Ruger Precision Rifle

6.5 Creedmoor

Winchester Large Primer

H4350 powder

Hornady 140 Gr ELD Match

Lyman turret press

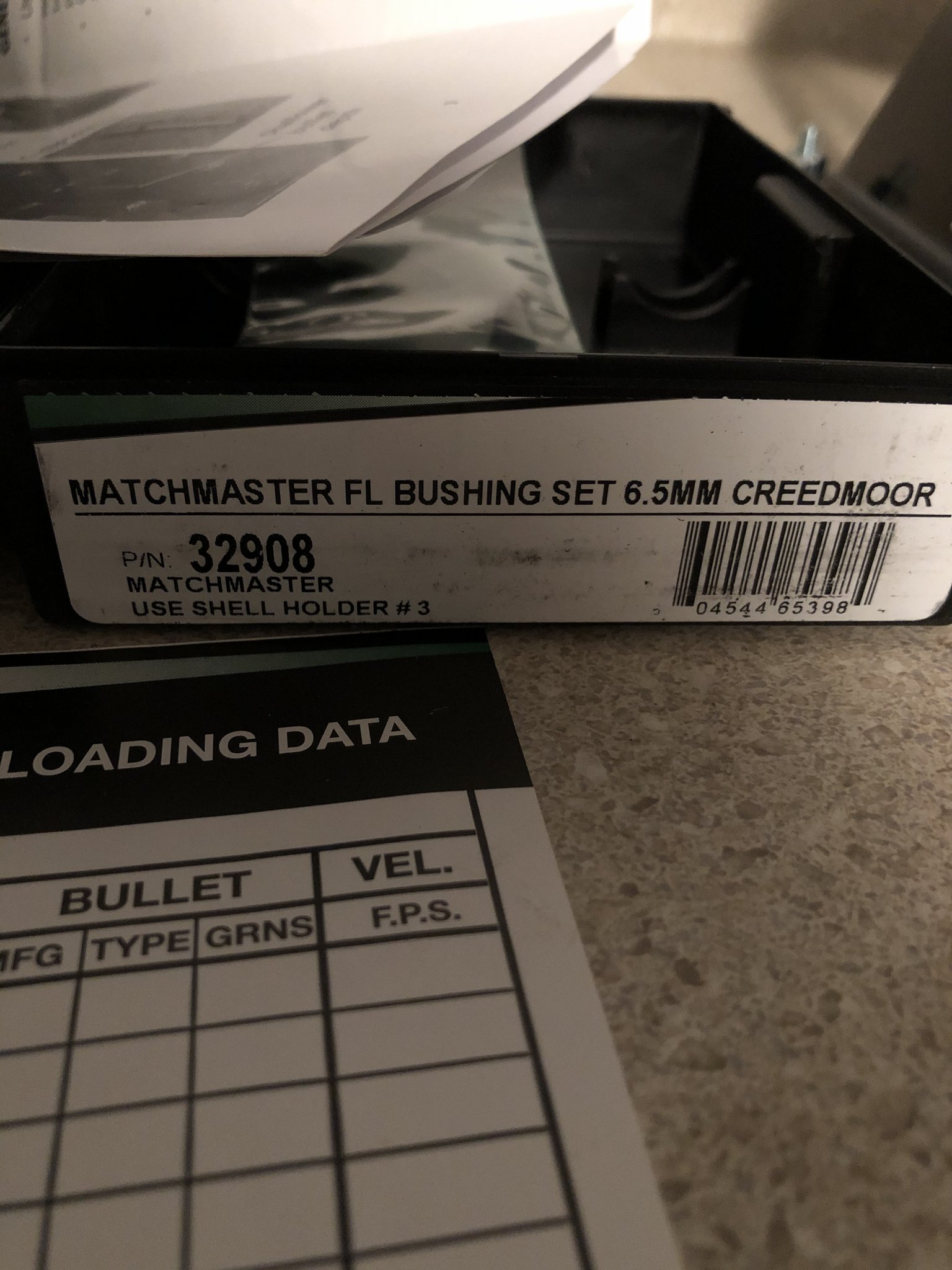

Rcbs matchmaster dies

I’ve really been caught by the long range bug and am doing the best I can handloading and am sure there is a ton I could be doing better. Any constructive criticism would be appreciated.

I’m using my RCBS Matchmaster dies to bump the shoulder on my once fired Hornady brass back .002 after each firing and trimming to 1.910 (because that’s what Hogdgon website says) with my RCBS power trimmer, chamfer and debur the case mouth and clean out the primer pocket.

Question: After I trim then use my hand tools to chamfer and debur, my cases consistently grow so I put them back in my power trimmer and it comes right back to size? What the.....

I hand prime and use my RCBS chargemaster 1500 to play with various weights of H4350. The first time I seated my bullets I set my micrometer die and left it at the same length for all 20 bullets and got a somewhat consistent measurement at the ojive on my Hornady bullet comparator but the OAL was all over the place.

The second time I sat each bullet long and used the micrometer die to adjust the oal of the loaded ammo to exactly where I wanted it and that length is based off of the internal length of the magazine.

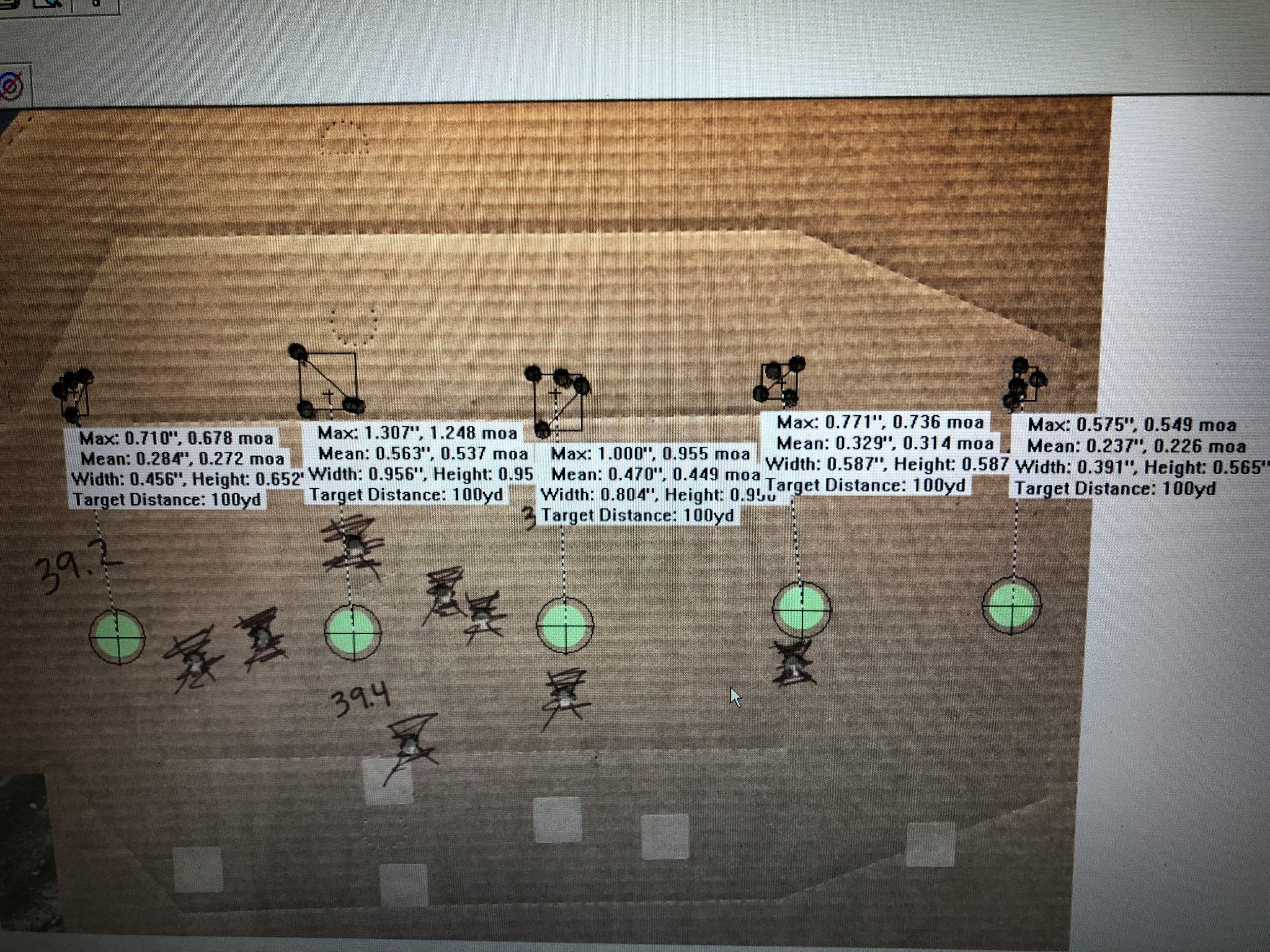

This was after measuring off of the Ojive:

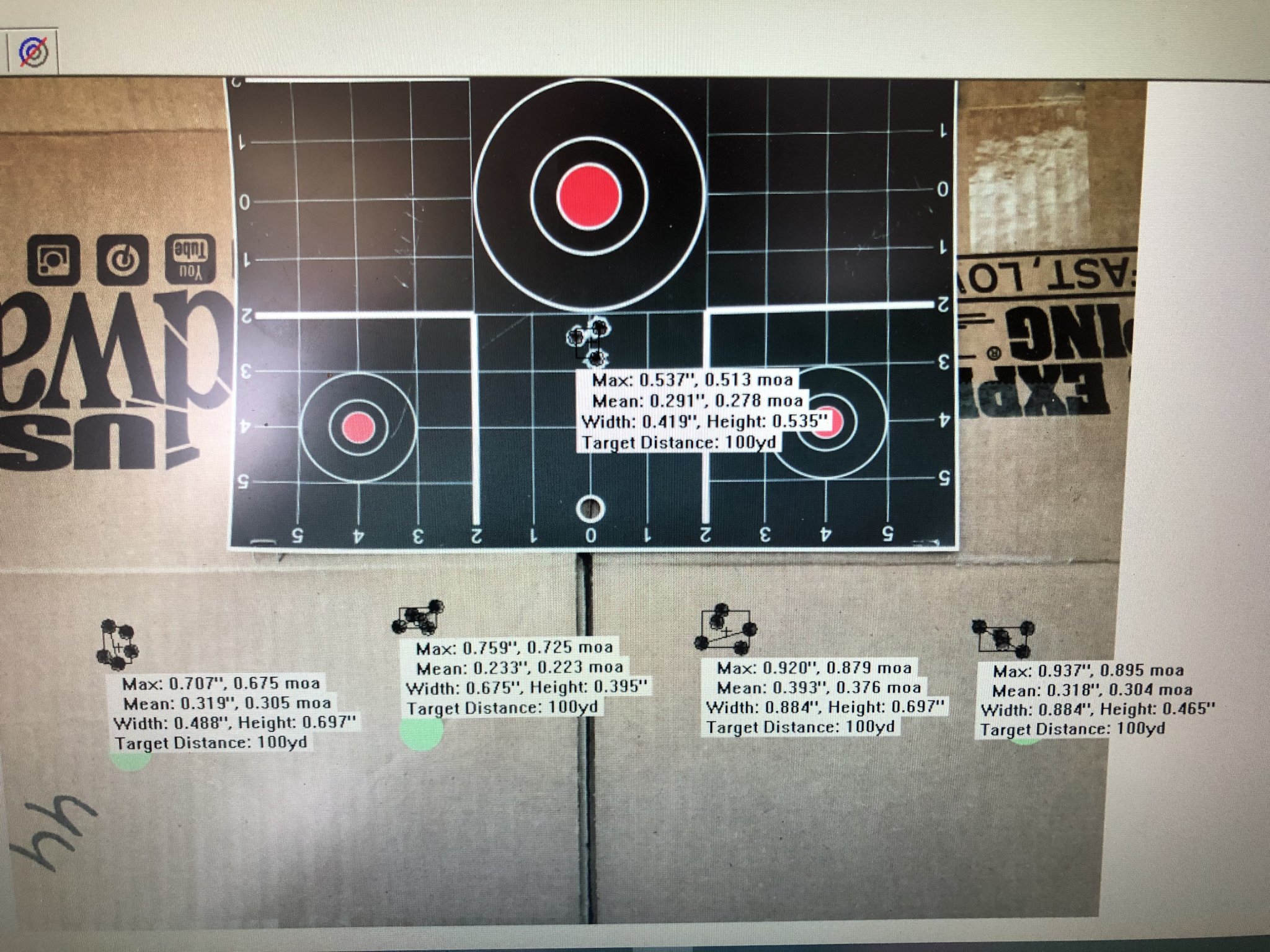

This was after measuring the OAL and adjusting the die each round. The black target was factory Hornady Match.

6.5 Creedmoor

Winchester Large Primer

H4350 powder

Hornady 140 Gr ELD Match

Lyman turret press

Rcbs matchmaster dies

I’ve really been caught by the long range bug and am doing the best I can handloading and am sure there is a ton I could be doing better. Any constructive criticism would be appreciated.

I’m using my RCBS Matchmaster dies to bump the shoulder on my once fired Hornady brass back .002 after each firing and trimming to 1.910 (because that’s what Hogdgon website says) with my RCBS power trimmer, chamfer and debur the case mouth and clean out the primer pocket.

Question: After I trim then use my hand tools to chamfer and debur, my cases consistently grow so I put them back in my power trimmer and it comes right back to size? What the.....

I hand prime and use my RCBS chargemaster 1500 to play with various weights of H4350. The first time I seated my bullets I set my micrometer die and left it at the same length for all 20 bullets and got a somewhat consistent measurement at the ojive on my Hornady bullet comparator but the OAL was all over the place.

The second time I sat each bullet long and used the micrometer die to adjust the oal of the loaded ammo to exactly where I wanted it and that length is based off of the internal length of the magazine.

This was after measuring off of the Ojive:

This was after measuring the OAL and adjusting the die each round. The black target was factory Hornady Match.