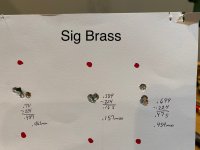

Just got a new barreled action from Keystone Accuracy in .223 Wylde, Origin action with a Rock Creek 7 twist cut rifled barrel. After 3 shots to zero with Federal GMM 69 SMK, the next 2 groups were .425 and .350. Looking good! Stopped there to do an initial cleaning.

Now on to develop a load for Hornady 75 ELD-M's. I have H4895 and Varget to try based on what I have seen on the site. When measuring OAL length for the 75 ELD-M with the Hornady tool, I get some interesting results. I feel some initial resistance at 2.385 OAL. Pushing a little harder, I get a definitive stop at 2.500 OAL, 1.940 to the Ogive.

I don't think I am jammed, as the bullet is not stuck in the lands and releases with the tool. The initial resistance at 2.385 seems short based on other's measurements that I have seen here. I think I should go with the 2.500, but I may back off something like .035 to start.

What do you guys think?

Now on to develop a load for Hornady 75 ELD-M's. I have H4895 and Varget to try based on what I have seen on the site. When measuring OAL length for the 75 ELD-M with the Hornady tool, I get some interesting results. I feel some initial resistance at 2.385 OAL. Pushing a little harder, I get a definitive stop at 2.500 OAL, 1.940 to the Ogive.

I don't think I am jammed, as the bullet is not stuck in the lands and releases with the tool. The initial resistance at 2.385 seems short based on other's measurements that I have seen here. I think I should go with the 2.500, but I may back off something like .035 to start.

What do you guys think?