Can some of u guys that are in the know help me with action strength, been hearing a lot lately about lug sheer on some of the bigger guns. Question is, what is a safe action as far as lug sheer for a 338 lapua. Is the big Weatherby safe with the 9 small lugs or is the REM700 and trg just as good. Heard some scary stories this week and this never crossed my mind till now, a bolt in the face is not something I care to worry about. Basically looking for the most suitable factory action for a build for a good friend. Got plenty of customs so no problems there I hope. Thanks.

Gunsmithing 338 Lapua and lug sheer

- Thread starter Xycod

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Re: 338 Lapua and lug sheer

Most will use a .750" diameter bolt body in the larger 338's. The standard Remington 700 uses a .699" to .701" diameter bolt body, this is too small in the minds of some builders including me. Lug shear is a legitimate concern in the 338LM. I'd run away from the 9 lug design.

Most will use a .750" diameter bolt body in the larger 338's. The standard Remington 700 uses a .699" to .701" diameter bolt body, this is too small in the minds of some builders including me. Lug shear is a legitimate concern in the 338LM. I'd run away from the 9 lug design.

Re: 338 Lapua and lug sheer

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: wnroscoe</div><div class="ubbcode-body">Most will use a .750" diameter bolt body in the larger 338's. The standard Remington 700 uses a .699" to .701" diameter bolt body, this is too small in the minds of some builders including me. Lug shear is a legitimate concern in the 338LM. I'd run away from the 9 lug design. </div></div>

Does this concern extend to the RUM series of cartridges or only the 338LM ?

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: wnroscoe</div><div class="ubbcode-body">Most will use a .750" diameter bolt body in the larger 338's. The standard Remington 700 uses a .699" to .701" diameter bolt body, this is too small in the minds of some builders including me. Lug shear is a legitimate concern in the 338LM. I'd run away from the 9 lug design. </div></div>

Does this concern extend to the RUM series of cartridges or only the 338LM ?

Re: 338 Lapua and lug sheer

I've built several 300RUM's on Remington 700's without issue. The 338LM is a different animal all together.

I've built several 300RUM's on Remington 700's without issue. The 338LM is a different animal all together.

Re: 338 Lapua and lug sheer

The big Weatherby mags operate at comparable PSI (65,000ish psi) as the 338LM. Lug shear is as much a concern (or lack of) in the other calibers as in the 338. I would choose something other than the Weatherby for a precision build but that's more because of the aftermarket options/dollar value than action strength.

The big Weatherby mags operate at comparable PSI (65,000ish psi) as the 338LM. Lug shear is as much a concern (or lack of) in the other calibers as in the 338. I would choose something other than the Weatherby for a precision build but that's more because of the aftermarket options/dollar value than action strength.

Re: 338 Lapua and lug sheer

I would trust a Weatherby MK-V (that has had the luggs lapped so they are all bearing) over ANY two lug bolt action even with bolt diameter of .750"

I hunt with a guy that shoots a custom 338-378Wby mag on a built MK-V action and he abuses the shit out of it , two reloads and his brass is toast.

But running a 225gr Accubond out at 3400+fps will do that , he has a few hundred rounds through it and the bolt moves a slick as the day he got it built.

That said , I know of a custom bolt action with .700" bolt that was WAY over pressured in a 7mm-338 Lapua , locked the bolt up tight but the action survived.

I have never seen nor even seen pics of or know anybody that has actualy seen a bolts lugs sheer off , I personaly think its an urban legand , not saying it can't happen but like big foot I'd have to see it to believe it.

I have seen an actions internal lugs get seriously abused and even seen the bottom lug on a rem 700 set back so that it would not bear at all and this was on a gun that had been fully blue printed. The rifle was chambered in 300 H&H and the owner was trying to get 300 Wby speeds from it with a 24" barrel , after a couple dozen shots it locked up.

After it all said and done if I were building a 338 Lapua I'd se a surgen XL action simply because it was desgined for that big round.

I would trust a Weatherby MK-V (that has had the luggs lapped so they are all bearing) over ANY two lug bolt action even with bolt diameter of .750"

I hunt with a guy that shoots a custom 338-378Wby mag on a built MK-V action and he abuses the shit out of it , two reloads and his brass is toast.

But running a 225gr Accubond out at 3400+fps will do that , he has a few hundred rounds through it and the bolt moves a slick as the day he got it built.

That said , I know of a custom bolt action with .700" bolt that was WAY over pressured in a 7mm-338 Lapua , locked the bolt up tight but the action survived.

I have never seen nor even seen pics of or know anybody that has actualy seen a bolts lugs sheer off , I personaly think its an urban legand , not saying it can't happen but like big foot I'd have to see it to believe it.

I have seen an actions internal lugs get seriously abused and even seen the bottom lug on a rem 700 set back so that it would not bear at all and this was on a gun that had been fully blue printed. The rifle was chambered in 300 H&H and the owner was trying to get 300 Wby speeds from it with a 24" barrel , after a couple dozen shots it locked up.

After it all said and done if I were building a 338 Lapua I'd se a surgen XL action simply because it was desgined for that big round.

Re: 338 Lapua and lug sheer

For what it is worth, here is my take on this situation.

There are other issues with using the standard 700 Rem size action in the Lapua boltface. Lug shear is one of them, but only one. The lugs have a lower factor of safety in pure shear than with the regular mag boltface due to the larger area, but is still above 1.0 even with a head failure. The issue comes in more with the lower lug abutments. The lower lug backing is pretty small and allows enough flexure in the action to allow the bolt to move back more and overload the top lug. It is an uneven loading which will cause setback and lug fatigue over time due to the upper lug taking more load.

The other big issue is the case diameter in the tenon, and this may be more important than the other. It can easily cause over straining of the barrel which can over a short time cause tough extraction, especially with heavy loads. Most .750 bolt actions have a bigger tenon also. I could go on about how the action needs to be heavier, but I think we can see the point from this. We did the TAC338 special for these reasons. SPF WILL NOT make a Lapua face on a small bolt period for these reasons. I have completed many analyses on the setup using classical and finite models and determined its just not right. Even though Remington and others will do it, I wont. I guess I am more conservative, probably due to my defense background. On our TAC338 the lugs are longer, wider and more balanced in the action for these reasaons with thicker abutments. I dont know about the other .750 bolt sized actions, but I would think they would have followed the same reasoning.

For what it is worth, here is my take on this situation.

There are other issues with using the standard 700 Rem size action in the Lapua boltface. Lug shear is one of them, but only one. The lugs have a lower factor of safety in pure shear than with the regular mag boltface due to the larger area, but is still above 1.0 even with a head failure. The issue comes in more with the lower lug abutments. The lower lug backing is pretty small and allows enough flexure in the action to allow the bolt to move back more and overload the top lug. It is an uneven loading which will cause setback and lug fatigue over time due to the upper lug taking more load.

The other big issue is the case diameter in the tenon, and this may be more important than the other. It can easily cause over straining of the barrel which can over a short time cause tough extraction, especially with heavy loads. Most .750 bolt actions have a bigger tenon also. I could go on about how the action needs to be heavier, but I think we can see the point from this. We did the TAC338 special for these reasons. SPF WILL NOT make a Lapua face on a small bolt period for these reasons. I have completed many analyses on the setup using classical and finite models and determined its just not right. Even though Remington and others will do it, I wont. I guess I am more conservative, probably due to my defense background. On our TAC338 the lugs are longer, wider and more balanced in the action for these reasaons with thicker abutments. I dont know about the other .750 bolt sized actions, but I would think they would have followed the same reasoning.

Re: 338 Lapua and lug sheer

Jerry-

Are "custom" action manufacturers required to perform pressure barrel testing to see where design/material failure will occur?

Are "factory" rifle manufacturers required to perform this pressure testing?

Thanks!

Jerry-

Are "custom" action manufacturers required to perform pressure barrel testing to see where design/material failure will occur?

Are "factory" rifle manufacturers required to perform this pressure testing?

Thanks!

Re: 338 Lapua and lug sheer

I would like to see specs from the companies as far as shear along with psi and bolt thrust so u could at least see where your safety margins are to at least have a guideline. BTW J Jones there is actually a thread on here where a guy sheared the a lug off a fn with pics, maybe someone can send u a link if they know where it is, 300wsm I think it was, again scary sight.

I would like to see specs from the companies as far as shear along with psi and bolt thrust so u could at least see where your safety margins are to at least have a guideline. BTW J Jones there is actually a thread on here where a guy sheared the a lug off a fn with pics, maybe someone can send u a link if they know where it is, 300wsm I think it was, again scary sight.

Re: 338 Lapua and lug sheer

The bolt thrust numbers between a 338Lm and say a 378 Weatherby are not too terribly far off. I don't have the hard numbers but I think the Weatherby receivers can handle 2 1/2 times that bolt thrust and I can't see the 338LM generating even 30 percent more bolt thrust. Is twice what you need, enough of a safety margin for you and your friend? Manufacturers usually err on the side of conservative to cover their butts and it's apparently within Remington's comfort level. If you find any hard numbers I'd be interested to see em too.

The bolt thrust numbers between a 338Lm and say a 378 Weatherby are not too terribly far off. I don't have the hard numbers but I think the Weatherby receivers can handle 2 1/2 times that bolt thrust and I can't see the 338LM generating even 30 percent more bolt thrust. Is twice what you need, enough of a safety margin for you and your friend? Manufacturers usually err on the side of conservative to cover their butts and it's apparently within Remington's comfort level. If you find any hard numbers I'd be interested to see em too.

Re: 338 Lapua and lug sheer

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: V-Ref</div><div class="ubbcode-body">Jerry-

Are "custom" action manufacturers required to perform pressure barrel testing to see where design/material failure will occur?

Are "factory" rifle manufacturers required to perform this pressure testing?

Thanks! </div></div>

There is no federal law that requires this like some other countries have. I am sure most big manufacturers have done explosion tests etc to prove out there products in the design cycle. I dont know if each gun goes through a pressure round or not though. We have done some destructive testing and unfortunately, some of our customers have also, if you know what I mean.

I have seen lots of our actions so over pressured that I makes me cringe and they have not been affected. Some others have been. The only one where a guy was hurt to my knowledge occurred when a brass rod was left in the barrel. The sliding plate extractor area sheared off and come out the port. A small piece of casing brass hit his eye and he has permanent damage. The bolt opens and closes, but is pushed back in the action some and wont come out of the raceway. It was a Viper by the way. Another guy left a cleaning rod in a Viper SS with a 6X47 and shot it. The bolt was screwed up on the end, but the body had no issues.

I dont know if this answers your questions, but it is here for info anyway. I am a state licensed mechanical engineer. By my nature I am pretty conservative and the last thing I want to do is hurt someone by being negligent. There are very few guidelines or codes to follow like other industries have. My defense and military equipment design experience has left me with a set of methods and values I try to follow. That is what I use when I design and build products. If I ever think we have a potential issue or a design that looks not quite right, I analyze and test it to death. Only then do I let it go on.

Lug shear is pretty easy to determine from a classic analysis. You just take the shear area and divide it into the bolt thrust and compare it to the shear only yield strength of the material. The judgement factor comes in here in determining the shape factor to apply to the lug width/length. In example, a very long lug that is narrow will hold less thrust because the strain dissipates before it gets to the end of the bolt. I use .55 for a standard width/length ratio for a normal lug. Where does that number come from? A few mil standards and some text books. It could just as easily be .5 or .65. This is really not a true exact science as you can see. My approach is to be conservative and still have a reasonable design that gives a good product.

Hopefully that is not too much of a run on post. Its still early in the day.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: V-Ref</div><div class="ubbcode-body">Jerry-

Are "custom" action manufacturers required to perform pressure barrel testing to see where design/material failure will occur?

Are "factory" rifle manufacturers required to perform this pressure testing?

Thanks! </div></div>

There is no federal law that requires this like some other countries have. I am sure most big manufacturers have done explosion tests etc to prove out there products in the design cycle. I dont know if each gun goes through a pressure round or not though. We have done some destructive testing and unfortunately, some of our customers have also, if you know what I mean.

I have seen lots of our actions so over pressured that I makes me cringe and they have not been affected. Some others have been. The only one where a guy was hurt to my knowledge occurred when a brass rod was left in the barrel. The sliding plate extractor area sheared off and come out the port. A small piece of casing brass hit his eye and he has permanent damage. The bolt opens and closes, but is pushed back in the action some and wont come out of the raceway. It was a Viper by the way. Another guy left a cleaning rod in a Viper SS with a 6X47 and shot it. The bolt was screwed up on the end, but the body had no issues.

I dont know if this answers your questions, but it is here for info anyway. I am a state licensed mechanical engineer. By my nature I am pretty conservative and the last thing I want to do is hurt someone by being negligent. There are very few guidelines or codes to follow like other industries have. My defense and military equipment design experience has left me with a set of methods and values I try to follow. That is what I use when I design and build products. If I ever think we have a potential issue or a design that looks not quite right, I analyze and test it to death. Only then do I let it go on.

Lug shear is pretty easy to determine from a classic analysis. You just take the shear area and divide it into the bolt thrust and compare it to the shear only yield strength of the material. The judgement factor comes in here in determining the shape factor to apply to the lug width/length. In example, a very long lug that is narrow will hold less thrust because the strain dissipates before it gets to the end of the bolt. I use .55 for a standard width/length ratio for a normal lug. Where does that number come from? A few mil standards and some text books. It could just as easily be .5 or .65. This is really not a true exact science as you can see. My approach is to be conservative and still have a reasonable design that gives a good product.

Hopefully that is not too much of a run on post. Its still early in the day.

Re: 338 Lapua and lug sheer

The numbers I've been able to track down put the 378 Wby bolt thrust around 12,700 ft/lbs and the lug strength of the Remington at 37,700 ft/lbs. Mr Lilja agrees wholeheartedly with you Mr Stiller and it's cool to get your feedback so I hope my posts aren't taken as argumentative. I don't know the inside case head diameter of the 338LM so I haven't calculated the bolt thrust but the 50BMG bolt thrust is in the neighborhood of 24,000. Even if the bolt thrust of the 338LM is 30 percent more than the 378 Wby, wouldn't the 338LM still be operating within a safe margin of error? I guesss I'm just curious what the numbers and standards are and how idiot proof the industry thinks things need to be.

The numbers I've been able to track down put the 378 Wby bolt thrust around 12,700 ft/lbs and the lug strength of the Remington at 37,700 ft/lbs. Mr Lilja agrees wholeheartedly with you Mr Stiller and it's cool to get your feedback so I hope my posts aren't taken as argumentative. I don't know the inside case head diameter of the 338LM so I haven't calculated the bolt thrust but the 50BMG bolt thrust is in the neighborhood of 24,000. Even if the bolt thrust of the 338LM is 30 percent more than the 378 Wby, wouldn't the 338LM still be operating within a safe margin of error? I guesss I'm just curious what the numbers and standards are and how idiot proof the industry thinks things need to be.

Re: 338 Lapua and lug sheer

Here is my analysis:

1. Use total case diameter versus inside so that during a case head failure, you have conservative number. Diameter is .588 therefore area is .271 inches. Using 65000 psi you get to 17650 lb of thrust. (not ft/lbs, just lb)

2. Each lug is about .45 X .43 cross section therefore total shear area is .39 sqin for both lugs.

3. Lug shear load is 17650/.39 which is 45250 psi.

4. Incorporate .55 shape factor. This is a judgement call. The last time I looked at Lilja's website, which was years ago, he didnt use one. My estimate and the head of our finite groups at Raytheons was .55 so shear is 45250/.55 which is 82250 psi.

5. Ultimate and yield is 165000 and 140000 for 4140 at Rc 36. You have to multiply these by .5 for pure shear load. Therefore break occurs at 82500 and yield at 70000.

6. If we apply 82250 psi the bolt will not break, but shows yielding. Without the .55 factor, we have about 2 to 1 safety on break and 1.7 to 1 on yield.

7. Face compression is the other important number. Face compression area is .13, load is 17650 therefore face compression is 136000 psi. Compare that to 140000 and 165000 and you see it is pretty close too. NO ESTIMATED FACTORS THERE TO JUDGE EITHER. This shows real close to setback of the lugs all the time. That is if both lugs are perfectly equal too, not the case with a repeater.

Look at the numbers and make the call.

Here is my analysis:

1. Use total case diameter versus inside so that during a case head failure, you have conservative number. Diameter is .588 therefore area is .271 inches. Using 65000 psi you get to 17650 lb of thrust. (not ft/lbs, just lb)

2. Each lug is about .45 X .43 cross section therefore total shear area is .39 sqin for both lugs.

3. Lug shear load is 17650/.39 which is 45250 psi.

4. Incorporate .55 shape factor. This is a judgement call. The last time I looked at Lilja's website, which was years ago, he didnt use one. My estimate and the head of our finite groups at Raytheons was .55 so shear is 45250/.55 which is 82250 psi.

5. Ultimate and yield is 165000 and 140000 for 4140 at Rc 36. You have to multiply these by .5 for pure shear load. Therefore break occurs at 82500 and yield at 70000.

6. If we apply 82250 psi the bolt will not break, but shows yielding. Without the .55 factor, we have about 2 to 1 safety on break and 1.7 to 1 on yield.

7. Face compression is the other important number. Face compression area is .13, load is 17650 therefore face compression is 136000 psi. Compare that to 140000 and 165000 and you see it is pretty close too. NO ESTIMATED FACTORS THERE TO JUDGE EITHER. This shows real close to setback of the lugs all the time. That is if both lugs are perfectly equal too, not the case with a repeater.

Look at the numbers and make the call.

Re: 338 Lapua and lug sheer

I agree with Jerry. He built the TAC338 to withstand the pressures created by the 338LM. Why not use an action that is clearly designed for this purpose which will eliminate any safety concerns for just a few more bucks. I consider it very inexpensive insurance when you look at the big picture. I have had a chance to use this particular action, and in my opinion it's hard to beat, and I don't mean just for safety sake. There are a few very well built custom action on the market today, and Jerry Stillers actions are among the very best, which is the reason they are my first choice when building a custom precision rifle.

I agree with Jerry. He built the TAC338 to withstand the pressures created by the 338LM. Why not use an action that is clearly designed for this purpose which will eliminate any safety concerns for just a few more bucks. I consider it very inexpensive insurance when you look at the big picture. I have had a chance to use this particular action, and in my opinion it's hard to beat, and I don't mean just for safety sake. There are a few very well built custom action on the market today, and Jerry Stillers actions are among the very best, which is the reason they are my first choice when building a custom precision rifle.

Re: 338 Lapua and lug sheer

Really appreciate the info Mr Stiller and the hard numbers really put it in perspective. Thanks for the time it took to spell it out for me and show me the math and where the lines are drawn. Truly.

I've always been into the edges of the debate and have always been a fan of guys like Mr Linebaugh, Mr Ackley, Mr Keith etc and where their experience/experimenting has taken the industry.

Really appreciate the info Mr Stiller and the hard numbers really put it in perspective. Thanks for the time it took to spell it out for me and show me the math and where the lines are drawn. Truly.

I've always been into the edges of the debate and have always been a fan of guys like Mr Linebaugh, Mr Ackley, Mr Keith etc and where their experience/experimenting has taken the industry.

Re: 338 Lapua and lug sheer

Not a problem. That is how we all learn.

Not a problem. That is how we all learn.

Re: 338 Lapua and lug sheer

Bravo Mr. Stiller ,

this is the best explanation I have ever seen or heard , even made it easy for a knuckle head like myself to understand.

I once asked a question about the "300 Varmiter" and being an unsafe round as its nothing more than an over pressured 300 WSM . I was told that you can't get the listed speeds unless your using a Bat action because of bolt strength issues.

Has anybody set any actions off to be destroyed with pressure testing? I'd like to see where (what pressure) some of the actions fail. I've heard that Bat actions hold up realy well due to the use of 17-4 in their desgine , not sure if the bolt are though as 17-4 gaulds bady and seems that a bolt and reciever of the same material would be a dissaster is over pressures.

So is the bolt head actualy wider(one lug to the next) on the .750" bolts than on the .700" bolts?

Bravo Mr. Stiller ,

this is the best explanation I have ever seen or heard , even made it easy for a knuckle head like myself to understand.

I once asked a question about the "300 Varmiter" and being an unsafe round as its nothing more than an over pressured 300 WSM . I was told that you can't get the listed speeds unless your using a Bat action because of bolt strength issues.

Has anybody set any actions off to be destroyed with pressure testing? I'd like to see where (what pressure) some of the actions fail. I've heard that Bat actions hold up realy well due to the use of 17-4 in their desgine , not sure if the bolt are though as 17-4 gaulds bady and seems that a bolt and reciever of the same material would be a dissaster is over pressures.

So is the bolt head actualy wider(one lug to the next) on the .750" bolts than on the .700" bolts?

Re: 338 Lapua and lug sheer

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Stiller</div><div class="ubbcode-body">Here is my analysis:

1. Use total case diameter versus inside so that during a case head failure, you have conservative number. Diameter is .588 therefore area is .271 inches. Using 65000 psi you get to 17650 lb of thrust. (not ft/lbs, just lb)

2. Each lug is about .45 X .43 cross section therefore total shear area is .39 sqin for both lugs.

3. Lug shear load is 17650/.39 which is 45250 psi.

4. Incorporate .55 shape factor. This is a judgement call. The last time I looked at Lilja's website, which was years ago, he didnt use one. My estimate and the head of our finite groups at Raytheons was .55 so shear is 45250/.55 which is 82250 psi.

5. Ultimate and yield is 165000 and 140000 for 4140 at Rc 36. You have to multiply these by .5 for pure shear load. Therefore break occurs at 82500 and yield at 70000.

6. If we apply 82250 psi the bolt will not break, but shows yielding. Without the .55 factor, we have about 2 to 1 safety on break and 1.7 to 1 on yield.

7. Face compression is the other important number. Face compression area is .13, load is 17650 therefore face compression is 136000 psi. Compare that to 140000 and 165000 and you see it is pretty close too. NO ESTIMATED FACTORS THERE TO JUDGE EITHER. This shows real close to setback of the lugs all the time. That is if both lugs are perfectly equal too, not the case with a repeater.

Look at the numbers and make the call.

</div></div>

Wow, That is a great bit of info there. A little over my head in "shape factor" but for the most part I understand it.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Stiller</div><div class="ubbcode-body">Here is my analysis:

1. Use total case diameter versus inside so that during a case head failure, you have conservative number. Diameter is .588 therefore area is .271 inches. Using 65000 psi you get to 17650 lb of thrust. (not ft/lbs, just lb)

2. Each lug is about .45 X .43 cross section therefore total shear area is .39 sqin for both lugs.

3. Lug shear load is 17650/.39 which is 45250 psi.

4. Incorporate .55 shape factor. This is a judgement call. The last time I looked at Lilja's website, which was years ago, he didnt use one. My estimate and the head of our finite groups at Raytheons was .55 so shear is 45250/.55 which is 82250 psi.

5. Ultimate and yield is 165000 and 140000 for 4140 at Rc 36. You have to multiply these by .5 for pure shear load. Therefore break occurs at 82500 and yield at 70000.

6. If we apply 82250 psi the bolt will not break, but shows yielding. Without the .55 factor, we have about 2 to 1 safety on break and 1.7 to 1 on yield.

7. Face compression is the other important number. Face compression area is .13, load is 17650 therefore face compression is 136000 psi. Compare that to 140000 and 165000 and you see it is pretty close too. NO ESTIMATED FACTORS THERE TO JUDGE EITHER. This shows real close to setback of the lugs all the time. That is if both lugs are perfectly equal too, not the case with a repeater.

Look at the numbers and make the call.

</div></div>

Wow, That is a great bit of info there. A little over my head in "shape factor" but for the most part I understand it.

Re: 338 Lapua and lug sheer

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: JJones75</div><div class="ubbcode-body">Bravo Mr. Stiller ,

this is the best explanation I have ever seen or heard , even made it easy for a knuckle head like myself to understand.

I once asked a question about the "300 Varmiter" and being an unsafe round as its nothing more than an over pressured 300 WSM . I was told that you can't get the listed speeds unless your using a Bat action because of bolt strength issues.

Has anybody set any actions off to be destroyed with pressure testing? I'd like to see where (what pressure) some of the actions fail. I've heard that Bat actions hold up realy well due to the use of 17-4 in their desgine , not sure if the bolt are though as 17-4 gaulds bady and seems that a bolt and reciever of the same material would be a dissaster is over pressures.

So is the bolt head actualy wider(one lug to the next) on the .750" bolts than on the .700" bolts? </div></div>

All bolts are alloy steel in general. Stainless does not make a good bolt. 17-4 galls too much and really doesnt have the right other properties either. Our TAC bolt lugs are .490 tall and .525 long and 1.06 diameter.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: JJones75</div><div class="ubbcode-body">Bravo Mr. Stiller ,

this is the best explanation I have ever seen or heard , even made it easy for a knuckle head like myself to understand.

I once asked a question about the "300 Varmiter" and being an unsafe round as its nothing more than an over pressured 300 WSM . I was told that you can't get the listed speeds unless your using a Bat action because of bolt strength issues.

Has anybody set any actions off to be destroyed with pressure testing? I'd like to see where (what pressure) some of the actions fail. I've heard that Bat actions hold up realy well due to the use of 17-4 in their desgine , not sure if the bolt are though as 17-4 gaulds bady and seems that a bolt and reciever of the same material would be a dissaster is over pressures.

So is the bolt head actualy wider(one lug to the next) on the .750" bolts than on the .700" bolts? </div></div>

All bolts are alloy steel in general. Stainless does not make a good bolt. 17-4 galls too much and really doesnt have the right other properties either. Our TAC bolt lugs are .490 tall and .525 long and 1.06 diameter.

Re: 338 Lapua and lug sheer

Jerry, does a break take any pressure of the lugs as far as bolt thrust goes. Also actions like bat and nesika have their lugs go to the end of the bolt where as mcmillan like remington has shorter lugs, doesn't this also effect lug strength

Jerry, does a break take any pressure of the lugs as far as bolt thrust goes. Also actions like bat and nesika have their lugs go to the end of the bolt where as mcmillan like remington has shorter lugs, doesn't this also effect lug strength

Re: 338 Lapua and lug sheer

So, you're saying that my Rem 700 MLR doesn't really have much of a margin of safety? Why would Remington be building these things if the safety margins are so close? Not that I'm disagreeing with you. Just as a layman, the 338 Lapua cartridge looks like it's pushing the 700 action to it's limits. Since buying mine two years ago, I've wondered how these rifles will hold up, especially with shooters who like to push the handloads a little too hot.

So, you're saying that my Rem 700 MLR doesn't really have much of a margin of safety? Why would Remington be building these things if the safety margins are so close? Not that I'm disagreeing with you. Just as a layman, the 338 Lapua cartridge looks like it's pushing the 700 action to it's limits. Since buying mine two years ago, I've wondered how these rifles will hold up, especially with shooters who like to push the handloads a little too hot.

Re: 338 Lapua and lug sheer

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Casscad</div><div class="ubbcode-body">Jerry, does a break take any pressure of the lugs as far as bolt thrust goes. Also actions like bat and nesika have their lugs go to the end of the bolt where as mcmillan like remington has shorter lugs, doesn't this also effect lug strength </div></div>

Brake has no effect on the pressure, it is way down before the bullet gets that far. Longer lugs are better. Its not a one to one though. The longer lugs have a slightly lower shape factor.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Casscad</div><div class="ubbcode-body">Jerry, does a break take any pressure of the lugs as far as bolt thrust goes. Also actions like bat and nesika have their lugs go to the end of the bolt where as mcmillan like remington has shorter lugs, doesn't this also effect lug strength </div></div>

Brake has no effect on the pressure, it is way down before the bullet gets that far. Longer lugs are better. Its not a one to one though. The longer lugs have a slightly lower shape factor.

Re: 338 Lapua and lug sheer

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Badshot308</div><div class="ubbcode-body">So, you're saying that my Rem 700 MLR doesn't really have much of a margin of safety? Why would Remington be building these things if the safety margins are so close? Not that I'm disagreeing with you. Just as a layman, the 338 Lapua cartridge looks like it's pushing the 700 action to it's limits. Since buying mine two years ago, I've wondered how these rifles will hold up, especially with shooters who like to push the handloads a little too hot. </div></div>

That is my question also. I am not saying that Remington didnt do their job. The analysis I shown was conservative in a few areas. One is the shape factor, although that is the correct method and is pretty much backed up in the computer finite element analysis also. The other is to use the .588 diameter versus the inside case diameter for the pressure area. The inside diameter will decrease the bolt loads up to 40%. IF there is not any issues, then the inside case size is the right one to use. Its when there are issues that safety becomes a concern though. In normal use, the lug setback is really the thing that will most likely happen along with barrel tenon expansion during the fire event and tougher extraction.

This was most likely the easiest and best path for Remington to supply their customers with a round they needed and wanted. Obviously there are not enough issues with it to alarm them as they are still building them. My customer base is a little different. Most handload and may push the limits more. I am just not comfortable with that solution. If I am not comfortable, have analyses that show what they show and have still build them that way, then I am negligent in doing my job as an engineer.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Badshot308</div><div class="ubbcode-body">So, you're saying that my Rem 700 MLR doesn't really have much of a margin of safety? Why would Remington be building these things if the safety margins are so close? Not that I'm disagreeing with you. Just as a layman, the 338 Lapua cartridge looks like it's pushing the 700 action to it's limits. Since buying mine two years ago, I've wondered how these rifles will hold up, especially with shooters who like to push the handloads a little too hot. </div></div>

That is my question also. I am not saying that Remington didnt do their job. The analysis I shown was conservative in a few areas. One is the shape factor, although that is the correct method and is pretty much backed up in the computer finite element analysis also. The other is to use the .588 diameter versus the inside case diameter for the pressure area. The inside diameter will decrease the bolt loads up to 40%. IF there is not any issues, then the inside case size is the right one to use. Its when there are issues that safety becomes a concern though. In normal use, the lug setback is really the thing that will most likely happen along with barrel tenon expansion during the fire event and tougher extraction.

This was most likely the easiest and best path for Remington to supply their customers with a round they needed and wanted. Obviously there are not enough issues with it to alarm them as they are still building them. My customer base is a little different. Most handload and may push the limits more. I am just not comfortable with that solution. If I am not comfortable, have analyses that show what they show and have still build them that way, then I am negligent in doing my job as an engineer.

Re: 338 Lapua and lug sheer

Type "Sheer" into Google and get this pic.

Type "Shear" into Google and get something like this.

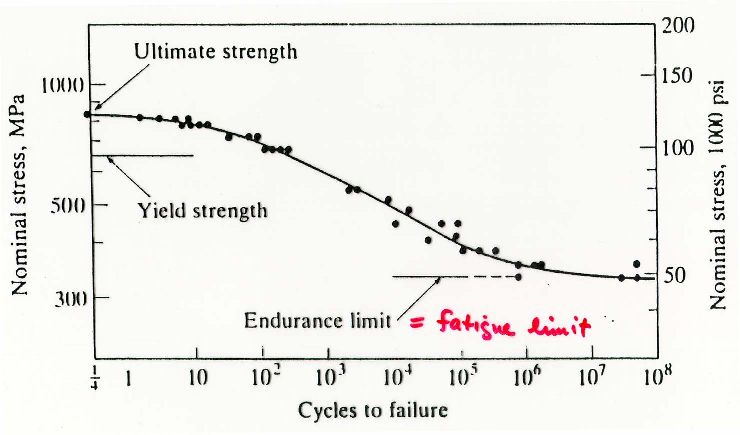

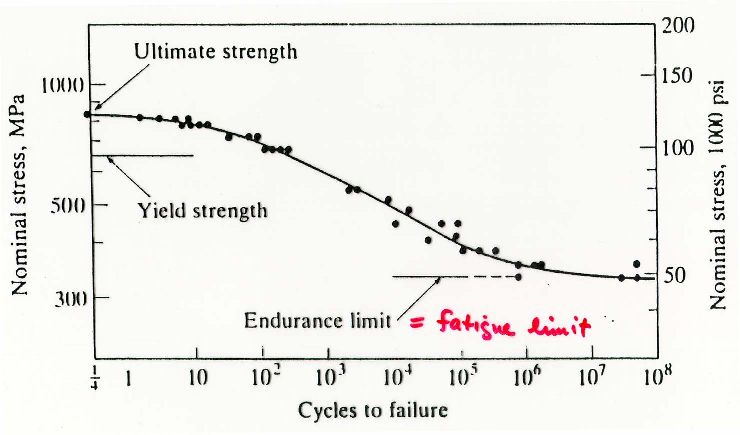

Many years ago the engineer known as Jon A on this forum made this graph for me to depict the fatigue of his Rem700 bolt lugs. I think Boeing pays him for that kind of thing, but I got the graph for free.

I can tell without doing it that if one takes the 338LM peak pressure, multiplies it by the inside diameter of the 338LM case, this is max bolt thrust. The cross sectional area of the two lugs in shear and going to be way under stressed for RC28 4140 or 4340 at 135ksi. If there is clearance from the lug abutments to the bolt body and the lugs are in bending, the section modulus calculation will show the lugs are far from yield.

What does it all mean?

This question is not going to boil down to a math problem.

There is lots of safety margin, and it will get down to how much you think you need.

Type "Sheer" into Google and get this pic.

Type "Shear" into Google and get something like this.

Many years ago the engineer known as Jon A on this forum made this graph for me to depict the fatigue of his Rem700 bolt lugs. I think Boeing pays him for that kind of thing, but I got the graph for free.

I can tell without doing it that if one takes the 338LM peak pressure, multiplies it by the inside diameter of the 338LM case, this is max bolt thrust. The cross sectional area of the two lugs in shear and going to be way under stressed for RC28 4140 or 4340 at 135ksi. If there is clearance from the lug abutments to the bolt body and the lugs are in bending, the section modulus calculation will show the lugs are far from yield.

What does it all mean?

This question is not going to boil down to a math problem.

There is lots of safety margin, and it will get down to how much you think you need.

Re: 338 Lapua and lug sheer

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Clark</div><div class="ubbcode-body">

Many years ago the engineer known as Jon A on this forum made this graph for me to depict the fatigue of his Rem700 bolt lugs. I think Boeing pays him for that kind of thing, but I got the graph for free.

I can tell without doing it that if one takes the 338LM peak pressure, multiplies it by the inside diameter of the 338LM case, this is max bolt thrust. The cross sectional area of the two lugs in shear and going to be way under stressed for RC28 4140 or 4340 at 135ksi. If there is clearance from the lug abutments to the bolt body and the lugs are in bending, the section modulus calculation will show the lugs are far from yield.

What does it all mean?

This question is not going to boil down to a math problem.

There is lots of safety margin, and it will get down to how much you think you need. </div></div>

You can believe however you like, but my analysis is correct. I am an engineer also, and do this kind of thing for Raytheon, another big defense company. The stress on that graph is for the material and is correct for the slightly lower hardness. However in pure shear, you have to half the value of allowable stress. The lugs really arent in bending much due to the clearance being a few thousands of an inch. There is a thing called Mohrs circle that helps explain that if you like to look it up. The shape factor for the lug cross section should also be incorporated. Even if the lug shear was fine, you still have to deal with the setback issues and tenon diameter being too small. I really dont have dog in this fight, just trying to help everyone understand what they are getting into.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Clark</div><div class="ubbcode-body">

Many years ago the engineer known as Jon A on this forum made this graph for me to depict the fatigue of his Rem700 bolt lugs. I think Boeing pays him for that kind of thing, but I got the graph for free.

I can tell without doing it that if one takes the 338LM peak pressure, multiplies it by the inside diameter of the 338LM case, this is max bolt thrust. The cross sectional area of the two lugs in shear and going to be way under stressed for RC28 4140 or 4340 at 135ksi. If there is clearance from the lug abutments to the bolt body and the lugs are in bending, the section modulus calculation will show the lugs are far from yield.

What does it all mean?

This question is not going to boil down to a math problem.

There is lots of safety margin, and it will get down to how much you think you need. </div></div>

You can believe however you like, but my analysis is correct. I am an engineer also, and do this kind of thing for Raytheon, another big defense company. The stress on that graph is for the material and is correct for the slightly lower hardness. However in pure shear, you have to half the value of allowable stress. The lugs really arent in bending much due to the clearance being a few thousands of an inch. There is a thing called Mohrs circle that helps explain that if you like to look it up. The shape factor for the lug cross section should also be incorporated. Even if the lug shear was fine, you still have to deal with the setback issues and tenon diameter being too small. I really dont have dog in this fight, just trying to help everyone understand what they are getting into.

Re: 338 Lapua and lug sheer

Mr Stiller , is their a safe ratio of chamber diameter to tenon diameter (ie wall thickness)

I have often wondering about that in reguards to the TC Encore and it being chambered in large case rounds like the 300WSM and Ultra Mags , I personaly think that the 1" OD of the barrel in the breach section is way to small for the fatter cases like the WSM yet some company's will make them and warnty them!!

I think that you can get into trouble getting stupid with handloading for a 223 as fast as you can a 338 Lapua if your constantly exceding the limits.

I also think that the case desgine has alot to do with it cases with alot of taper like the 300 H&H mag and 220 Swift that have ALOT of case taper are sadi to lead to alot higher bolt thrust than cases with little taper like the Ackly improved rounds

To the OP , sorry to jack your post this wil be my last question

Mr Stiller , is their a safe ratio of chamber diameter to tenon diameter (ie wall thickness)

I have often wondering about that in reguards to the TC Encore and it being chambered in large case rounds like the 300WSM and Ultra Mags , I personaly think that the 1" OD of the barrel in the breach section is way to small for the fatter cases like the WSM yet some company's will make them and warnty them!!

I think that you can get into trouble getting stupid with handloading for a 223 as fast as you can a 338 Lapua if your constantly exceding the limits.

I also think that the case desgine has alot to do with it cases with alot of taper like the 300 H&H mag and 220 Swift that have ALOT of case taper are sadi to lead to alot higher bolt thrust than cases with little taper like the Ackly improved rounds

To the OP , sorry to jack your post this wil be my last question

Re: 338 Lapua and lug sheer

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: JJones75</div><div class="ubbcode-body">Mr Stiller , is their a safe ratio of chamber diameter to tenon diameter (ie wall thickness)

</div></div>

It depends on the pressure and some other dimensions. I dont have the numbers of the top of my head. I know in a PPC, we had some people getting tenons in the 7/8 category and got into trouble. That is a .450 or do dia case, but at high pressures. It seems like it takes at least .225 all around the case on most case sizes we tend to use. The larger cases need a little more as the hoop stretches more as the diameter goes up. The thread minor diameter is also the determining dimension. I dont really have an exact answer. Pressure vessel equations are where I would start though.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: JJones75</div><div class="ubbcode-body">Mr Stiller , is their a safe ratio of chamber diameter to tenon diameter (ie wall thickness)

</div></div>

It depends on the pressure and some other dimensions. I dont have the numbers of the top of my head. I know in a PPC, we had some people getting tenons in the 7/8 category and got into trouble. That is a .450 or do dia case, but at high pressures. It seems like it takes at least .225 all around the case on most case sizes we tend to use. The larger cases need a little more as the hoop stretches more as the diameter goes up. The thread minor diameter is also the determining dimension. I dont really have an exact answer. Pressure vessel equations are where I would start though.

Re: 338 Lapua and lug sheer

Thanks for the info. I think I'll keep my handloads on the conservative side.

Thanks for the info. I think I'll keep my handloads on the conservative side.

Re: 338 Lapua and lug sheer

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Stiller</div><div class="ubbcode-body">

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Stiller</div><div class="ubbcode-body">

Clark said:You can believe however you like, but my analysis is correct. I am an engineer also, and do this kind of thing for Raytheon, another big defense company. </div></div>

My father is a gun designer, but I am not.

I have bought hundreds of guns for destructive test.

I bought those on my own nickel for my hobby, de bunking gun culture myths.

My father got rich off this, but this effort to do research and share it on the internet is costing me money.

I don't do Von Mises calculations, but I get help with that.

I think I met with Raytheon 22 years ago for Tacit Rainbow missile. They subbed to Northrup and Northrup subbed to me for the power control. I designed that. Now Raytheon is out of that missile and the company that built my design has changed hands again and again, but a descendant of that missile is still being produced by Williams.

Re: 338 Lapua and lug sheer

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Badshot308</div><div class="ubbcode-body">Thanks for the info. I think I'll keep my handloads on the conservative side. </div></div>

+1 on this statement. There has been a thread running on the Savage site that is directly parallel to this one, except it concerns the 338LM being built on the old 110 actions and the new 110BAs with a somewhat modified action, but still having widespread extraction problems that don't seem to be connected to over-pressures.

Fred of sharpshooter Supply posted the very same thing as Mr. Stiller has posted here concerning tennon swell and lug setback being the likely outcome of any up loading. I have drawn the inference that no one is really concerned that any of these rifles is going to blow up using factory level ammunition, but beyond that, all bets are off.

Thank You, Mr.Stiller, Clark and all that have contributed to this thread. I have learned a tremendous amount in a very short period of time, and paid absolutely nothing for it. Free Education, "PRICELESS"!!

Thanks,

Emory Jones

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: Badshot308</div><div class="ubbcode-body">Thanks for the info. I think I'll keep my handloads on the conservative side. </div></div>

+1 on this statement. There has been a thread running on the Savage site that is directly parallel to this one, except it concerns the 338LM being built on the old 110 actions and the new 110BAs with a somewhat modified action, but still having widespread extraction problems that don't seem to be connected to over-pressures.

Fred of sharpshooter Supply posted the very same thing as Mr. Stiller has posted here concerning tennon swell and lug setback being the likely outcome of any up loading. I have drawn the inference that no one is really concerned that any of these rifles is going to blow up using factory level ammunition, but beyond that, all bets are off.

Thank You, Mr.Stiller, Clark and all that have contributed to this thread. I have learned a tremendous amount in a very short period of time, and paid absolutely nothing for it. Free Education, "PRICELESS"!!

Thanks,

Emory Jones

Re: 338 Lapua and lug sheer

thank you Jerry for your imput and maths as you have shown a remington is marginal with safety now if everyone reads a remington manual like we all do they will not warrant any rifle shot with handloads so the factory ammo is loaded conservitaly but as soon as a handloader gets one they try to make a 338-378wby from the 338 lapua with massive pressures. I for one dont like using a .700 bolt for a 338 Lapua or a similar sized boltface. the 378Wby case also imparts the same rearward thrust but the 9 lug desighn is a lot stronget than the remington one. if you wish to build the custom 338 lapua the Wby mark 5 is a perfect donor. we import Lawton actions and will not make a 338 lapua for anyone on a 7000 action we only use the 8500 with the .750 bolts as the margin for error is to small. you would be amased with the number of rifles that come in with lug setback even 6mmBR's and 223's. people hear that their mate has loaded to a certain velocity so they try and beat it. try people putting 32gr Varget behind a 107gr MAtchKing in a 6mmBR nad they wonder shy the cases dont last and the logs are buggered.

the other think is people making 338 Lapuas out of stainless remingtons they are worse and should never be converted.

I have trued a rem MLR and we fitted a new barrel as it was the worst factory rifle i have ever seen from Remington and i like their rifles. the extractor cracked in half after 10 shots of factory ammo and the breaks are worthless the mags were to short so i trued it replaced the recoil lug bedded the rifle fitted a SSG V port breal and fitted a seekins mag system now the rifle shoots realy well but he has to be carefull not to overload. the one thing that was interesting is that the MLR action was a lot harder than any other remington action we have ever trued and i suspect they are either heat treating the actions diferently or using a diferent grade of steel for them these actions are NOT the standard long actions that they use for the rest of production.

I would not buy one buy a stillar or lawton or another action with a .750 bolt and build the rifle correctly or just build a 338 ultramag on the standard mag boltface and action it duplicates the 338 Lapua with less powder and does not overstress the tennon on the barrel.

when you look at other actions like Win actions and Howas with WSM's in them if they over load them the cases stick because the tennon diameter was not large enough and this is why the Win WSSM and WSM actions were changed to a larger thread diameter and finer thread to stop the tenon expansion.

If you use a rem action use an ultramag as the largest case diameter to use and you will be OK if you want a bigger case get a bigger action.

thank you Jerry for your imput and maths as you have shown a remington is marginal with safety now if everyone reads a remington manual like we all do they will not warrant any rifle shot with handloads so the factory ammo is loaded conservitaly but as soon as a handloader gets one they try to make a 338-378wby from the 338 lapua with massive pressures. I for one dont like using a .700 bolt for a 338 Lapua or a similar sized boltface. the 378Wby case also imparts the same rearward thrust but the 9 lug desighn is a lot stronget than the remington one. if you wish to build the custom 338 lapua the Wby mark 5 is a perfect donor. we import Lawton actions and will not make a 338 lapua for anyone on a 7000 action we only use the 8500 with the .750 bolts as the margin for error is to small. you would be amased with the number of rifles that come in with lug setback even 6mmBR's and 223's. people hear that their mate has loaded to a certain velocity so they try and beat it. try people putting 32gr Varget behind a 107gr MAtchKing in a 6mmBR nad they wonder shy the cases dont last and the logs are buggered.

the other think is people making 338 Lapuas out of stainless remingtons they are worse and should never be converted.

I have trued a rem MLR and we fitted a new barrel as it was the worst factory rifle i have ever seen from Remington and i like their rifles. the extractor cracked in half after 10 shots of factory ammo and the breaks are worthless the mags were to short so i trued it replaced the recoil lug bedded the rifle fitted a SSG V port breal and fitted a seekins mag system now the rifle shoots realy well but he has to be carefull not to overload. the one thing that was interesting is that the MLR action was a lot harder than any other remington action we have ever trued and i suspect they are either heat treating the actions diferently or using a diferent grade of steel for them these actions are NOT the standard long actions that they use for the rest of production.

I would not buy one buy a stillar or lawton or another action with a .750 bolt and build the rifle correctly or just build a 338 ultramag on the standard mag boltface and action it duplicates the 338 Lapua with less powder and does not overstress the tennon on the barrel.

when you look at other actions like Win actions and Howas with WSM's in them if they over load them the cases stick because the tennon diameter was not large enough and this is why the Win WSSM and WSM actions were changed to a larger thread diameter and finer thread to stop the tenon expansion.

If you use a rem action use an ultramag as the largest case diameter to use and you will be OK if you want a bigger case get a bigger action.

Re: 338 Lapua and lug sheer

Thanks for the info Jerry. Great to have knowledgeable info to read through here. BTW, purchased a TAC30 a little over a year ago, put about 500 round through it so far with great results!

This all makes me want to mesure up a Barrett model 99 w/15 lugs and see how strong it is built for the 416 & 50 CAL. Anyone have one available to measure?

Also, is there advantages to angling the bolt face to increase surface area? In addition, what benefit is there by adding a fillet around the base of the lug to further prevent shearing? Is it possible to calculate this by hand or must FEA be used?

Thanks Again,

Jason

Thanks for the info Jerry. Great to have knowledgeable info to read through here. BTW, purchased a TAC30 a little over a year ago, put about 500 round through it so far with great results!

This all makes me want to mesure up a Barrett model 99 w/15 lugs and see how strong it is built for the 416 & 50 CAL. Anyone have one available to measure?

Also, is there advantages to angling the bolt face to increase surface area? In addition, what benefit is there by adding a fillet around the base of the lug to further prevent shearing? Is it possible to calculate this by hand or must FEA be used?

Thanks Again,

Jason

Re: 338 Lapua and lug sheer

Great thread.

I think that I understand the essence of the analysis, if not all of the the details.

The problem with lug setback and the other lug related issues seems to center

on bolt thrust trying to push the bolt rearwards.

I'm wondering how (maximum?) bolt thrust numbers are determined?

Are these somehow actual measurements or a calculation based on chamber pressure and case dimensions?

Do these numbers take into account the ability of the chamber walls to grip the case

during firing (affected by case shape and other factors?) and how that affects actual bolt thrust?

Thanks!

Great thread.

I think that I understand the essence of the analysis, if not all of the the details.

The problem with lug setback and the other lug related issues seems to center

on bolt thrust trying to push the bolt rearwards.

I'm wondering how (maximum?) bolt thrust numbers are determined?

Are these somehow actual measurements or a calculation based on chamber pressure and case dimensions?

Do these numbers take into account the ability of the chamber walls to grip the case

during firing (affected by case shape and other factors?) and how that affects actual bolt thrust?

Thanks!

Re: 338 Lapua and lug sheer

As Jerry has said, the internal case dimensions are not used, but the external dimensions.

And case taper does not factor in.

Reasons?

When case head separation occurs, case cling, and case head internal dimensions are factored out of the process.

As Jerry has said, the internal case dimensions are not used, but the external dimensions.

And case taper does not factor in.

Reasons?

When case head separation occurs, case cling, and case head internal dimensions are factored out of the process.

Re: 338 Lapua and lug sheer

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: longshooter</div><div class="ubbcode-body">As Jerry has said, the internal case dimensions are not used, but the external dimensions.

And case taper does not factor in.

Reasons?

<span style="font-weight: bold">When case head separation occurs, case cling, and case head internal dimensions are factored out of the process.</span> </div></div>

Ahhh, so these numbers are a 'worst case' scenario as the result of a case head separation with the case head being driven back.

That makes sense.

So under normal conditions the bolt thrust is much less and these problems with bolt lug shearing would not manifest themselves?

Thanks

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: longshooter</div><div class="ubbcode-body">As Jerry has said, the internal case dimensions are not used, but the external dimensions.

And case taper does not factor in.

Reasons?

<span style="font-weight: bold">When case head separation occurs, case cling, and case head internal dimensions are factored out of the process.</span> </div></div>

Ahhh, so these numbers are a 'worst case' scenario as the result of a case head separation with the case head being driven back.

That makes sense.

So under normal conditions the bolt thrust is much less and these problems with bolt lug shearing would not manifest themselves?

Thanks

Re: 338 Lapua and lug sheer

Jerry,

First, this is an excellent thread as it deals with a something so often lacking: FACTS.

Bravo sir!

Now for questions from Chad's little mind.

1. A gent you may know named Justin also works for Ratheon out in Tuscon, AZ. He too is an engineer (ME) and over dinner one evening years ago at nationals he was describing a gun as nothing more than a pressure vessel. Pressure reacts to whatever surface it contacts with at a right angle.

So, this has lead to my squeaky wheels turning a bit. If this is indeed the case then how does one go about configuring exactly how much pressure is exerted on the bolt face and consequently transmitted to the lugs? I realize the thin walled case isn't going to resist the pressures in a cartridge all that much, but it is a viable component to determining this kind of stuff. (Isn't it? I wonder. . .)

I base this on a little experiment I did once upon a time. I shot my 1022 with my thumb holding the charging handle closed. With sufficient force I was able to prevent the bolt from moving to the rear. According to a chart I have (click link below) the lowly 22LR is rated to 24K psi. If this is indeed correct then was I able to overcome 24Kpsi with nothing more elaborate than my "manly" thumb? (my ego's at stake here, be gentle )

)

Common sense suggests to me that no I'm not because I can still dislocate my right thumb by looking at it funny due to a H/S football mishap.

Does it then become a function of surface area? The 22LR rim measures a bit over a quarter inch in diameter. Equating to around .055" square inches. It would stand to reason that if we bumped that up to say a whole square inch then there's a bit more "traction" for the case head to push stuff around.

The 338LM rim measures .585" and has .266" of surface area. If memory serves me correct it runs around 64Kpsi (CUP) I don't know the conversions between CUP and PSI.

So we have a cartridge developing 2.6 times the pressure as the 22 LR with 4.8 times the case head surface area.

How many "thumbs" is that?

Your thoughts are encouraged and I appreciate your time.

All the best,

C

http://www.lasc.us/SAAMIMaxPressure.htm

Jerry,

First, this is an excellent thread as it deals with a something so often lacking: FACTS.

Bravo sir!

Now for questions from Chad's little mind.

1. A gent you may know named Justin also works for Ratheon out in Tuscon, AZ. He too is an engineer (ME) and over dinner one evening years ago at nationals he was describing a gun as nothing more than a pressure vessel. Pressure reacts to whatever surface it contacts with at a right angle.

So, this has lead to my squeaky wheels turning a bit. If this is indeed the case then how does one go about configuring exactly how much pressure is exerted on the bolt face and consequently transmitted to the lugs? I realize the thin walled case isn't going to resist the pressures in a cartridge all that much, but it is a viable component to determining this kind of stuff. (Isn't it? I wonder. . .)

I base this on a little experiment I did once upon a time. I shot my 1022 with my thumb holding the charging handle closed. With sufficient force I was able to prevent the bolt from moving to the rear. According to a chart I have (click link below) the lowly 22LR is rated to 24K psi. If this is indeed correct then was I able to overcome 24Kpsi with nothing more elaborate than my "manly" thumb? (my ego's at stake here, be gentle

Common sense suggests to me that no I'm not because I can still dislocate my right thumb by looking at it funny due to a H/S football mishap.

Does it then become a function of surface area? The 22LR rim measures a bit over a quarter inch in diameter. Equating to around .055" square inches. It would stand to reason that if we bumped that up to say a whole square inch then there's a bit more "traction" for the case head to push stuff around.

The 338LM rim measures .585" and has .266" of surface area. If memory serves me correct it runs around 64Kpsi (CUP) I don't know the conversions between CUP and PSI.

So we have a cartridge developing 2.6 times the pressure as the 22 LR with 4.8 times the case head surface area.

How many "thumbs" is that?

Your thoughts are encouraged and I appreciate your time.

All the best,

C

http://www.lasc.us/SAAMIMaxPressure.htm

Re: 338 Lapua and lug sheer

Chad-

You're thinking along the right lines here. Commonly when calculating bolt thrust it is reasonable to take the internal web diameter as the "wetted surface" which is transfering the load to the bolt face.

Using just the case head diameter is very conservative and will result in bolt thrust numbers that are higher than actual, but just for easy argument's sake, then I'll use your numbers from above:

22LR @ 24 ksi over 0.055 in^2 of area:

Force = Pressure * Area = 24,000 psi * 0.055 in^2 = 1320lb of bolt thrust.

For the 338LM that would be

F = 64e3*0.266 ~ 17,024 lb

The 22 that you fired is RATED to go 24 ksi, though depending what ammo you fired, it's likely that the load was significantly lower due to the pressure in the case and also the internal web, not the external rim diameter.

Case head vs. web diameter in the 22LR and 338 LM case I don't know off the top of my head, however for a 30-06 I know it's 0.473 vs. ~ 0.408" and bolt thrust loads are in the vicinity of 8000 lb.

I've done the same experiment with the 10/22 and held the slide shut, or at least I thought I did.

What was happening was that the peak pressure was only present for mere milliseconds and the bolt did actually come out of battery but the inertial damping of my hand pushing against the charging handle didn't let the case extract all the way. In fact from the accelerometer data that I had, the calculated travel of the bolt was about 0.18" axially before my hand snapped it shut again. Again, this was perceived by me as having kept it locked shut, but in reality the motion was so minute and fast that I couldn't tell until I got the DAQ data analyzed.

Does that answer what you're looking for? Hopefully I've made things more clear instead of stirring the mud.

Chad-

You're thinking along the right lines here. Commonly when calculating bolt thrust it is reasonable to take the internal web diameter as the "wetted surface" which is transfering the load to the bolt face.

Using just the case head diameter is very conservative and will result in bolt thrust numbers that are higher than actual, but just for easy argument's sake, then I'll use your numbers from above:

22LR @ 24 ksi over 0.055 in^2 of area:

Force = Pressure * Area = 24,000 psi * 0.055 in^2 = 1320lb of bolt thrust.

For the 338LM that would be

F = 64e3*0.266 ~ 17,024 lb

The 22 that you fired is RATED to go 24 ksi, though depending what ammo you fired, it's likely that the load was significantly lower due to the pressure in the case and also the internal web, not the external rim diameter.

Case head vs. web diameter in the 22LR and 338 LM case I don't know off the top of my head, however for a 30-06 I know it's 0.473 vs. ~ 0.408" and bolt thrust loads are in the vicinity of 8000 lb.

I've done the same experiment with the 10/22 and held the slide shut, or at least I thought I did.

What was happening was that the peak pressure was only present for mere milliseconds and the bolt did actually come out of battery but the inertial damping of my hand pushing against the charging handle didn't let the case extract all the way. In fact from the accelerometer data that I had, the calculated travel of the bolt was about 0.18" axially before my hand snapped it shut again. Again, this was perceived by me as having kept it locked shut, but in reality the motion was so minute and fast that I couldn't tell until I got the DAQ data analyzed.

Does that answer what you're looking for? Hopefully I've made things more clear instead of stirring the mud.

Re: 338 Lapua and lug sheer

Gentlemen, what do you think about it?

http://www.snipershide.com/forum/ubbthreads.php?ubb=showflat&Number=2419869&page=2

http://www.snipershide.com/forum/ubbthreads.php?ubb=showflat&Number=2419869&page=1

Gentlemen, what do you think about it?

http://www.snipershide.com/forum/ubbthreads.php?ubb=showflat&Number=2419869&page=2

http://www.snipershide.com/forum/ubbthreads.php?ubb=showflat&Number=2419869&page=1

Re: 338 Lapua and lug sheer

Probably no comments. Or do not want to comment.

Or may be not profile topic. )))

[img:center]http:// [/img]

[/img]

[img:center]http:// [/img]

[/img]

Probably no comments. Or do not want to comment.

Or may be not profile topic. )))

[img:center]http://

[img:center]http://

Similar threads

- Replies

- 1

- Views

- 385

- Replies

- 5

- Views

- 469

- Replies

- 8

- Views

- 254