I have been intrigued by the new incarnation of the SSK "300 Whisper®" concept introduced this month by AAC.

This looks like it will be a nice solution in many areas.

Since the 300 AAC BLACKOUT is an official SAAMI spec cartridge now, hopefully more innovation in this platform will come about.

Listed Below is the suggested loading info released by AAC.

http://www.300aacblackout.com/

HANDLOADING INFORMATION

If you load your own ammo, pay special attention to all of the normal safety practices.

Recommended powder for most supersonic loads is Hodgdon H110.

For subsonic, there are special requirements and nearly all published loads are non-optimal for the 300 BLK upper.

Many existing loads were developed for Thompson Center® single-shot pistols,

or for ARs by people not aware of the magazine limitations.

These loads pay no attention to automatic rifle function and should not be used.

Look for a load which results in a cyclic rate of 700 rpm or more.

AA1680 is recommended because its bulk density matches the case capacity and it will generate enough gas pressure to cycle the weapon.

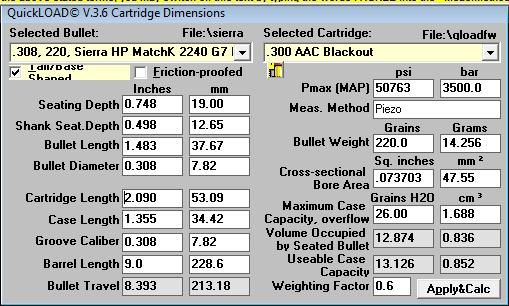

Suggested subsonic load:

• R-P 300 AAC BLACKOUT brass

• Remington 7.5 primers

• 11.2 grains of AA 1680 powder

• Case length is 1.368 +0.000 -0.020

• Sierra 220 MK loaded to 2.089 OAL (this length is optimal for reliable feeding from USGI magazines)

• Chamber pressure 21,100 psi.

Existing AR magazines have a rib which normally contacts the 5.56mm case-neck.

With 300 BLK ammo, the contact is on the bullet.

Because the bullet is a larger diameter, the rib will push the cartridges out of alignment,

and can lead to binding potentially resulting in Failures to Feed.

For this reason, it is important to load ammunition so that the contact point with the magazine rib is on the bullet ogive in an area of about 0.250 inch diameter.

Here are some suggested OAL for popular bullets:

• Hornady 110 V-Max, OAL: 2.000

• 110 TSX, 2.015 OAL

• Sierra 155 Palma, 2.150 OAL

• Sierra 220, 2.089 OAL

• Lapua B416 200 grain, 1.960 OAL

• Hornady 150 FMJ-BT 3037, 2.065 OAL

• Nosler Ballistic Tip 125 grain, OAL: 2.085

• Remington AccuTip 125 grain, OAL: 2.085

• Hornady 130 SP #3020, OAL: 2.010

• Sierra H2120 125 ProHunter, OAL: 1.950

• Speer TNT 125 1986, OAL: 2.010

Reloading Dies are available from Forster

•Full Length Sizing Die only, 300 BLK, Part # 005545

•Standard Seating Die only, 300 BLK, Part #006205

•Ultra Micrometer Seating Die only, 300 BLK, Part #U00099

•Set of Full Length Sizing Die and Standard Seating Die, 300 BLK, Part #004453

•Set of Full Length Sizing Die and Ultra Micrometer Seating Die, 300 BLK, Part #U04453

-----Forster Products

-----310 East Lanark Avenue

-----Lanark, Illinois 61046

-----PHONE & FAX

-----p: (815) 493-6360

-----f: (815) 493-2371

It would be awesome to see Redding pickup this cartridge as well.

(AAC has stated on other forums that they would provide the cartridge drawings to them if asked.)

http://www.silencertalk.com/forum/viewtopic.php?f=2&t=62883&start=100

The more people that ask for it the more likely they will produce it:

-----Redding Reloading Equipment

-----1089 Starr Road

-----Cortland, NY 13045

-----Phone (607)753-3331

-----FAX (607) 756-8445

AFAIK

- 5.56x45mm NATO Brass can be used as the parent brass and then resized / trimmed.

- 300 BLK cartridges and 300-221 Rem Fireball cartridges should be thought of in the same way .223 Rem and 5.56 NATO is.

The 300 BLK has a larger throat and therfore 300 BLK factory loading could cause excess pressure in 300 Whisper (R) / 300 Fireball chambers.

(Check with the manufacture for compatibility and always have the chamber reamed when in doubt.)

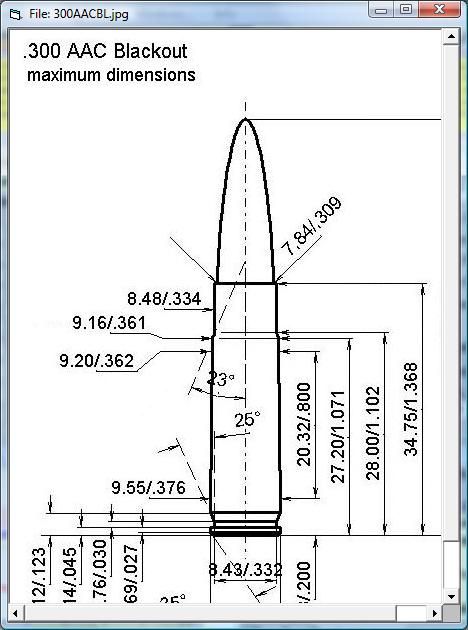

Chamber details as posted on another forum:

http://www.oa2.org/forums/viewtopic.php?t=11304&highlight=

The headspace is exactly the same as 221 Fireball, the chamber is exactly the same as the 221 Fireball except the neck is .337 tapering to .335. The max case length is 1.368", chamber is 1.378 to where the case mouth would be. Throat is .309 for about .18 then it's a 1.5 degree into the bore.

Please post both supersonic and subsonic load data.

When posting please be sure to include barrel length, twist rate, chamber type and gas tube position. (If using an AR.)

AAC is currently using a pistol length gas system in their 9" barrels and a carbine length one in 16".

Gas port diameters remain undisclosed and have been deemed proprietary corporate information by AAC / Robert Silvers.

http://www.silencertalk.com/forum/viewtopic.php?f=2&t=62883&start=100

Wilson Combat is using the following gas port sizes:

11" pistol gas .073 (.093 was required when using subsonics)

11 CAR gas .093

16" CAR gas .110 (some guns run at .105)

http://www.silencertalk.com/forum/viewtopic.php?f=128&t=63547

Noveske is developing barrel assemblies for 300 BLK.

http://noveskerifleworks.com/cgi-bin/imcart/display.cgi?cat=168

Other companies developing products for the 300 BLK can be found here:

http://www.silencertalk.com/forum/viewtopic.php?f=128&t=63922

*NOTE*

I am not affiliated in any way with AAC or the Freedom Group.

I started this thread in an effort to expedite the development of this cartridge.

This looks like it will be a nice solution in many areas.

Since the 300 AAC BLACKOUT is an official SAAMI spec cartridge now, hopefully more innovation in this platform will come about.

Listed Below is the suggested loading info released by AAC.

http://www.300aacblackout.com/

HANDLOADING INFORMATION

If you load your own ammo, pay special attention to all of the normal safety practices.

Recommended powder for most supersonic loads is Hodgdon H110.

For subsonic, there are special requirements and nearly all published loads are non-optimal for the 300 BLK upper.

Many existing loads were developed for Thompson Center® single-shot pistols,

or for ARs by people not aware of the magazine limitations.

These loads pay no attention to automatic rifle function and should not be used.

Look for a load which results in a cyclic rate of 700 rpm or more.

AA1680 is recommended because its bulk density matches the case capacity and it will generate enough gas pressure to cycle the weapon.

Suggested subsonic load:

• R-P 300 AAC BLACKOUT brass

• Remington 7.5 primers

• 11.2 grains of AA 1680 powder

• Case length is 1.368 +0.000 -0.020

• Sierra 220 MK loaded to 2.089 OAL (this length is optimal for reliable feeding from USGI magazines)

• Chamber pressure 21,100 psi.

Existing AR magazines have a rib which normally contacts the 5.56mm case-neck.

With 300 BLK ammo, the contact is on the bullet.

Because the bullet is a larger diameter, the rib will push the cartridges out of alignment,

and can lead to binding potentially resulting in Failures to Feed.

For this reason, it is important to load ammunition so that the contact point with the magazine rib is on the bullet ogive in an area of about 0.250 inch diameter.

Here are some suggested OAL for popular bullets:

• Hornady 110 V-Max, OAL: 2.000

• 110 TSX, 2.015 OAL

• Sierra 155 Palma, 2.150 OAL

• Sierra 220, 2.089 OAL

• Lapua B416 200 grain, 1.960 OAL

• Hornady 150 FMJ-BT 3037, 2.065 OAL

• Nosler Ballistic Tip 125 grain, OAL: 2.085

• Remington AccuTip 125 grain, OAL: 2.085

• Hornady 130 SP #3020, OAL: 2.010

• Sierra H2120 125 ProHunter, OAL: 1.950

• Speer TNT 125 1986, OAL: 2.010

Reloading Dies are available from Forster

•Full Length Sizing Die only, 300 BLK, Part # 005545

•Standard Seating Die only, 300 BLK, Part #006205

•Ultra Micrometer Seating Die only, 300 BLK, Part #U00099

•Set of Full Length Sizing Die and Standard Seating Die, 300 BLK, Part #004453

•Set of Full Length Sizing Die and Ultra Micrometer Seating Die, 300 BLK, Part #U04453

-----Forster Products

-----310 East Lanark Avenue

-----Lanark, Illinois 61046

-----PHONE & FAX

-----p: (815) 493-6360

-----f: (815) 493-2371

It would be awesome to see Redding pickup this cartridge as well.

(AAC has stated on other forums that they would provide the cartridge drawings to them if asked.)

http://www.silencertalk.com/forum/viewtopic.php?f=2&t=62883&start=100

The more people that ask for it the more likely they will produce it:

-----Redding Reloading Equipment

-----1089 Starr Road

-----Cortland, NY 13045

-----Phone (607)753-3331

-----FAX (607) 756-8445

AFAIK

- 5.56x45mm NATO Brass can be used as the parent brass and then resized / trimmed.

- 300 BLK cartridges and 300-221 Rem Fireball cartridges should be thought of in the same way .223 Rem and 5.56 NATO is.

The 300 BLK has a larger throat and therfore 300 BLK factory loading could cause excess pressure in 300 Whisper (R) / 300 Fireball chambers.

(Check with the manufacture for compatibility and always have the chamber reamed when in doubt.)

Chamber details as posted on another forum:

http://www.oa2.org/forums/viewtopic.php?t=11304&highlight=

The headspace is exactly the same as 221 Fireball, the chamber is exactly the same as the 221 Fireball except the neck is .337 tapering to .335. The max case length is 1.368", chamber is 1.378 to where the case mouth would be. Throat is .309 for about .18 then it's a 1.5 degree into the bore.

Please post both supersonic and subsonic load data.

When posting please be sure to include barrel length, twist rate, chamber type and gas tube position. (If using an AR.)

AAC is currently using a pistol length gas system in their 9" barrels and a carbine length one in 16".

Gas port diameters remain undisclosed and have been deemed proprietary corporate information by AAC / Robert Silvers.

http://www.silencertalk.com/forum/viewtopic.php?f=2&t=62883&start=100

Wilson Combat is using the following gas port sizes:

11" pistol gas .073 (.093 was required when using subsonics)

11 CAR gas .093

16" CAR gas .110 (some guns run at .105)

http://www.silencertalk.com/forum/viewtopic.php?f=128&t=63547

Noveske is developing barrel assemblies for 300 BLK.

http://noveskerifleworks.com/cgi-bin/imcart/display.cgi?cat=168

Other companies developing products for the 300 BLK can be found here:

http://www.silencertalk.com/forum/viewtopic.php?f=128&t=63922

*NOTE*

I am not affiliated in any way with AAC or the Freedom Group.

I started this thread in an effort to expedite the development of this cartridge.