All great questions ... let me take a shot at answering them.

- Get your point about the red-flag ... need to think about that a bit.

- "struggle seating bullets" ... means I hit a hard-stop-break when the bullet starts to seat that requires too much pressure to get past, and once past, there's no pressure. Also, the base of the bullet (if it's pulled) is scarred from the pressure seating and I actually get a tiny ring of discharge from inside the die that falls out ... seems to be part of the case mouth. Now part of my problem is that I was getting a very slight "flaring" in the mouth from the mandrel, that disappears from the case mouth when it's sized with a bushing. I was starting to believe that "this" was my problem, and it was solved when the bushing goes after the mandrel. All of this is starting to make me believe the mandrel "is" the problem. Still pondering that ... but confused by it since that's not the case on several other calibers.

- Regarding the mandrel not hitting anything on a fired case ... I just tried that, and you're absolutely right. Thought about it and realized I had been doing my testing with cases that had already been sized, and I was actually "re-sizing" them. This is a fatal flaw in my testing process ... I now realize that. Shit !!!

- I use SAC bushings that are machined very precisely, so I'm not worried about that issue.

- I did post before that I had a good result, and was told I didn't have enough data points to draw the assumptions I'd drawn. Went back and tried again, and hit all the sizing and seating problems that caused me to start over.

- Not sure what that last paragraph about the 225 ammo is saying, other than the advice to stop wasting components ... which is always good advice.

So ... Sir ... you've thrown a hell of a monkey wrench into my assumptions,

and I sincerely than you for that.

I learn the most when I screw up the most. I obviously have more work to do here.

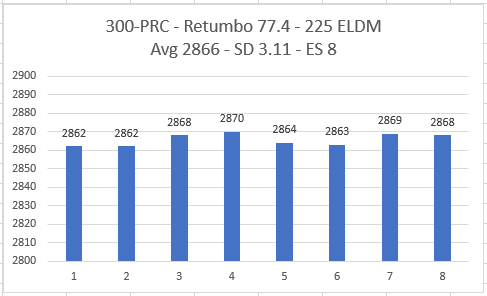

OK ... my next test will be 10 rounds that are bushing-sized ONLY with a .337 SAC bushing that gave these last results. I'm going to leave the mandrel on the shelf, and see if I can reproduce that low SD and consistency. If I can, then "that" is my process. If I can't ... then I guess I start over.