I just purchased an Annie from a member here that should be here in the next week. It has the water cooled coil. I'm going to start annealing my brass every firing to keep things consistent. Any pointers to help me with the learning curve? Probably going to start out with Hornady 6.5 creedmoor brass. Haven't decided if I'm going to build a drop through table or not. Opinions appreciated.

- Thread starter giannid

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I love my Annie annealer! Works great, does everything I need it to do. I’d say the highest I’ve set it to is for Gunwerks 6.5prc brass. I built the stand and everything myself, I used a lab scale jack I bought off of eBay and built my own cooler and everything. The one thing I have neglected doing is building the trap door. I really need to do that but just not that important yet.

You have to play it by ear on settings, get some brass that you are going to use or using that is shot up and test on that if you have any.

You have to play it by ear on settings, get some brass that you are going to use or using that is shot up and test on that if you have any.

Get some 750 tempilaq and a bottle of thinner. Once the tempilaq gets almost empty it’ll have started to dry out a bit with lots of goopy dry stuff so just pour some thinner in and shake it up and it’ll redissolve some of that build up, it’ll last a long time like that.

Put a thin layer of tempilaq on the outside of 10 case necks and let it dry until it’s powdery looking.

Grab some scrap brass to run 10-20 cases through to make sure it’s hot.

I don’t have the water coil but with the normal depending on how deep you position the neck and shoulder in the gap will vary how much energy goes into each and thus how soon or late each will heat with respect to each other. I like to keep it around the shoulder-body to mid shoulder in the middle so that a bit more energy goes into the shoulder which has more material. That’s in an effort to have the neck and shoulder turn the temp close to each other.

And then start with a creed case at 2 seconds and see what you get. Then 2.2. Then 2.4. At some point when the tempilaq starts to go clear (and then black if you keep cooking it) you will know you hit your temp, I go until it just gets started down the body a smidge. Do a couple more to verify and you’re done. The necks will always go before the shoulder though, can’t help it but that’s alright.

Steel wool 0000 will help you clean the tempilaq off those cases, scraping with another cases rim helps too.

In between these two examples with the green arrows that were .2 seconds apart is where I would try to set it at.

There is a non lacquered example case next to each to show that you can’t tell on bare color alone.

Put a thin layer of tempilaq on the outside of 10 case necks and let it dry until it’s powdery looking.

Grab some scrap brass to run 10-20 cases through to make sure it’s hot.

I don’t have the water coil but with the normal depending on how deep you position the neck and shoulder in the gap will vary how much energy goes into each and thus how soon or late each will heat with respect to each other. I like to keep it around the shoulder-body to mid shoulder in the middle so that a bit more energy goes into the shoulder which has more material. That’s in an effort to have the neck and shoulder turn the temp close to each other.

And then start with a creed case at 2 seconds and see what you get. Then 2.2. Then 2.4. At some point when the tempilaq starts to go clear (and then black if you keep cooking it) you will know you hit your temp, I go until it just gets started down the body a smidge. Do a couple more to verify and you’re done. The necks will always go before the shoulder though, can’t help it but that’s alright.

Steel wool 0000 will help you clean the tempilaq off those cases, scraping with another cases rim helps too.

In between these two examples with the green arrows that were .2 seconds apart is where I would try to set it at.

There is a non lacquered example case next to each to show that you can’t tell on bare color alone.

Last edited:

Get some 750 tempilaq and a bottle of thinner. Once the tempilaq gets almost empty it’ll have started to dry out a bit with lots of goopy dry stuff so just pour some thinner in and shake it up and it’ll redissolve some of that build up, it’ll last a long time like that.

Put a thin layer of tempilaq on the outside of 10 case necks and let it dry until it’s powdery looking.

Grab some scrap brass to run 10-20 cases through to make sure it’s hot.

I don’t have the water coil but with the normal depending on how deep you position the neck and shoulder in the gap will vary how much energy goes into each and thus how soon or late each will heat with respect to each other. I like to keep it around the shoulder-body to mid shoulder in the middle so that a bit more energy goes into the shoulder which has more material. That’s in an effort to have the neck and shoulder turn the temp close to each other.

And then start with a creed case at 2 seconds and see what you get. Then 2.2. Then 2.4. At some point when the tempilaq starts to go clear (and then black if you keep cooking it) you will know you hit your temp, I go until it just gets started down the body a smidge. Do a couple more to verify and you’re done. The necks will always go before the shoulder though, can’t help it but that’s alright.

Steel wool 0000 will help you clean the tempilaq off those cases, scraping with another cases rim helps too.

In between these two examples with the green arrows that were .2 seconds apart is where I would try to set it at.

View attachment 7508626

There is a non lacquered example case next to each to show that you can’t tell on bare color alone.

Thank you. That's really good information. For what I've found poking around, most people anneal the Hornady 6.5 brass 1.6 to 1.8 seconds. I'm wondering if the water cooled coil gets a little hotter than the regular setup like you have. My other concern is setting up the coil to the case. Do you want the case so it's at the even with top of the coil, above the top of the coil, or below the top of the coil.

Did you end up making a table with a drop hole/door for yours? One guy on youtube said it was just as easy/fast to use tweezers on a table.

I dont have hornady, just peterson 6.5 cred brass so I was basing off of that. Start at 1.6 and work up from there then, I think you would see that at 2 seconds would way past cook it then based on most people and you would know to turn down because it would turn black and cook on hard. Once you see it happen in person its sort of intuitive.

I didnt build a table. I just take it outside on the porch and hold them in my fingers. Just holding the rim it doesnt get hot unless I sit there and hold onto it after the fact. Once the heat light goes off I quickly drop it in an old bread pan a few inches over and go to work on the next one. And, when Im holding it by hand, you can feel it vibrate with magnetic field so you also feel exactly when its done sort of instinctually and then toss it in the pan so you dont have to stare at the light.

As for how to position to coil Im not sure, Im going to say to do one at 1.8 seconds and test it with the neck centered in the coil and then one with the base of the shoulder centered and see how the tempilaq turns pahse between the shoulder and the neck, if the neck cooks but the shoulder doesnt then put it a bit deeper to get more energy into the shoulder and less into the neck in an attempt to have them arrive as close together as you can. And vice versa. Youll have to play with it a bit but once you see what each action between time vs location it will be easy from there on out.

And once you figure out what the brass likes you can remember and not have to do all that again.

I didnt build a table. I just take it outside on the porch and hold them in my fingers. Just holding the rim it doesnt get hot unless I sit there and hold onto it after the fact. Once the heat light goes off I quickly drop it in an old bread pan a few inches over and go to work on the next one. And, when Im holding it by hand, you can feel it vibrate with magnetic field so you also feel exactly when its done sort of instinctually and then toss it in the pan so you dont have to stare at the light.

As for how to position to coil Im not sure, Im going to say to do one at 1.8 seconds and test it with the neck centered in the coil and then one with the base of the shoulder centered and see how the tempilaq turns pahse between the shoulder and the neck, if the neck cooks but the shoulder doesnt then put it a bit deeper to get more energy into the shoulder and less into the neck in an attempt to have them arrive as close together as you can. And vice versa. Youll have to play with it a bit but once you see what each action between time vs location it will be easy from there on out.

And once you figure out what the brass likes you can remember and not have to do all that again.

i always cycle mine really quickly about a half dozen times before i start dropping brass. also, do some googling and build yourself one of the little tables with the hole/trap door to allow you to place the brass and then drop it through after annealing.

Interesting, I’ve thought about that but didn’t know if it would hurt anything.i always cycle mine really quickly about a half dozen times before i start dropping brass. also, do some googling and build yourself one of the little tables with the hole/trap door to allow you to place the brass and then drop it through after annealing.

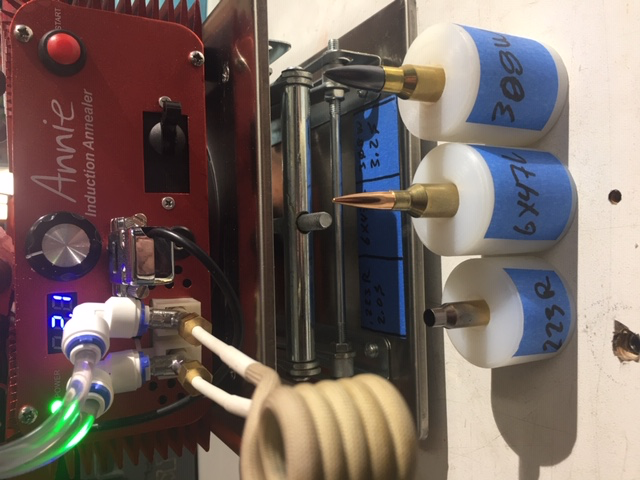

In lieu of the drop table, I made these Delrin shell holders. I just load a round of brass into the proper size holder, run it up under the coil until the top of the holder hits the bottom of the coil and press the start button. Simple and works like a champ. (loaded rounds for visual representation only......).

I think the glass tube ideal I seen on another forum is the best ideal yet. You get a solid glass rod smaller that bullet size and mount it to the surface. Glass rod needs to be cut to right size to allow upside down case to sit at the proper coil height. Put case on glass, annel, remove case with your hand.

Just annealed 200 cases of 6.5 creedmoor with the Annie. Went through them really quick and am pretty happy with it. I got two coils with it, large and small. The small one is plugged up and water wouldn't flow through it. Must be some solder stuck in it when they built it so I was stuck using the bigger coil. I think the smaller could would be better for 308 class brass. Tested with the tempilaq and ended up using 2 seconds for the Hornady cases. This stuff is kind of an ass ache to use as It really never went clear. At 1.9 seconds it was still kind of green and 2 seconds was pretty much black.

Attachments

i always cycle mine really quickly about a half dozen times before i start dropping brass. also, do some googling and build yourself one of the little tables with the hole/trap door to allow you to place the brass and then drop it through after annealing.

I have the water-cooled coils and do the same. I'm not sure why that's needed, but it is.

Also, here is a video of my drop table.

Also, here is a video of my drop table.

nice setup. mine is not nearly as refined. I only use 3 legs (removed the one in the 430 position) to allow a larger space and easier access for a metal dog bowl. I also offset the hole in the table top, allowing the leg in the 730 position to act as a 'stop' for the trap door.

Wanted to give this a bump and see how guys are liking the Annie Annealer after they had a chance to use it more? I really like the idea of the induction Annealer vs flame Annealer and I know the AMP is super simple with no setup and the Cats Meow, but with Tempilaq and a little practice can the Annie be “as good” as the Amp results wise? I won’t be needing to anneal hundreds of rounds per week so the Annie with drop table seems fast enough for me and much closer to my price range, but I also don’t want to drop coin only to get an AMP a few months from now.

I have another more general annealing question, I hear guys talking about ruining cases by under/over annealing when setting up flame Annealers, but why does under annealing ruin brass? Couldn’t it just be re-annealed after cooling it down and getting the settings right? If it didn’t get hot enough then wouldn’t it mean there was little change to the hardness of the Brass? Or am I thinking about this wrong?

Thanks in advance for any help you can provide!

I have another more general annealing question, I hear guys talking about ruining cases by under/over annealing when setting up flame Annealers, but why does under annealing ruin brass? Couldn’t it just be re-annealed after cooling it down and getting the settings right? If it didn’t get hot enough then wouldn’t it mean there was little change to the hardness of the Brass? Or am I thinking about this wrong?

Thanks in advance for any help you can provide!

AMP = no flame, speed, volume, less set up, consistency without thinking about it

Annie = no flame, not as fast as AMP, quicker than flame, consistency with less thought

Flame = ??

When I was doing flame annealing, my results were very consistent because of the process I used and the fact that I paid attention to the details. With my Annie, I get similar consistency, but don't have the flame to worry about, and it's quicker. Like you, I'm not doing hundreds of cases per week - I seldom shoot more than 100 in an outing and I don't go every week.

As to the over/under-annealing thing, you won't ruin cases by under annealing, and you won't over-anneal if you're careful. Does the AMP or Annie take the over-annealing out of the picture? No - what if you set it up wrong? I've actually over-annealed infinitely more times with my Annie than I did with flame (1 case in my Annie - after getting the flame process set, NEVER did I over-anneal a case with flame - not once - again, because of my process and the fact that I tediously adhered to it).

Annie = no flame, not as fast as AMP, quicker than flame, consistency with less thought

Flame = ??

When I was doing flame annealing, my results were very consistent because of the process I used and the fact that I paid attention to the details. With my Annie, I get similar consistency, but don't have the flame to worry about, and it's quicker. Like you, I'm not doing hundreds of cases per week - I seldom shoot more than 100 in an outing and I don't go every week.

As to the over/under-annealing thing, you won't ruin cases by under annealing, and you won't over-anneal if you're careful. Does the AMP or Annie take the over-annealing out of the picture? No - what if you set it up wrong? I've actually over-annealed infinitely more times with my Annie than I did with flame (1 case in my Annie - after getting the flame process set, NEVER did I over-anneal a case with flame - not once - again, because of my process and the fact that I tediously adhered to it).

@Rocketmandb could you share your flame anneal process? From your above post:

Would love to know your flame anneal steps. I'm interested in the Annie, but also interested in getting better with my flame work before jumping across to something fancier.

When I was doing flame annealing, my results were very consistent because of the process I used and the fact that I paid attention to the details

Would love to know your flame anneal steps. I'm interested in the Annie, but also interested in getting better with my flame work before jumping across to something fancier.

@Rocketmandb could you share your flame anneal process? From your above post:

Would love to know your flame anneal steps. I'm interested in the Annie, but also interested in getting better with my flame work before jumping across to something fancier.

Here's the basics:

- Started with the Anneal Rite stand and torch holders, though if you have time and a little skill, you can easily make alternatives.

- Modified the case holder by adding a bracket and electric motor so it would rotate - this is pretty important. Powered using a 6v battery (one of the big flash light ones)

- I set the torches such that the very ends of the flame meet where the case holder/case will be. This means it takes longer for each case to heat up, but I find that to be an advantage (except from a time perspective).

- I have a metronome app on my phone and used that for basic timing.

- Drop a case in, rotate it into the flames

- I aligned the case height such that the flames hit in the middle of the shoulder taper

- As the appropriate time approaches, watch closely at the base of the shoulder for the color change. Because it is heating slower, you have a bigger window for consistency.

- As soon as the color change progresses past the shoulder, dump the case out.

Pic of the main mount and case holder:

Similar threads

- Replies

- 11

- Views

- 686

- Replies

- 8

- Views

- 948