Building a new 6mm ARC using a a Satern barrel. 22” 1:7.5 twist 5R. Plan on using Aero parts, uppers and lowers. Adjustable gas block, JPS buffer system. I’m looking to make this as accurate as possible. What’s the best way to get the best accuracy out of this barrel? Comes with a headspaced bolt. Do I need to lap the upper receiver, use 620 loctite or shim stock? There are several companies using these barrels with great results. I have built several uppers and lowers over the years.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

-

Get 25% Off Access To Frank's Online Training

Use code FRIDAY25 and SATURDAY25 to get 25% off access to Frank’s online training. Want a better deal? Subscribe to get 50% off.

Get Access Subscribe

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

6mm ARC Build

- Thread starter 806guns

- Start date

Make sure the barrel extension is a tight fit with the upper receiver without the nut applied. this was a discovery made by several guys around the same time when they were doing workups for national match shooting, and makes a pretty significant difference. The other big contributor to raw accuracy out of any AR is carrier tilt. There are some carriers out there designed to minimize it out of the box, which is preferable over the old school method of drilling and tapping for some rider screws.Building a new 6mm ARC using a a Satern barrel. 22” 1:7.5 twist 5R. Plan on using Aero parts, uppers and lowers. Adjustable gas block, JPS buffer system. I’m looking to make this as accurate as possible. What’s the best way to get the best accuracy out of this barrel? Comes with a headspaced bolt. Do I need to lap the upper receiver, use 620 loctite or shim stock? There are several companies using these barrels with great results. I have built several uppers and lowers over the years.

gassing for maximum dwell time is also important, that way any disturbance in the rifle from components moving happens well after the projectile has left the barrel.

good luck with the build!

Barrel quality/headspacing to bolt in use, barrel fit to upper (undersized upper, shim, bedding, or otherwise), and gas tube alignment are the big ones in my book, in that order. Everything else is 1/2 to 1/4 MOA magic, and if you’re shooting at that level, you’ll figure it out - it becomes more personal preference.

My 10.5” 6ARC outshoots my 18” by a hair at shorter distances. Same exact components on both. I went nuts, the upper receivers are even lathe faced. Aside from the above, everything else was splitting hairs. I think I just like the 10.5” better, so I shoot it better because of my mood.

My 10.5” 6ARC outshoots my 18” by a hair at shorter distances. Same exact components on both. I went nuts, the upper receivers are even lathe faced. Aside from the above, everything else was splitting hairs. I think I just like the 10.5” better, so I shoot it better because of my mood.

What 10.5" barrel do you have?Barrel quality/headspacing to bolt in use, barrel fit to upper (undersized upper, shim, bedding, or otherwise), and gas tube alignment are the big ones in my book, in that order. Everything else is 1/2 to 1/4 MOA magic, and if you’re shooting at that level, you’ll figure it out - it becomes more personal preference.

My 10.5” 6ARC outshoots my 18” by a hair at shorter distances. Same exact components on both. I went nuts, the upper receivers are even lathe faced. Aside from the above, everything else was splitting hairs. I think I just like the 10.5” better, so I shoot it better because of my mood.

Craddock Bartlein (.750), carbine +1” gas.What 10.5" barrel do you have?

This is anecdotal, but compelling IMO... I have a 24" 6 ARC Bartlein barrel in my Seekins upper. I picked a load that shot reasonably well and shot 20 rounds at 200yd into a single group. It was 2.8". I pulled the upper apart and red loctited the barrel into the upper, torqued it up and let everything sit a few days, re-assembled and shot the same ammo for another 20 shots. 1.8" this time. So this is a sample size of 1 but it would appear that a tight upper-barrel fit is worth doing, and it makes sense because the optic is mounted to the upper and the barrel, if it has room to move, will misalign with the optic. Someone should make press-fit stainless uppers.

Thank you all for the information. I have lapped this aero upper with 220 grit and a PTG lapping tool. Did it by hand in the vertical position so gravity would help. Next I installed the barrel and found the fit wasn’t the best. Used .001 shim stock and cut a price the circumference and width of the barrel extension. Used masking tape to hold the two ends together and installed the barrel. Removing the masking tape after the barrel was started and the shin stock stayed in place. The fit is 100 times better, had to use a rubber mallet (protecting the threads) to get it all the way flush. Used my snap on torque wrench and torqued the barrel nut to 45 ft lbs per Aero’s torque specification. Now I need a adjustable gas block, the barrel is dimpled and I have checked the alignment of the gas tube.

Attachments

and be sure to check the alignment of the barrel extension feed ramps with the upper receiver feed ramps.Thank you all for the information. I have lapped this aero upper with 220 grit and a PTG lapping tool. Did it by hand in the vertical position so gravity would help. Next I installed the barrel and found the fit wasn’t the best. Used .001 shim stock and cut a price the circumference and width of the barrel extension. Used masking tape to hold the two ends together and installed the barrel. Removing the masking tape after the barrel was started and the shin stock stayed in place. The fit is 100 times better, had to use a rubber mallet (protecting the threads) to get it all the way flush. Used my snap on torque wrench and torqued the barrel nut to 45 ft lbs per Aero’s torque specification. Now I need a adjustable gas block, the barrel is dimpled and I have checked the alignment of the gas tube.

Here she is in built form, weighs 12.2 lbs. Riton x5 Conquer 5-25x50, Luth-ar buttstock, Rave 140 trigger, EC tuner brake. Found a box of 108 gr hornady ammo. I plan on using 105gr barnes , SW match powder, Lapua brass I converted with SR mag primers. I was getting 2750fps out of my Uintah Precision. I will back the charge weight down 2 gr and work back up for the gas gun.

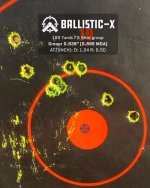

Here are real results from the 6mm Arc build. 15mph winds shooting with the wind. Gun is definitely over gassed and needs buffer assembly adjusted or an adjustable gas block. Overall I’m happy and can’t wait to get a load worked up.

Attachments

will depend on the barrel length.Hey guys, will an adjustable gas block help my ejector swipe issue? Also this is a rifle length gas system what size should the gas port be?

Hornady brass? You'll have that.Installed adjustable gas block and adjusted it till the bolt didn’t lock back. Still getting ejector swipes on the brass.

Brass has a edge too it. Never seen it before.

Hornady brass? You'll have that.

I've seen it every time I've seen Hornady brass in 6.5G, 6G or 6ARC.Brass has a edge too it. Never seen it before.

since you have the ejector out, you might as well polish the knob on the ejector. smooth it out, so it glides acrosst the back face of the brass as bolt is rotating out of battery. take off the sharp edge, so that it doesn't dig into the brassMy dumb*** had a carbine buffer in a rifle length system. Also going to clip the ejector spring.

Did the gas key beat the shit out of your receiver?My dumb*** had a carbine buffer in a rifle length system. Also going to clip the ejector spring.

The brass in my proof barreled 6arc comes out looking fine. What are you talking about?I've seen it every time I've seen Hornady brass in 6.5G, 6G or 6ARC.

No everything looks fine.Did the gas key beat the shit out of your receiver?

I've been shooting, reloading and tuning guns for 6.5 Grendel for years. 6mm Grendel for years. Observing 6 ARC since it's release. I've tried light loads, heavy loads, light and heavy reciprocating mass, various springs, turned the gas almost off, chamfered and polished the ejector and ejector hole, trimmed the spring.The brass in my proof barreled 6arc comes out looking fine. What are you talking about?

Doesn't matter with Hornady brass, it all shows ejector swipe. Lapua brass and it never happens. Far as I can tell Hornady brass is just softer.

I guess that's good, kinda hard to understand how a carbine buffer in a rifle buffer tube didn't allow for so much BCG over travel that it beat things up.No everything looks fine.

Bet the rifle length spring is the only thing that saved it. Should have an update this weekend with the correct parts.I guess that's good, kinda hard to understand how a carbine buffer in a rifle buffer tube didn't allow for so much BCG over travel that it beat things up.

I don't have that issue on my fired brass. This is from a 10.5" 6mm ARC, suppressed with a Sandman-S, H2 buffer in a carbine length receiver extension, with an AGB adjusted for reliability with various ammunition (not tweaked to the hilt for soft shooting). I'm using a Toolcraft DLC BCG/bolt, with a Craddock Bartlein barrel ( I did carbine+1" on the 10.5" for gas length. PM if you want port sizing - works great unsuppressed and suppressed even without the AGB, I just only shoot suppressed.) The barrel was headspaced to the bolt I'm using, FWIW. This is just about the worst case, in a _properly setup rifle_, with correct gas. This is factory Hornady Match 108gr ELD-M, not a reload:I've been shooting, reloading and tuning guns for 6.5 Grendel for years. 6mm Grendel for years. Observing 6 ARC since it's release. I've tried light loads, heavy loads, light and heavy reciprocating mass, various springs, turned the gas almost off, chamfered and polished the ejector and ejector hole, trimmed the spring.

Doesn't matter with Hornady brass, it all shows ejector swipe. Lapua brass and it never happens. Far as I can tell Hornady brass is just softer.

Brass from my 18" (rifle+1", again, properly sized gas port) isn't much different. I'm well north of a few thousand rounds on each barrel and haven't had any issues with factory ammunition or reloads (which I keep gas-gun friendly).

Last edited:

I can't get the pic to show for some reason. Either way, I no longer consider the swipes an issue, just the way it is. Maybe Hornady has improved their brass, everything I'm using is from 2016-2020. No amount of tinkering in both home brewed and factory guns and ammo could completely eliminate the swipes.I don't have that issue on my fired brass. This is from a 10.5" 6mm ARC, suppressed with a Sandman-S, H2 buffer in a carbine length receiver extension, with an AGB adjusted for reliability with various ammunition (not tweaked to the hilt for soft shooting). I'm using a Toolcraft DLC BCG/bolt, with a Craddock Bartlein barrel ( I did carbine+1" on the 10.5" for gas length. PM if you want port sizing - works great unsuppressed and suppressed even without the AGB, I just only shoot suppressed.) The barrel was headspaced to the bolt I'm using, FWIW. This is just about the worst case, in a _properly setup rifle_, with correct gas. This is factory Hornady Match 108gr ELD-M, not a reload:

Brass from my 18" (rifle+1", again, properly sized gas port) isn't much different. I'm well north of a few thousand rounds on each barrel and haven't had any issues with factory ammunition or reloads (which I keep gas-gun friendly).

I'll attach it directly:I can't get the pic to show for some reason. Either way, I no longer consider the swipes an issue, just the way it is. Maybe Hornady has improved their brass, everything I'm using is from 2016-2020. No amount of tinkering in both home brewed and factory guns and ammo could completely eliminate the swipes.

Hornady brass is definitely softer, I've been using it for years too. I definitely prefer Peterson/ADG/Lapua, but you shouldn't see ejector swipes like you are, something is funky with that, especially if you've done all the work you indicate. I agree, though, if you know you're in the safe range re: loading, it's not the end of the world, but I sure hate seeing brass chewed up for no reason.

The good news is that the beat up brass hasn't caused any function issues, the brass pictured is 10x fired and still works great even if it's ugly. This was my early 6mm Grendel stuff, I've since modified the gun and the loads and greatly reduced the swiping.I agree, though, if you know you're in the safe range re: loading, it's not the end of the world, but I sure hate seeing brass chewed up for no reason.

About .75 at 100 if not better. Great shooter for sureHow has that 22" satern liberty barrel been shooting. I was wondering how they shoot.

Similar threads

- Replies

- 17

- Views

- 831

- Replies

- 41

- Views

- 1K