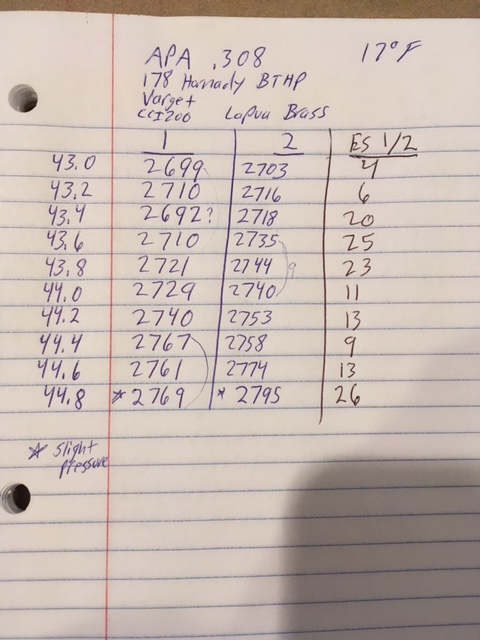

I ran (2) 10 shot ladder test with my .308 watching the magneto speed. Not sure if anyone has done this 10 round ladder test as seen in this video.

But as you can see, the first time I ran through it (column on the left) there seems to be a velocity flat line between 43.0 and 43.6. There is also another one between 44.4 and 44.8. Things are going as planned. Then 15 minutes later I shot it again and that is the column on the right. There seems to be a node between 43.6 and 44.0 which is exactly what didn't look good in the first test. The far right column shows the ES's between the first round and the second round. All this ammo was loaded at the same time. The only think I could think of possible making a difference was my rifle came out of a warm truck for the first set and then sat out in the cold for a bit for the second set. The ammo was all cold except for the 10 minute ride to the range. This is all once fired, trimmed and uniformed lapua brass. Any ideas what any of this means and where to go from here?

Thanks

But as you can see, the first time I ran through it (column on the left) there seems to be a velocity flat line between 43.0 and 43.6. There is also another one between 44.4 and 44.8. Things are going as planned. Then 15 minutes later I shot it again and that is the column on the right. There seems to be a node between 43.6 and 44.0 which is exactly what didn't look good in the first test. The far right column shows the ES's between the first round and the second round. All this ammo was loaded at the same time. The only think I could think of possible making a difference was my rifle came out of a warm truck for the first set and then sat out in the cold for a bit for the second set. The ammo was all cold except for the 10 minute ride to the range. This is all once fired, trimmed and uniformed lapua brass. Any ideas what any of this means and where to go from here?

Thanks