I'm getting an occasional jam in my Armalite AR10 in .260Rem. This is particularly annoying when it happens during a match.

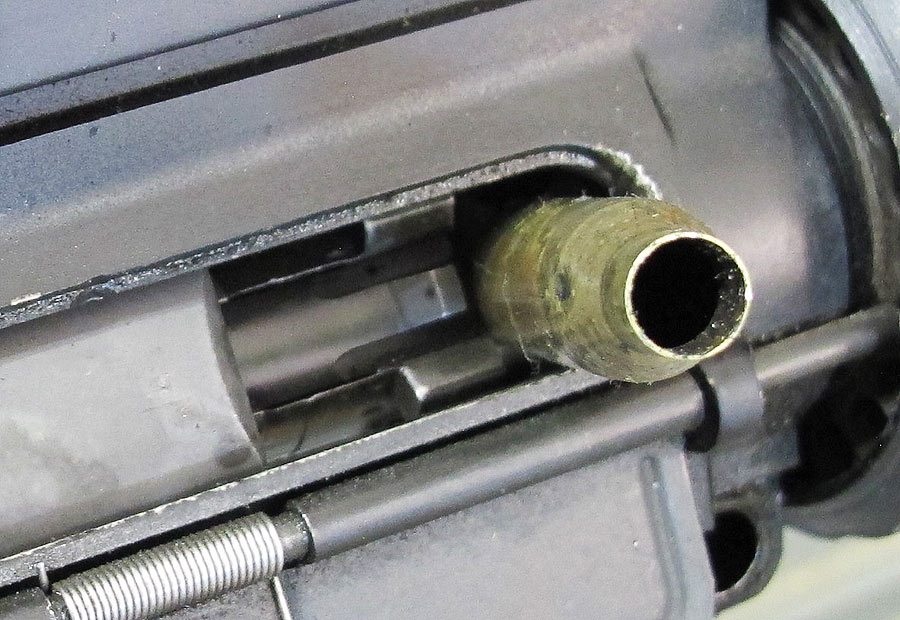

The bolt goes back far enough to catch and chamber a round, but the fired case is not ejected. (images are a recreation of what happens)

The equipment is:

- Armalite AR10

- Armalite 10-round magazines

- Krieger barrel, .260 Rem

- Cases are surplus RA64 cases that are resized and neck-turned. (I got tired of losing Lapua brass. Problem also happens with Lapua brass.)

- Buffer tube with 3 tungsten weights

- SLR adjustable gas block, open almost all the way

- Thunderbeast silencer, direct-thread

- Load: Berger 140 VLD, 41.6 gr H4350, Federal GM Match LRP, 2720fps (Oehler 35P chrono)

Cases land anywhere from 20 feet away to on the bench.

The buffer tube weights are necessary to slow the bolt sufficiently that the case has time to shrink back down enough that the rim is not torn off. (This is caused by the requirements I gave to to my 'smith. He recommended that I really didn't want what I was asking. Now I know why.)

About 75 percent of ejected cases are dented at the mouth:

Primers show no indication of an excessive load (I know primers are not the best way to tell, but they do give some idea):

Because the ejection/feed problem is intermittent, I have not opened up the gas block any more, since it already is almost all the way open.

Thank you for any suggestions I should try.

Richard

The bolt goes back far enough to catch and chamber a round, but the fired case is not ejected. (images are a recreation of what happens)

The equipment is:

- Armalite AR10

- Armalite 10-round magazines

- Krieger barrel, .260 Rem

- Cases are surplus RA64 cases that are resized and neck-turned. (I got tired of losing Lapua brass. Problem also happens with Lapua brass.)

- Buffer tube with 3 tungsten weights

- SLR adjustable gas block, open almost all the way

- Thunderbeast silencer, direct-thread

- Load: Berger 140 VLD, 41.6 gr H4350, Federal GM Match LRP, 2720fps (Oehler 35P chrono)

Cases land anywhere from 20 feet away to on the bench.

The buffer tube weights are necessary to slow the bolt sufficiently that the case has time to shrink back down enough that the rim is not torn off. (This is caused by the requirements I gave to to my 'smith. He recommended that I really didn't want what I was asking. Now I know why.)

About 75 percent of ejected cases are dented at the mouth:

Primers show no indication of an excessive load (I know primers are not the best way to tell, but they do give some idea):

Because the ejection/feed problem is intermittent, I have not opened up the gas block any more, since it already is almost all the way open.

Thank you for any suggestions I should try.

Richard