Gunsmithing Barrel Swap Tools

- Thread starter SporterII

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Is the factory barrel already removed?

If so, you just need a barrel vise and the correct action wrench.

I prefer the type that fit into the action vs the external type.

I modified my Zermatt wrench to fit into other actions. That's why it appears to have been filed down.

If so, you just need a barrel vise and the correct action wrench.

I prefer the type that fit into the action vs the external type.

I modified my Zermatt wrench to fit into other actions. That's why it appears to have been filed down.

With the above items pickup this lug alinement tool if you have your stock bedded .

https://www.brownells.com/gunsmith-...00-h-recoil-lug-alignment-tool-prod72388.aspx

https://www.brownells.com/gunsmith-...00-h-recoil-lug-alignment-tool-prod72388.aspx

Got for basically all rem and sav footprint actions without an integral scope base. Swapping out the bolts for longer will let you flip the top and use it on flat bottom actions even.

northlandshooterssupply.com

northlandshooterssupply.com

Plus other parts and tools like the lug alignment mentioned above etc

northlandshooterssupply.com

northlandshooterssupply.com

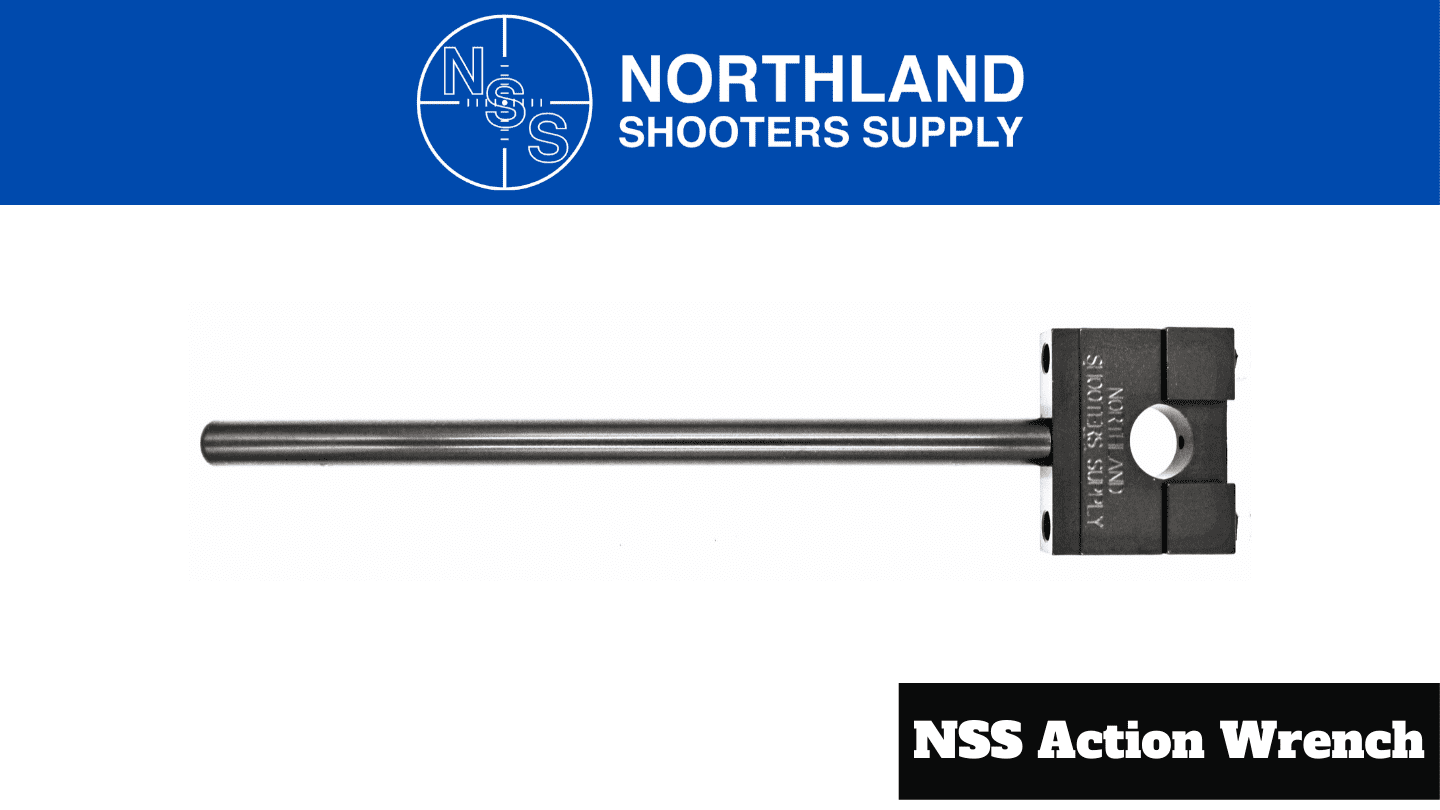

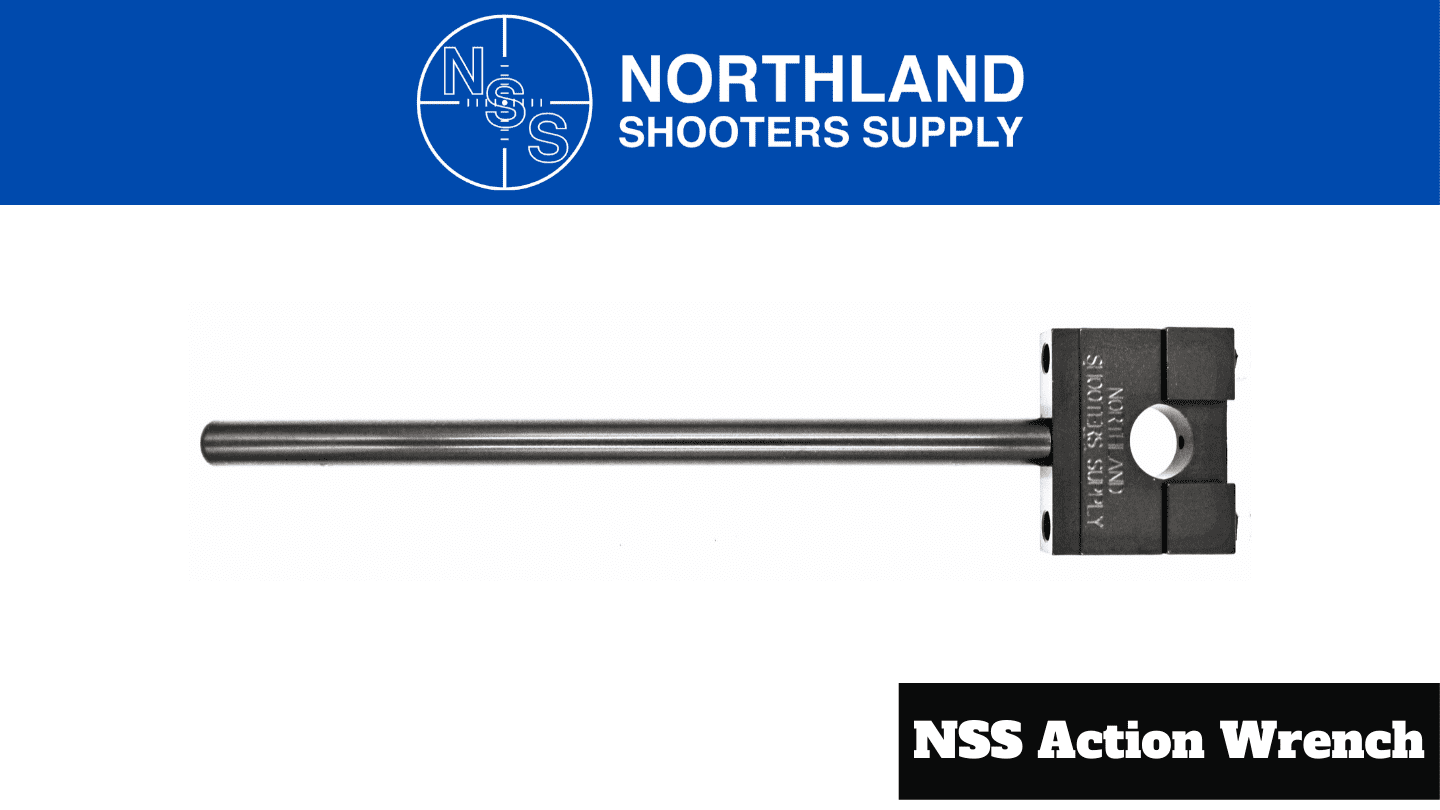

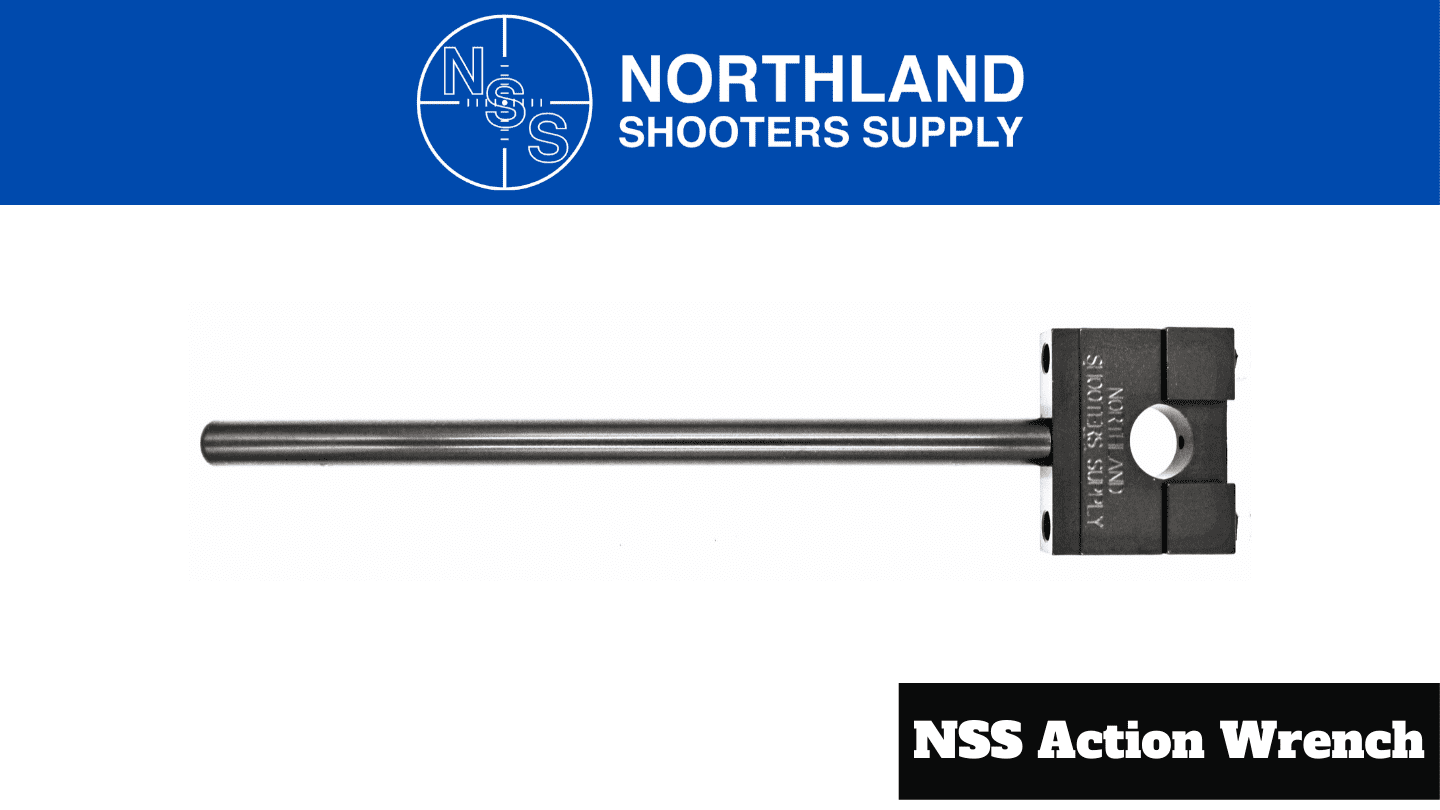

NSS ACTION WRENCH | Northland Shooters Supply

Northland Shooters Supply (NSS) designed an action wrench called the NSS Action Wrench which corrects the interference issues created when Savage went to the 4.4″ short-action action-screw spacing.

Plus other parts and tools like the lug alignment mentioned above etc

Parts and Tools| Northland Shooters Supply

Northland Shooters Supply (NSS) offers parts and tools for your next custom rifle build.

Yup those tools in the first post but I would advise to get your recoil lug pinned. That way you won’t have to worry about alignment.

Yep, forgot about that because everything I have with an aftermarket barrel has a pinned lug.

15 or so years ago I bought a PTG bolt body and Tig welded it to a 3/8" drive socket extension.

Figure our burn rate is around 150 barrels a month. That is at least 3 installs and 3 removals before final assembly. More if we stock the gun, ceracote, or finish the parts. For the sake of keeping this relatively easy to estimate, I'm ignoring removals of take-off barrels and the other riff-raff jobs like muzzle threading, fluting, etc... Long story short, 150x3 is a very, very conservative number.

150*3= 450

X 15 years. That lands you somewhere around 81,000 duty cycles.

Still going. . .

Hope this helps.

C.

If you want a barrel vise that'll be here when the roaches take over the planet, here's one answer to that problem.

LRI SuperDuty Barrel Vise and Collet set. 100% machined steel.

Shown here in Case Color Hardening.

Figure our burn rate is around 150 barrels a month. That is at least 3 installs and 3 removals before final assembly. More if we stock the gun, ceracote, or finish the parts. For the sake of keeping this relatively easy to estimate, I'm ignoring removals of take-off barrels and the other riff-raff jobs like muzzle threading, fluting, etc... Long story short, 150x3 is a very, very conservative number.

150*3= 450

X 15 years. That lands you somewhere around 81,000 duty cycles.

Still going. . .

Hope this helps.

C.

If you want a barrel vise that'll be here when the roaches take over the planet, here's one answer to that problem.

LRI SuperDuty Barrel Vise and Collet set. 100% machined steel.

LRI SuperDuty Series: Professional Gunsmithing Barrel Vise

The "LRI SuperDuty Series" of products are made to answer the need for commercial-grade tools specific to the gunsmithing industry. These tools have been vetted in our own facility for years (sometimes in excess of a decade) prior to being offered to the public. The SuperDuty Barrel Vise has...

www.longriflesinc.com

Shown here in Case Color Hardening.

worse thing about moving from the black hills is losing the ability to stop into LRI regularly and see cool shit like a case hardened barrel vice.

I left there in late '04 and not a day has gone by that I haven't thought about returning.

Been back a few times for visits and I still miss the people and the place.

Last edited:

James was advising me to get this for my Origin. I like the idea of not putting load on the lugs by using this.Got for basically all rem and sav footprint actions without an integral scope base. Swapping out the bolts for longer will let you flip the top and use it on flat bottom actions even.

NSS ACTION WRENCH | Northland Shooters Supply

Northland Shooters Supply (NSS) designed an action wrench called the NSS Action Wrench which corrects the interference issues created when Savage went to the 4.4″ short-action action-screw spacing.northlandshooterssupply.com

Plus other parts and tools like the lug alignment mentioned above etc

Parts and Tools| Northland Shooters Supply

Northland Shooters Supply (NSS) offers parts and tools for your next custom rifle build.northlandshooterssupply.com

I also like the idea of not needing to remove the scope rail, and not potentially scratching up the finish on the receiver by using an internal wrench.

Thoughts?

I find that the scope rail isnt a big issue, its pinned, it goes right back to where it was and its just 4 little screws, its easy.James was advising me to get this for my Origin. I like the idea of not putting load on the lugs by using this.

I also like the idea of not needing to remove the scope rail, and not potentially scratching up the finish on the receiver by using an internal wrench.

Thoughts?

I like that Ive used the same nss action wrench on rem 700s, howa 1500, origins, nucleus, rugers.

The only finish Ive had marred at all is the one I cerakoted myself and globed the shit on thicker than hell so it doesnt surprise me in the least it has a faint shading difference because I made it so much fatter that it should have been before I squeezed the wrench on it.

What do you torque your barrel nuts to on your Origin?I find that the scope rail isnt a big issue, its pinned, it goes right back to where it was and its just 4 little screws, its easy.

I like that Ive used the same nss action wrench on rem 700s, howa 1500, origins, nucleus, rugers.

The only finish Ive had marred at all is the one I cerakoted myself and globed the shit on thicker than hell so it doesnt surprise me in the least it has a faint shading difference because it got so much fatter that it should have been before I squeezed the wrench on it.

I'm consolidating a few rifles down into a single action with the Origin so I only need the tool for one rifle.

70-100, depends on if I ate my wheaties that morning or notWhat do you torque your barrel nuts to on your Origin?

I'm consolidating a few rifles down into a single action with the Origin so I only need the tool for one rifle.

if you want an outside action wrench I would look into Brownells as they have heads for just about any action you might have. The action wrench is extremely well made and you will be able to pass it off to your progeny after you get too old to use it.

If swapping shouldered prefits then just get an inside the action wrench. They don’t hurt anything and are easier to use. Slide it in like the bolt. Done.

Similar threads

- Replies

- 12

- Views

- 386