

1. The bcg is hitting my Radian SD charging handle. It doesn’t have enough relief at the rear for the SFAR bolt throw.

2. My vortex 1-10 gen3 packed it in. Replaced with a known good optic. I continued troubleshooting as this barrel scoped good and had good es/Sd. Usually indicates it will shoot.

After changing the optic:

1. The bcg is hitting my Radian SD charging handle. It doesn’t have enough relief at the rear for the SFAR bolt throw.

2. My vortex 1-10 gen3 packed it in. Replaced with a known good optic. I continued troubleshooting as this barrel scoped good and had good es/Sd. Usually indicates it will shoot.

After changing the optic:

More troubleshooting today.

1. The bcg is hitting my Radian SD charging handle. It doesn’t have enough relief at the rear for the SFAR bolt throw.

2. My vortex 1-10 gen3 packed it in. Replaced with a known good optic. I continued troubleshooting as this barrel scoped good and had good es/Sd. Usually indicates it will shoot.

After changing the optic:

View attachment 8341014

View attachment 8341017View attachment 8341018View attachment 8341020

Nice shooting. Will your charging handle not latch?

I don't know the specs on the SFAR CH original spring, but if it's Mil-Spec, a Tromix heavy duty CH latch spring might help.It unlatches under recoil and has obvious strike marks on it.

Thanks. Just curious more than anything else. I've been following this thread just to learn a little about what works and what doesn't. At everyone else's expense since I'm a poor LOL.ar15.

Think the bolt could be coming back TOO far? Or just because the charging handle is designed for a shorter cartridge.?

i think it'll be OK now that I took a diamond ball end bit to the inside of the handle and smoothed it out. It shouldn't contact in the rear any more - it was minimal to begin with and now Ive clearanced until the divots in the metal are gone.

I hope you have better luck than I did. I sent it back because it made a Timber Creek tube look like a space shuttle part.Got it and ordered. Smooth inside I hope - not lawnmower cut like the ruger is?

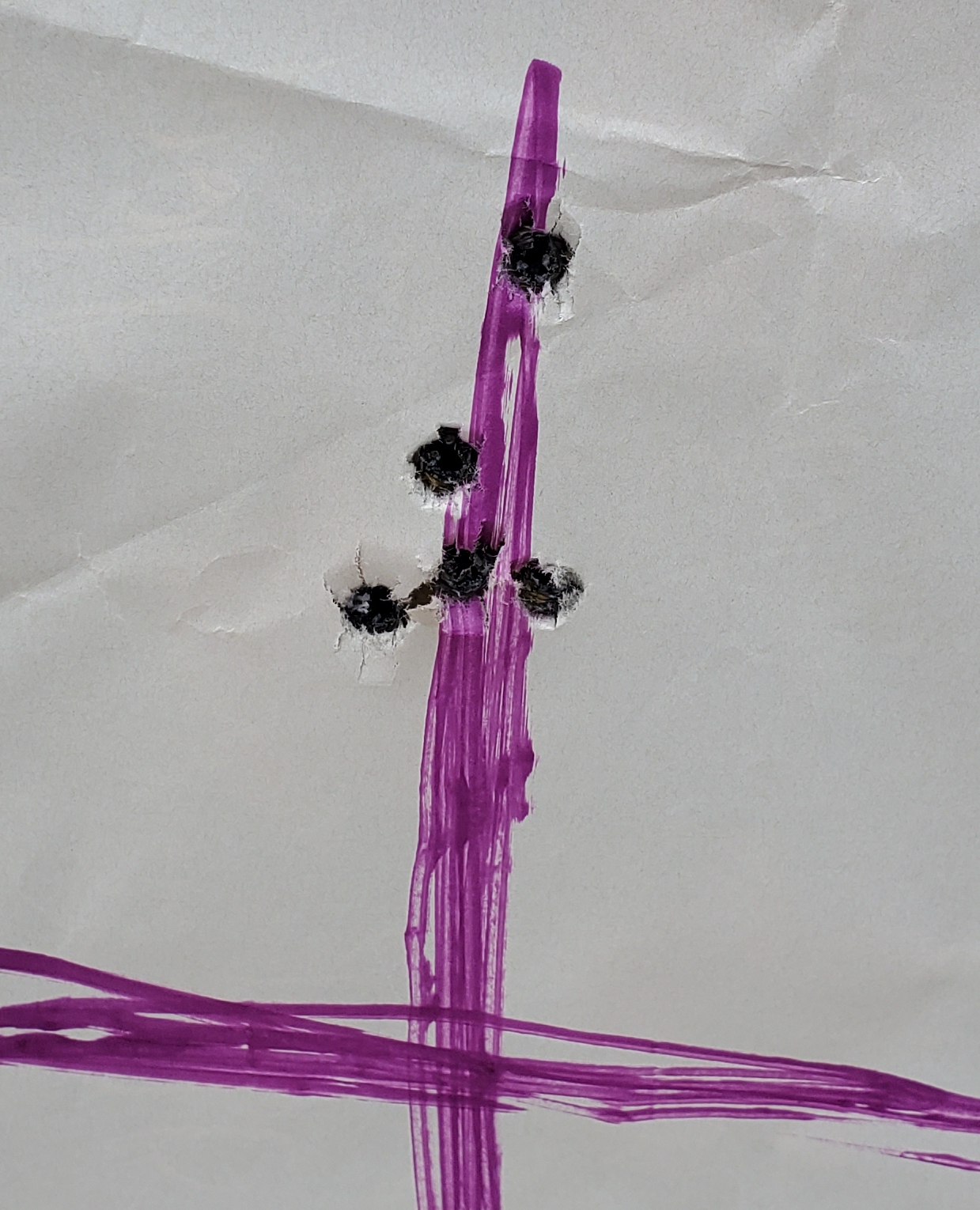

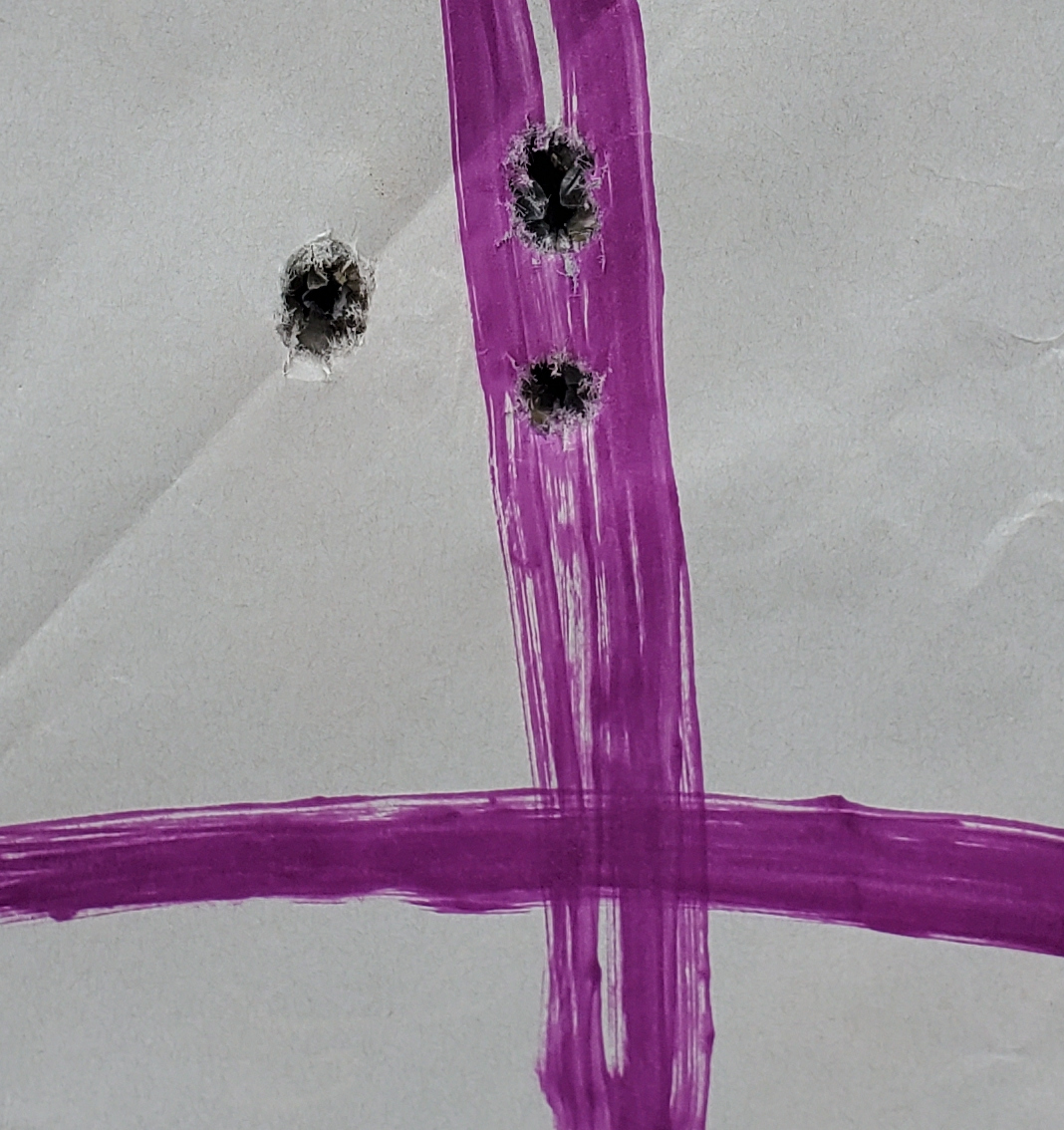

3 round group at 400 yards and a head shot for good measure

Fusion 165gr

vxh5d windplex

I threw in a CMC trigger, suppressor, and a cheap strike industries charging handle. Still no issues and I've been lazy and haven't cleaned it

Fusion 165gr

vxh5d windplex

I threw in a CMC trigger, suppressor, and a cheap strike industries charging handle. Still no issues and I've been lazy and haven't cleaned it

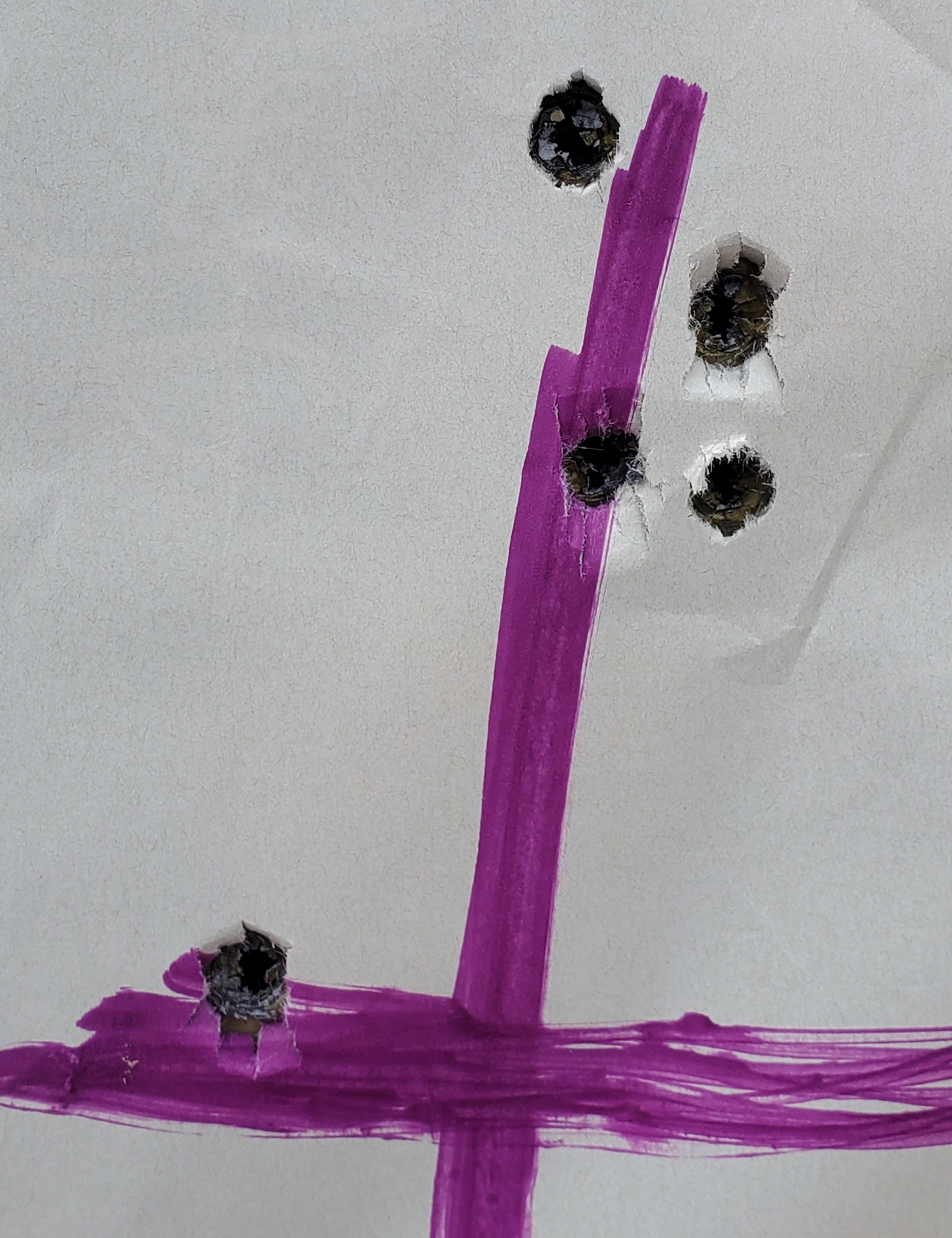

I finally made it back out. I'm pretty sure my most recent accuracy problem, minute of Tuff Shed at 200 yds, was due to the bottom of the superlative clamp on gas block contacting the bottom of the handguard.

I swapped in my LR-308 spring and a heavy AR-15 buffer before running the Tubbs through the barrel based on the assumption of what could it hurt. I ran the first 10 rounds of Tubbs with the gas completely shut off. Manually cycling the bolt it was obvious the LR spring didn't have enough oomph to reliably return the bolt to battery. It would chatter and stick then break itself loose and lightly click into place. So I swapped the Ruger spring back in. Near the end of the first 10 rounds cases started sticking making it a PITA to cycle so I opened the SA block 3 full turns and everything seemed OK, even the brass looked good.

I haven't looked at the bore yet, no idea what Tubbs did or didn't do for it but at one point I was ready to swear the bore was made out of copper for all patches I went through between the 5 round sessions.

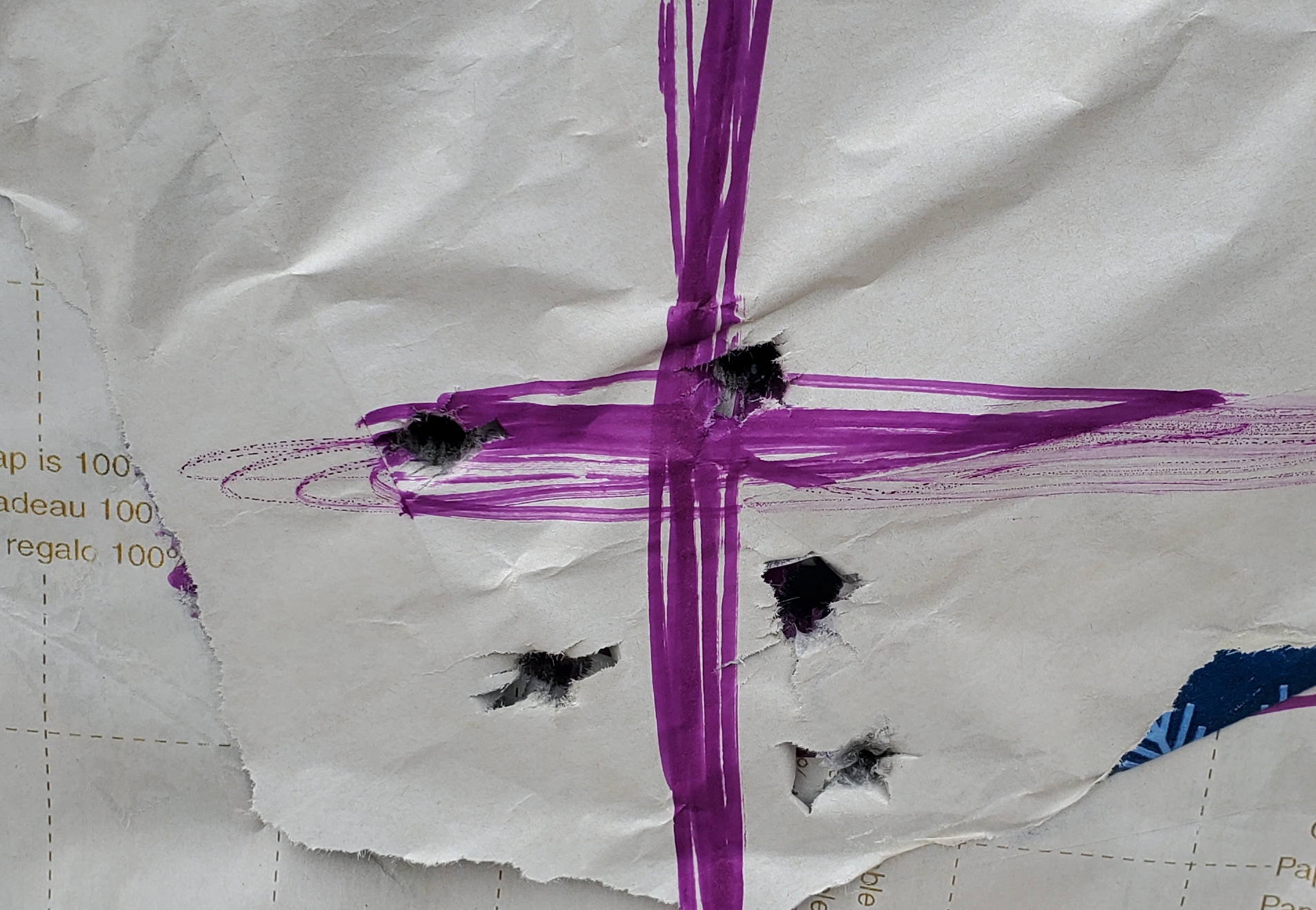

I put 15 rounds of PPU 145gr (FMJ) range fodder barely on paper at 100 yds resting on a single soft bag with a 3-9x40 scope that wasn't nearly zeroed but was good enough to get a grouping, it made a fine shotgun pattern. I spun a bunch of clicks and put 5 PPU 165gr (SP) Rifle Line on paper below and left of the 15. Marginally better but not exciting.

I spun a few more clicks and sent 5 rounds of PPU 165gr (SP) "Standard Rifle" rounds downrange. It may seem silly but one of my rifles can tell the difference between the two. The result was almost encouraging, probably mostly because I was finally hitting POA. Those are not keyholes, that's just completely unsupported christmas wrapping paper catching a bullet.

Clicked it up a bit and tried 5 more Standard ... OK but not exciting.

What the hell, why not put the suppressor on it.

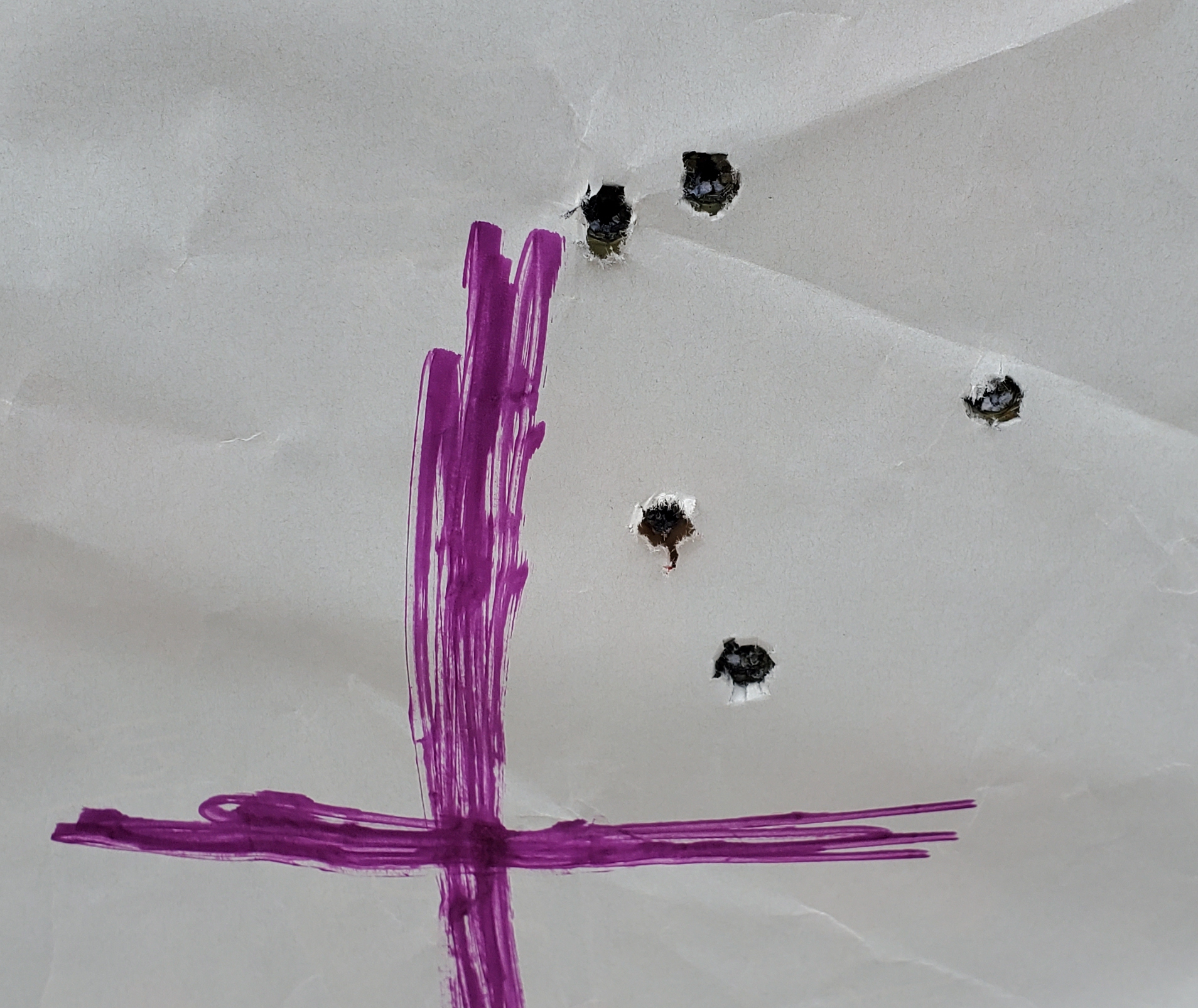

That can't be right ... try it again but concentrate a little this time.

Hmm, maybe this rifle likes copper in the bore. Rifle line? The "flyer" is probably on me.

I'm pretty stoked now so I decide to switch to the thermal. By now I've got 40 rounds into it after the last cleaning from the Tubbs experiment. While I'm printing my version of the Big Dipper on paper because I forgot, for just a minute, how the Thermal sighting worked I got a couple three feed issues so I upped the gas two clicks and then this happened. I had to tap the case out with a cleaning rod. Obviously, now, it was an extraction issue not a gas problem and I managed to mangle one empty case mouth and crush one soft point because I was just clearing jans letting the brass fall into the catcher and not paying attention.

But I did manage to get a couple hits on the Hot Hands before the case stuck. Don't pay any attention to those 4 wandering jews out in the desert, they were following the wrong star.

I feel like I'm comfortable with the accuracy now. It's at least headed in the right direction. Superlative gas block and heavy buffer are the sum of my mechanical changes right now. Recoil was not bad at all with this ammo in this configuration.

I think may next step might be to cast the chamber or something to try to figure out what the problem is with this case sticking issue. I don't have this issue with any other rifle I own.

I swapped in my LR-308 spring and a heavy AR-15 buffer before running the Tubbs through the barrel based on the assumption of what could it hurt. I ran the first 10 rounds of Tubbs with the gas completely shut off. Manually cycling the bolt it was obvious the LR spring didn't have enough oomph to reliably return the bolt to battery. It would chatter and stick then break itself loose and lightly click into place. So I swapped the Ruger spring back in. Near the end of the first 10 rounds cases started sticking making it a PITA to cycle so I opened the SA block 3 full turns and everything seemed OK, even the brass looked good.

I haven't looked at the bore yet, no idea what Tubbs did or didn't do for it but at one point I was ready to swear the bore was made out of copper for all patches I went through between the 5 round sessions.

I put 15 rounds of PPU 145gr (FMJ) range fodder barely on paper at 100 yds resting on a single soft bag with a 3-9x40 scope that wasn't nearly zeroed but was good enough to get a grouping, it made a fine shotgun pattern. I spun a bunch of clicks and put 5 PPU 165gr (SP) Rifle Line on paper below and left of the 15. Marginally better but not exciting.

I spun a few more clicks and sent 5 rounds of PPU 165gr (SP) "Standard Rifle" rounds downrange. It may seem silly but one of my rifles can tell the difference between the two. The result was almost encouraging, probably mostly because I was finally hitting POA. Those are not keyholes, that's just completely unsupported christmas wrapping paper catching a bullet.

Clicked it up a bit and tried 5 more Standard ... OK but not exciting.

What the hell, why not put the suppressor on it.

That can't be right ... try it again but concentrate a little this time.

Hmm, maybe this rifle likes copper in the bore. Rifle line? The "flyer" is probably on me.

I'm pretty stoked now so I decide to switch to the thermal. By now I've got 40 rounds into it after the last cleaning from the Tubbs experiment. While I'm printing my version of the Big Dipper on paper because I forgot, for just a minute, how the Thermal sighting worked I got a couple three feed issues so I upped the gas two clicks and then this happened. I had to tap the case out with a cleaning rod. Obviously, now, it was an extraction issue not a gas problem and I managed to mangle one empty case mouth and crush one soft point because I was just clearing jans letting the brass fall into the catcher and not paying attention.

But I did manage to get a couple hits on the Hot Hands before the case stuck. Don't pay any attention to those 4 wandering jews out in the desert, they were following the wrong star.

I feel like I'm comfortable with the accuracy now. It's at least headed in the right direction. Superlative gas block and heavy buffer are the sum of my mechanical changes right now. Recoil was not bad at all with this ammo in this configuration.

I think may next step might be to cast the chamber or something to try to figure out what the problem is with this case sticking issue. I don't have this issue with any other rifle I own.

Last edited:

The case rim being ripped off is over gassing.

You tune a gas system like this by turning it off, then open it 3 clicks and fire 1 round with a mag in it. Keep opening it until the mag locks back the bolt. Then open it 1-2 more clicks and that’s generally the setting.

When the rifle fires, for a moment the case is stiction jammed in the chamber at 55,000 psi of pressure. It’s completely immobile and can’t be rotated or pulled out.

If the bolt tries opening in the stiction time zone it’ll rip the rim off not eject it. More gas makes this more likely.

You tune a gas system like this by turning it off, then open it 3 clicks and fire 1 round with a mag in it. Keep opening it until the mag locks back the bolt. Then open it 1-2 more clicks and that’s generally the setting.

When the rifle fires, for a moment the case is stiction jammed in the chamber at 55,000 psi of pressure. It’s completely immobile and can’t be rotated or pulled out.

If the bolt tries opening in the stiction time zone it’ll rip the rim off not eject it. More gas makes this more likely.

The case rim

The physics makes sense. The cases were sticking with no gas at all and required love taps on the charging handle with a screwdriver to eject them.

Familiar with "tuning" adjustable gas blocks just took a shortcut to move the Tubbs work along.

At one point I dialed the gas down two clicks and had cycling issues, wouldn't pick up the next round, but that was before I put the suppressor on. To your point, I did not try an empty mag for lock back which I'd normally do.

I guess I could try it again and dial it down with the original featherweight buffer and/or a weaker spring. Maybe take the brass catcher off and see where it's slinging the cases too.

The LR-308 spring is plenty weak compared to the ruger factory but it seems either too short for the Ruger tube or maybe the bolt and receiver need polishing ... don't know.

I did run across those spring numbers on bench from my compression contraption. Compresses to roughly tube length, resting state, the SFAR spring held 10lbs, AR-15 rifle spring 5lbs and the LR-308 spring 8lbs. At roughly 4.5" of compression, "active" state, the SFAR held 18lbs, AR-15 10lbs and LR-308 12lbs. If that means anything to anybody, springs in ARs are generally all voodoo for me.

Last edited:

I destroyed brass rims like that from having to mortar the rounds out when I tried ammo that my SFAR didn't like. Now that I switched to what it does like - it's all good.The physics makes sense. The cases were sticking with no gas at all and required love taps on the charging handle with a screwdriver to eject them.

Familiar with "tuning" adjustable gas blocks just took a shortcut to move the Tubbs work along.

At one point I dialed the gas down two clicks and had cycling issues, wouldn't pick up the next round, but that was before I put the suppressor on. To your point, I did not try an empty mag for lock back which I'd normally do.

I guess I could try it again and dial it down with the original featherweight buffer and/or a weaker spring. Maybe take the brass catcher off and see where it's slinging the cases too.

The LR-308 spring is plenty weak compared to the ruger factory but it seems either too short for the Ruger tube or maybe the bolt and receiver need polishing ... don't know.

I did run across those spring numbers on bench from my compression contraption. Compresses to roughly tube length, resting state, the SFAR spring held 10lbs, AR-15 rifle spring 5lbs and the LR-308 spring 8lbs. At roughly 4.5" of compression, "active" state, the SFAR held 18lbs, AR-15 10lbs and LR-308 12lbs. If that means anything to anybody, springs in ARs are generally all voodoo for me.

I destroyed brass rims like that from having to mortar the rounds out when I tried ammo that my SFAR didn't like. Now that I switched to what it does like - it's all good.

Yeah, I've switched ammo to mitigate accuracy issues many times, pretty much in every gun I own.

I may be misremembering but I only seem to recall one post where you said the only malfunction you've ever had with your SFAR was with one particular brand of surplus ammo but I don't recall the malfunction type. I was assuming most of the ammo switching you've done is chasing accuracy but I may have missed a post or two about the sticktion and case damage you just mentioned..

This outing was the longest string of consecutive shots I've had with this rifle without case damage and minimal feed/extraction issues. I've put a couple three types of each from Remington, Hornady, Winchester and Federal all though this rifle with similar sticktion and rim damage results regardless of the gas setting. Worst so far was Remington Core-Lokt which popped the primers out.

Here's a link to the other thread.Yeah, I've switched ammo to mitigate accuracy issues many times, pretty much in every gun I own.

I may be misremembering but I only seem to recall one post where you said the only malfunction you've ever had with your SFAR was with one particular brand of surplus ammo but I don't recall the malfunction type. I was assuming most of the ammo switching you've done is chasing accuracy but I may have missed a post or two about the sticktion and case damage you just mentioned..

This outing was the longest string of consecutive shots I've had with this rifle without case damage and minimal feed/extraction issues. I've put a couple three types of each from Remington, Hornady, Winchester and Federal all though this rifle with similar sticktion and rim damage results regardless of the gas setting. Worst so far was Remington Core-Lokt which popped the primers out.

Now that it's had a more rounds through it - I may try the Igman again.

https://www.snipershide.com/shooting/threads/sfar-hates-one-brand-of-m80-ball.7169989/

Here's a link to the other thread.

Now that it's had a more rounds through it - I may try the Igman again.

https://www.snipershide.com/shooting/threads/sfar-hates-one-brand-of-m80-ball.7169989/

Yeah, that's what most of the Remington cases looked like for me.

Which is so very odd after seeing everything else I put through it without any issues.Yeah, that's what most of the Remington cases looked like for me.

Which is so very odd after seeing everything else I put through it without any issues.

Si, it's odd to me but I am not nearly as skilled in rifle construction or debugging as many here.

I've never had any rifle treat factory loaded cases the way this one does or sticks cases in the chamber. It's easy, even with my limited skills and knowledge, to understand smear marks and shredded brass being related to early/over gassing trying to move the case while it's still under pressure. But I'm not sure I completely follow how gas on the key might cause cases to stick, especially when cases stick with the gas completely shut off ... essentially bolt action.

So I got the POF buffer tube. Its interior is completely smooth and well made - the outside has poor surface finishing due to machining on a worn/improperly setup machine. It is within spec and my stock is tight and works good on it.

This is the sort of part I don't mind seeing - its functional areas are like a mirror and its cosmetic stuff doesn't warrant a premium price. And a $50 buffer tube isn't a premium part.

Its certainly going to work better than the cosmetically more attractive Ruger tube with awful critical surfaces.

Also, JP extra power AR15 (not AR10) on the left,ROGUE spring in the middle, and Ruger on the right.

This is the sort of part I don't mind seeing - its functional areas are like a mirror and its cosmetic stuff doesn't warrant a premium price. And a $50 buffer tube isn't a premium part.

Its certainly going to work better than the cosmetically more attractive Ruger tube with awful critical surfaces.

Also, JP extra power AR15 (not AR10) on the left,ROGUE spring in the middle, and Ruger on the right.

Attachments

Last edited:

Ruger spring could be a regular A2 rifle length spring, I think POF and Armalite did that at one time

My 716i rifles both had flatwire springs that were a mile long

My 716i rifles both had flatwire springs that were a mile long

Between 13.5" - 14" is what I think mine measured out to.Ruger spring could be a regular A2 rifle length spring

Still watching these with interest.

My understanding is that Ruger's spring is longer than rifle or carbine?

Has anyone been able to switch out the whole buffer/tube/spring setup yet?

My understanding is that Ruger's spring is longer than rifle or carbine?

Has anyone been able to switch out the whole buffer/tube/spring setup yet?

My understanding is that Ruger's spring is longer than rifle or carbine?

Basically yes but some brands of rifle springs are pretty long ... close to or right at 13", "most" are around 12" maybe less and some are pretty short but still called "rifle" springs.

The guy in this video covers some decent ground on bolt/spring/buffer differences between several AR-10s at the beginning of the video ... he's pretty chatty but still good info.

ETA: If you watch this video long enough to get to him shooting his SFAR both unsuppresed and suppressed you'll see the brass ejection rotate back and forth between around 4:00 to 2:00 within 20 rounds from the same magazine. This is one of the things I experienced early on with my SFAR but I've been using the brass catcher lately so I don't know what it's doing now. When running hotter hunting loads like Core Lokt the recoil would change dramatically between shots ... one relatively normal, the next kicking like a mule.

Last edited:

My barrel is excellent on the 20” 6.5. Scopes fantastically, and has very good ES/SD and it shoots good.When comparing the 6.5 to the 308 is there any consensus on accuracy or reliability differences? More specifically with the 20" versions.

Some of the 308 users have reported good accuracy outcomes as well.

I suspect it’s a typical ruger - serials 1-1000 are complete shit, 1001-10000 had some stuff fixed, and 10,001 on are very serviceable.

That said - i’m most displeased by the gas block. it really needed .1 shaved off the top and sides to not hit the rail and ruger still DGAFd it on the 6.5.

And it doesn’t have a suppressed setting as far as I know on the 6.5. It goes from 1 which is nothing. Might even be “off”. To 2 which is wayyyy too much gas. To 3/4 that seem to be buttfucking insane / you broke your puny milspec

nightforce from the recoil.

My barrel is excellent on the 20” 6.5. Scopes fantastically, and has very good ES/SD and it shoots good.

Some of the 308 users have reported good accuracy outcomes as well.

I suspect it’s a typical ruger - serials 1-1000 are complete shit, 1001-10000 had some stuff fixed, and 10,001 on are very serviceable.

That said - i’m most displeased by the gas block. it really needed .1 shaved off the top and sides to not hit the rail and ruger still DGAFd it on the 6.5.

And it doesn’t have a suppressed setting as far as I know on the 6.5. It goes from 1 which is nothing. Might even be “off”. To 2 which is wayyyy too much gas. To 3/4 that seem to be buttfucking insane / you broke your puny milspec

nightforce from the recoil.

Thanks. Sounds like I should wait a few months, grab one, and expect to tinker with it a little bit. Just need to make my mind up on 308 or 6.5. I like the high BC ammo in either.

My barrel is excellent on the 20” 6.5. Scopes fantastically, and has very good ES/SD and it shoots good.

Some of the 308 users have reported good accuracy outcomes as well.

I suspect it’s a typical ruger - serials 1-1000 are complete shit, 1001-10000 had some stuff fixed, and 10,001 on are very serviceable.

That said - i’m most displeased by the gas block. it really needed .1 shaved off the top and sides to not hit the rail and ruger still DGAFd it on the 6.5.

And it doesn’t have a suppressed setting as far as I know on the 6.5. It goes from 1 which is nothing. Might even be “off”. To 2 which is wayyyy too much gas. To 3/4 that seem to be buttfucking insane / you broke your puny milspec

nightforce from the recoil.

Did they restart serials on the 6.5 or keep going from the 308 range?

Not sure

Has anyone tried 6arc in the sfar yet?

Sounds like a very custom endeavor, and also, why?Has anyone tried 6arc in the sfar yet?

Longer magazinesSounds like a very custom endeavor, and also, why?

Proof already makes a 14.5” barrel in 6arc for a small frame ar

I get the longer mags thing, but does the SFAR use standard small frame barrels? I haven't been following this very closely.Longer magazines

Proof already makes a 14.5” barrel in 6arc for a small frame ar

View attachment 8347382

Did they restart serials on the 6.5 or keep going from the 308 range?

If anybody has eyes on serial numbers from both a quick check on the three digit prefix might sort it out.

###-#####

But I would hazard a guess the serial numbers do not start over since it's the non-caliber specific lower that is serialized.

Has anyone tried 6arc in the sfar yet?

There's a machinist/smith somewhere out there who rebarreled his SFAR himself but I forget the caliber.

Would a proof carbon 6.5 creed prefit ar barrel drop in for an sfar?

ETA: Proof doesn’t make a 14.5 in 6.5 creed or 6 creed

ETA: Proof doesn’t make a 14.5 in 6.5 creed or 6 creed

6 ARC is AR-15 mag well, small frame, .441” compatible Grendel bolt face, Grendel mags, 2.260” Cartridge Overall Length (COL).Has anyone tried 6arc in the sfar yet?

The Ruger SFAR is designed around .308/.473” case head cartridges and magazines with 2.800” COL. It’s basically an AR-15 sized receiver set with an AR-10 magazine well incorporated into the lower receiver, with the FCG moved back ~.625” like POF did with the Revolution and Rogue. The upper receiver mag well orifice is elongated slightly to the rear to accommodate AR-10 mags.

The Revolution, Rogue, and SFAR use fatter magazines with feed lips designed to contain .473” diameter case head cartridges with .470” bodies.

If you wanted longer COL in 6mm based on PPC/Grendel cases, you would be looking for the smaller .441" width mags/magwell, with 2.500” COL.

If you work out the trajectories, you’re looking at very marginal improvements for pretty significant back-end efforts in receiver and magazine design, testing, development, and evaluation before going into production.

An easier solution is to make magazines with thinner walls up front like PRI and get 2.300” COL. These are the AR-15 magazine well specs as seen from above:

You can see the maximum absolute internal length for double-stack, alternate feed presentation is 2.398” for a press-fit, stuck magazine, not taking into account the wall thicknesses. Once you account for magazine wall thicknesses and variations, slip-fit clearance and drop-free on its own weight, you realize why we’re limited to 2.260” COL for the loaded cartridges in the AR-15. You can load Grendel, 6mm AR, and 6mm ARC longer in some mags like from ASC and CProducts, but others won’t allow it like Elander.

Last edited:

10-4. Doesn’t seem worth it in the sfar6 ARC is AR-15 mag well, small frame, .441” compatible Grendel bolt face, Grendel mags, 2.260” Cartridge Overall Length (COL).

The Ruger SFAR is designed around .308/.473” case head cartridges and magazines with 2.800” COL. It’s basically an AR-15 sized receiver set with an AR-10 magazine well incorporated into the lower receiver, with the FCG moved back ~.625” like POF did with the Revolution and Rogue. The upper receiver mag well cavity is elongated slightly to the rear to accommodate AR-10 mags.

The Revolution, Rogue, and SFAR use fatter magazines with feed lips designed to contain .473” diameter case head cartridges with .470” bodies.

If you wanted longer COL in 6mm based on PPC/Grendel cases, you would be looking for the smaller .441" width mags/magwell, with 2.500” COL.

If you work out the trajectories, you’re looking at very marginal improvements for pretty significant back-end efforts in receiver and magazine design, testing, development, and evaluation before going into production.

An easier solution is to make magazines with thinner walls up front like PRI and get 2.300” COL. These are the AR-15 magazine well specs as seen from above:

View attachment 8347427

You can see the maximum absolute internal length for double-stack, alternate feed presentation is 2.398” for a press-fit, stuck magazine, not taking into account the wall thicknesses. Once you account for magazine wall thicknesses and variations, slip-fit clearance and drop-free on its own weight, you realize why we’re limited to 2.260” COL for the loaded cartridges in the AR-15. You can load Grendel, 6mm AR, and 6mm ARC longer in some mags like from ASC and CProducts, but others won’t allow it like Elander.

6 ARC is AR-15 mag well, small frame, .441” compatible Grendel bolt face, Grendel mags, 2.260” Cartridge Overall Length (COL).

The Ruger SFAR is designed around .308/.473” case head cartridges and magazines with 2.800” COL. It’s basically an AR-15 sized receiver set with an AR-10 magazine well incorporated into the lower receiver, with the FCG moved back ~.625” like POF did with the Revolution and Rogue. The upper receiver mag well cavity is elongated slightly to the rear to accommodate AR-10 mags.

The Revolution, Rogue, and SFAR use fatter magazines with feed lips designed to contain .473” diameter case head cartridges with .470” bodies.

If you wanted longer COL in 6mm based on PPC/Grendel cases, you would be looking for the smaller .441" width mags/magwell, with 2.500” COL.

If you work out the trajectories, you’re looking at very marginal improvements for pretty significant back-end efforts in receiver and magazine design, testing, development, and evaluation before going into production.

An easier solution is to make magazines with thinner walls up front like PRI and get 2.300” COL. These are the AR-15 magazine well specs as seen from above:

View attachment 8347427

You can see the maximum absolute internal length for double-stack, alternate feed presentation is 2.398” for a press-fit, stuck magazine, not taking into account the wall thicknesses. Once you account for magazine wall thicknesses and variations, slip-fit clearance and drop-free on its own weight, you realize why we’re limited to 2.260” COL for the loaded cartridges in the AR-15. You can load Grendel, 6mm AR, and 6mm ARC longer in some mags like from ASC and CProducts, but others won’t allow it like Elander.

Good info! Wouldn't that make it a "perfect" 6 creed candidate?

Of course. There’s already 6.5 Creedmoor and the 6mm is essentially the same. I can’t see why not.Good info! Wouldn't that make it a "perfect" 6 creed candidate?

It becomes a different rifle from an engineering perspective due to the significantly reduced bore volume. From a schematics approach, it looks like the exact same rifle, but bore ratio makes it a different animal.Good info! Wouldn't that make it a "perfect" 6 creed candidate?

Shooting lighter weight bullets in 6mm, it would be easier to get it to run reliably, like what we see in .243 Winchester box ammo. With the longer bullets common to 6mm Creedmoor, you have a long bore plug in a tight bore, with high chamber pressure and high case volume.

This means you’re going to hit the gas port with really high port pressure and a lot of expanding hot gas volume behind the bullet trying to get out, with a bullet that doesn’t like being forced out. It would take a culture from a company who only accepts top-end performance in reliability to get it to work right.

If I was doing it, I would start off with a port at the calculated port pressure window to be in the happy range of reliability for the system, which means a certain set of pressures inside the carrier’s expansion chamber.

You would want to limit it to a specific and narrow range of bullet weights/lengths as well.

I would personally just shoot 6mm ARC from the AR-15. The juice from 6 Creedmoor doesn’t seem worth the squeeze in comparison when you look at the performance difference between the 2.

Would be great if the rifle gets popular enough for Proof and others to make barrels for it.

Yeah... unfortunately with the proprietary alloy of the extensions, that probably won't happenWould be great if the rifle gets popular enough for Proof and others to make barrels for it.

Has anyone got word on people making barrels for this?

Id love to throw a 6GT barrel on the Sfar. Like a 6arc on steroids

Id love to throw a 6GT barrel on the Sfar. Like a 6arc on steroids

Similar threads

- Replies

- 38

- Views

- 739

- Replies

- 3

- Views

- 366

- Replies

- 21

- Views

- 1K

- Replies

- 115

- Views

- 6K