Do we have a stickie somewhere with instructions for bedding an action? The search function isn’t yielding anything, but I can’t be the first to ask…

- Thread starter Woolsocks

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I think there used to be one but info for bedding an action is all over YT and the internet in general.

Search results for query: Bedding action

Tried that, but it’s all threads with specific questions. I’m looking for a generic “how to” tutorial. Tend to trust what I hear on this forum more that random websites and YouTube…

Search results for query: Bedding action

www.snipershide.com

Where do you think we get it from? lol

There are some good sources on YT that walk a person through the bedding process from channels like Ultimate Reloader, MidwayUSA, Robert Gradous, etc...

At the heart of it, bedding an action isn't complicated albeit a little scary the first couple of times because you're afraid you'll glue your action in. Just like anything else firearms related there are numerous debates over what epoxy to use, what release agent, etc....

Most people use Devcon 10110 or MarineTex Gray with some SteelBed or Brownells Acraglass thrown in.

Release agents run the gammut of Johnson's Paste Wax and neutral shoe polish to silicone mold release or Brownells aerosol release agent.

Cover anything you don't want epoxy to stick to with release agent....anything...even things you didn't think epoxy would find itself attached to.

Plug holes with modeling clay

Tape off the front and sides of the recoil lug with electrical tape or blue painters tape and put release agent on it.

One of the most important things to do is mix way more epoxy then you think you need....a lot more. Nothing sucks worse then getting the action out and seeing you have voids and incomplete spaces because there wasn't enough epoxy.

There's multiple ways to clamp the action, some guys use the action screws, some guys use c-clamps, some use surgical tubing. I don't know if one way works better than another but something else I've used is bicycle inner tubes that I'd cut into long strips.

When it comes to stock bedding there's more than one way to skin a cat..

There are some good sources on YT that walk a person through the bedding process from channels like Ultimate Reloader, MidwayUSA, Robert Gradous, etc...

At the heart of it, bedding an action isn't complicated albeit a little scary the first couple of times because you're afraid you'll glue your action in. Just like anything else firearms related there are numerous debates over what epoxy to use, what release agent, etc....

Most people use Devcon 10110 or MarineTex Gray with some SteelBed or Brownells Acraglass thrown in.

Release agents run the gammut of Johnson's Paste Wax and neutral shoe polish to silicone mold release or Brownells aerosol release agent.

Cover anything you don't want epoxy to stick to with release agent....anything...even things you didn't think epoxy would find itself attached to.

Plug holes with modeling clay

Tape off the front and sides of the recoil lug with electrical tape or blue painters tape and put release agent on it.

One of the most important things to do is mix way more epoxy then you think you need....a lot more. Nothing sucks worse then getting the action out and seeing you have voids and incomplete spaces because there wasn't enough epoxy.

There's multiple ways to clamp the action, some guys use the action screws, some guys use c-clamps, some use surgical tubing. I don't know if one way works better than another but something else I've used is bicycle inner tubes that I'd cut into long strips.

When it comes to stock bedding there's more than one way to skin a cat..

As mentioned above, if you want to get "good" at it, you'll end up reading everything on google and watching everything on YouTube, then figure out what works best for you. And it takes practice.

Prep work is almost the most important. Followed by a good clean up procedure. Especially if you want to to look good.

Prep work is almost the most important. Followed by a good clean up procedure. Especially if you want to to look good.

While I love me some JB Weld and have used it for bedding 10/22's and some cheaper rifles I would step up to a better 2-part epoxy for something that's getting dropped in a Manners, McMillan, or Greyboe to be used for competition or similar long range endeavors.

JB Weld is good for bedding scope bases and learning the general mechanics of bedding actions without being overly expensive since it's much more readily available on the local level. It's also fairly easy to grind out and sand away when you screw up.

JB Weld is good for bedding scope bases and learning the general mechanics of bedding actions without being overly expensive since it's much more readily available on the local level. It's also fairly easy to grind out and sand away when you screw up.

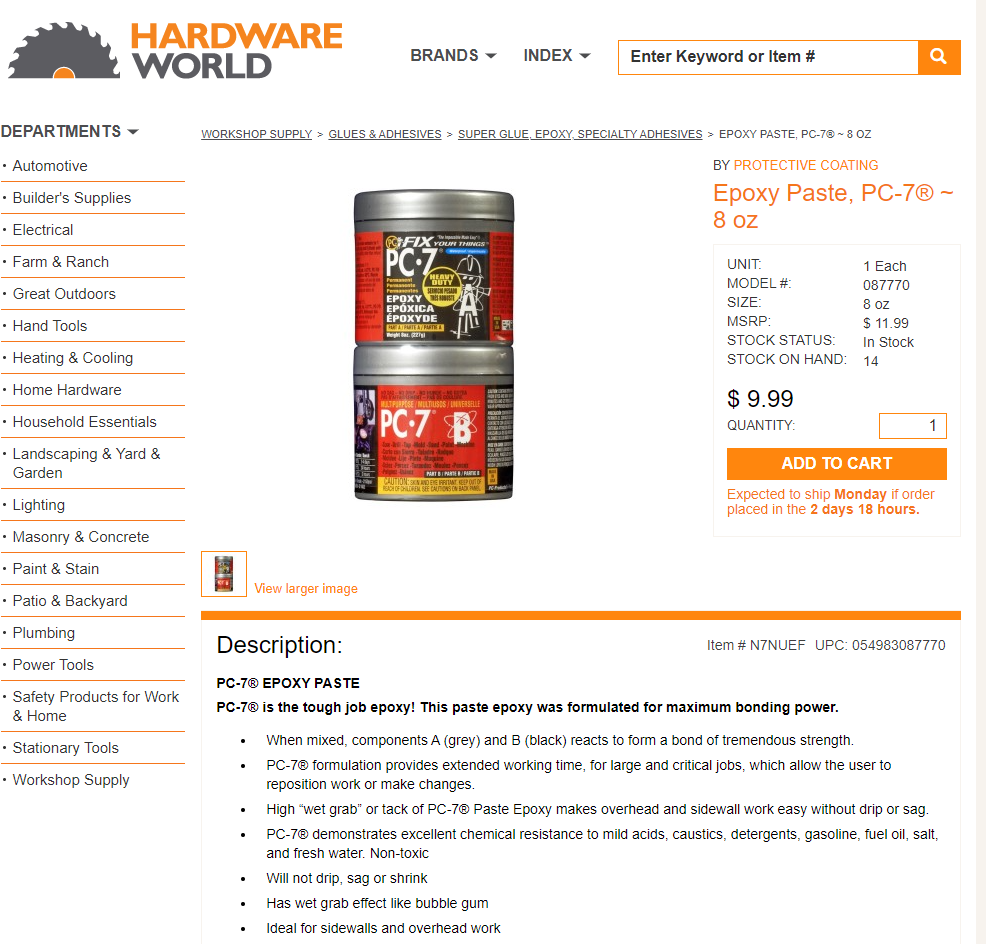

I have done a couple of bedding jobs and ran across this product. There should be enough in both containers to do a rifle with some left over. It cures somewhat slowly which in my case is a plus. It is also very thick and will not run or sag. Compared to some other products I have used it is very affordable.

I’ve used that same stuff twice with good resultsI have done a couple of bedding jobs and ran across this product. There should be enough in both containers to do a rifle with some left over. It cures somewhat slowly which in my case is a plus. It is also very thick and will not run or sag. Compared to some other products I have used it is very affordable.View attachment 8362218

Robert Gradous did a multi-part YouTube upload on bedding.Do we have a stickie somewhere with instructions for bedding an action? The search function isn’t yielding anything, but I can’t be the first to ask…

Worth watching.

Robert Gradous did a multi-part YouTube upload on bedding.

Worth watching.

Dang Terry...I was about to post the YT link to Mr. Gradous' channel and his bedding job.

You just too damn fast for this old guy! haha

Robert Gradous did a multi-part YouTube upload on bedding.

Worth watching.

Terry...just noticed...only vid #1 and 2 of 4 are still up on YT as far as I can tell. I could swear there really was four of them.

Any insight or is my YT-fu particularly weak today?

Awsome. A product recommendation and a YouTube video. That should cover it!

Devcon 10110 or gray Marine Tex both are excellent choices. I use both in Diesel engine cylinder blocks to fill in pitting in the cooling system. I have overhauled several engines thousands of hours after I made the repairs (800,000 plus or minus a few hundred thousand miles) and the repair is still good to go. Same with bedding, I have bedded so many rifles with wonderful results with both. I use neutral shoe polish as a release agent, apply it generously then buff lightly. Also fill in any etching or engraving that is close to the bedding area with the shoe polish so bedding material doesn’t get into those areas. Q-tips and WD-40 is a great way to clean the excess that squeeze out.

Test fit everything first to make sure the fit is proper and sitting even in the inlet. Bed the pillars in first paying careful attention to bottom metal location to the action for proper feeding, test it first! Rough up the inlet a little and clean / degrease it well. Use studs to align the action to the inlet / pillars / screw holes. I wrap them with tape to achieve a slip fit between the stud and pillar so they are centered or you can use flat head screws that have a taper under the head to center things up, but test this first too.

It is a very easy job, just take your time and think about it.

Test fit everything first to make sure the fit is proper and sitting even in the inlet. Bed the pillars in first paying careful attention to bottom metal location to the action for proper feeding, test it first! Rough up the inlet a little and clean / degrease it well. Use studs to align the action to the inlet / pillars / screw holes. I wrap them with tape to achieve a slip fit between the stud and pillar so they are centered or you can use flat head screws that have a taper under the head to center things up, but test this first too.

It is a very easy job, just take your time and think about it.

There are a lot of good tips in this one

www.snipershide.com

www.snipershide.com

First bedding job

Hey guys. I’m building my first bolt action and need some help/insight on my thought processes based on what I’ve read and looked up on YouTube on the bedding of the barreled action. I understand that there’s more than one way to skin a cat and achieve the same results. I’ve been gathering...

100% - as a rookie I made this mistake. Penny wise and pound foolish - "oh, maybe I can get two bedding jobs out of this, I should try to save $20 by not buying more compound." Dumb. You might get lucky and the job will shoot well and only look like hell. Using enough compound and really slathering it in there is particularly important for toffee like materials - it's easy to place and it stays put, but it STAYS PUT. It's not going to flow somewhere you missed or didn't get enough compound in. At least that was my experience.I think Gradous mentions it. Or it's possible it's in an LRI video. But, always use more compound than you think you'll need.

Once we started being generous with the bedding compound and squeezing the excess out, things started looking a lot better.

So you do that and make ammo all in the same place Dave?As mentioned above, if you want to get "good" at it, you'll end up reading everything on google and watching everything on YouTube, then figure out what works best for you. And it takes practice.

Prep work is almost the most important. Followed by a good clean up procedure. Especially if you want to to look good.

View attachment 8361972

Similar threads

- Replies

- 88

- Views

- 2K

- Replies

- 5

- Views

- 435

- Replies

- 5

- Views

- 262