Thanks for the in-depth response on this! I actually haven't bedded the barrel. I have Permatex, but chickened out when I was putting everything together. I remember putting the extension the upper and it would line up, but as soon as torque was applied it should shift over a few degrees, so you're likely dead on.

Is there anywhere that goes over bedding with Permatex? I'm assuming you just coat the barrel extension, place it in the upper, and let it cure. Not sure if the barrel nut should be torqued on while it cures or afterwards.

Bedding barrels was something the US Army AMU started doing on their match AR-15s to tighten them up.

Pretty much every precision shop does some form of bedding or tight-fitting of the extension to the upper, whether it be:

Thermo-fit

Press fit

Sealant and shims

Sealant alone

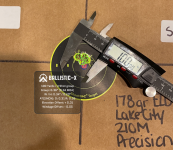

There are some sealants meant for threads and others meant for joints, although I haven’t really seen a difference. Some swear by Loc-tite 648 which is meant for joining cylinders with high heat tolerance. I’ve used Blue 242 with measurable results showing groups dropping from 1.7 MOA down into the .6s, .5s, .4s, and even .3s for 5rd groups. This has all been with top-tier barrels, not rack-grade pipes, across multiple rifles-both AR-15s and AR-10s.

Some companies have even applied some type of red sealant, either Loc-tite or Permatex (used to be the same company).

648 is purpose-built for this application though.

You can also use steel shim foil if there is enough of a gap, combined with Loc-tite.

If you did the assembly, I would consider clocking the barrel extension correctly and ensuring you have positive lock-up and unlocking with no clipping of the lugs through the extension teeth.

I also like to de-edge, blend, and polish my feed ramps on AR-15s and AR-10s, so that the brass is babied, and that meplats from hollow points don’t get hung up on the transition in a worst-case scenario of the cyclic rate competing with the magazine spring.

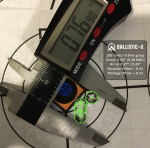

When you seat the barrel with the appropriate bedding approach for your upper and extension, make sure it’s clocked Top Dead Center (TDC) by visually inspecting like you did for the photo. Let the barrel cure into the upper for at least 24hr.

Make sure to grease your upper threads, then torque on the barrel nut. There are different approaches to torque value with the AR-10 and harmonics in general.

One of the AMU armorers did a lot of experimenting with barrel nut torque value and found that with heavier barrels in the AR-15, they required less torque for maximum accuracy, whereas lighter barrels required more torque.

With the AR-10 and larger calibers in the AR-15, we have seen a lean towards higher torque values being preferred.

I’m not aware of a fleet/larger sample size study being done on AR-10 barrel nut torque and its relationship to accuracy, so from personal experience, I will just say that I torque until it “feels right”, not based on a specific value but a more intuitive feeling for the resonant harmonics. Sometimes you can just tell when something feels stressed, versus a happy place. I’ve seen an arbitrary value of at least 60ft-lbs for AR-10s off the top of my head, but I don’t really care about arbitrary values when it comes to seeking accuracy.

Sounds like pseudo-science, but resonant harmonics is a very real thing and is the underlying principle in physics for rifle accuracy. If you have harmonic choke points or loose points that aren’t resolved, they will try to resolve with each shot.

This also applies to the muzzle device and scope ring fastener torque values. Anything with tension on it that can vibrate like a tuning fork in the rifle/mount/optic system contributes to the overall resonant harmonics. The more we can deaden any of the tension points, the better. What we’re doing in effect is making the barrel and upper receiver behave like one piece, vs the barrel rattling around in the upper.