- Thread starter kurt.w.andrews

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pretty hard to get all that you need from any one manufacturer .

Also depends on how for you want to go on the list of possibilities.

MM

Also depends on how for you want to go on the list of possibilities.

MM

Wheeler makes an entire "AR Armorers" kit for <$200 if I remember.

Top tier? Probably not.

"Essential" for when you need it? Probably.

Top tier? Probably not.

"Essential" for when you need it? Probably.

AR Toolkit | Fix It Sticks

Fix It Sticks' AR Toolkit includes all the specialty tools and bits you need to maintain your AR-15 or AR-10 anywhere you take it.

My idea of an essentials toolkit is one you can easily have with or at least real near you at any given moment. The reality, though, is that you can replace the military grade stuff that might fail with your fingers and a piece of brass. Trigger parts, bolt parts...and those are all small enough to carry spares of inside the butt stock or maybe the pistol grip...or in a fag bag on your hip.

I don't carry spare parts around with me but I do carry some tools.

I agree with the above for the most part, I believe your best bet is to go to Brownells and get something like the Real Avid master kit that comes with pretty much everything you would need.

www.brownells.com

www.brownells.com

Or you can peruse Brownells and get stuff piecemeal but the above kit would probably work just fine for the hobbyist and DIYer.

AR-15 ARMORER'S MASTER KIT | Brownells

The Real Avid AR-15 Armorer’s Master kit includes Master Grade Tools and how-to information that equips you to confidently tackle everything from building your own gun from the ground up to customizing or modifying an existing gun. With better tol...

Or you can peruse Brownells and get stuff piecemeal but the above kit would probably work just fine for the hobbyist and DIYer.

It's honestly best to just peace it together. I would start off with these, and don't cheap out on them.

Bench Vise

Standard Punch Set

Roll Pin Punch set and Roll pin starter punch.

Armors wrench and hammer.

JP universal vise clamp

AR15/AR10 Vise Block (Real Avid makes a decent one)

Gas Block assembly Jig

Ft- LBS Torque Wrench

In-Lbs Torque Wrench

Crowfoot Flare Nut Wrench Set

Reaction Rod for AR15/AR10

Bolt disassembly Tool.

Everything else you can pick up at your local hardware store.

Bench Vise

Standard Punch Set

Roll Pin Punch set and Roll pin starter punch.

Armors wrench and hammer.

JP universal vise clamp

AR15/AR10 Vise Block (Real Avid makes a decent one)

Gas Block assembly Jig

Ft- LBS Torque Wrench

In-Lbs Torque Wrench

Crowfoot Flare Nut Wrench Set

Reaction Rod for AR15/AR10

Bolt disassembly Tool.

Everything else you can pick up at your local hardware store.

That's what I'm trying to figure out, what companies sell the quality tools. I'm familiar with automotive work,and woodworking, so I know what the quality tools are and where to buy them, but building ARs is new to me so aside from general tools like, bit drivers, screwdrivers etc, I need to know who makes the best specialized tools.It's honestly best to just peace it together. I would start off with these, and don't cheap out on them.

Bench Vise

Standard Punch Set

Roll Pin Punch set and Roll pin starter punch.

Armors wrench and hammer.

JP universal vise clamp

AR15/AR10 Vise Block (Real Avid makes a decent one)

Gas Block assembly Jig

Ft- LBS Torque Wrench

In-Lbs Torque Wrench

Crowfoot Flare Nut Wrench Set

Reaction Rod for AR15/AR10

Bolt disassembly Tool.

Everything else you can pick up at your local hardware store.

PSA has that kit on sale for $79.99 (plus tax & shipping, as applicable) "today only".Wheeler makes an entire "AR Armorers" kit for <$200 if I remember.

Top tier? Probably not.

"Essential" for when you need it? Probably.

No vested interest. Just happened to see it in an e-mail this morning.

+1 to this, and the Geissele reaction rod (or similar) in that list above. That reaction rod is my most-used tool.The Magpul armorer's wrench is a must have

The MI reaction type rod is nice. It fits tight to every receiver I have tried and it does not move when torqueing the barrel nuts.

Why? I don't really follow him that closely but it seems like he knows things.I don’t like SOTAR

Start with a good vice attached to a good bench/work surface.

I don't use any hammers or punches. But the action rods are a must have. Torque wrench is good to have with varrying barrel nut tools to suit what ever you are working on. I do barrel nut torque by feel now but if you want to make sure get a torque wrench.

Good Allen wrenches, a torch possibly, loctite red and blue, etc.

I don't use any hammers or punches. But the action rods are a must have. Torque wrench is good to have with varrying barrel nut tools to suit what ever you are working on. I do barrel nut torque by feel now but if you want to make sure get a torque wrench.

Good Allen wrenches, a torch possibly, loctite red and blue, etc.

I just started another thread but I found this today and some other handy tools to keep around.

AR Ejector Tool

If you've ever tried to remove or install the ejector roll pin from your AR bolt, you know that, without a tool, the ejector and spring can go flying out, never to be seen again. Enter the 3DGearGuy AR ejector tool... This simple tool allows you to place tension on the ejector, making it easy to...

threedgearguy.com

I just started another thread but I found this today and some other handy tools to keep around.

AR Ejector Tool

If you've ever tried to remove or install the ejector roll pin from your AR bolt, you know that, without a tool, the ejector and spring can go flying out, never to be seen again. Enter the 3DGearGuy AR ejector tool... This simple tool allows you to place tension on the ejector, making it easy to...threedgearguy.com

I just bought this thing which has that and more stuff built in. I haven't used it yet it's so new but seems decent.

Master Bench Block® – AR15

HOLDS 5 KEY GUN PARTS TO EASILY REMOVE & INSTALL PINS. The AR15 Master Bench Block holds 5 key AR15 components in 8 different orientations to allow you to knock out and install up to 13 different pins. The block is wrapped in over-molding that grips your bench so it won’t slide around.

.

Well thiught out designs and of quality.

obsidianarms.com

obsidianarms.com

Complete AR-15 Armorer's Punch Set, 12-piece - Obsidian Arms

With feedback from our customers, our armorers, and other professional armorers in the industry we have made the best AR-15 armorer's punch set.

obsidianarms.com

obsidianarms.com you don't need that, don't waste your moneyI just started another thread but I found this today and some other handy tools to keep around.

AR Ejector Tool

If you've ever tried to remove or install the ejector roll pin from your AR bolt, you know that, without a tool, the ejector and spring can go flying out, never to be seen again. Enter the 3DGearGuy AR ejector tool... This simple tool allows you to place tension on the ejector, making it easy to...threedgearguy.com

The Real Avid master block includes this feature, is inexpensive and has provided more than adequate service for a hobby builder and servicing.you don't need that, don't waste your money

I do t need 50+ guns but here I am.you don't need that, don't waste your money

Which companies make the best quality armorer's/Gunsmithing tools to build AR-15s? I'm trying to put together an essentials tool kit.

@MontanaMan nailed it. You won't be able to get all of the best tools from 1 company. For example, the best armorer's wrench I've used is my Magpul armorer's wrench. And either a Geissele Reaction Rod, or Real Avid reaction rod are a must-have. You will also need at least a good Wilton 4" bench vise. One tool I cannot recommend enough, is if you're building standard forged lowers, where you press in the trigger guard roll pin, get yourself a Wheeler Engineering Trigger Guard Install Tool. Don't try to hammer it in, you can break one of the flanges if you're not careful, or if you have the pin in crooked, or miss and hit the receiver. They are NOT very thick flanges.Pretty hard to get all that you need from any one manufacturer .

Also depends on how for you want to go on the list of possibilities.

MM

One tool I cannot recommend enough, is if you're building standard forged lowers, where you press in the trigger guard roll pin, get yourself a Wheeler Engineering Trigger Guard Install Tool. Don't try to hammer it in, you can break one of the flanges if you're not careful, or if you have the pin in crooked, or miss and hit the receiver. They are NOT very thick flanges.

You are right that tool is awesome and it comes in this set which has some great AR punches.

The only thing Geissele that I own is a set of punches. They are awesome.You are right that tool is awesome and it comes in this set which has some great AR punches.

Can’t recommend the reaction rods enough.The only thing Geissele that I own is a set of punches. They are awesome.

Sorry, I didn't link the set I was talking about above. Here it is with that trigger guard roll pin tool.

.

.

If you're only buying one I find the Midwest Industries reaction rod the most functional hands down. The "sail" on it helps prevent clocking of the barrel extension in the upper. It's also less expensive than the Geissele.

Last edited:

100% agreef you're only buying one I find the Midwest Industries reaction rod the most functional hands down. The "sail" on it helps prevent clocking of the barrel extension in the upper. It's also less expensive than the Geissele.

I have most of the Wheeler punch sets and I’ll say the Avid Accupunch Master set is much nicer and all in one. Like a lot of the Avid stuff

Last edited:

I favor the design of MWI as well. Surprised KAC and Geissele did not incorporate the sail profile.

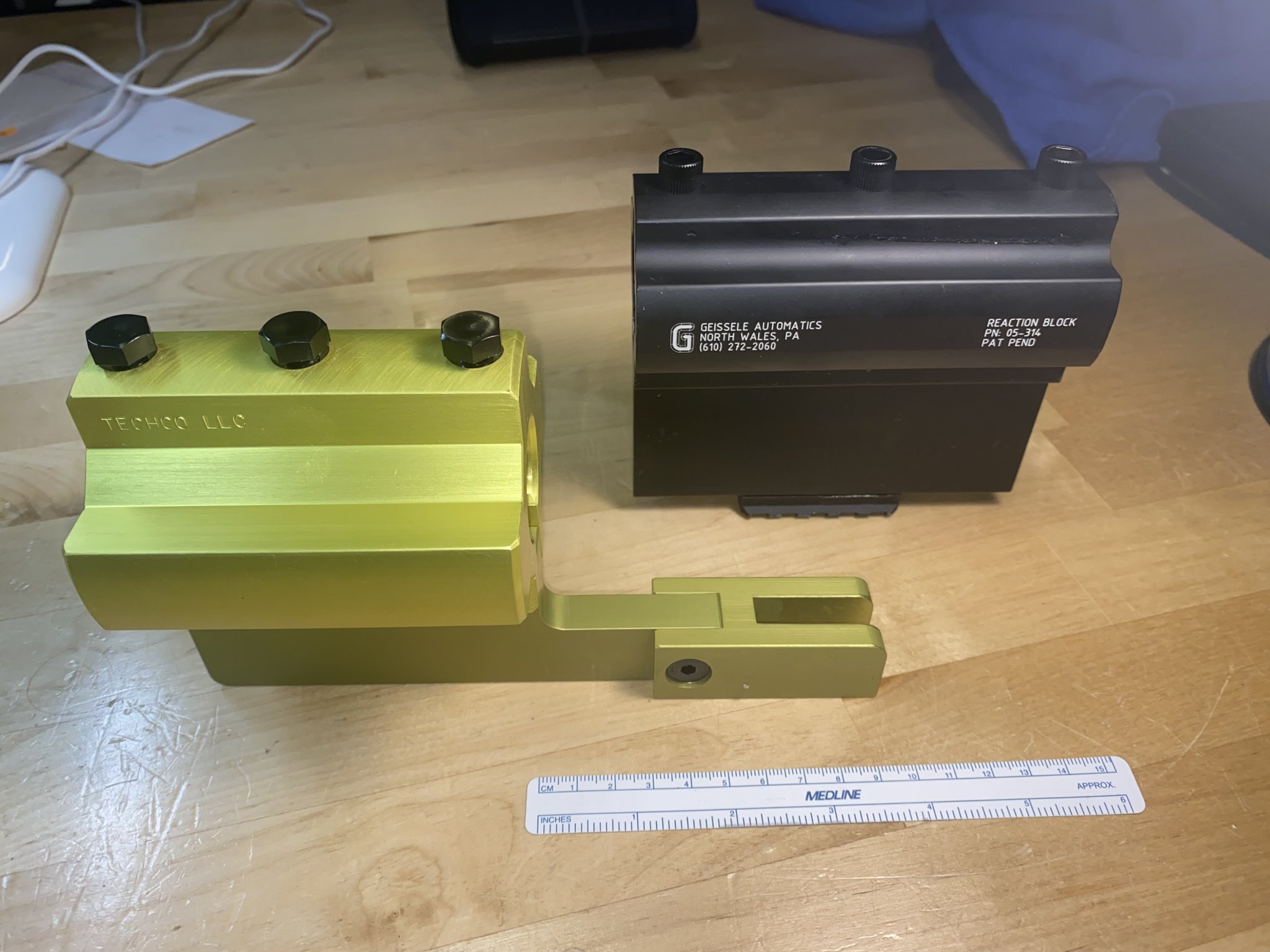

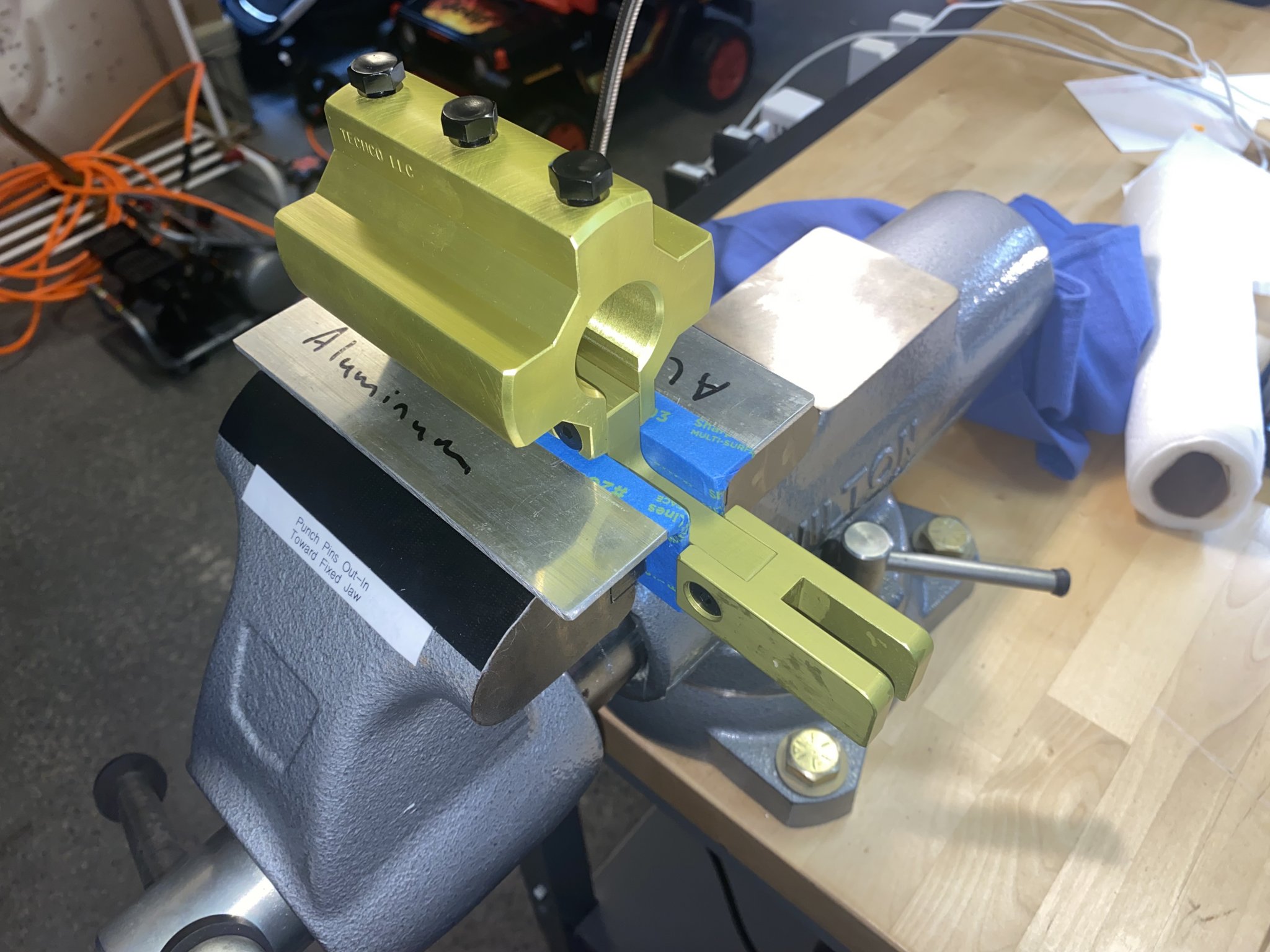

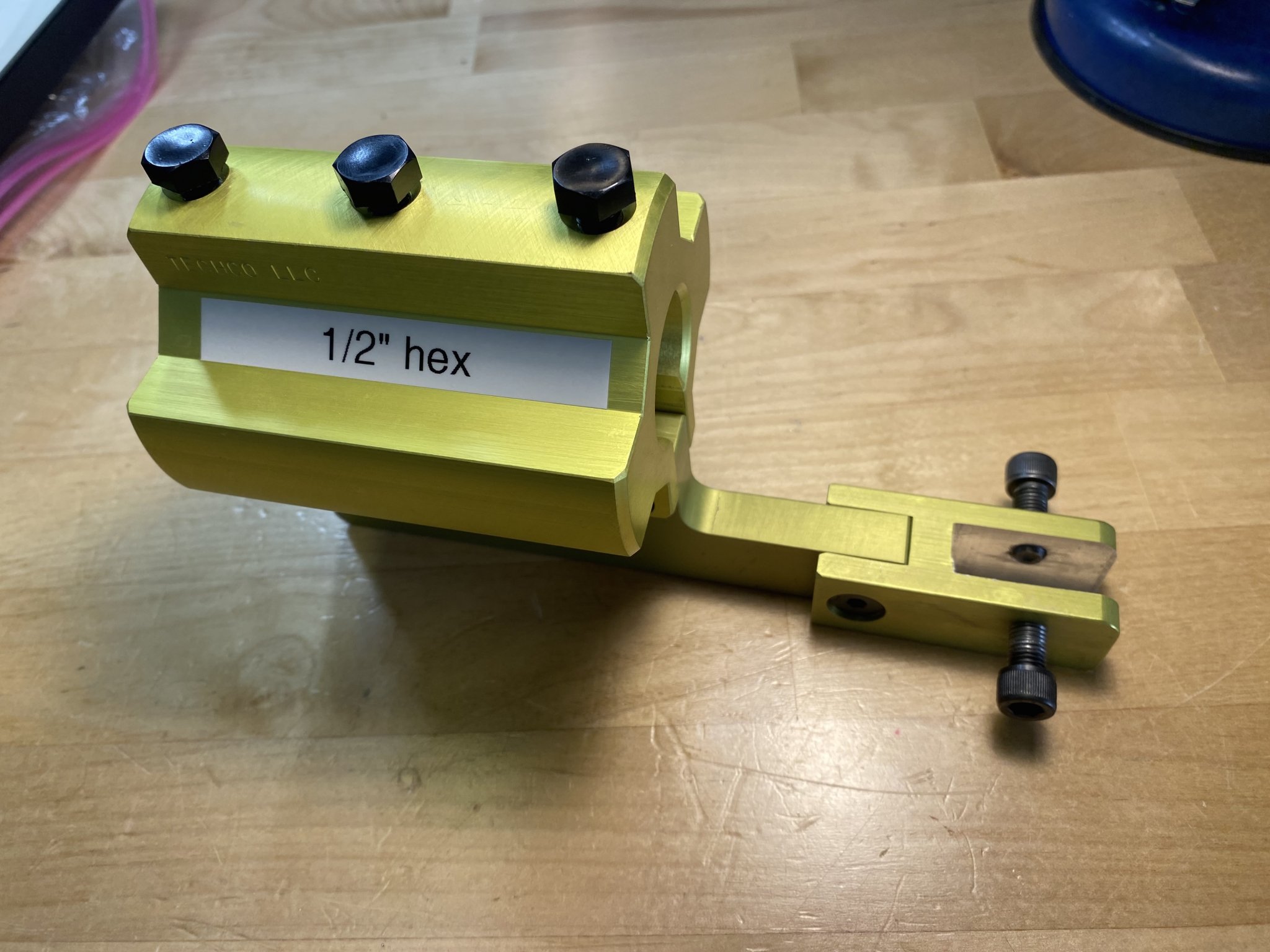

Geissele's and TechCo's receiver extension blocks are pretty handy as well. The extension on the TechCo allows the

lower to remain perfectly square with the receiver extension while tightening / torquing the castle nut.

Geissele's and TechCo's receiver extension blocks are pretty handy as well. The extension on the TechCo allows the

lower to remain perfectly square with the receiver extension while tightening / torquing the castle nut.

For trigger guard installations you can use small hardware store brass plumbing fittings or Delrin drilled with a few relief holes which essentially are small bench blocks, Grade 8 bolt / nut being adjustable in height ; tape protect the brass before using. Need a proper sized roll pin holder starter punch as well. Receivers with coatings will almost always have reduced sized pin holes; chamfer the leading pin edge, use a little grease on the pin hole, cold blue the pin end after installation.

Last edited:

Geiselle makes a set of the gas bllck roll pint starter punches too, but w/o the hammer......................a must have if you many, makes life easy.Sorry, I didn't link the set I was talking about above. Here it is with that trigger guard roll pin tool.

.

MM

How do you install the bolt catch? How do you install the forward assist?I don't use any hammers or punches.

I still use a roll pin starter punch for the trigger guard, FA and bolt stop pins to get them started. But I press them the rest of the way with a 10" Knipex pliers wrench with some tape on the jaws. I've done it for gas tube pins as well.How do you install the bolt catch? How do you install the forward assist?

A real man just pushes those pins in with his fingers. You a real man, right?How do you install the bolt catch? How do you install the forward assist?

Pressed them in with my tiny bench vise quite a few times. And I've used hammers. I've assembled quite a few AR's with no specialized tools actually.How do you install the bolt catch? How do you install the forward assist?

Forward Controls has a nice jig to hold the gas block while inserting the roll pin with proper size punch.Geiselle makes a set of the gas bllck roll pint starter punches

Check out Classified Defense.That's what I'm trying to figure out, what companies sell the quality tools. I'm familiar with automotive work,and woodworking, so I know what the quality tools are and where to buy them, but building ARs is new to me so aside from general tools like, bit drivers, screwdrivers etc, I need to know who makes the best specialized tools.

How do you install the bolt catch? How do you install the forward assist?

Knipex cobra with one soft jaw. And for recessed lowers I have a pin hole drilled on one jaw. A couple quick safe squeezes and the roll pin is in. These are the chrome version with the smooth faces and linear jaw movement.

Last edited:

If you 3d print..a lot of the jigs for pins, gas blocks, etc. can be made for cheap/free.

Tekton for the punches on my end, snagged their gunsmith set on clearance for 60% off, and they'll replace any broken ones for a lifetime.

the old tapco wrench is my favorite as far as armorer wrenches go..and midwest industries reaction rod.

As others have said, you'll likely be better off piecing together your set than buying a premade one.

Tekton for the punches on my end, snagged their gunsmith set on clearance for 60% off, and they'll replace any broken ones for a lifetime.

the old tapco wrench is my favorite as far as armorer wrenches go..and midwest industries reaction rod.

As others have said, you'll likely be better off piecing together your set than buying a premade one.

And when you buy, get off the wallet and get a life time tool you won't regret buying the best tool to avoid screwing up a nice rifle art form.you'll likely be better off piecing together your set than buying a premade one.

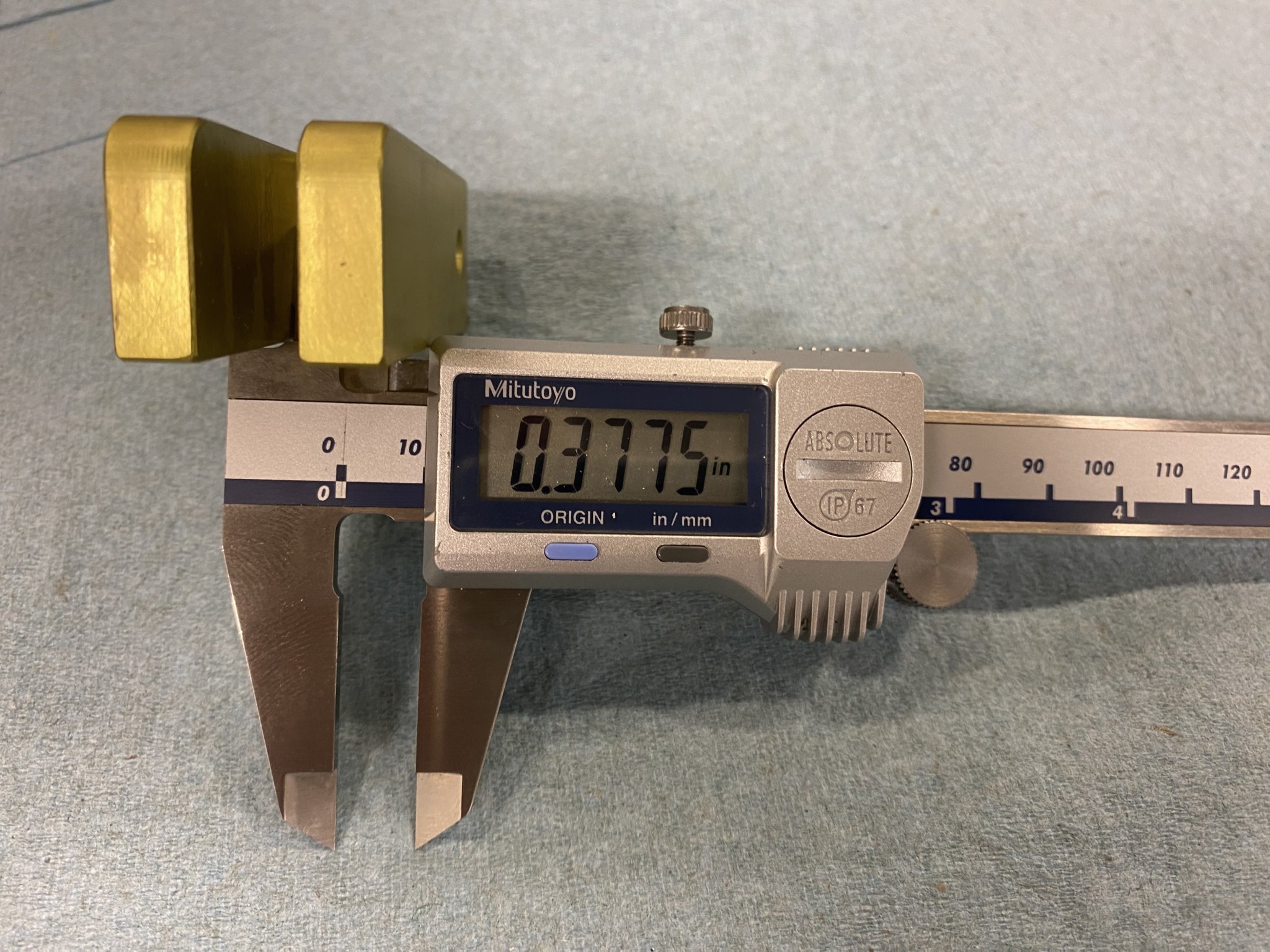

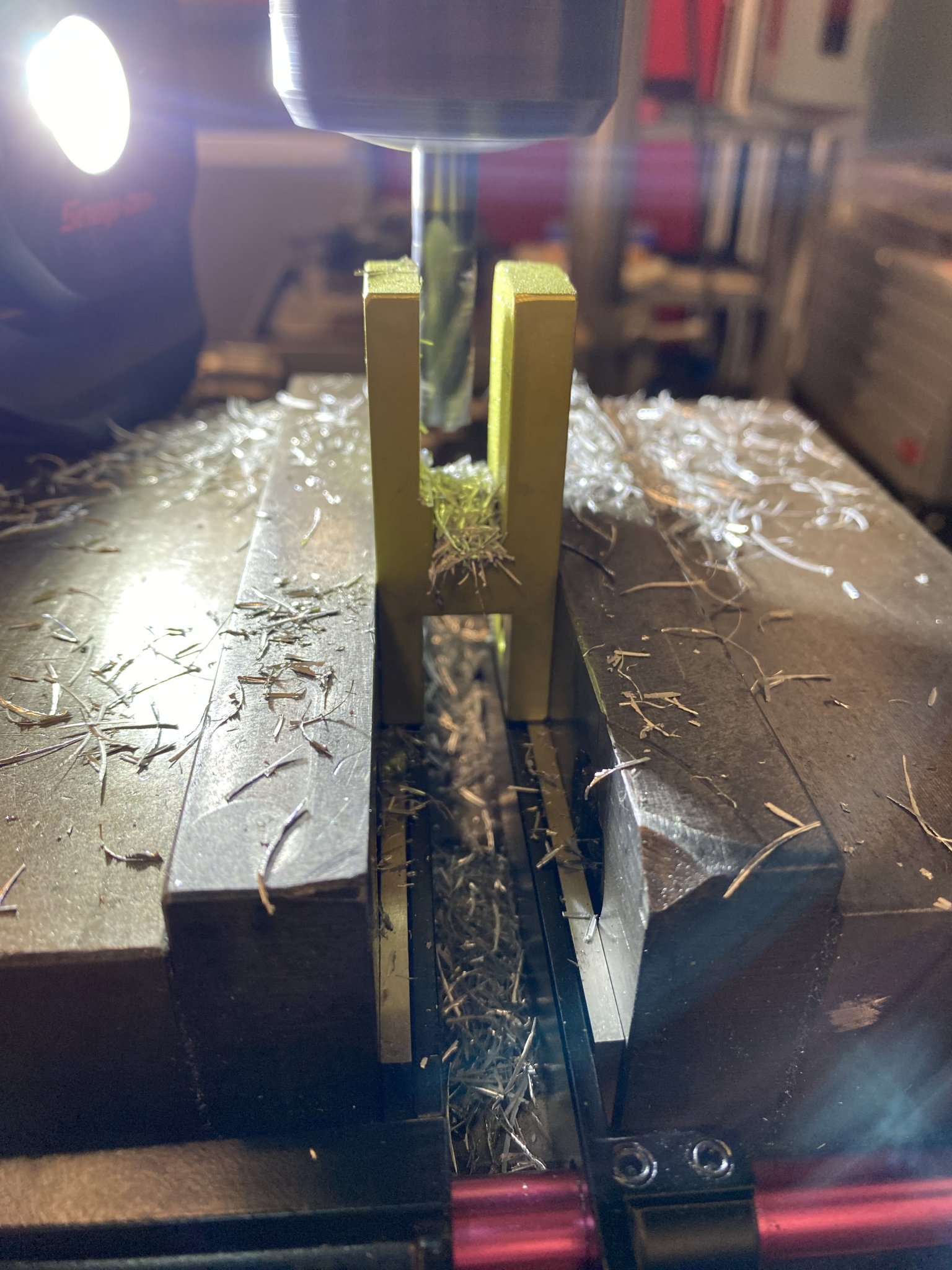

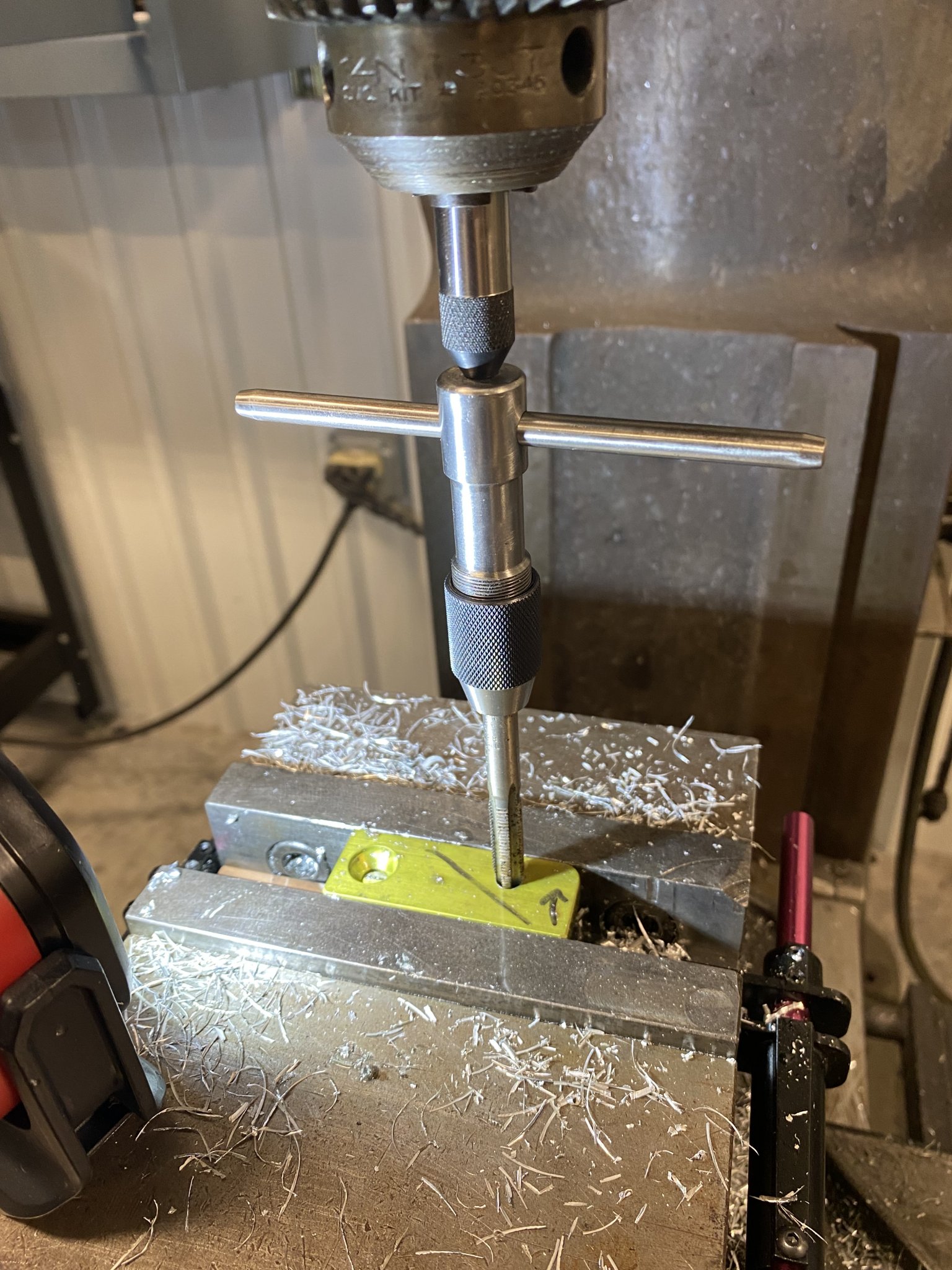

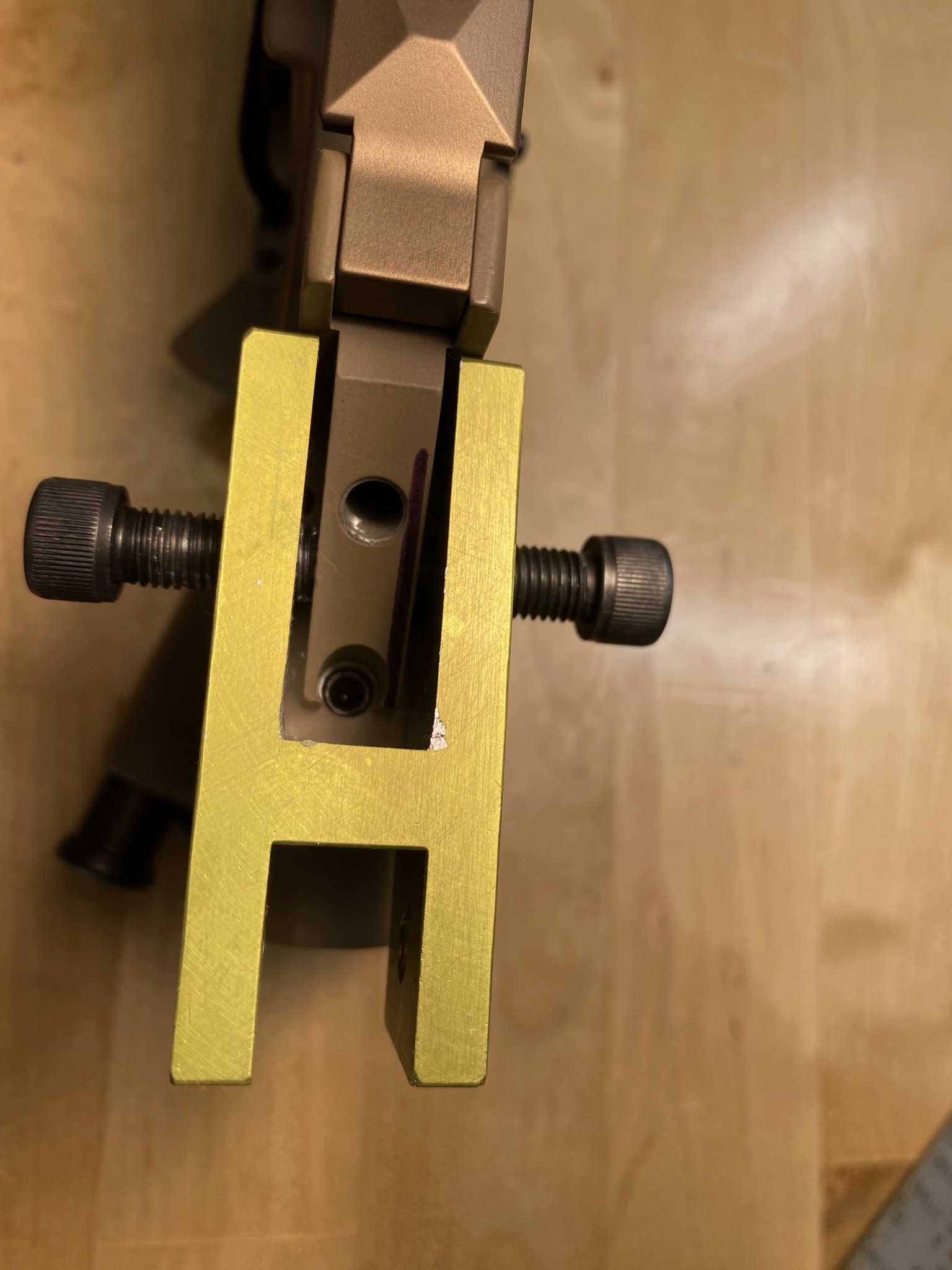

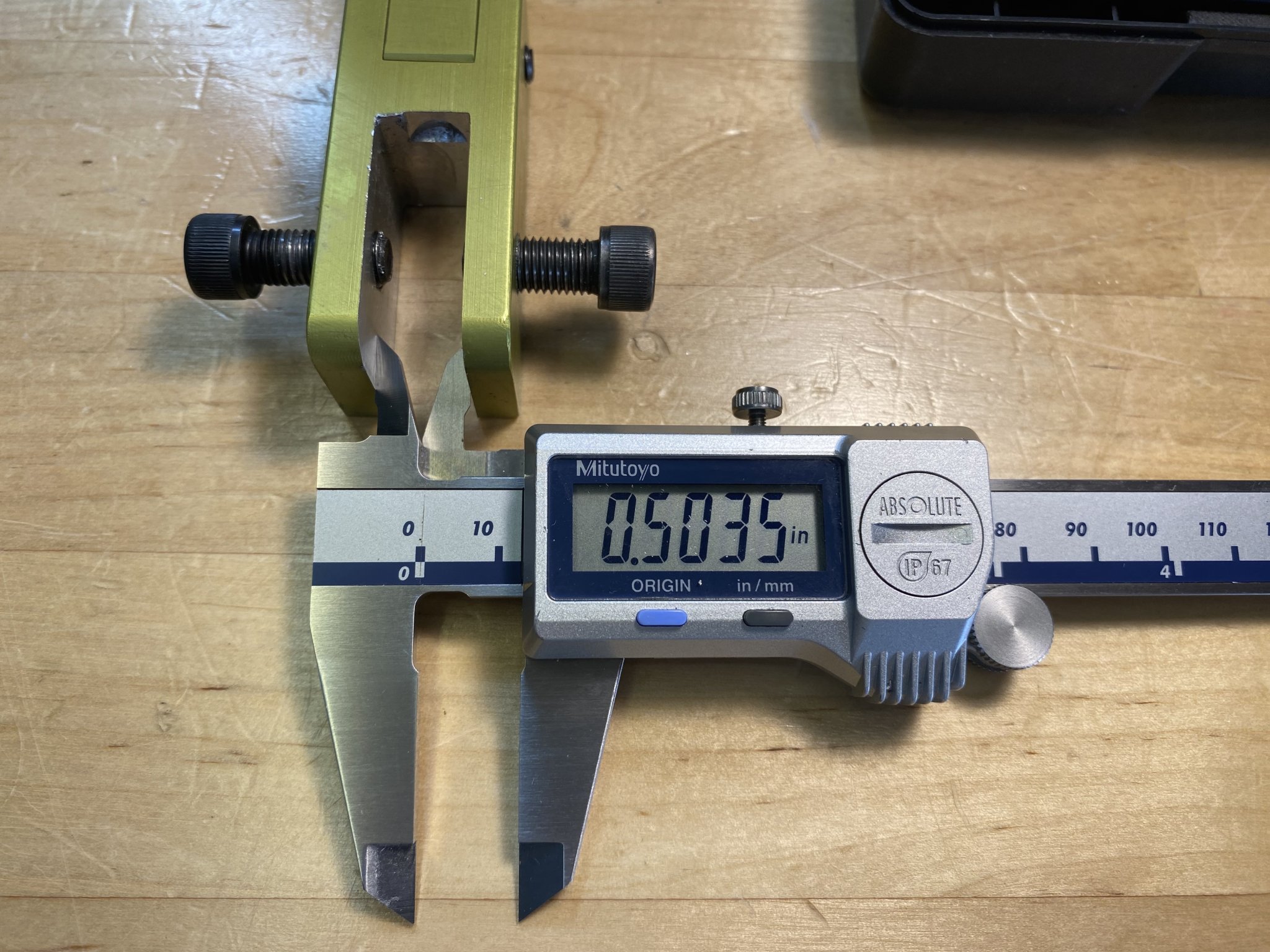

Recently modified that above mentioned TechCo reaction block as it had no flexibility to adjust the width of various AR lower grip tang widths.

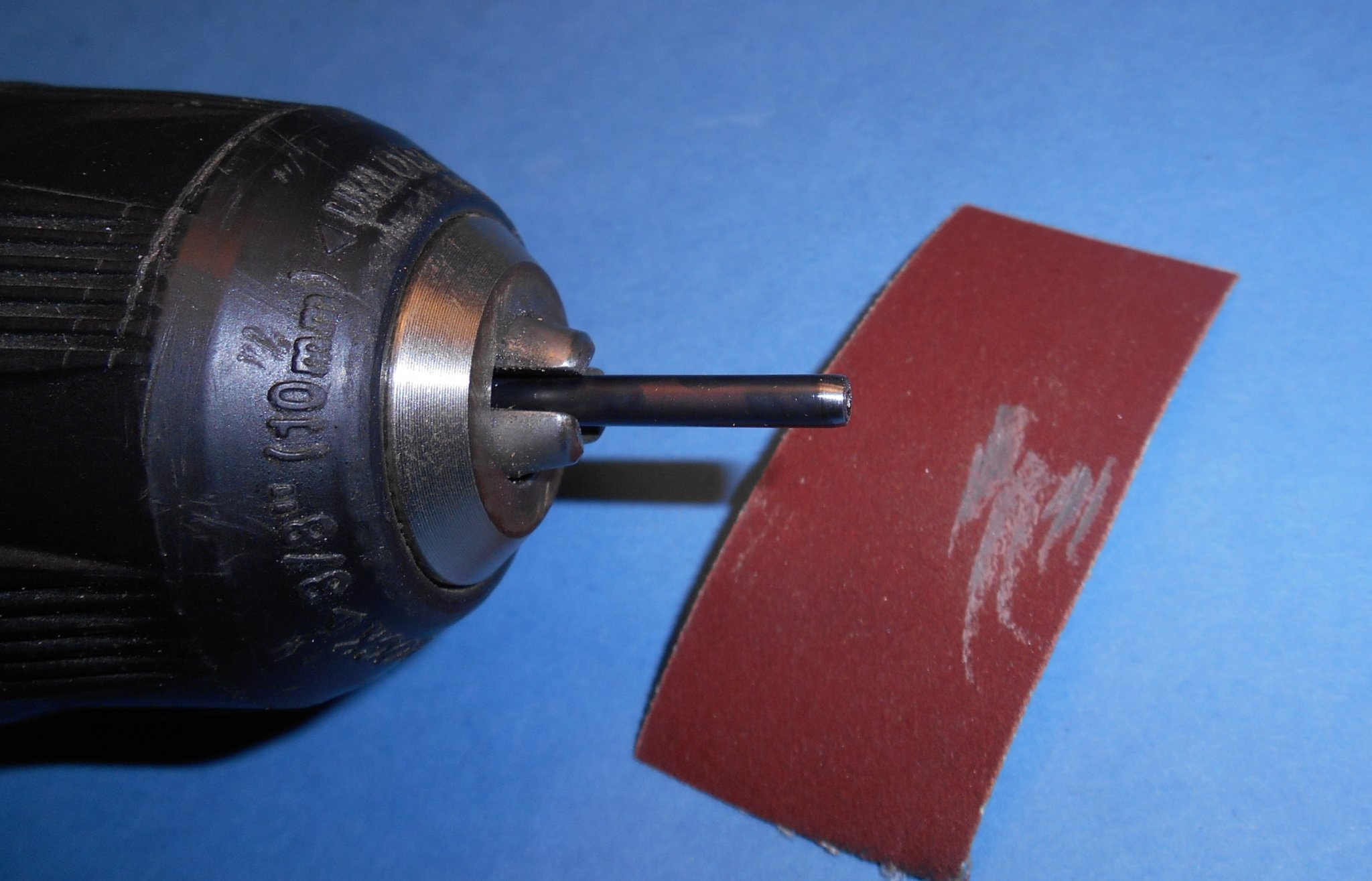

This new Arizona Ranger M4 lower was cerakoted, undoubtedly the root cause for being a few thousandths out of spec., but surprised the tool jig designer did not incorporate a simple method to accommodate tolerance variations. So, the jig grip tang element was 0.3775" of internal space; the M4 grip tang was .03880". Probably could have tapped into the jig at the expense of ruining the cerakote on the grip tang, albeit would never be seen by the judging public. Milled the jig to 0.050" width, the receiver extension jig will secure the lower perfectly square and with some polymer set screws to abut the grip tang for additional stability during use. Now the M4 at hand and for future projects this will not be an issue. Also an excuse to use my new set of Noga internal de-burring tools.

This new Arizona Ranger M4 lower was cerakoted, undoubtedly the root cause for being a few thousandths out of spec., but surprised the tool jig designer did not incorporate a simple method to accommodate tolerance variations. So, the jig grip tang element was 0.3775" of internal space; the M4 grip tang was .03880". Probably could have tapped into the jig at the expense of ruining the cerakote on the grip tang, albeit would never be seen by the judging public. Milled the jig to 0.050" width, the receiver extension jig will secure the lower perfectly square and with some polymer set screws to abut the grip tang for additional stability during use. Now the M4 at hand and for future projects this will not be an issue. Also an excuse to use my new set of Noga internal de-burring tools.

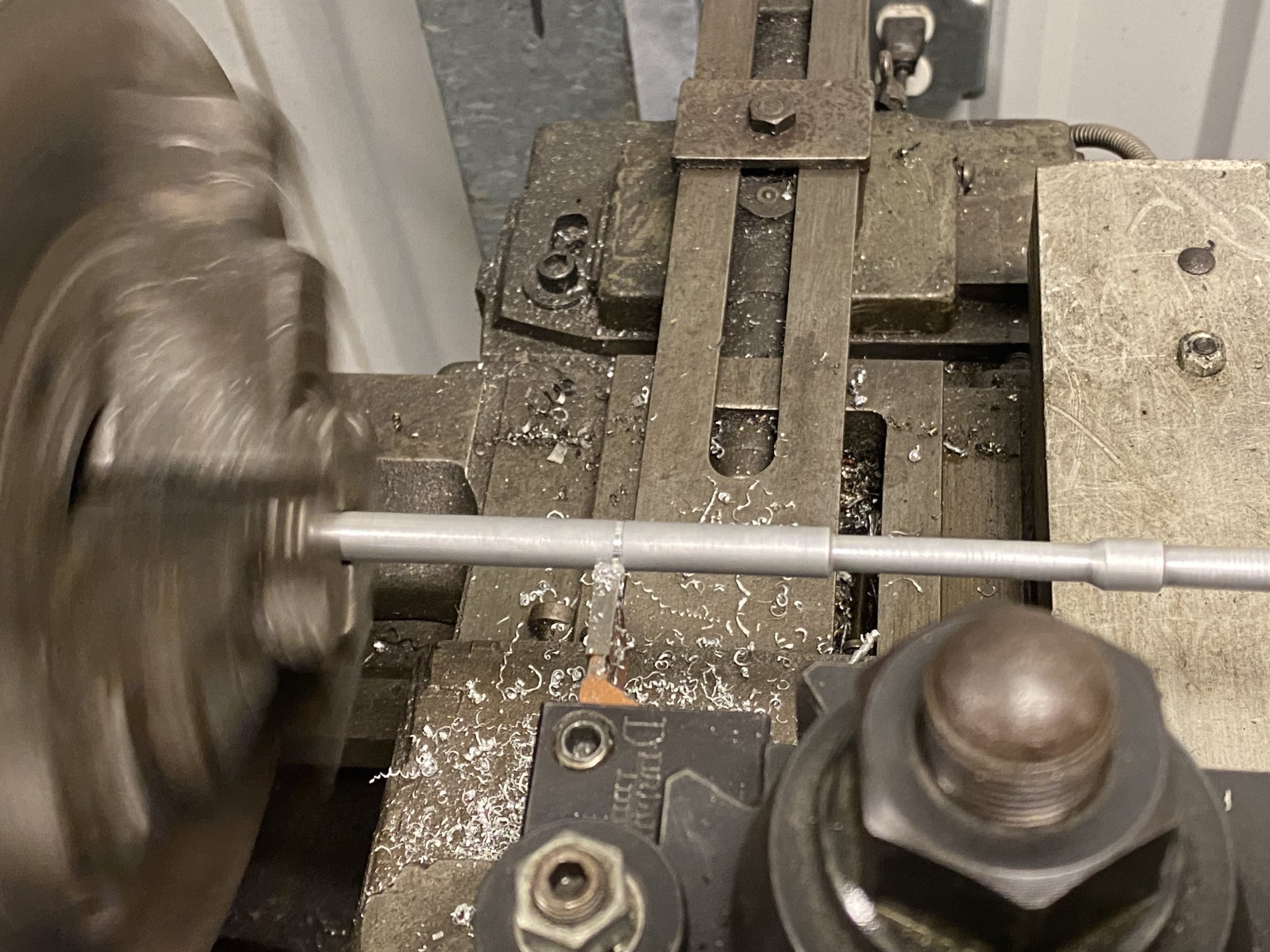

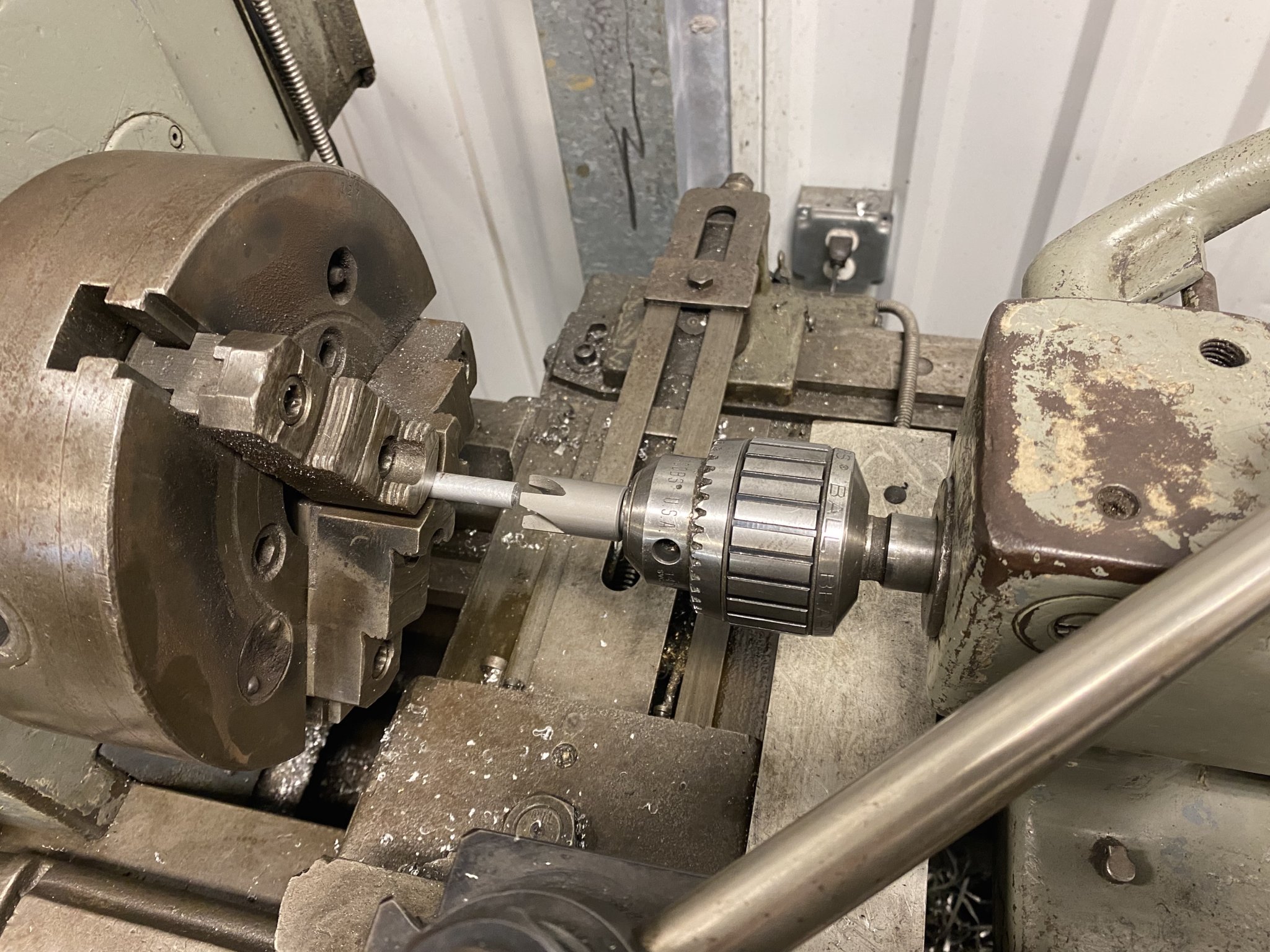

Musing on the lathe today. Fabricated a quick-reference guide gauge for AR carbine / rifle buffer spring lengths. I have observed some AR gunsmiths apply an adhesive measuring tape to the work bench, others take a yard stick for reference. Used 3/8" 6061 aluminum round stock to fabricate a 15" OAL gauge, creating precision Go-NoGo color coded zones for the two common spring lengths.

Sweet!Musing on the lathe today. Fabricated a quick-reference guide gauge for AR carbine / rifle buffer spring lengths. I have observed some AR gunsmiths apply an adhesive measuring tape to the work bench, others take a yard stick for reference. Used 3/8" 6061 aluminum round stock to fabricate a 15" OAL gauge, creating precision Go-NoGo color coded zones for the two common spring lengths.

View attachment 8239611View attachment 8239612View attachment 8239613View attachment 8239614View attachment 8239615View attachment 8239616View attachment 8239617View attachment 8239618View attachment 8239620

Similar threads

- Replies

- 3

- Views

- 143

- Replies

- 18

- Views

- 197