Hey guys I am new to the threads, but I would really appreciate any help you guys could offer.

I have a custom Remington 700 with a Bartlein 5R 1:11.25" twist barrel 26" in an XLR Envy chassis.

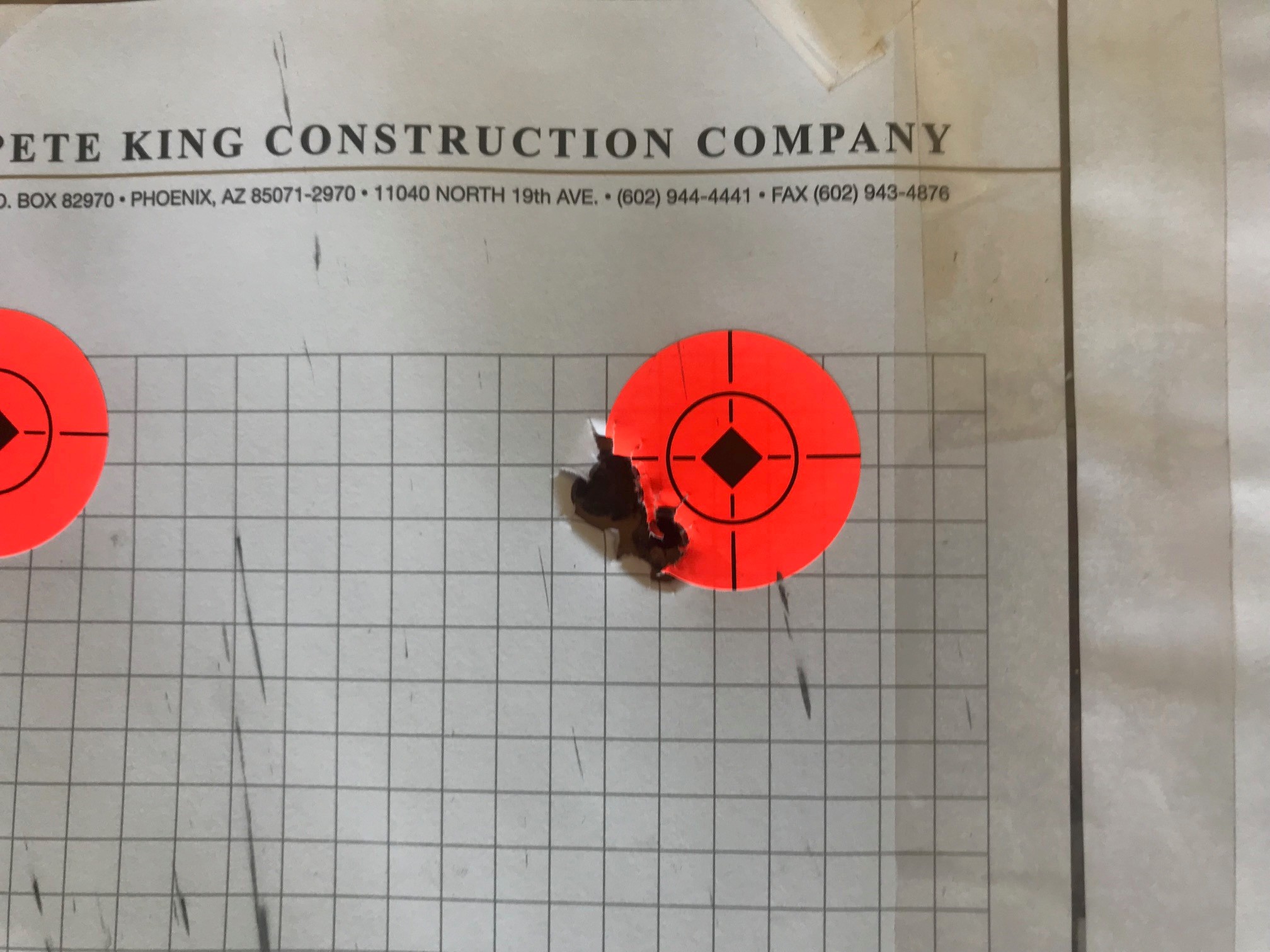

I know it shoots really well. This is 4 shots at 100 yards with Federal Gold Medal Match 175 Sierra.

This is a 4 shot group at 300 yards with hand loads.

VIRGIN Lapua Brass

CCI BR-2

42.9 grains of Varget

175 Sierra TMK

2680 fps with SD of 8

So I know that its a tack driver. My problem is that once I resize the brass I can not get anything close to these results. I am using a Redding full length sizer (non-bushing) die. The gun is a 308 win tac match chamber. I set the headspace back .0015", I trim them to 2.005" every firing, I checked the neck tension and it is about .002". I'm not sure what I'm doing wrong that is giving me such inconsistencies after I resize. Any ideas?

I have a custom Remington 700 with a Bartlein 5R 1:11.25" twist barrel 26" in an XLR Envy chassis.

I know it shoots really well. This is 4 shots at 100 yards with Federal Gold Medal Match 175 Sierra.

This is a 4 shot group at 300 yards with hand loads.

VIRGIN Lapua Brass

CCI BR-2

42.9 grains of Varget

175 Sierra TMK

2680 fps with SD of 8

So I know that its a tack driver. My problem is that once I resize the brass I can not get anything close to these results. I am using a Redding full length sizer (non-bushing) die. The gun is a 308 win tac match chamber. I set the headspace back .0015", I trim them to 2.005" every firing, I checked the neck tension and it is about .002". I'm not sure what I'm doing wrong that is giving me such inconsistencies after I resize. Any ideas?