I regularly see the threads pertaining to knives and knife selection, wondering if there are any other knifemakers around here?

If so, share some of your work.

Alternatively, if anyone has questions on steel selection, heat treat, construction styles, etc to help with the selection of a knife, post it up. Seemed to me like there should be a thread to ask questions and share work or favorite custom knives, etc.

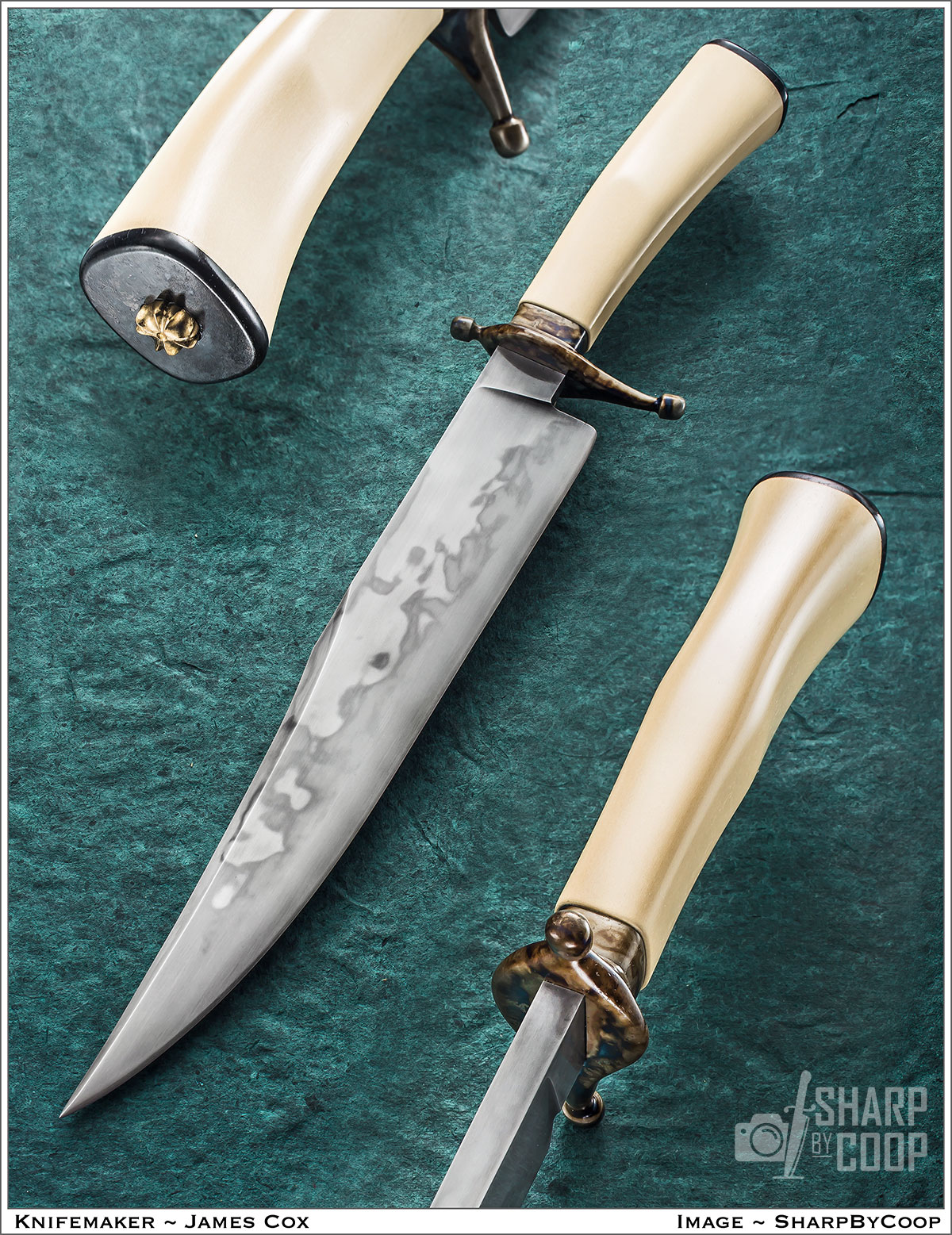

A little about me. I’m mostly a bladesmith, I forge and do stock removal, bowies and other big stuff, hunting knives, fighters (as much as I hate that term for a knife), folders, bushcraft, etc. I do a lot of dabbling. My area of expertise is controlled heat treat of forging steels, and forging blades by hand. I also have experience with “super” steels such as Vanadis 4 Extra.

Here’s one of mine, same one that’s my avatar:

If so, share some of your work.

Alternatively, if anyone has questions on steel selection, heat treat, construction styles, etc to help with the selection of a knife, post it up. Seemed to me like there should be a thread to ask questions and share work or favorite custom knives, etc.

A little about me. I’m mostly a bladesmith, I forge and do stock removal, bowies and other big stuff, hunting knives, fighters (as much as I hate that term for a knife), folders, bushcraft, etc. I do a lot of dabbling. My area of expertise is controlled heat treat of forging steels, and forging blades by hand. I also have experience with “super” steels such as Vanadis 4 Extra.

Here’s one of mine, same one that’s my avatar: