Does anyone run into this problem?

I'm loading 24.5gr of Varget at mag length 2.260" using Hornady and Forster Competition seater.

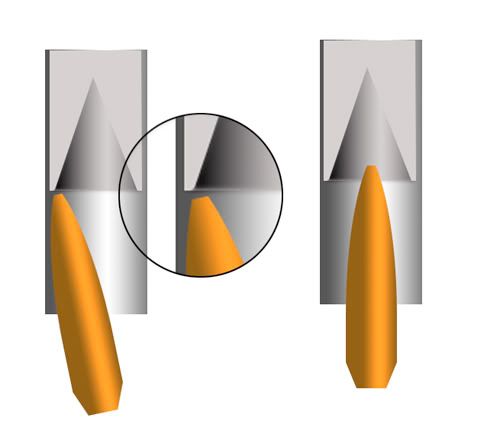

I know I;'m compressing the powder but why the hollow point are getting slightly mangled? (Can't be good for accuracy)

Thanks

Pauli

I'm loading 24.5gr of Varget at mag length 2.260" using Hornady and Forster Competition seater.

I know I;'m compressing the powder but why the hollow point are getting slightly mangled? (Can't be good for accuracy)

Thanks

Pauli