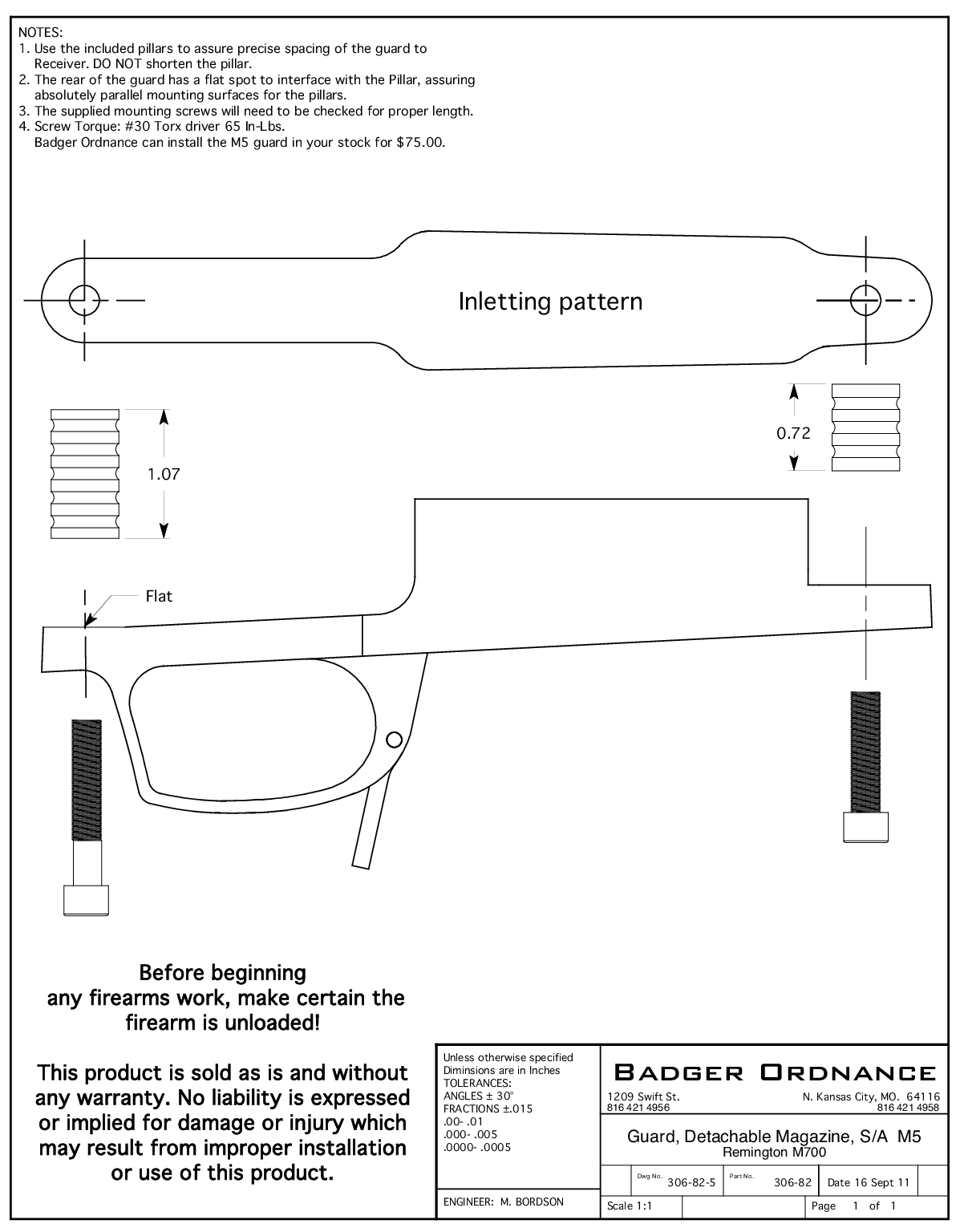

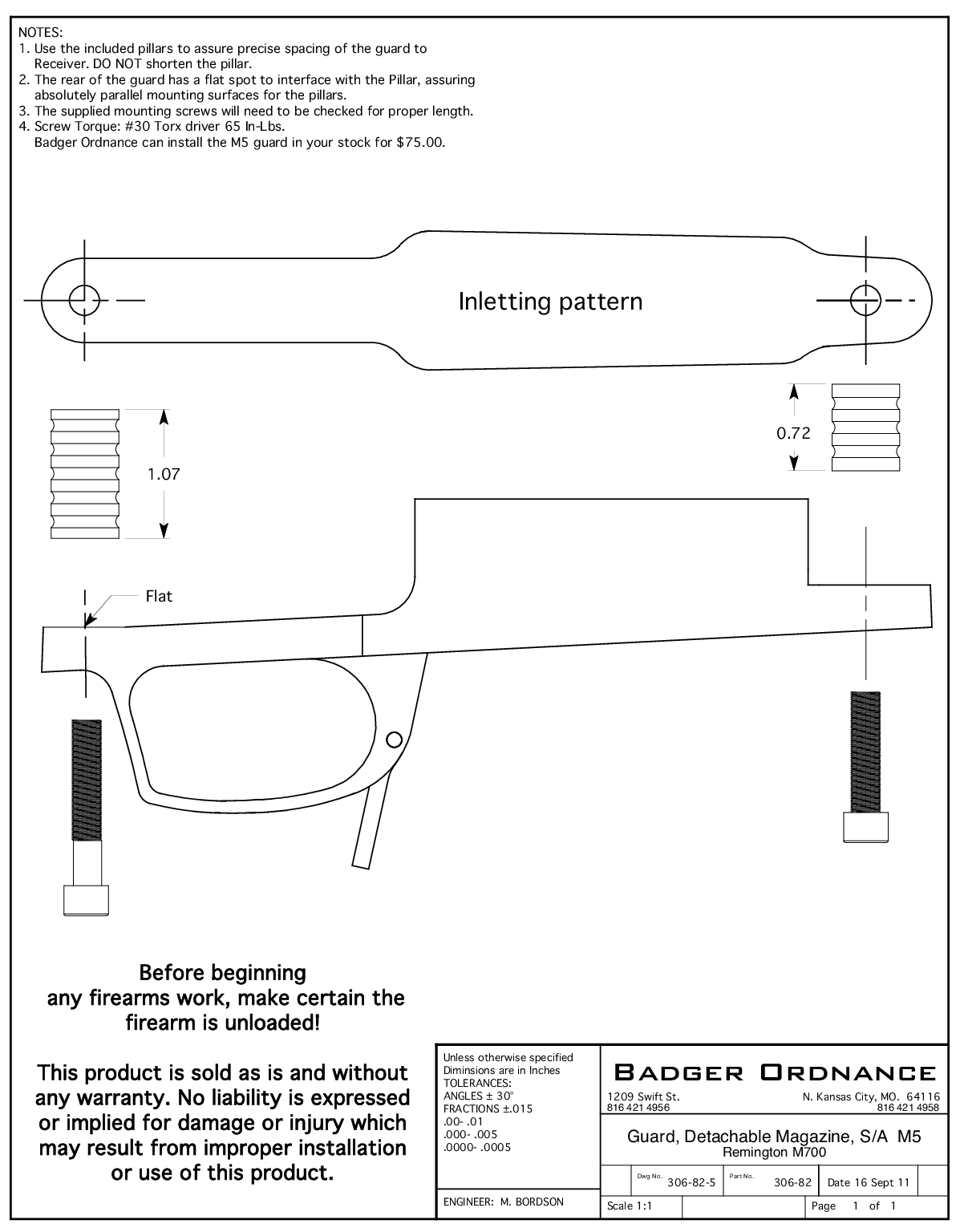

I'm setting up the mill for this and was wondering about what to do about the bedding block. The instructions (see image) for the DBM assume you're installing on a composite stock (I assume) and will be using the included pillar bedding dowels. I've got an HS Precision (R700 S/A) that has an aluminum bedding block so the pillars won't be used, but I'll need to mill the aluminum around the screw holes at the DBM side of the stock to accommodate the deeper seating of the DBM. I suspect that I need to shave them down to 1.07" and 0.72" as per the included dowels, but the current bedding block is curved where it accepts the receiver and the hole is countersunk somewhat on the HSP (see picture). So my question is, where should I measure from to set my mill?