So it's been a while since there's been a 3D printer thread. Looking at one of these to make some simple gun related items (loadling blocks, data cards, etc), but I know nothing about them. Looking for a decent starter type machine. What's the new hotness with these machines in the $300-$500 range?

- Thread starter D1gger

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Following out of curiosity myself.

Just ordered my first printer on Black Friday, a Prusa MK3S+. Hope I can make something interesting / useful. I'll be watching this thread.

All the best,

J

All the best,

J

Due to the modelling I'm doing on the side, (1:96 scale ship) I have been thinking about a 'resin' unit. Not completely sold on that though, and still in the learning phase. So yeah, this is an interesting topic.

My 3D printing setup is a little old, probably time for an upgrade.

Having two filament printers, I would never buy one again. Resin is the way to go. I just can't justify buying one having invested in the two filament ones I have, and a mountain of materials, but I curse every time I use them.

The Prusa machines are highly regarded. The Creality Ender line is another very popular option. I have a Creality CR-10 Smart Pro, and I’m quite happy with it. I wanted the larger build volume for potential larger projects. I’m interested in adding a resin printer at some point for the finer detail.

Things to look at, IMO, to guide your decision are:

Build volume

All metal hot end, will allow higher temps for more options on filament type

Direct drive extruder, also allows you to use flexible filament easier and no PTFE tube to deal with

I had a large volume CNC router for a couple years prior to getting the printer so software and design is quite similar as well as adjusting gantries so it wasn’t too hard to jump right in and get satisfactory prints. But after some research and further adjustments, settings tweaks, I’m cranking out some quality prints.

Things to look at, IMO, to guide your decision are:

Build volume

All metal hot end, will allow higher temps for more options on filament type

Direct drive extruder, also allows you to use flexible filament easier and no PTFE tube to deal with

I had a large volume CNC router for a couple years prior to getting the printer so software and design is quite similar as well as adjusting gantries so it wasn’t too hard to jump right in and get satisfactory prints. But after some research and further adjustments, settings tweaks, I’m cranking out some quality prints.

If it was me I’d go with the S1 Pro. All metal hot end with direct drive, and it’s the latest model I believe.

No matter what you get, when it arrives double check every single nut and bolt for tightness, and verify all gantry parts are exactly square before you even do a test print. Then look at YouTube for manual bed leveling techniques and then run your auto bed level sequence.

You’ll tinker with it for a while before you get it dialed into exactly how you want it to perform. I replaced my build surface with a mirror and I’ve got my settings pretty well dialed now so mishaps are pretty few and far between.

TinkerCAD is a free design software that’s really easy to use if you’re looking to make some accessories for reloading, etc.

You’ll tinker with it for a while before you get it dialed into exactly how you want it to perform. I replaced my build surface with a mirror and I’ve got my settings pretty well dialed now so mishaps are pretty few and far between.

TinkerCAD is a free design software that’s really easy to use if you’re looking to make some accessories for reloading, etc.

found this. pretty good write up on differences and features.

Having experience and access to a CAD program enhances the ownership.

R

R

Get the ender. By the time you’ve got it put together, you’ll feel like you’ve really done something. Even if you never actually use it. We’ve made some stuff on ours. I built a binno mount for my tripod setup.

3D printing will teach you very fast that you‘re not a cad expert...

3D printing will teach you very fast that you‘re not a cad expert...

Get an ender 6 or an ender 5 s1. The 5 s1 is new but should be great based on the other ender series’s. I have a 6 and also got 2 more at work to go along side a bunch of much more expensive printers. The ender 6s get used more than the high end printers we have.

Watching.

I have a Ender-3 V2 from Amazon for $270. I use Blender for modeling and Cura for splicing. After assembling and properly leveling the darn thing it works really well. I have built ARCA rails and ARDs and more.

If it was me I’d go with the S1 Pro. All metal hot end with direct drive, and it’s the latest model I believe.

I got the Ender 3 Pro and upgraded the hot end and to direct drive. It ended up being about the same price as the S1 Pro.

Its a deep rabbit hole.

Bed adhesion is a huge issue. Sugar water trick is awesome. Learn it, use it.

Filament choice is also huge. PLA+ is "easy mode" and forgiving. Then look into whatever interests you. UV stable is important if you plan to have the print live outdoors, rather than "lens covers which see sunlight a few mins a week at most".

Nozzle size also changes things. 0.4mm is a sort of standard, but limits print speed. I use 0.6mm and csn print fine detail from 0.1mm layers no issue, up to 0.45mm per layer and speed print for prototyping things.

Calibration is key. Being able to either "log in" to your printer and manually mess with settings, so when you print a 20mm calibration cube, its exactly 20mm on all axis, and round things are on diameter (inside and out). Your slider can (should) also be able to do this.

As stated, knowing how to 3d model helps, thats a whole challenge in itself.

Filament is not filament. Cheap stuff is cheap, expensive stuff has a reason to be expensive. Like projectiles, they are not equal.

Good luck !

Bed adhesion is a huge issue. Sugar water trick is awesome. Learn it, use it.

Filament choice is also huge. PLA+ is "easy mode" and forgiving. Then look into whatever interests you. UV stable is important if you plan to have the print live outdoors, rather than "lens covers which see sunlight a few mins a week at most".

Nozzle size also changes things. 0.4mm is a sort of standard, but limits print speed. I use 0.6mm and csn print fine detail from 0.1mm layers no issue, up to 0.45mm per layer and speed print for prototyping things.

Calibration is key. Being able to either "log in" to your printer and manually mess with settings, so when you print a 20mm calibration cube, its exactly 20mm on all axis, and round things are on diameter (inside and out). Your slider can (should) also be able to do this.

As stated, knowing how to 3d model helps, thats a whole challenge in itself.

Filament is not filament. Cheap stuff is cheap, expensive stuff has a reason to be expensive. Like projectiles, they are not equal.

Good luck !

Prusa deceptively looks like kind of retrograde in comparison to many 3d printers but in reality, its only really no fuss printer on the market as the manufacturer developed every detail and software to match .For pure beginers it will by far the easyest to get printing good prints, with many other printers there are lots of small adjustments that finaly get you the print quality you get from Prusa out of the box particulary if you want to make PETG prints ,that can handle out-doors better than PLA ,for no problem start is also great to use the Prusament filament for which the settings are well optimized in their slicers.

Otherwise, i would pick Ender-3 v2 or even more likely Elegoo Neptune 3 which is now probably by far best bang for the buck

Otherwise, i would pick Ender-3 v2 or even more likely Elegoo Neptune 3 which is now probably by far best bang for the buck

Last edited:

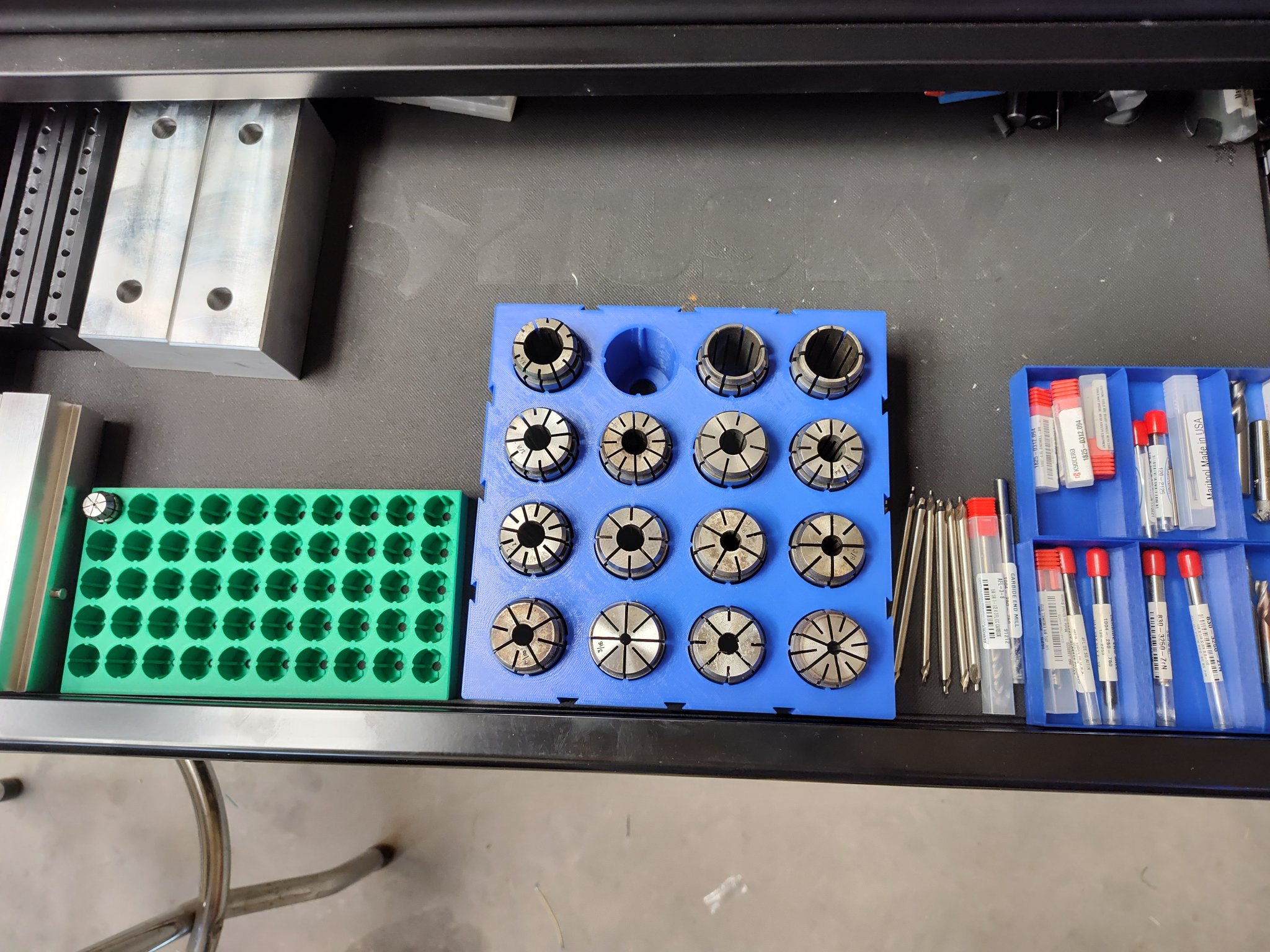

Easier to prototype in plastic, find issues, and then machine full size. Yes, a tikka t3 fits and bolts in perfectly to this print.

Edit . I should do a machinist mondays for this, the jig and setup for it is mental. Plus tool pathing was.... Fun.

Before I saw this thread, I had decided to get into 3d printing (reloading stuff and shooting items). I got a good deal on the Creality Ender-3 S1 Pro 3D Printer and went ahead and ordered it. Another rabbit hole to get into.

is the the deal going on?Before I saw this thread, I had decided to get into 3d printing (reloading stuff and shooting items). I got a good deal on the Creality Ender-3 S1 Pro 3D Printer and went ahead and ordered it. Another rabbit hole to get into.

I have 3 Prusa printers, the oldest has over 9000 hrs of print time and still holds tolerances as well as the newest one that has 800 hrs. The Prusa slicer is great IMO, lots of love out there for Cura also. But you will still need to learn some solid modeling. Even though I am balls deep daily in manufacturing and use the all the required software for modern manufacturing,I still recomend getting a hobbiest license from Fusion 360, watch a bunch of tutorials and then get after it. Regardless what people do for a living I highly recommend that everyone get a 3d printer and learn to use it. You will be suprised how fast the printer will get intergrated into your life.

Got mine thru: https://www.geekbuying.com/item/Creality-Ender-3-S1-Pro-3D-Printer-499962.html?is the the deal going on?

Determine the filament you want based on the strength and other attributes your project will require. Then cross check to ensure the printers you are looking at can reach that temperature required to correctly melt the filament. Also double check the filament diameter and what your printer will accept.

Very handy to have is a filament dryer and vacuum bags to store them in when not in use.

Very handy to have is a filament dryer and vacuum bags to store them in when not in use.

this is going to be a new venture for me. I love reloading and shooting. I'm looking forward on this new venture. Especially when it to cold and wet outside.

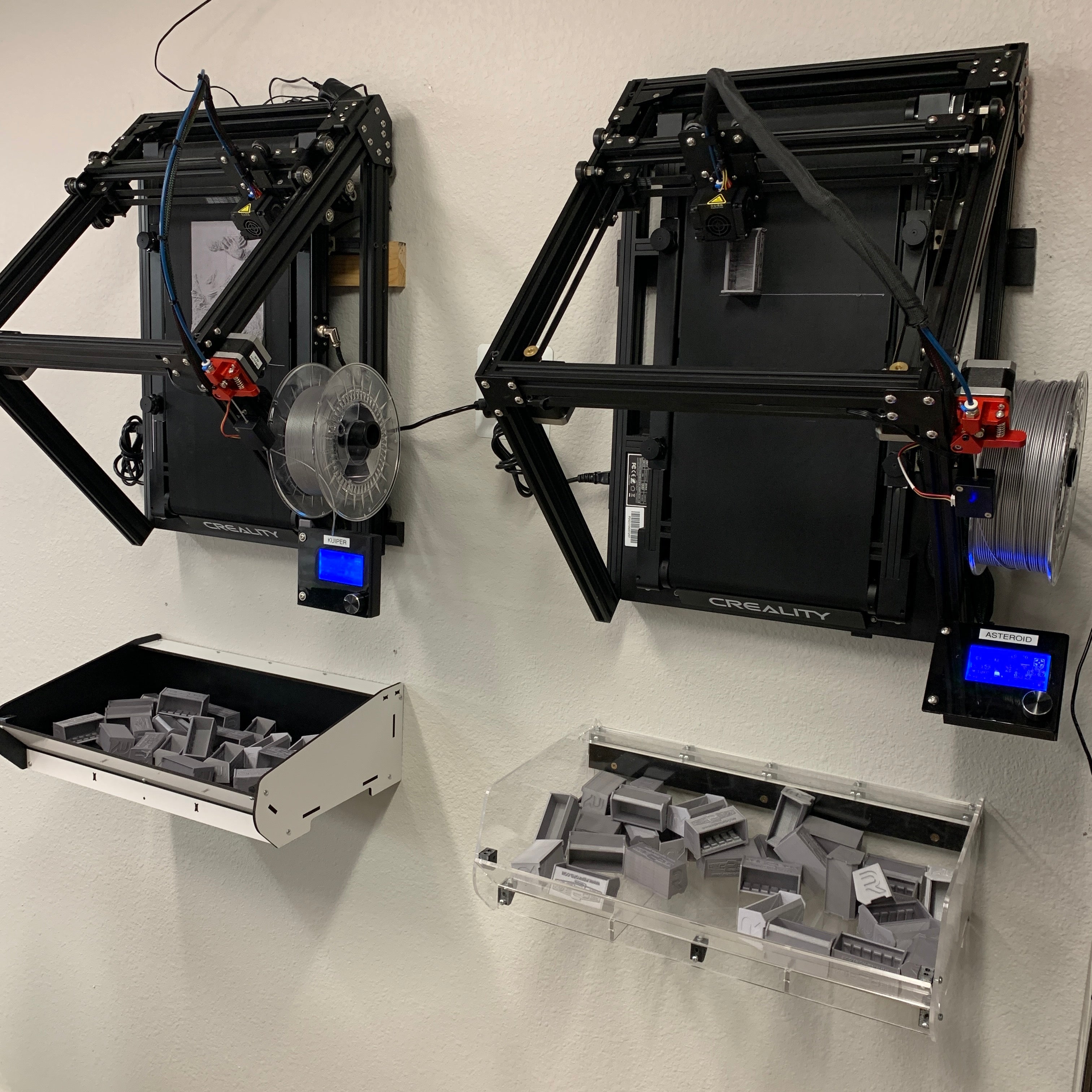

We have 2 Prusa Mk3S and they run nearly continuously. Were going to add a XL soon as I can get one. I was looking at more expensive printers with supposed more capabilities, everything I have looked at was just barley any better. We do have the MK3's in server rack cabinets to keep them clean and help with thermal control.

We have a few that we use daily. The biggest disappointment so far has been the BC3Ps. Nothing but problems. I’m very seriously considering springing for a Markforged. Their Onyx filament is durable and holds up to what we put it through. Although Matterhackers has nylonX and nylonG that are pretty good too for some applications and cheaper

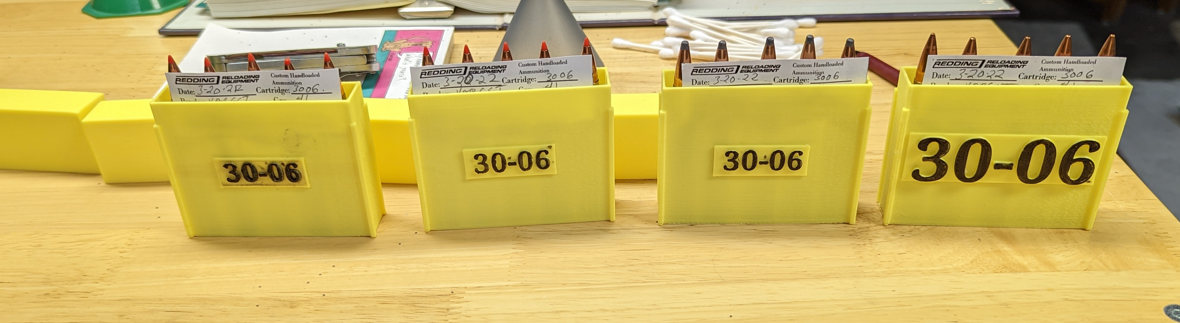

This. Exactly this. In a machine shop many people say "you dont want a junky printer parts in your work shop.. they are useless".You will be suprised how fast the printer will get intergrated into your life.

If i remember ill grab a photo at work, but i made a few different "spindle liners" for cnc lathe. Work like a charm, cost like $20 of filament, print in 24hrs, and super simple. Original OEM HAAS ones are $750 aud.... Each...

Indeed once you have it you are going to be using it more than you would have thought. Like folks mentioned Prusa is like gold standard, no fuss no fiddling, and you are not going to get substantially better prints till you are dropping thousands of $.

Just ordered an Elegoo Neptune 3 Plus as i would like to try printing some FPVs and Drones and needed a larger printer with direct drive .

One to avoid at all cost is any kind of belt printer ,like this Creality CR30, i set one up for a friend that uses it to make long profiles for his boat building business.

It enables long parts to be printed or continuous production of many smaller parts, but its absolute PITA to get it working well ,mostly due to slicer limitations .Once you get it working , stop messing with it.

Just ordered an Elegoo Neptune 3 Plus as i would like to try printing some FPVs and Drones and needed a larger printer with direct drive .

One to avoid at all cost is any kind of belt printer ,like this Creality CR30, i set one up for a friend that uses it to make long profiles for his boat building business.

It enables long parts to be printed or continuous production of many smaller parts, but its absolute PITA to get it working well ,mostly due to slicer limitations .Once you get it working , stop messing with it.

Last edited:

Having experience and access to a CAD program enhances the ownership.

R

99% of the people will be just fine with tinkercad.

Tinkercad.com.

One thing you can say about all, as in ALL even the resin or "liquid" machines is they are fiddley, you need to fiddle with them all the darn time. If you get lucky your settings will stay for an entire spool, of "tub" of material, but you better run some tests when you change out.

I have an Anycubic Chiron and it works just fine, like any of the others I have had, a level bed is the key and having your "print head" at a constant distance from the print bed is one of the most critical things.

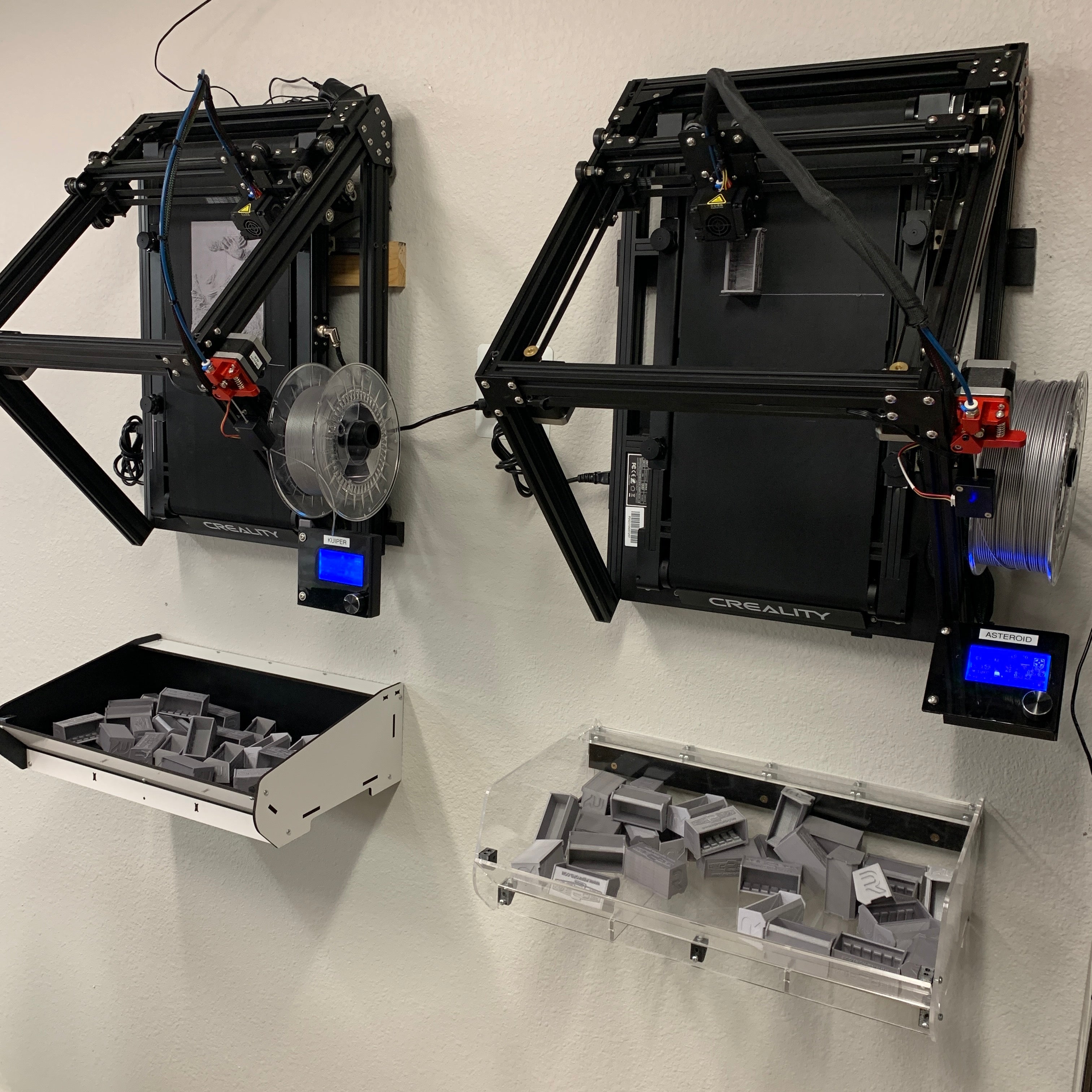

I have made some "gun stuff". I made some small boxes for when I am testing out different loads:

I also made some signs for the "home range"...these have held up really well, been down there from about May of this year and they still look good.

I don't have photos, but I also made a tray to hold 45-70, so I can put them in when reloading, you know the normal shell holder, you can buy them or just drill a bunch of holes in wood, I made one on the printer. I also made a little wrench I use when changing out dies, works well.

If you enjoy to "tinker" you can make about anything out of any form of "plastic" and there are MANY different kinds of "plastic".

Tinkercad.com is a free site that will let you "build" some pretty complex "models". I know a guy that took the blue prints to his house, scaled them down and printed his entire house in miniture as a gift to his wife, that is really cool I thought.

You can basically build anything you can think of.

I have an Anycubic Chiron and it works just fine, like any of the others I have had, a level bed is the key and having your "print head" at a constant distance from the print bed is one of the most critical things.

I have made some "gun stuff". I made some small boxes for when I am testing out different loads:

I also made some signs for the "home range"...these have held up really well, been down there from about May of this year and they still look good.

I don't have photos, but I also made a tray to hold 45-70, so I can put them in when reloading, you know the normal shell holder, you can buy them or just drill a bunch of holes in wood, I made one on the printer. I also made a little wrench I use when changing out dies, works well.

If you enjoy to "tinker" you can make about anything out of any form of "plastic" and there are MANY different kinds of "plastic".

Tinkercad.com is a free site that will let you "build" some pretty complex "models". I know a guy that took the blue prints to his house, scaled them down and printed his entire house in miniture as a gift to his wife, that is really cool I thought.

You can basically build anything you can think of.

I wanted to add, every one of those boxes is different, if you look close at the first box you will see the lid looks a little wavy. This is the fiddle with it that everyone is talking about. All those boxes have different settings, and there are about a billion different settings on these printers.....and you always want to be able to go back to the "factory suggested settings" sometimes you will print a rats nest. Sometimes you will have a print fail after two days of printing. And they do not do anything fast.

There is a bit of a "smell" to them, it bothers some folks and not others. Generally the resin printers have more smell to them over the filiment printers. It is a bit of a melted plastic smell.....go figure. Different materials differ in the smell, and that is one thing you get with the more expensive material, is less stink to them.

They are also a bit noisy, and the filament printers do "shake" a bit....they don't move, you want them to have as little movement as possible, but stuff is moving on the printer, the bed and the head and gantry that is what I mean by shake, but you don't want the printer to move....don't think I explaned that right.

So if you have little ones, or issues sleeping with random noises keep that in mind. The resin printers are a little more quiet IMHO, but to get ones with a large build area they cost more over the filament printers.

There is a bit of a "smell" to them, it bothers some folks and not others. Generally the resin printers have more smell to them over the filiment printers. It is a bit of a melted plastic smell.....go figure. Different materials differ in the smell, and that is one thing you get with the more expensive material, is less stink to them.

They are also a bit noisy, and the filament printers do "shake" a bit....they don't move, you want them to have as little movement as possible, but stuff is moving on the printer, the bed and the head and gantry that is what I mean by shake, but you don't want the printer to move....don't think I explaned that right.

So if you have little ones, or issues sleeping with random noises keep that in mind. The resin printers are a little more quiet IMHO, but to get ones with a large build area they cost more over the filament printers.

This is Art, the pig.

Art is a physical “thing.” Art is also meta as fuck. So is this little blue pig. This Art represents my 3D printing journey. There are a number of reasons why. It is incomplete. The parts that is complete is perfectly serviceable. The print failed for no known reason. The printer continued to print until it was “done” even though the part had failed. I found Art with a halo of extruded filament perched atop his head. This Art was not supposed to be. It is a test file that came with the printer. In my haste to print something else, I scrolled past my file and started the pig. Art sits on top of the print bed when the printer is not in use as a reminder to measure once and cut twice.

Art is a physical “thing.” Art is also meta as fuck. So is this little blue pig. This Art represents my 3D printing journey. There are a number of reasons why. It is incomplete. The parts that is complete is perfectly serviceable. The print failed for no known reason. The printer continued to print until it was “done” even though the part had failed. I found Art with a halo of extruded filament perched atop his head. This Art was not supposed to be. It is a test file that came with the printer. In my haste to print something else, I scrolled past my file and started the pig. Art sits on top of the print bed when the printer is not in use as a reminder to measure once and cut twice.

You really need to look at what your needs are. Tensile strength is not the only factor you need to look at. I print a ton in PLA and PETG, it has good tensile strength and good impact resistance, and it's really easy to print with. I do use poly carb PC occasionally. It can be finicky to print, it does have higher tensile and impact resistance.

I resisted getting I printer for a long time, now were about to have 3. About everywhere I look in the shop there are 3D printed parts. The kids are printing stuff up about everytime there is availability.

I resisted getting I printer for a long time, now were about to have 3. About everywhere I look in the shop there are 3D printed parts. The kids are printing stuff up about everytime there is availability.

I too am finding this topic very interesting, and am interested in 'resin printer' moreso. Am I fooling myself in thinking that there are less issues with a resin printer? Or are 'art pigs' more/just as likely to happen?

Resin is a totally different style and type of plastic. Generally they can be solid models, so stronger, and they can print MUCH finer detail.

Be aware that you need to wash your print, then UV cure it. Im told you dont want to get the raw liquid on your skin also.

Be aware that you need to wash your print, then UV cure it. Im told you dont want to get the raw liquid on your skin also.

Carbon fiber will wear out the nozzles and its not really worth it for most applications and polycarbonate is beyond the Ender 3 capability. PLA + , PETG are your standard options, and in the end strength depends on both print orientation(3d prints are strong across the grain but not as much along the grain if we use wood analogy, layers being grain orientation.) and settings for infill and wall and will again increase by switching to a larger nozzle o.6mm over 0.4mmJust pulled the trigger on an Ender3 s1Pro. it came with some Creality PLA. I'm looking at something stronger and more durable either Carbon fiber or Polycarbonate.

From what I understand the Ender3 S1 plus is supposed to be capable to run Polycarbonate.Carbon fiber will wear out the nozzles and its not really worth it for most applications and polycarbonate is beyond the Ender 3 capability. PLA + , PETG are your standard options, and in the end strength depends on both print orientation(3d prints are strong across the grain but not as much along the grain if we use wood analogy, layers being grain orientation.) and settings for infill and wall and will again increase by switching to a larger nozzle o.6mm over 0.4mm

I want to try the nylonX stuff which is carbon fiber nylon for gears in small robotics projects, which is why I got the all metal hotend in the first place. I haven’t determined whether I’ll need an enclosure or if I can get away with the space I’m using which is pretty efficient without any drafts. I suppose I could leave the door closed to keep the room a bit warmer too.

I’ve been using PETG exclusively since I finished the crap filament that came with the printer and it does seem pretty sturdy, especially when adjusting wall count and infill. There’s a definite learning curve.

I’ve been using PETG exclusively since I finished the crap filament that came with the printer and it does seem pretty sturdy, especially when adjusting wall count and infill. There’s a definite learning curve.

We run nylonX daily for parts that will take the load you are referring to. We had serious issues with detail and delaminating until we added an enclosure and a filament dryer. NylonX and NylonG are hygroscopic.I want to try the nylonX stuff which is carbon fiber nylon for gears in small robotics projects, which is why I got the all metal hotend in the first place. I haven’t determined whether I’ll need an enclosure or if I can get away with the space I’m using which is pretty efficient without any drafts. I suppose I could leave the door closed to keep the room a bit warmer too.

I’ve been using PETG exclusively since I finished the crap filament that came with the printer and it does seem pretty sturdy, especially when adjusting wall count and infill. There’s a definite learning curve.

The nozzles matter. A lot. We have performed tests on them during a troubleshooting period and found that they all will affect the print results. Some don’t hold heat well enough to make a detailed print. This will vary in importance depending on the filament and printer you use (this will be more of an issue if you are trying to use filament that needs a temp that is at the upper boundary of your printers capabilities).

A fuck ton cheaper than the aluminum baseplates I found on line. PLA. I just dropped a loaded mag square on the pad, onto the tile floor in the kitchen. No damage. On the off chance a mag spontaneously disassembles, I can drop a handful in the range bag. Maybe I wouldn’t use them for carry. But they work well for range duty. And, I’d rather drop these sub $1 parts on concrete than the $45 aluminum alternatives.

Can I overcomplicate the plot by asking about 'dual head' printers? Those who run two different kinds of filament OR the 'support' filament that washes off the part?

I'm probably not using the right terminology, but last year when I was looking more into this, these 'dual heads' were being touted. I figured 'time will tell' but I honestly have lost track with this topic due to other 'adulting' and whatnot going on in our lives. My interest is still there though.

I'm probably not using the right terminology, but last year when I was looking more into this, these 'dual heads' were being touted. I figured 'time will tell' but I honestly have lost track with this topic due to other 'adulting' and whatnot going on in our lives. My interest is still there though.

We run dual heads. They work well. The water soluble filament works well and saves time and frustration when the cleaning out of supports is considered.Can I overcomplicate the plot by asking about 'dual head' printers? Those who run two different kinds of filament OR the 'support' filament that washes off the part?

I'm probably not using the right terminology, but last year when I was looking more into this, these 'dual heads' were being touted. I figured 'time will tell' but I honestly have lost track with this topic due to other 'adulting' and whatnot going on in our lives. My interest is still there though.

The dual heads also work well when you can fit multiple parts on the printing bed. Saves time. If we are printing gaskets in TPU we will run all the bed can hold.

Last edited:

Similar threads

- Replies

- 24

- Views

- 536