If I recall the A1 was just to the m40 spec so I believe I'm good in that.

Best I could find was the info on this link (picture attached)

In this post Rifleshooter.com will build a clone of the United States Marine Corps M40A3 Sniper Rifle. Replacing the M40A1 in 1999, and used by the Marines until 2009, the M40A3 is characterized by…

rifleshooter.com

***

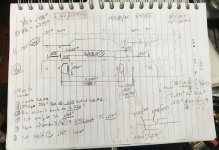

Fwiw, attached is the hand drawing that the author mentioned. Dave Clark did my M40A5, and I think he used the lugs on the BO scope rail to mark-up the receiver for the 'lug-slot.' I didn't ask him about a drawing, but I think the above information is correct. (I have noted slightly different shapes on the 'thumb relief' cuts on original M40A1s, presumably as that has done by hand back then).

One nuance, the 1966-1969 M40s were factory "

clip slotted" and thus had two small divots or semi-circular cuts on each side- to accommodate the 5-rd stripper clip so they would be held in the receiver's clip slot. (These were used back then to rapidly load 5 rds from the top for the rapid fire section of a rifle match, but obviously superfluous for a scoped rifle). White arrows are what I mean by factory "clip slotting" on the original M40s.

In a slight contrast, when it came to modifying the C, E, G M700 receivers for the M40A1/A3/A5 variants, my understanding is the USMC just "

lug slotted" the receivers - and didn't bother with the two semi-circular "clip" slots as their was no need to do that extra machining - as 5-rd stripper clips would never be used on those sniper rifles. Here's what a retired 2112 did for my replica, and it looks hand-done. It lacks the "clip" cuts as seen above. (Fwiw, years ago at a match at Quantico, I heard one old 2112 joke/confess that he screwed up one time doing the lug slot on an M40A1 in mid-90s, as it done by hand).

Lastly, two retired MOS 2112s told me that on M40A1s they cut the rear slot a tiny bit short (maybe 0.001?), and would hand-file the back of the lug on the Unertl scope mount so it would

just fit into the slot on the receiver, with no play. (see white arrow where they would hand-file to fit a particular lug slot).

Yes, it was tedious, but that's what I was told was the SOP back in the 1990s. That's also what they did on my replica as well - its a tight fit.

Anyhow, that's all I know. Perhaps others know more, and good luck with your project.