I am not sure if I want to bed my MPA chassis. Has anyone found that theirs absolutely needed or did not need to be bedded?

Gunsmithing Bed or Not, MPA Competition chassis

- Thread starter antithesis

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

No need to.

I'm of the opinion that while chassis' are remarkably consistent, tolerances are tolerances. A light bedding of the recoil lug specifically can help any rifle be more consistent.

But it's not without a downside: on metal chassis, it can be difficult to apply/remove bedding without scuffing surface to an extent. This will *potentially* hurt any resale value if that's important. For me, I'd rather be confident in every shot while I own the system rather than worry about possibly selling for a few bucks less in the future.

Every bolt rifle I've owned has been bedded to some extent to ensure consistency. My .02 cents anyway.

But it's not without a downside: on metal chassis, it can be difficult to apply/remove bedding without scuffing surface to an extent. This will *potentially* hurt any resale value if that's important. For me, I'd rather be confident in every shot while I own the system rather than worry about possibly selling for a few bucks less in the future.

Every bolt rifle I've owned has been bedded to some extent to ensure consistency. My .02 cents anyway.

I should add though that MPA has the ability to use wedge lock recoil lug system which would likely help with consistency nearly as much as bedding. But it could also add some stress to system if tolerances are off slightly.

No need to bed, especially with the new lock lug

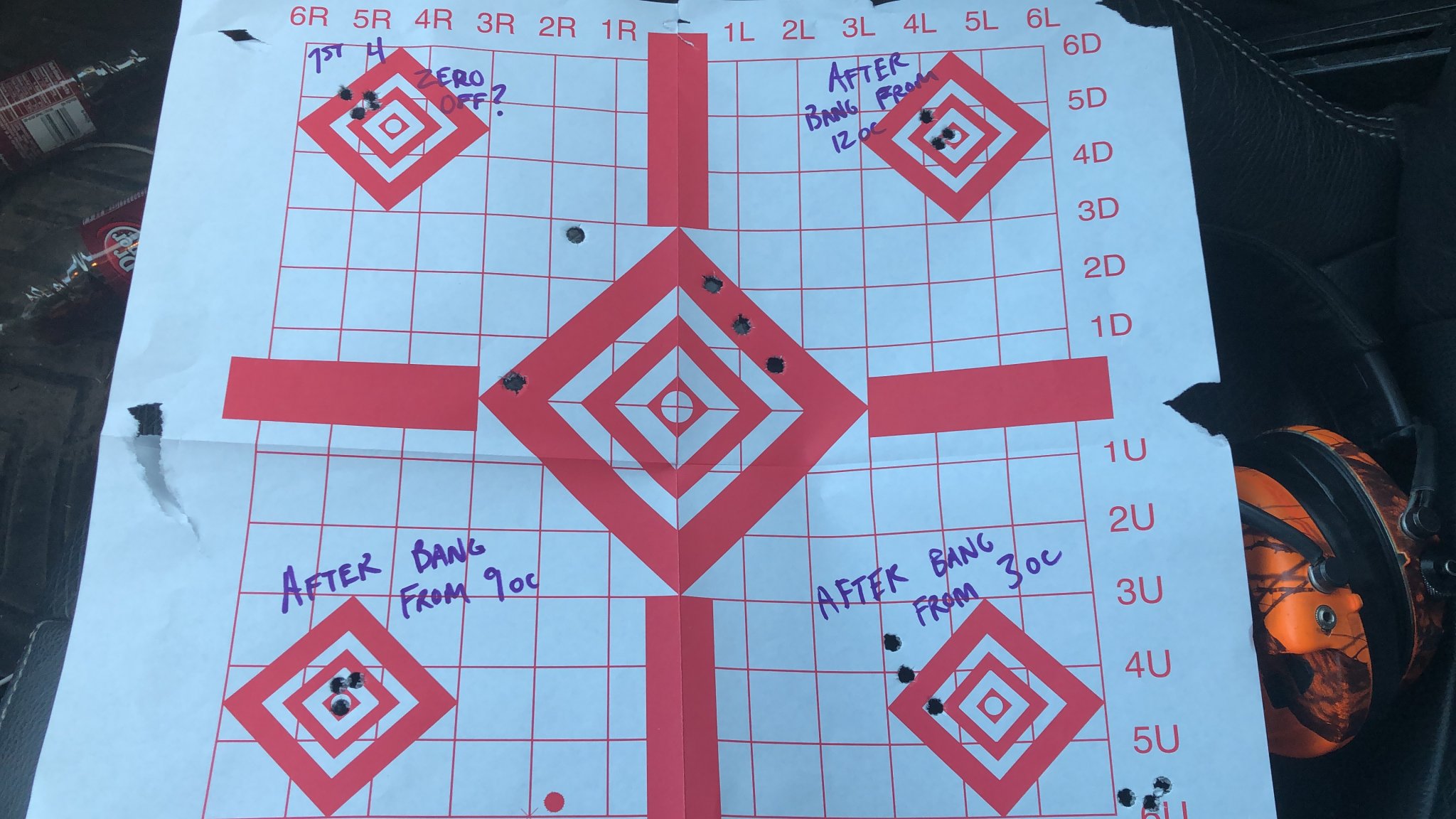

4 outside diamonds are my rounds...after bumping the barrel on the bench between each group...

It ain’t me that was shifting...Cause my AI holds and after bedding the MPA, now it does also

It ain’t me that was shifting...Cause my AI holds and after bedding the MPA, now it does also

I've bedded both my MPA chassis for exactly the same reason. More repeatable when taking action in/out of the chassis. No shifting of zero if you bang it against something.

My 300wm in an MPA chassis kept coming loose. I tried blue lock tight, re torquing the action screws mid way through the matches, but it kept working loose. I finally got fed up and bedded the recoil lug. Boom-it’s been rock solid since with zero issues.

4 outside diamonds are my rounds...after bumping the barrel on the bench between each group...

It ain’t me that was shifting...Cause my AI holds and after bedding the MPA, now it does also

Well that is rather definitive. Thanks. Did you only bed the lug or the 3/4 receiver?

I have bedded aluminum before. I have a blaster box which makes it rather easy to get the bedding to stick. Resale? Yeah would likely lower it for sure. The plus (negative?) side of that one is if I don't like it I will be pissed enough that I would happily take a noticeable loss just to make it go away.

I just bed the front pad/recoil lug recess and then the back pad...I don’t worry about getting everything full length and perfect

If your chassis is not supporting the sides of the action all the way up to the waterline it could be more prone to POI shifts when bumped. Exceptions would be glue-in systems like factory A.I.

If the user insures the rear of the lug is seated against the lug seating face of whatever the chassis is before torquing the action screws, why would you need a lug pinching / locking lug type of hardware?

./

If the user insures the rear of the lug is seated against the lug seating face of whatever the chassis is before torquing the action screws, why would you need a lug pinching / locking lug type of hardware?

./

I get it on a high recoil cartridge. Certainly it ought to help for magnums or ELR cartridges no matter what it's in. However, on a low recoil cartridge (CM, x47L, Dasher, BR, etc.) I cannot imagine it doing much if everything is correct, and I would avoid unless the rifle is just not grouping across the nodes. I've bedded and accurized quite a few Rugers and other hunting rifles, but I completely expect a chassis, competition to not need this. That said, some people bed scopes, so whatever works!

If it won't shoot under 1MOA consistently I might bed it, but I'd probably suspect something else and at least switch barrels first. It's in my log, but I want to say that during load development I shot 30+ (almost 40 shot string before a flier) with the comp rifle under 1MOA. I'm on barrel #3, and it is absolutely repeatable. My rifle probably won't hunt in a BR comp, but in tactical steel it is all me. Further precision is pointless. You could chase it for 100 years and it'll still be less than 1% of your wind calls and mirage reading. Chasing tiny groups really isn't very helpful IMHO. That is what I really love about our sport. You need an accurate rifle, but that only gets you a ticket to play.

If it won't shoot under 1MOA consistently I might bed it, but I'd probably suspect something else and at least switch barrels first. It's in my log, but I want to say that during load development I shot 30+ (almost 40 shot string before a flier) with the comp rifle under 1MOA. I'm on barrel #3, and it is absolutely repeatable. My rifle probably won't hunt in a BR comp, but in tactical steel it is all me. Further precision is pointless. You could chase it for 100 years and it'll still be less than 1% of your wind calls and mirage reading. Chasing tiny groups really isn't very helpful IMHO. That is what I really love about our sport. You need an accurate rifle, but that only gets you a ticket to play.

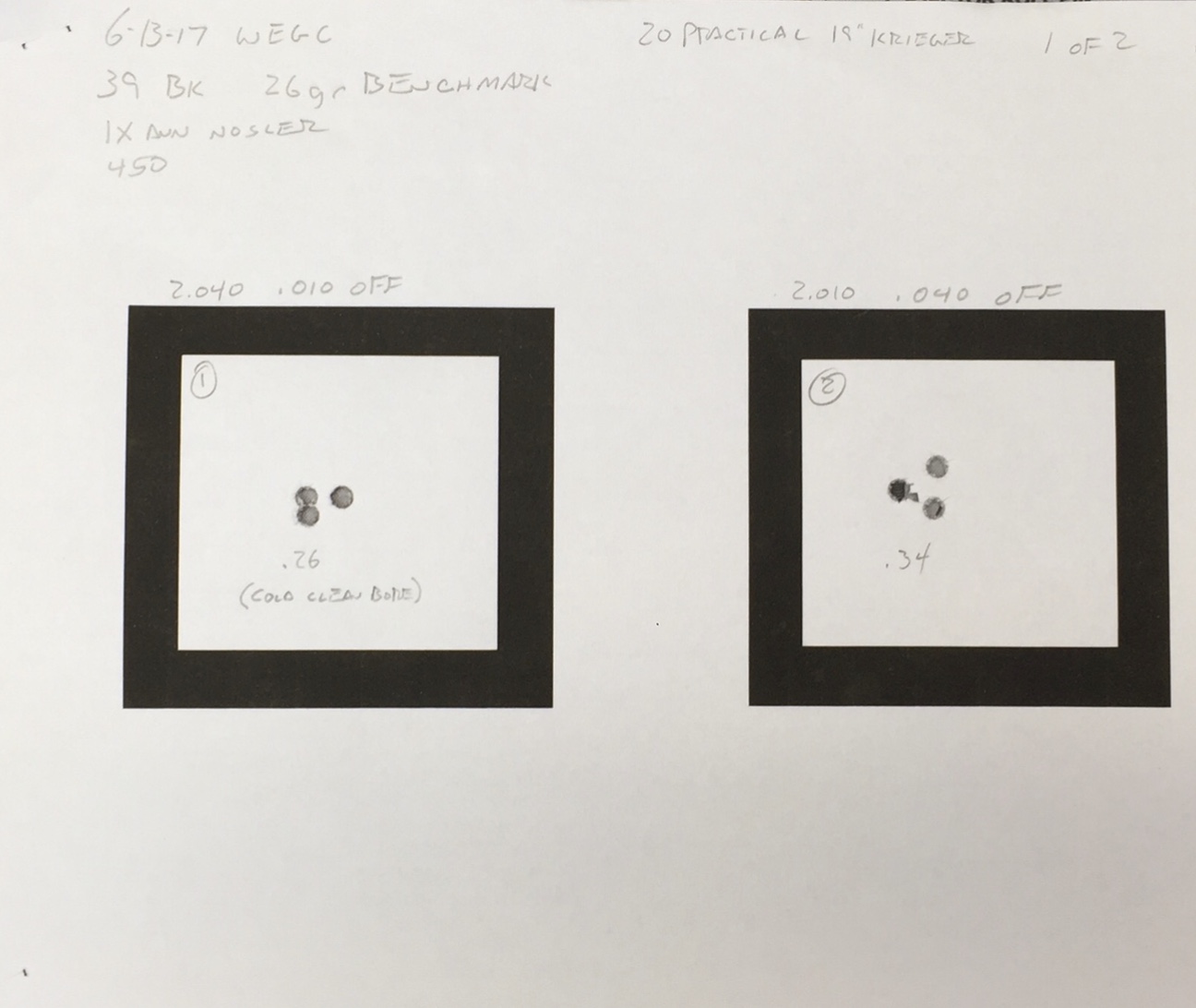

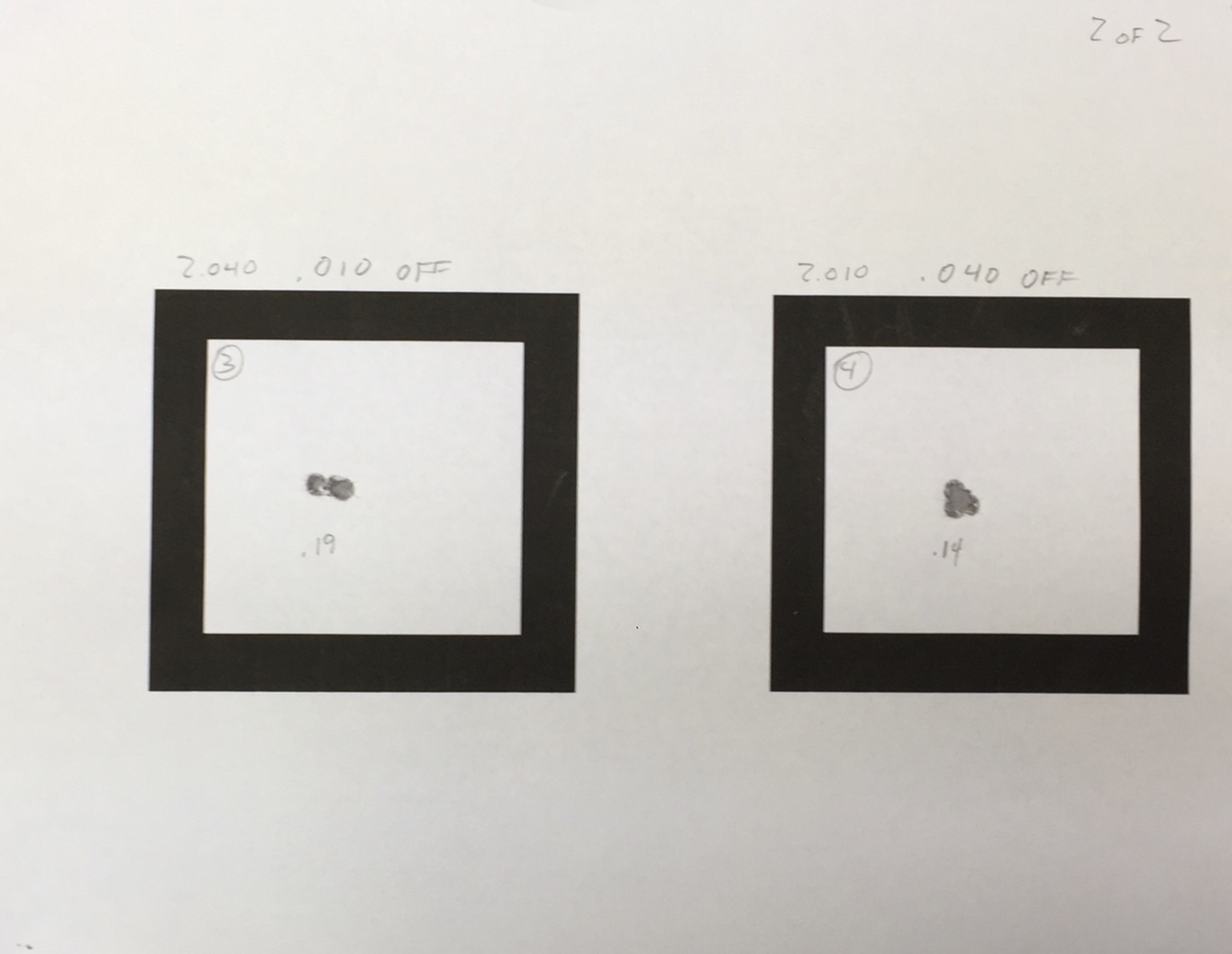

I suspect this has a lot to do with the specific receiver you’re using, and how true and square it is. I built a TL3 20 practical using a Krieger, and put it in an imbedded BA Lite MPA. The gun shot really well but thanks to PT&G, the ass end of the reamer was tighter than I had specified. I took the entire gun apart so I could hone the back of the chamber in the lathe. Screwed it all back together with the same torque values everywhere, and the zero didn’t move at all. I continued with the load development with no adjustments.

Here are the targets after the chamber adjustment.

Here are the targets after the chamber adjustment.

Last edited:

I suspect this has a lot to do with the specific receiver you’re using, and how true and square it is.

Deviant Tactical action, Bartein barrels. APR is doing the machine work.

I get it on a high recoil cartridge. Certainly it ought to help for magnums or ELR cartridges no matter what it's in. However, on a low recoil cartridge (CM, x47L, Dasher, BR, etc.) I cannot imagine it doing much if everything is correct, and I would avoid unless the rifle is just not grouping across the nodes. I've bedded and accurized quite a few Rugers and other hunting rifles, but I completely expect a chassis, competition to not need this.

More about holding zero than tiny groups. Go to a competition, hike around, get in the back of a pickup truck for a ride to the next stage, etc. Rifle gets bumped... all of a sudden you are hitting 0.3 mils off on everything. I've seen it happen in unbedded chassis many times. Doesn't matter if it groups good if the group isn't on the target.

I don't bed my MPA or use the locking lug. Haven't seen any POI shifts. Wouldn't mess with it in my opinion. But my action came from SAC...… Never had a problem with their defiance actions needing to be bedded on an MPA chassis.

More about holding zero than tiny groups. Go to a competition, hike around, get in the back of a pickup truck for a ride to the next stage, etc. Rifle gets bumped... all of a sudden you are hitting 0.3 mils off on everything. I've seen it happen in unbedded chassis many times. Doesn't matter if it groups good if the group isn't on the target.

Do you or @morganlamprecht have any resources on how to do this type of bedding?

Do you or @morganlamprecht have any resources on how to do this type of bedding?

Not really that complicated. I loosely followed this series of videos (starts at 1, goes through part 8)

.

Dremmeled/sanded the v-block in the chassis to roughen up the cerakote. Cleaned with acetone. Prepped the action with putty in holes, johnson paste wax for release, taped up sides and front of recoil lug like in the video. MarineTex, put into chassis with just light screw pressure, then let it set up. Worked great. Not pretty like an LRI bedding job but did the trick well enough.

Not really that complicated. I loosely followed this series of videos (starts at 1, goes through part 8)

.

Dremmeled/sanded the v-block in the chassis to roughen up the cerakote. Cleaned with acetone. Prepped the action with putty in holes, johnson paste wax for release, taped up sides and front of recoil lug like in the video. MarineTex, put into chassis with just light screw pressure, then let it set up. Worked great. Not pretty like an LRI bedding job but did the trick well enough.

Thanks man

I don't believe that its needed.

Necro post because I have a question....If your chassis is not supporting the sides of the action all the way up to the waterline it could be more prone to POI shifts when bumped. Exceptions would be glue-in systems like factory A.I.

If the user insures the rear of the lug is seated against the lug seating face of whatever the chassis is before torquing the action screws, why would you need a lug pinching / locking lug type of hardware?

./

Tagging because Im not sure you willremember this when it pops up

@Terry Cross

Mr Cross, say some moron (not me this time!) bedded an IMB and it causes the barreled action to sit wonky as crap in the IMB (about 1/8 sideways shift of the barrel at the end of the stock).

Bedding has been removed from recoil lug area (was poorly done can came out with minimal effort) but still some in the chassis where the bottom of the action contacts and it is still sittingcrooked.

Any good tips on a hillbilly removing the bedding from an IMB at home without buggering it?

Honestly, I can't offer any direction for that.Necro post because I have a question....

Tagging because Im not sure you willremember this when it pops up

@Terry Cross

Mr Cross, say some moron (not me this time!) bedded an IMB and it causes the barreled action to sit wonky as crap in the IMB (about 1/8 sideways shift of the barrel at the end of the stock).

Bedding has been removed from recoil lug area (was poorly done can came out with minimal effort) but still some in the chassis where the bottom of the action contacts and it is still sittingcrooked.

Any good tips on a hillbilly removing the bedding from an IMB at home without buggering it?

I have to assume that if somebody bedded over the IMB, they "prepped" the surfaces or else the bedding wouldn't have a good mechanical bond to the anodizing. If that is the case, the bedding will not likely be removed in any uniform manner.

Apologies for not being much help on this one.

Sometimes people sink their truck in the mud too far to get out.

./

Honestly, I can't offer any direction for that.

I have to assume that if somebody bedded over the IMB, they "prepped" the surfaces or else the bedding wouldn't have a good mechanical bond to the anodizing. If that is the case, the bedding will not likely be removed in any uniform manner.

Apologies for not being much help on this one.

Sometimes people sink their truck in the mud too far to get out.

./

Well,

The bedding I removed in the lug I was able to do with a 1/8' tip screw driver and a little work. used a small drill bit spun by fingers to make a little hole for purchase and 5 min later it was pretty clean.

Seems there wasnt too much prep (like roughing or some drilling to create some lock)

I will give it a bit more of a go and see what I can sort out.

I have a plastic scraper (like a wood scraper) for ski base work that shouldn't bugger the metal of the IMB.

Will post pics if my old dad brain can remember!

This is the KMW IMB in their Sentinel stock.Use a heatgun amd a plastic scraper (obviously don’t heat the scraper). A lot of epoxy softens up around 200 F.

I am guessing it has some sort of bonding agent between it and the stock and am quite leery of heating the entire thing with a heat gun.

However, a disposable tip for a solder iron and focused heat might be a great idea for the stuff I thats stubborn.

Most of the junk I have removed came pretty easily.

This is the KMW IMB in their Sentinel stock.

I am guessing it has some sort of bonding agent between it and the stock and am quite leery of heating the entire thing with a heat gun.

However, a disposable tip for a solder iron and focused heat might be a great idea for the stuff I thats stubborn.

Most of the junk I have removed came pretty easily.

My bad, I was thinking it was an MPA. A soldering iron would probably work well without transferring much heat to the stock.

I will do a bedding job on my XRS Envy Pro chassis because it's obvious the action only makes contact in part of the aluminum and the action is expected to hold a heavy Proof competition profile barrel with two little screws whilst pressured against said parts of the aluminum.

Similar threads

- Replies

- 88

- Views

- 3K

- Replies

- 5

- Views

- 212

- Replies

- 8

- Views

- 787

- Replies

- 2

- Views

- 139