I remember seeing a post sometime ago that referred to a "sagging barrel". Is this in reference to a heavy barrel that has been fre-floated? I have just free-floated a 26" barrel that is 1" in diameter at the muzzle and all of a sudden I have lost some accuracy. Is there a problem with trying to free-float barrels of high weight? Must heavy barrels be fully bedded to obtain maximum accuracy. If not, I have generated a problem somewhere else. Sometimes it is best to leave well enough alone.

Gunsmithing Bedding Question

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Re: Bedding Question

There are a couple of people you might seek out who have been very helpful regarding stock bedding techniques. 7mmRem and Scimitar have done some excellent, Pic Heavy, threads available in this forum.

They may be able to answer your questions. Do you have any photos you could share that might shed some light on your problem?

Good luck.

There are a couple of people you might seek out who have been very helpful regarding stock bedding techniques. 7mmRem and Scimitar have done some excellent, Pic Heavy, threads available in this forum.

They may be able to answer your questions. Do you have any photos you could share that might shed some light on your problem?

Good luck.

Re: Bedding Question

No pictures at this time. This rifle was once a <0.5 inch rifle at 100yds and bestgroup of 2.25 " at 500 yards. It has been in my gun safe since 1996. Recently I pulled it out to play with it again. As of today, it has 217 rounds through it. I bought some new Remington 300WM nickle cases to load. The fresh loads did not shoot worth a darn. I figured that the wood stock had warpted during its safe days and the barrel may be slightly touching the stock as it fires. The action and barrel was glass bedded with the barrel being bedded about 2" out from the receiver ring. I relieved the barrel so a double thickness of printer paper doe not have any resistance from the stock tip to the bedded area. The freshly loaded rounds I shot today did not do any better. So it is either the free-floated barrel or the new nickle brass. I am still shooting virgin brass and have not shot any fire-formed nickle brass yet. I did notice that the virgin brass was shaving the bullets when I was seating them. That can't help accuracy. Powder and bullets were the same load that I had used before with good success.

Current plans are to load some old "plain" brass and some of the 1X fired nickle brass and see if the problem disappears. If it does not, I will do a complete glass bedding of the barrel channel. The more I think about it, the harder for me to believe the free-floated barrel is the problem. But I have been wrong many times before. Will provide an update after I shoot again next weekend. In the meantime, all comments and sugestions are greatly appreciated. Thanks for the references.

No pictures at this time. This rifle was once a <0.5 inch rifle at 100yds and bestgroup of 2.25 " at 500 yards. It has been in my gun safe since 1996. Recently I pulled it out to play with it again. As of today, it has 217 rounds through it. I bought some new Remington 300WM nickle cases to load. The fresh loads did not shoot worth a darn. I figured that the wood stock had warpted during its safe days and the barrel may be slightly touching the stock as it fires. The action and barrel was glass bedded with the barrel being bedded about 2" out from the receiver ring. I relieved the barrel so a double thickness of printer paper doe not have any resistance from the stock tip to the bedded area. The freshly loaded rounds I shot today did not do any better. So it is either the free-floated barrel or the new nickle brass. I am still shooting virgin brass and have not shot any fire-formed nickle brass yet. I did notice that the virgin brass was shaving the bullets when I was seating them. That can't help accuracy. Powder and bullets were the same load that I had used before with good success.

Current plans are to load some old "plain" brass and some of the 1X fired nickle brass and see if the problem disappears. If it does not, I will do a complete glass bedding of the barrel channel. The more I think about it, the harder for me to believe the free-floated barrel is the problem. But I have been wrong many times before. Will provide an update after I shoot again next weekend. In the meantime, all comments and sugestions are greatly appreciated. Thanks for the references.

Re: Bedding Question

They were very helpful to me. It may not be a bedding problem at all though. What load did you work up?

With no barrel contact with the stock as you describe, have you ruled out any bore conditions, powder, primer, bullet, etc., stock or scope/mount screw combo that might be conspiring against you?

Factory match ammo is a great control for erasing doubts about rifle or shooter when firing errant reloads.

They were very helpful to me. It may not be a bedding problem at all though. What load did you work up?

With no barrel contact with the stock as you describe, have you ruled out any bore conditions, powder, primer, bullet, etc., stock or scope/mount screw combo that might be conspiring against you?

Factory match ammo is a great control for erasing doubts about rifle or shooter when firing errant reloads.

Re: Bedding Question

If the accuracy fell off after a change of brass, I'd venture that the nickel brass is of a slightly different case capacity that the pervious brass you had worked the load up in. Plus the neck tension may be way different if the brass is shaving the cases. You may consider chamfering the neck and running them through an FL die to have the expander uniform up the necks. Or just mic the ID of the nickel and the ID of known good brass brass.

A 2" barrel pad forward of the recoil lug should suffice in lending support to the heavy tube.

Wood stocks aren't my strong suit, but I'd check the load again in the brass it worked with before.

If the accuracy fell off after a change of brass, I'd venture that the nickel brass is of a slightly different case capacity that the pervious brass you had worked the load up in. Plus the neck tension may be way different if the brass is shaving the cases. You may consider chamfering the neck and running them through an FL die to have the expander uniform up the necks. Or just mic the ID of the nickel and the ID of known good brass brass.

A 2" barrel pad forward of the recoil lug should suffice in lending support to the heavy tube.

Wood stocks aren't my strong suit, but I'd check the load again in the brass it worked with before.

Re: Bedding Question

Like previously said, it sounds like a load issue, not a bedding issue.

Like previously said, it sounds like a load issue, not a bedding issue.

Re: Bedding Question

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: sobrbiker883</div><div class="ubbcode-body"> I'd venture that the nickel brass is of a slightly different case capacity that the pervious brass you had worked the load up in. Plus the neck tension may be way different if the brass is shaving the cases. </div></div>

+1

More times than not, brass is the culprit. For general conversation, Nickel Brass is junk and useless for accuracy. Shaving copper from the bullet is from using a 45 degree chamfer tool in the case mouths. Purchase the VLD tool for chamfering and use dry lube in the case necks and use the FL bushing dies.

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: sobrbiker883</div><div class="ubbcode-body"> I'd venture that the nickel brass is of a slightly different case capacity that the pervious brass you had worked the load up in. Plus the neck tension may be way different if the brass is shaving the cases. </div></div>

+1

More times than not, brass is the culprit. For general conversation, Nickel Brass is junk and useless for accuracy. Shaving copper from the bullet is from using a 45 degree chamfer tool in the case mouths. Purchase the VLD tool for chamfering and use dry lube in the case necks and use the FL bushing dies.

Re: Bedding Question

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: wnroscoe</div><div class="ubbcode-body">...Shaving copper from the bullet is from using a 45 degree chamfer tool in the case mouths. Purchase the VLD tool for chamfering and use dry lube in the case necks ... </div></div>

Can you provide a product name or reference for the VLD tool?

<div class="ubbcode-block"><div class="ubbcode-header">Originally Posted By: wnroscoe</div><div class="ubbcode-body">...Shaving copper from the bullet is from using a 45 degree chamfer tool in the case mouths. Purchase the VLD tool for chamfering and use dry lube in the case necks ... </div></div>

Can you provide a product name or reference for the VLD tool?

Re: Bedding Question

RCBS, Sinclair, and several others make them. I personally have the RCBS unit. Good stuff.

RCBS, Sinclair, and several others make them. I personally have the RCBS unit. Good stuff.

Re: Bedding Question

The load is 69.0 grains of IMR 4350 hehind a 180 grain Sierra SBT (#2160). The last time I chronographed the load, ten rounds averaged 3048 fps. I have checked screws for tightness and have not found anything obvious. Bore is clean; a SS barrel, always babied during cleaning.

I checked the inside and outside diameters of three cases of both virgin and necksized brass. Two reading were taken at 90 degrees. The outside diameter of loaded brass was also checked. The table reflects the readings. Is neck tension the amount that the inside diameter expands or is it the amount that the outside expands when the pull is seated? The table gives the outside values. It appears the virgin, unsized brass is tighter than the neck sized and that is probaly the reason that the bullet is getting shaved and gashed when seated. The inside diameter of the virgin brass gives wide readng due to the roughness of the mouth of the case. It is now oblivous I need to resized the virgin brass before I use it. If I am correct in what I think neck tension is; what is a good value for it?

Raw data removed and summary given in next post.

The load is 69.0 grains of IMR 4350 hehind a 180 grain Sierra SBT (#2160). The last time I chronographed the load, ten rounds averaged 3048 fps. I have checked screws for tightness and have not found anything obvious. Bore is clean; a SS barrel, always babied during cleaning.

I checked the inside and outside diameters of three cases of both virgin and necksized brass. Two reading were taken at 90 degrees. The outside diameter of loaded brass was also checked. The table reflects the readings. Is neck tension the amount that the inside diameter expands or is it the amount that the outside expands when the pull is seated? The table gives the outside values. It appears the virgin, unsized brass is tighter than the neck sized and that is probaly the reason that the bullet is getting shaved and gashed when seated. The inside diameter of the virgin brass gives wide readng due to the roughness of the mouth of the case. It is now oblivous I need to resized the virgin brass before I use it. If I am correct in what I think neck tension is; what is a good value for it?

Raw data removed and summary given in next post.

Re: Bedding Question

Wow!!! Not sure what happened to the formatting but it looked good in the preview. I will redo.

R-P 300WM Nickel Virgin Brass

Average inside case mouth diameter: 0.3015"

Average outside case mouth diameter: 0.3348"

Average neck thickness: 0.0167"

Winchester 300WM Nickel-necksized brass

Average inside case mouth diameter: 0.3040"

Average outside case mouth diameter: 0.3340"

Average neck thickness: 0.0150"

Winchester 300WM Plain necksized brass

Average inside case mouth diameter: 0.3035"

Average outside case mouth diameter: 0.3332"

Average neck thickness: 0.0148"

Loaded R-P 300WM Nickel necksized brass

Average outside case mouth diameter: 0.3362"

Neck tension: 0.0022"

Loaded Winchester 300WM Plain necksized brass

Average outside case mouth diameter: 0.3354"

Neck tension: 0.0022"

Wow!!! Not sure what happened to the formatting but it looked good in the preview. I will redo.

R-P 300WM Nickel Virgin Brass

Average inside case mouth diameter: 0.3015"

Average outside case mouth diameter: 0.3348"

Average neck thickness: 0.0167"

Winchester 300WM Nickel-necksized brass

Average inside case mouth diameter: 0.3040"

Average outside case mouth diameter: 0.3340"

Average neck thickness: 0.0150"

Winchester 300WM Plain necksized brass

Average inside case mouth diameter: 0.3035"

Average outside case mouth diameter: 0.3332"

Average neck thickness: 0.0148"

Loaded R-P 300WM Nickel necksized brass

Average outside case mouth diameter: 0.3362"

Neck tension: 0.0022"

Loaded Winchester 300WM Plain necksized brass

Average outside case mouth diameter: 0.3354"

Neck tension: 0.0022"

Re: Bedding Question

You free floated it, and accuracy went away. Did you try seeing if it would come back if you re-established the contact? I would.

Take a 1" square piece of matchbook cardboard, slip it between the barrel and stock at the front end of the barrel channel, and see what that does to accuracy. Floating a barrel is one way to make a rifle shoot, but it's not the only way.

Greg

You free floated it, and accuracy went away. Did you try seeing if it would come back if you re-established the contact? I would.

Take a 1" square piece of matchbook cardboard, slip it between the barrel and stock at the front end of the barrel channel, and see what that does to accuracy. Floating a barrel is one way to make a rifle shoot, but it's not the only way.

Greg

Re: Bedding Question

shaving jackets upon insertion is death to accuracy

shaving jackets upon insertion is death to accuracy

Re: Bedding Question

I'd try some Fed. GMM through it as a baseline. It'd be a really quick way to either conferm or eliminate your load (or brass) as the problem. Good luck.

okie

I'd try some Fed. GMM through it as a baseline. It'd be a really quick way to either conferm or eliminate your load (or brass) as the problem. Good luck.

okie

Re: Bedding Question

# 1 take all that Nickel Brass and throw it as far as you can. That stuff is junk....Start over with new brass.

# 1 take all that Nickel Brass and throw it as far as you can. That stuff is junk....Start over with new brass.

Re: Bedding Question

Loaded some rounds to test on Saturday. Used some of my old brass and some of the nickel brass. Both had been fired in the rifle so I only neck sized. The bullets seated in the plain brass without any indication of bullet shaving. I could still see slight shaving with the nickel brass. I am beginning to believe that the nickel brass is a lot of my problems. Well the range will tell the tale.

Loaded some rounds to test on Saturday. Used some of my old brass and some of the nickel brass. Both had been fired in the rifle so I only neck sized. The bullets seated in the plain brass without any indication of bullet shaving. I could still see slight shaving with the nickel brass. I am beginning to believe that the nickel brass is a lot of my problems. Well the range will tell the tale.

Re: Bedding Question

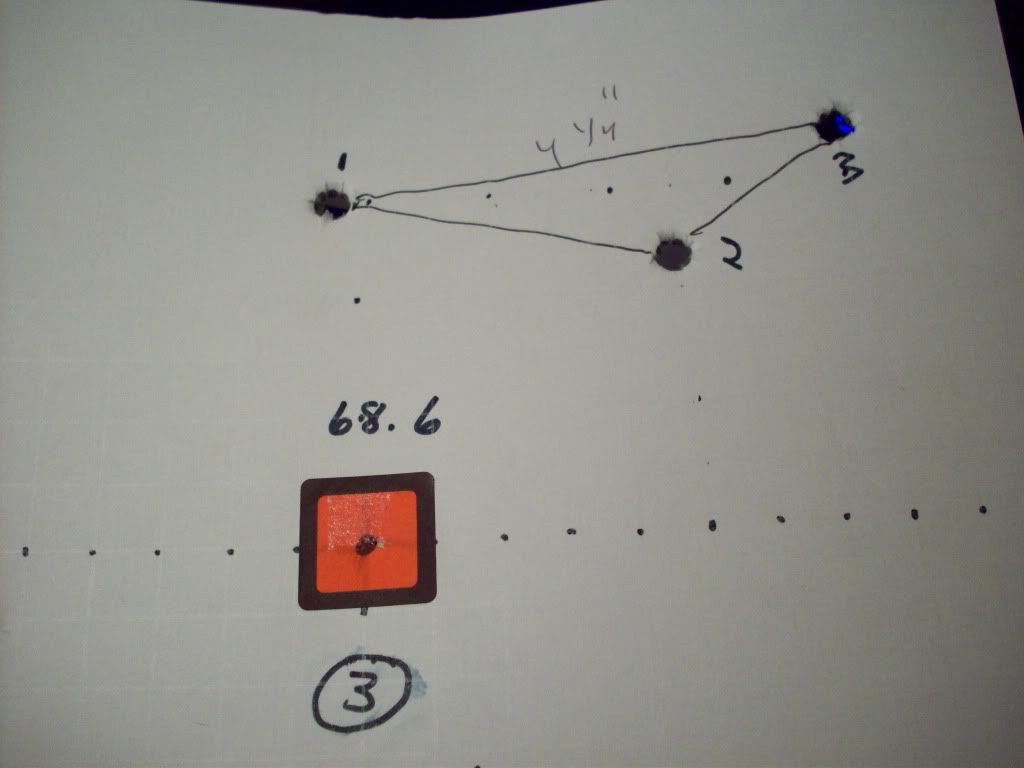

Got a chance to shoot a test of the regular brass vs the nickel brass Saturday. I think I learned a few things. First thing I learned was that I need to put some more trigger time behind this rifle. I am not shooting it as well as I did in 1996-97. Here are the test results.

All loads were charged with 69.0 grains IMR 4350 and a CCI 250 primer. Bullets were seated 0.010" off the lands. Bullets of 168 grains and 180 grains were used. All groups are center to center measurements.

Top Left Group: Plain brass and 180 grain Sierra SBT. 5-shots 0.99"; best 4-shots 0.69". First group with cold, clean barrel. Scope at 40X; lots of heat waves in the scope.

Top Right Group: Plain brass and 180 grain Sierra SBT. 5-shots 0.83"; best 4-shots 0.48". Scope was powered down to 30X.

Bottom Left Group: Plain brass and 168 gain Nosler CC. 7-shots 0.92"; best 6-shots 0.64". Only had enough brass left to load seven rounds. Scope was powered down to 30X.

Bottom Right Group: Nickel brass and 180 grain Sierra SBT. 5-shots 2.25"; best 4-shots 1.22". Scope was powered down to 30X. This is what I was seeing earlier and it was driving me crazy.

Nickel brass is not performing. It appears a lot of my earlier problems was the nickel brass. The group really opened-up with the nickel. I think I will be using the nickel brass in my Winchester Model 70 hunting rifle in the future, if I keep the brass at all.

This is a photo of the old girl. She needs some good glass and maybe a stock; but I think I can get her performing again if I do my part behind the trigger. As of Saturday, my log says she only has 255 rounds through her.

The following are a couple of the targets I saved from the 90's. One is 180 grain bullets and the other 168 grain bullets. The 180 grain load (11/4/96) was the first group I shot with the rifle after getting it sighted in. It uses 71 grains of IMR4350. I later bought a box of 168 grainers and the other target (3/8/97)is the first group with them. Used 70.0 grains of IMR4350.

This is my shooting range. I have 570 yards to play with.

Got a chance to shoot a test of the regular brass vs the nickel brass Saturday. I think I learned a few things. First thing I learned was that I need to put some more trigger time behind this rifle. I am not shooting it as well as I did in 1996-97. Here are the test results.

All loads were charged with 69.0 grains IMR 4350 and a CCI 250 primer. Bullets were seated 0.010" off the lands. Bullets of 168 grains and 180 grains were used. All groups are center to center measurements.

Top Left Group: Plain brass and 180 grain Sierra SBT. 5-shots 0.99"; best 4-shots 0.69". First group with cold, clean barrel. Scope at 40X; lots of heat waves in the scope.

Top Right Group: Plain brass and 180 grain Sierra SBT. 5-shots 0.83"; best 4-shots 0.48". Scope was powered down to 30X.

Bottom Left Group: Plain brass and 168 gain Nosler CC. 7-shots 0.92"; best 6-shots 0.64". Only had enough brass left to load seven rounds. Scope was powered down to 30X.

Bottom Right Group: Nickel brass and 180 grain Sierra SBT. 5-shots 2.25"; best 4-shots 1.22". Scope was powered down to 30X. This is what I was seeing earlier and it was driving me crazy.

Nickel brass is not performing. It appears a lot of my earlier problems was the nickel brass. The group really opened-up with the nickel. I think I will be using the nickel brass in my Winchester Model 70 hunting rifle in the future, if I keep the brass at all.

This is a photo of the old girl. She needs some good glass and maybe a stock; but I think I can get her performing again if I do my part behind the trigger. As of Saturday, my log says she only has 255 rounds through her.

The following are a couple of the targets I saved from the 90's. One is 180 grain bullets and the other 168 grain bullets. The 180 grain load (11/4/96) was the first group I shot with the rifle after getting it sighted in. It uses 71 grains of IMR4350. I later bought a box of 168 grainers and the other target (3/8/97)is the first group with them. Used 70.0 grains of IMR4350.

This is my shooting range. I have 570 yards to play with.

Re: Bedding Question

The pictures are too small because...the pictures are too small.

This one:

http://s718.photobucket.com/albums/ww187/Pirate69-photo/th_100_0976.jpg

measures 160 by 120 pixels. So is the second one. And that is too small. I didn't check the rest.

The pictures are too small because...the pictures are too small.

This one:

http://s718.photobucket.com/albums/ww187/Pirate69-photo/th_100_0976.jpg

measures 160 by 120 pixels. So is the second one. And that is too small. I didn't check the rest.

Re: Bedding Question

Hopefully, the photos are OK.

Hopefully, the photos are OK.

Re: Bedding Question

Well, I think I may have my rifle back. I loaded some 168 grain Noslers with 70 grains of IMR 4350 and tried them a week ago. The rifle still was not shooting as expected. I decided there was nothing left to do but to bed it. So I did a full bedding and tried it again with the rounds I had left. After shooting four rounds to condition the barrel, I shoot two 5-round groups. The first group yielded a 0.49" center to center group. Four rounds were 0.38" C to C. The second group measured 0.78" C to C. Pictures attached.

I have not done any load development; I have only fired Sierra 180 SBT (#2160)and 168 grain Nosler BT CC with IMR 4350 69.0 grains and 70.0 grains, respectively. I think it is time to do a OCW Ladder.

It was hot yesterday and the mirage came into play a little at 100 yards. But when I looked downrange 300-400 yards; it was a real problem, even after trying to adjust the parallax out. I guess this is a problem with the quality of my scope. Are there suggestions on a good scope that is reasonably priced that will overcome this problem? Or is good and cheap not an option? How does everyone handle the mirage problem?

Well, I think I may have my rifle back. I loaded some 168 grain Noslers with 70 grains of IMR 4350 and tried them a week ago. The rifle still was not shooting as expected. I decided there was nothing left to do but to bed it. So I did a full bedding and tried it again with the rounds I had left. After shooting four rounds to condition the barrel, I shoot two 5-round groups. The first group yielded a 0.49" center to center group. Four rounds were 0.38" C to C. The second group measured 0.78" C to C. Pictures attached.

I have not done any load development; I have only fired Sierra 180 SBT (#2160)and 168 grain Nosler BT CC with IMR 4350 69.0 grains and 70.0 grains, respectively. I think it is time to do a OCW Ladder.

It was hot yesterday and the mirage came into play a little at 100 yards. But when I looked downrange 300-400 yards; it was a real problem, even after trying to adjust the parallax out. I guess this is a problem with the quality of my scope. Are there suggestions on a good scope that is reasonably priced that will overcome this problem? Or is good and cheap not an option? How does everyone handle the mirage problem?

Re: Bedding Question

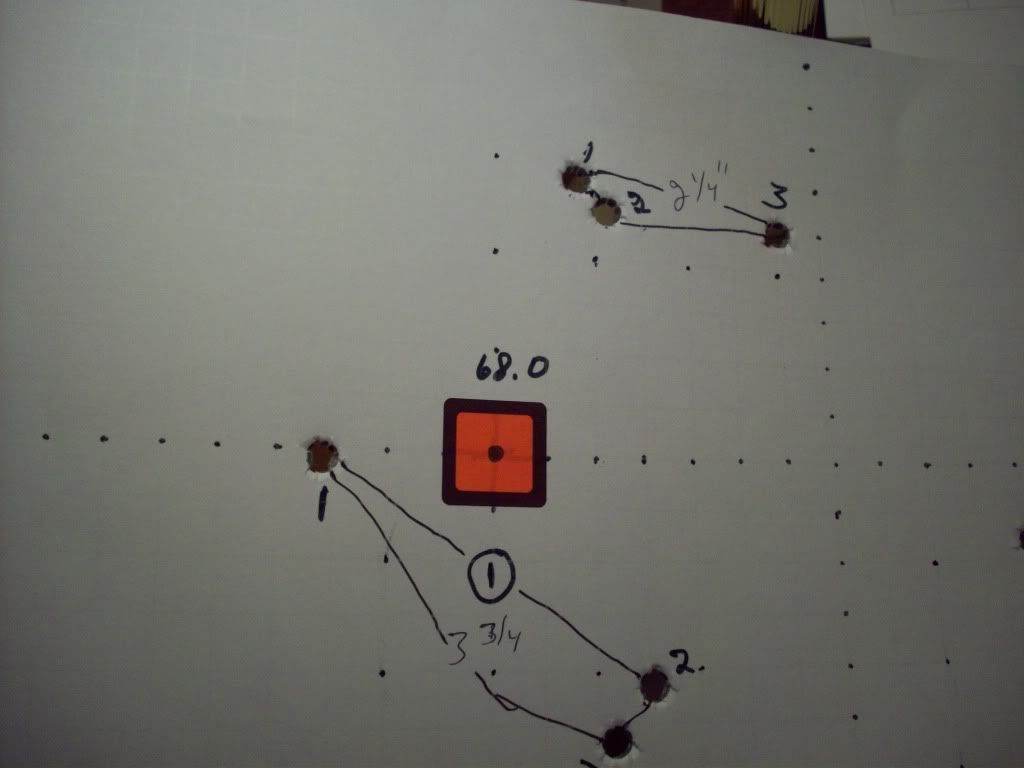

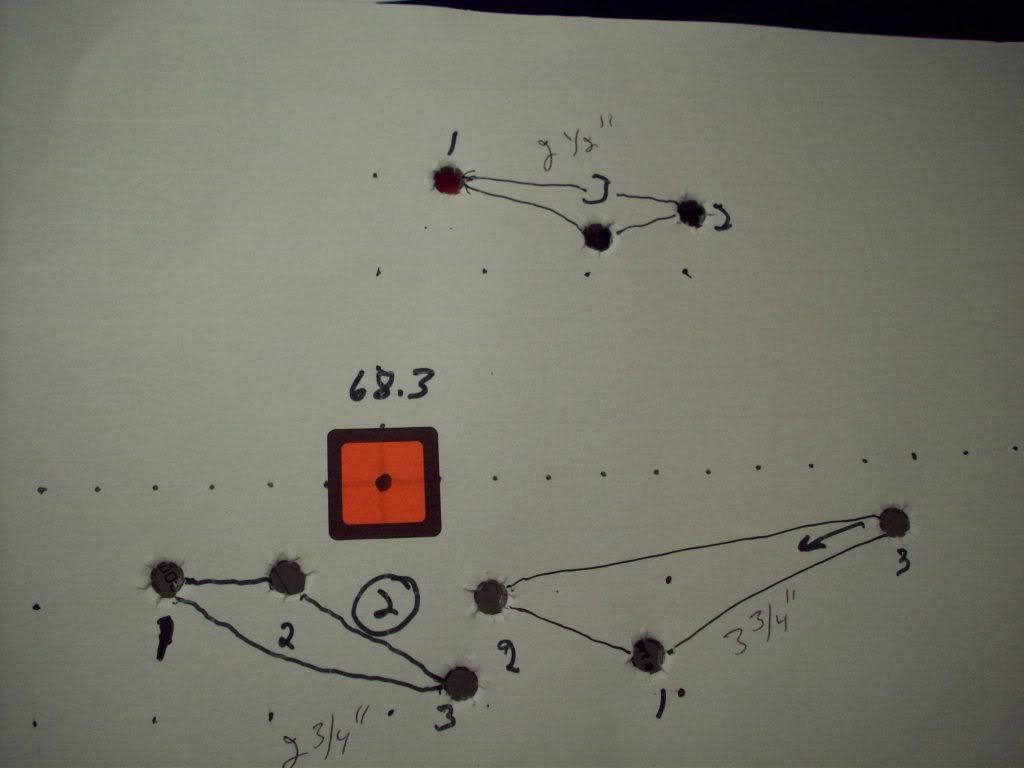

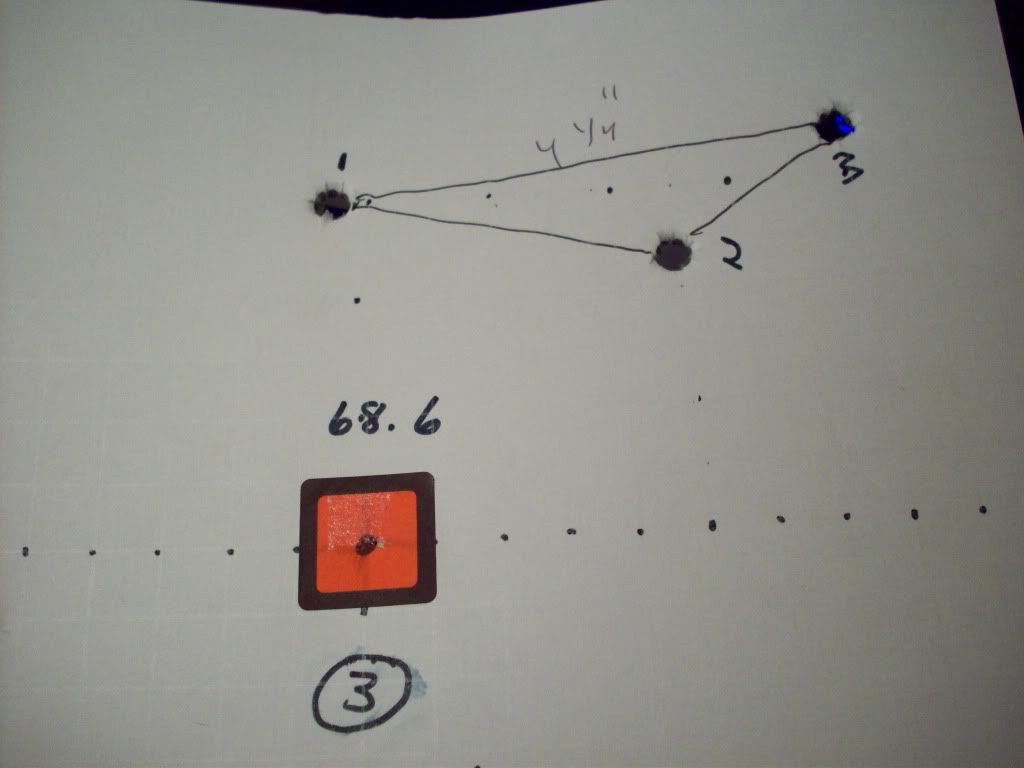

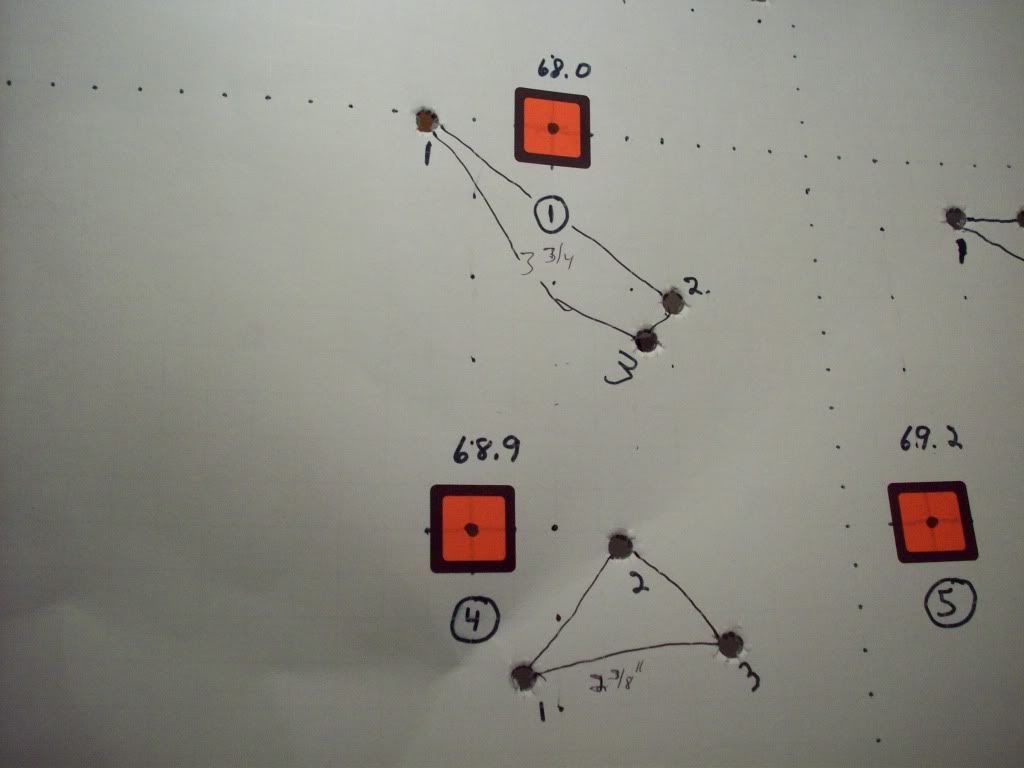

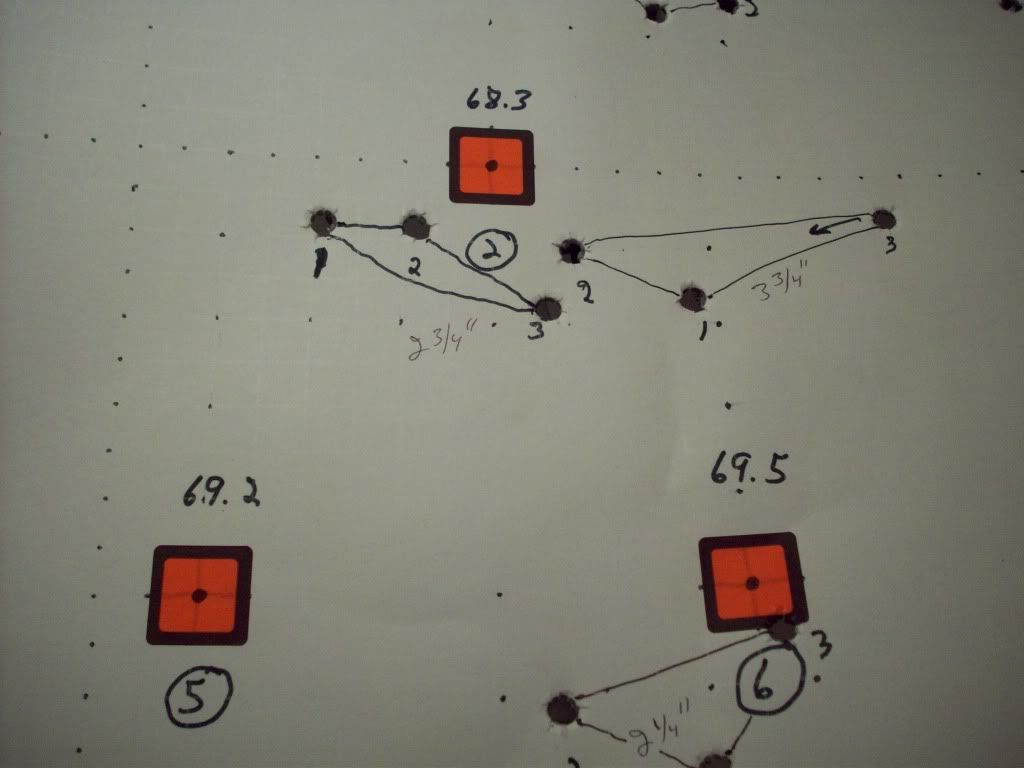

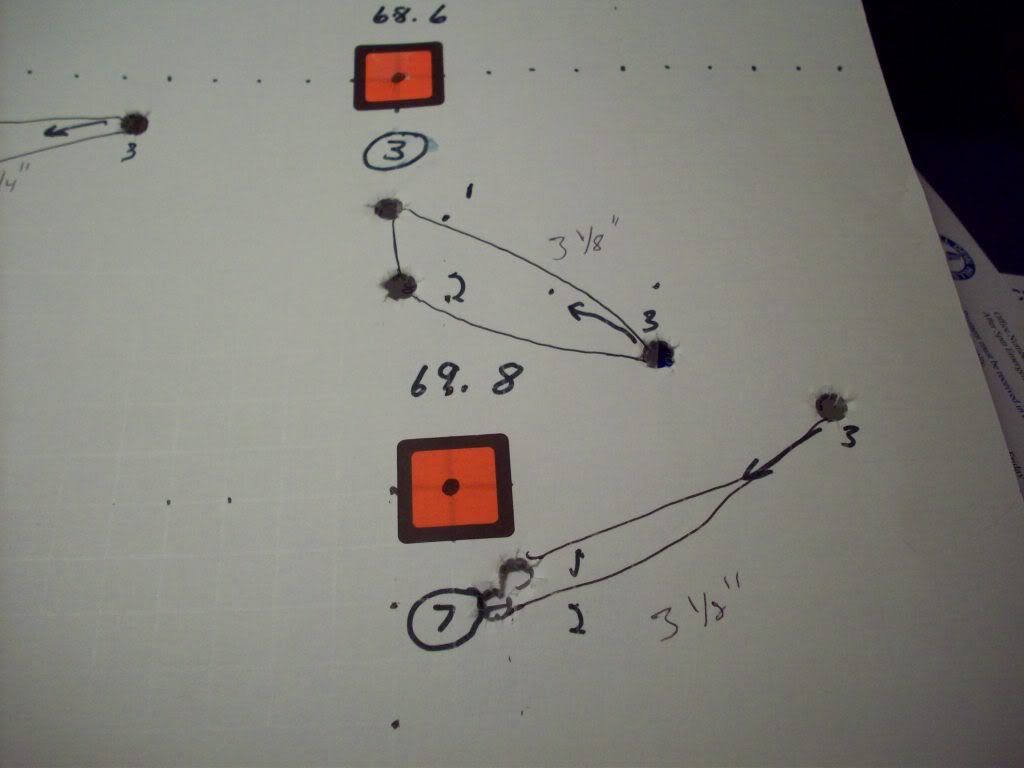

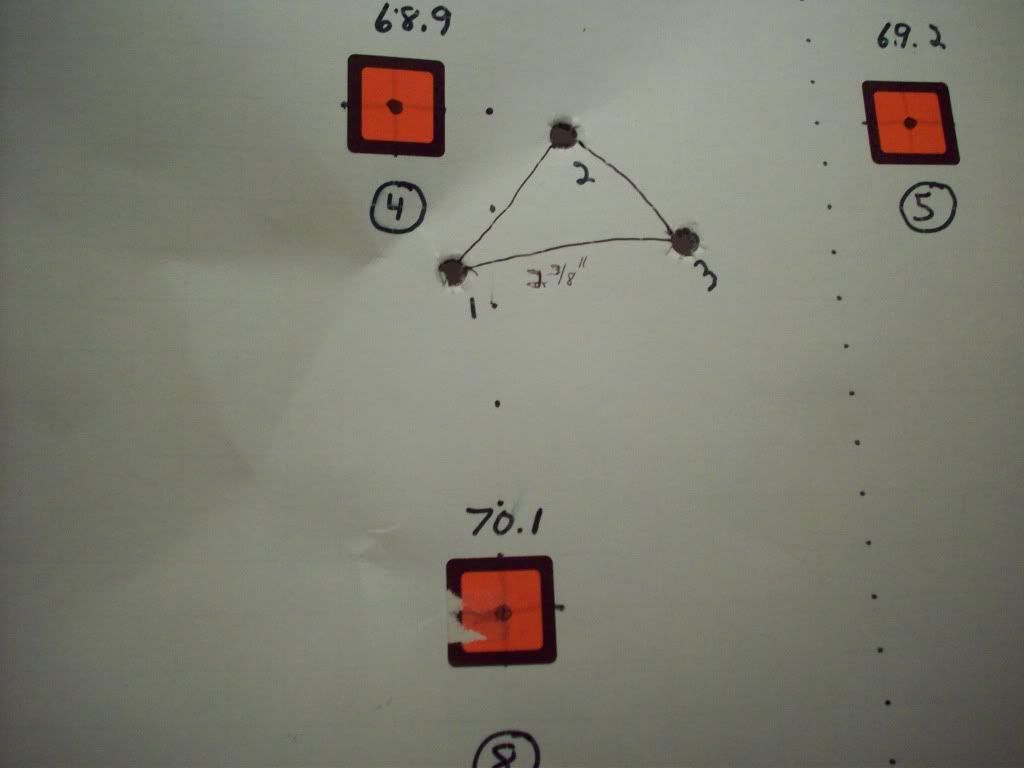

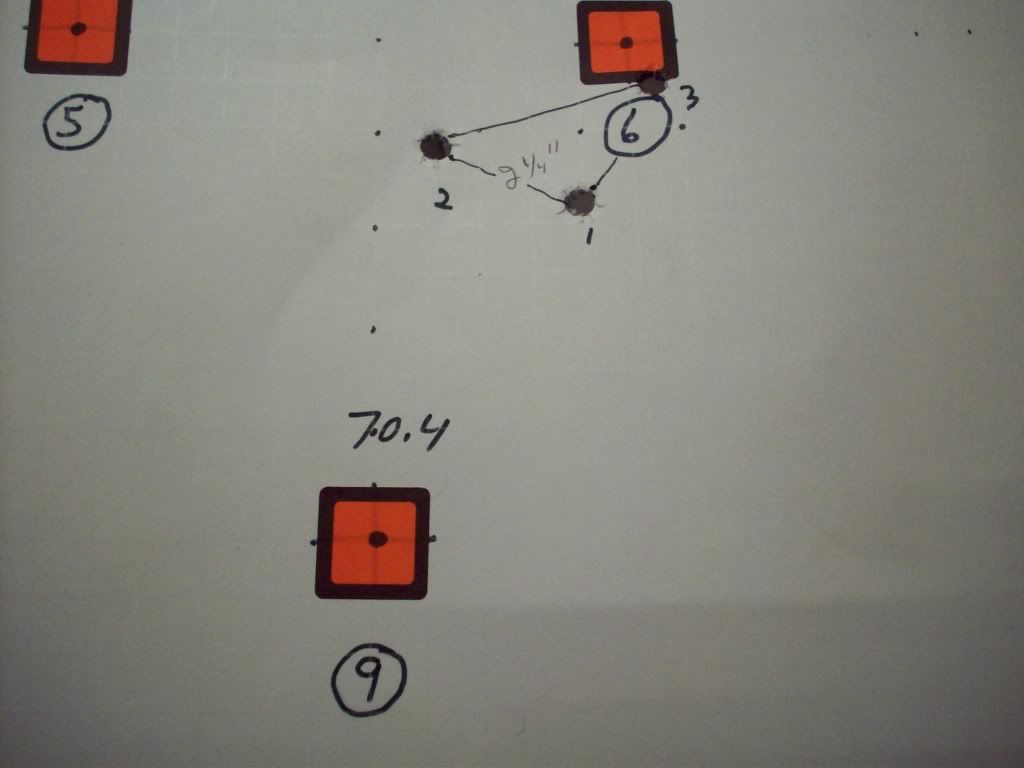

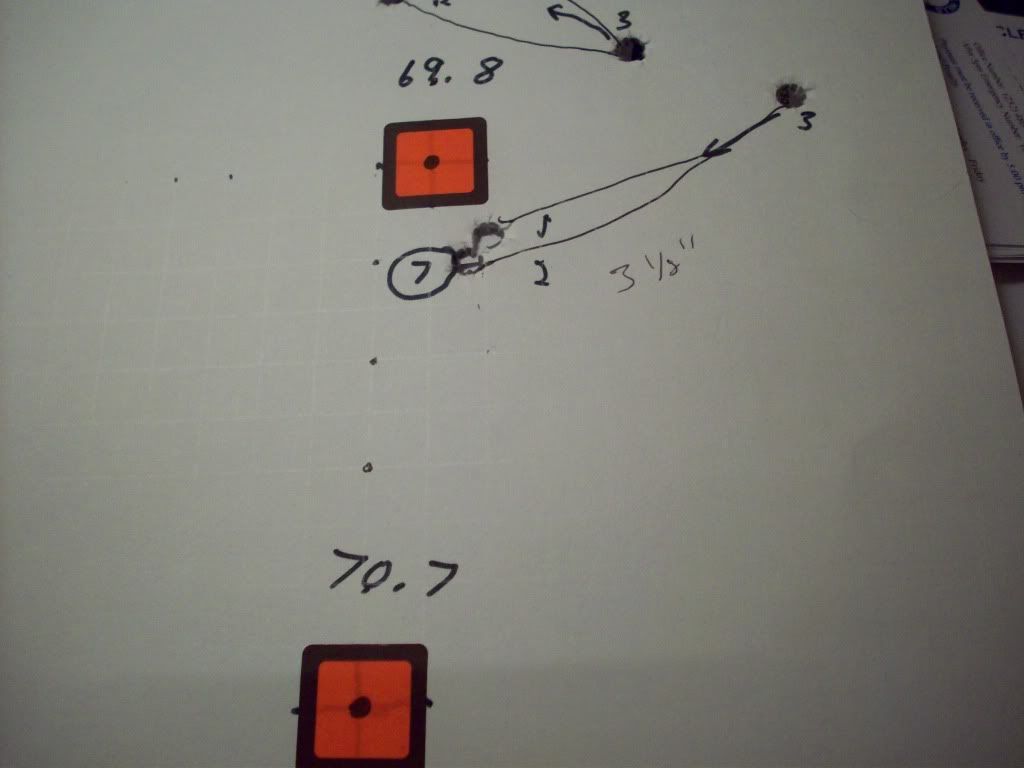

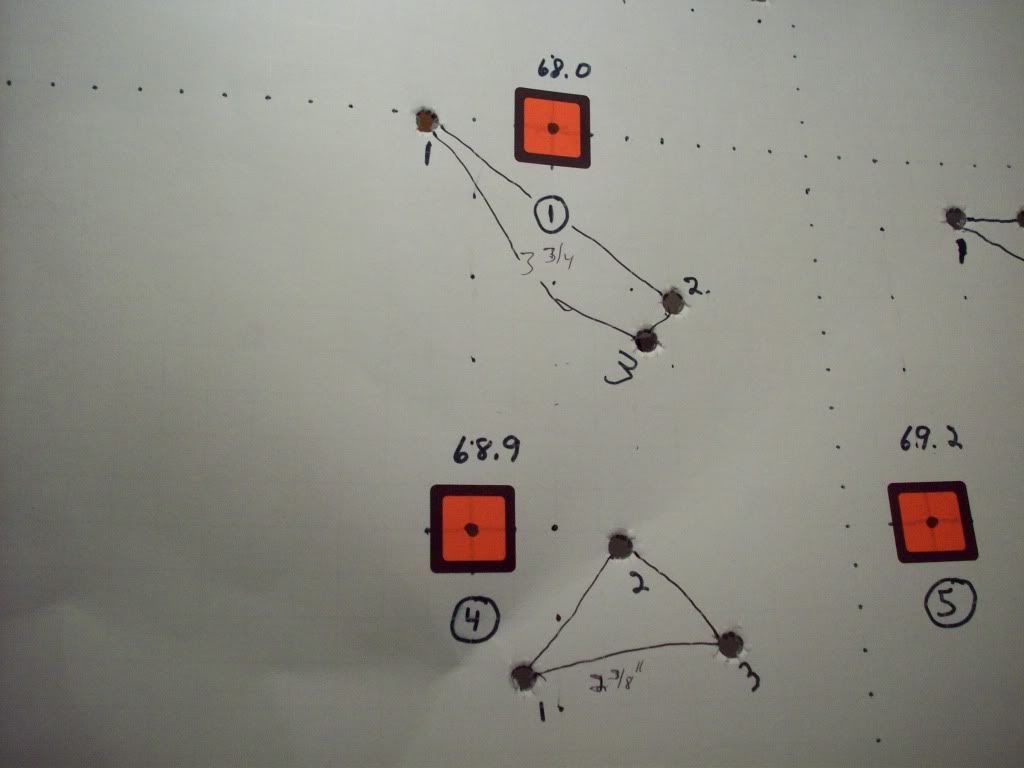

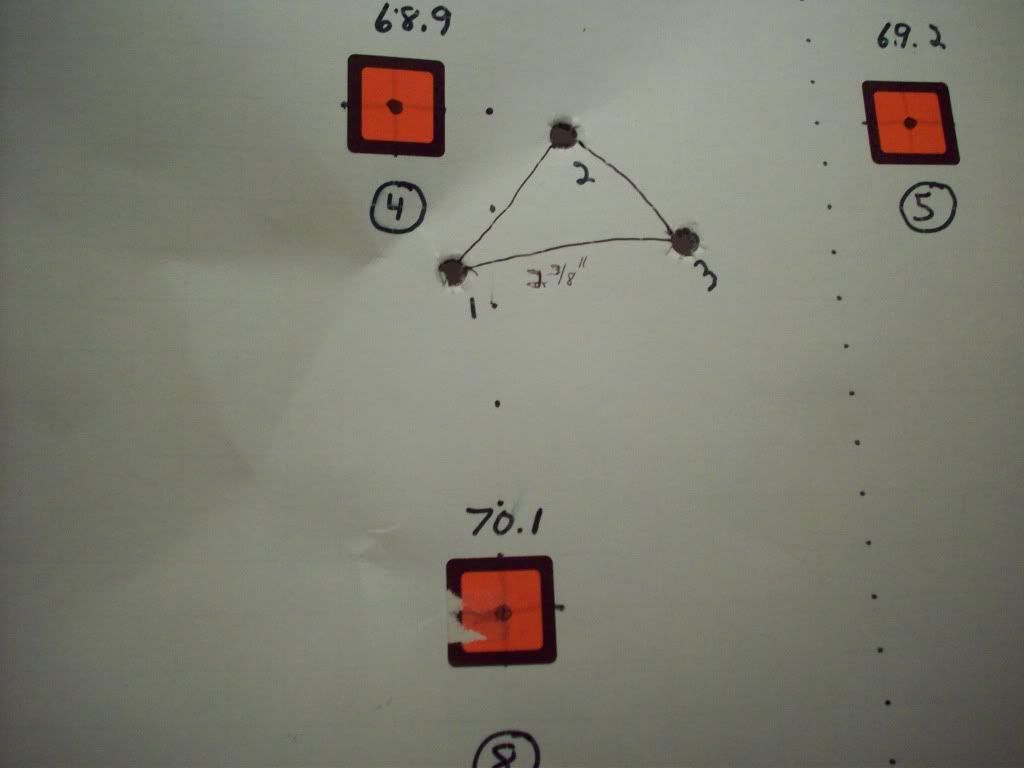

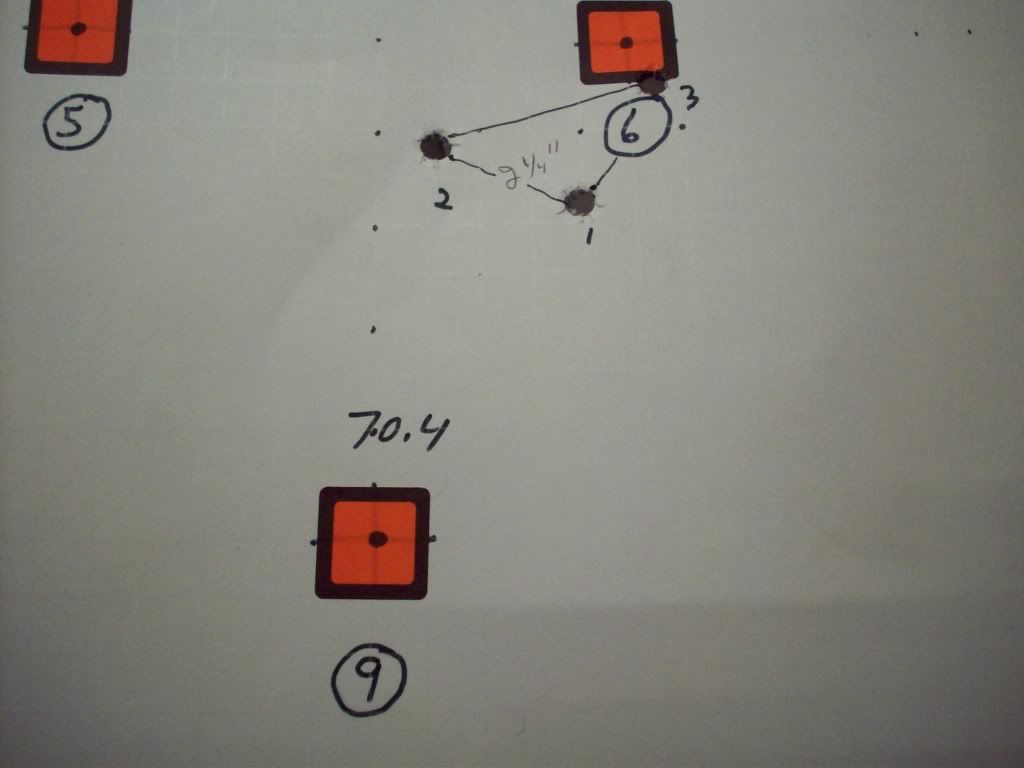

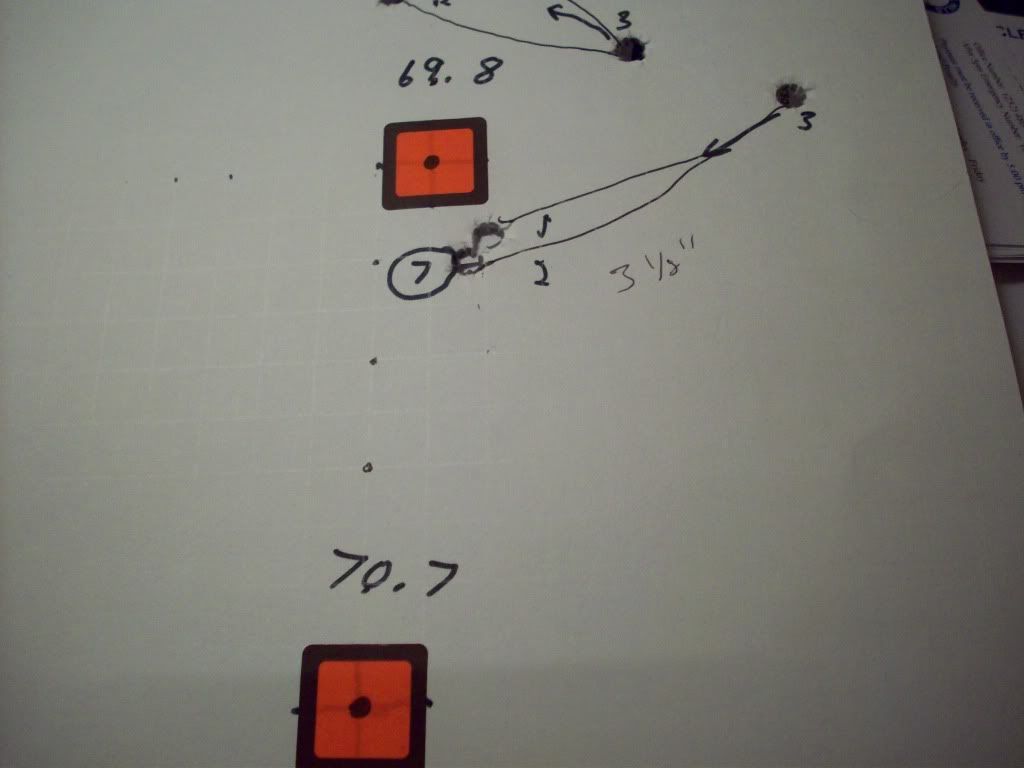

Finally got around to doing an OCW. This is my first OCW. The rifle is a Mauser action with a 26" Douglas SS target barrel. It has a wood stock which is now fully glass bedded.

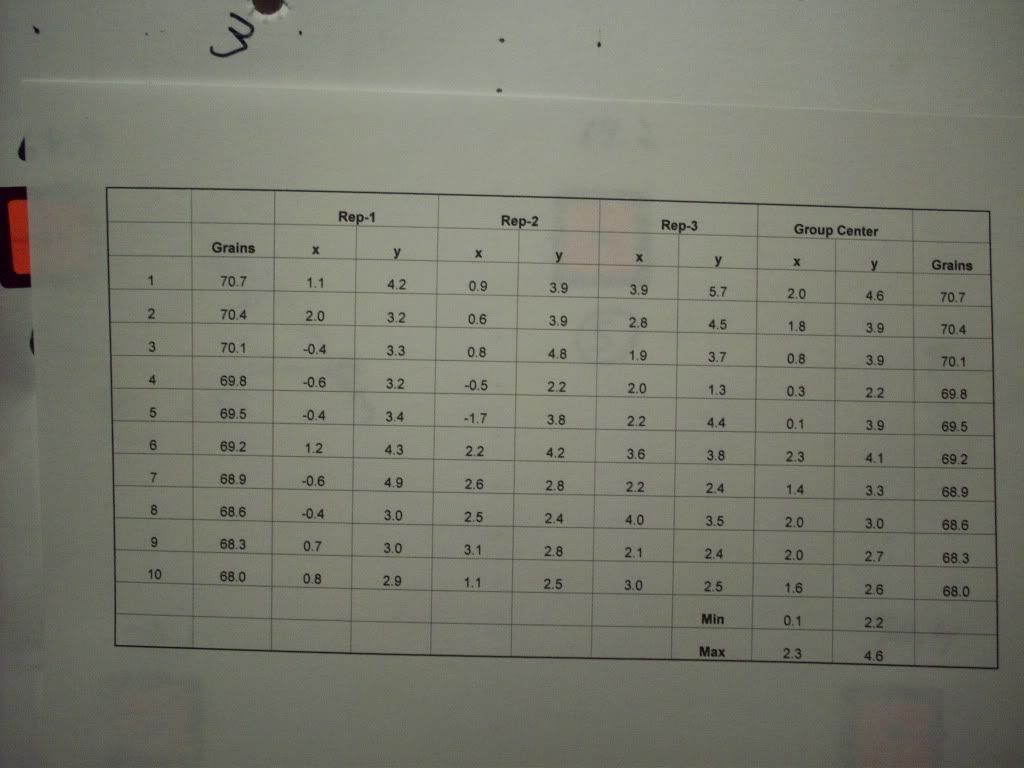

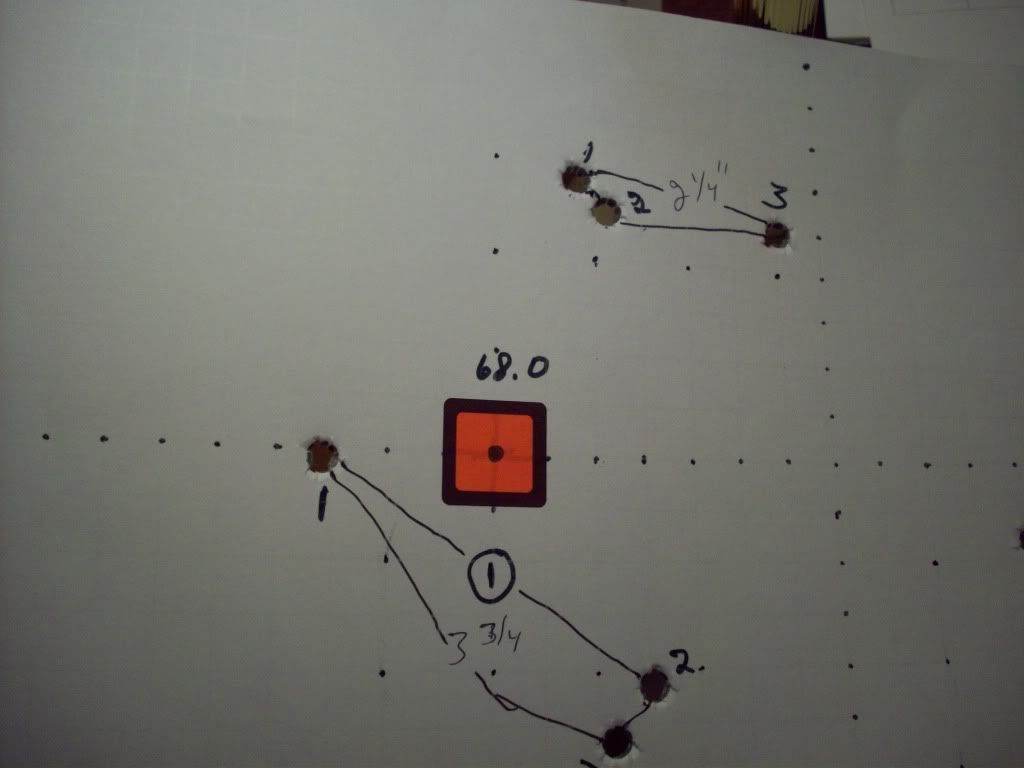

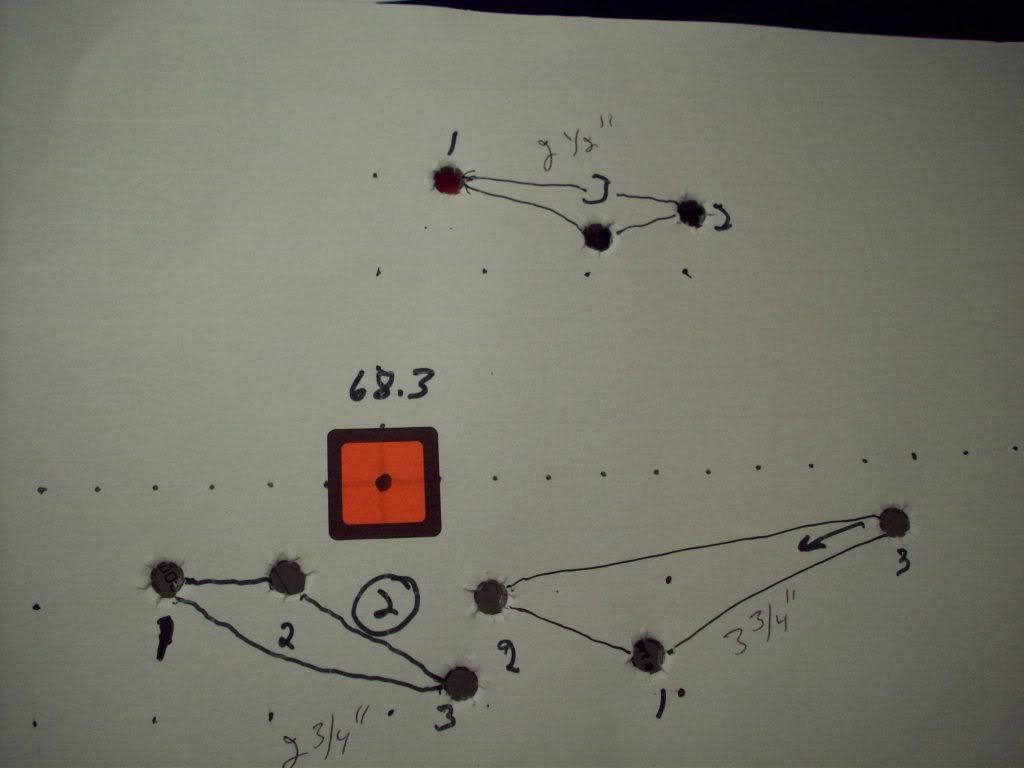

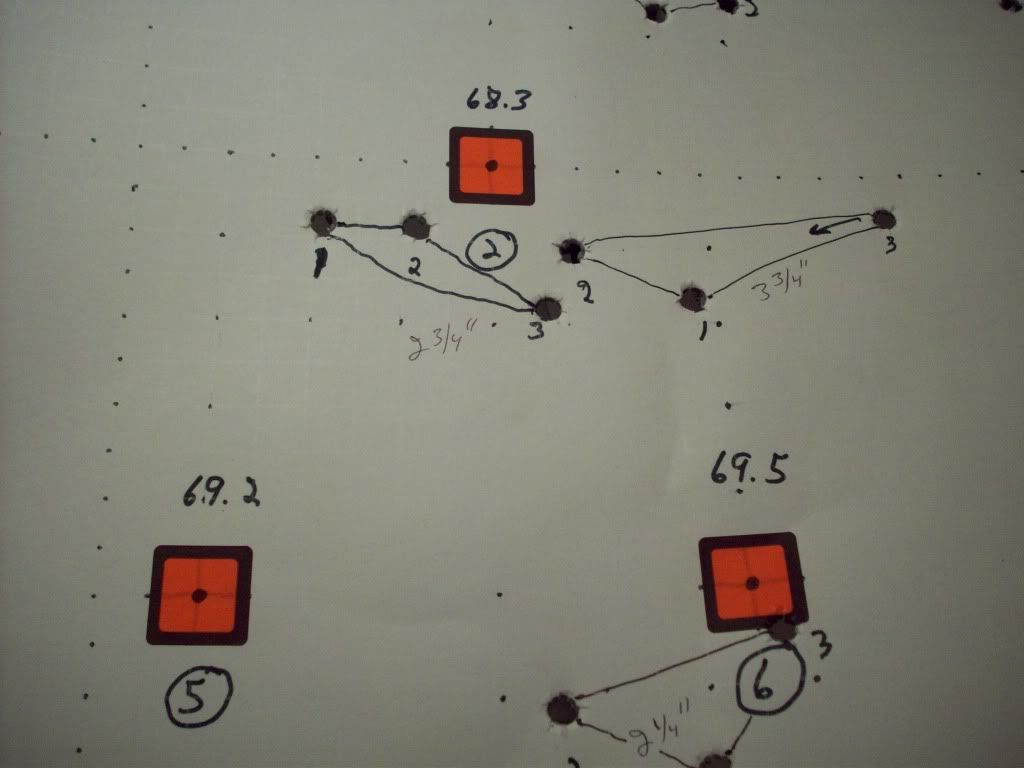

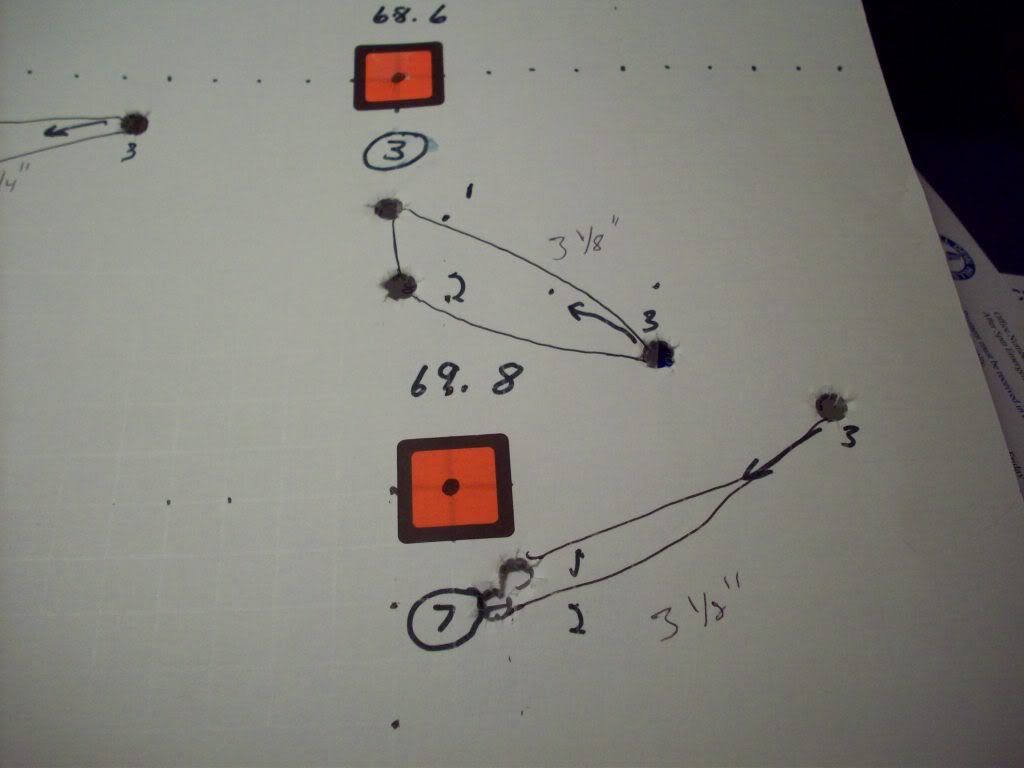

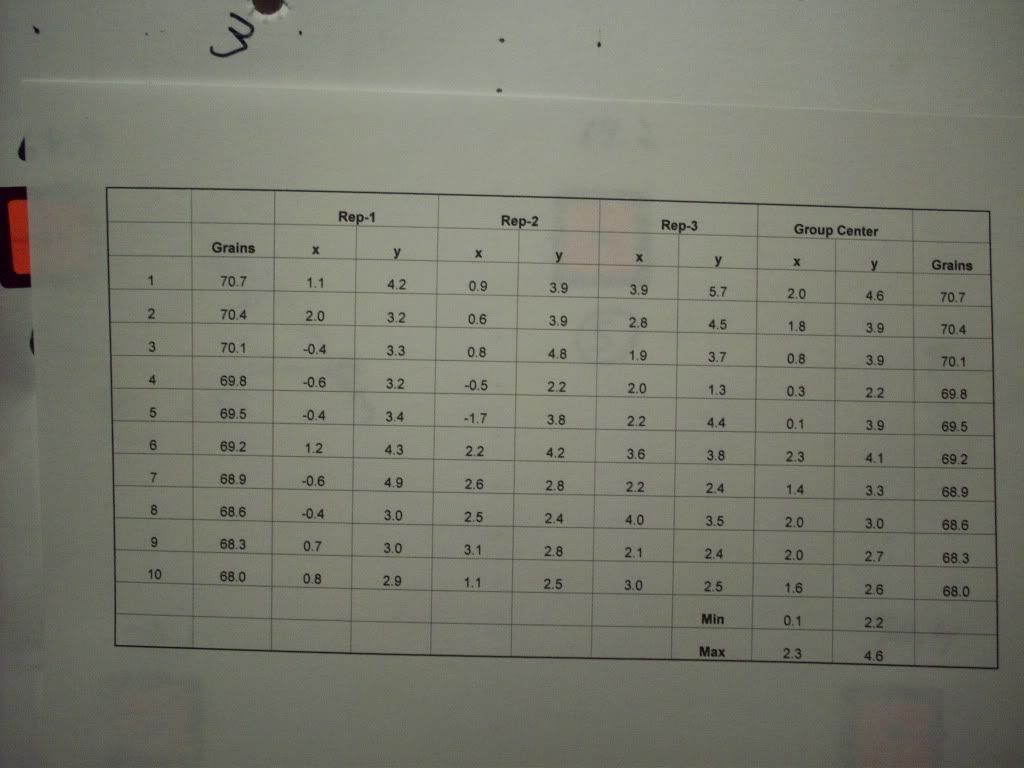

The OCW was shot with 168 grain Nosler HPBT and IMR 4350. The range was 300 yards with some wind from 140 degrees. There are 10 groups, with 0.3 grain increases, starting at the upper left with 68.0 grains. The shot group is always above the 1” red square. This was my first surprise. I had previously loaded some identical rounds with 68.0 grains of IMR4350 to use to get on the paper and establish where I wanted the groups to be on the target. I was using old Remington brass for these loads. The POI was zero elevation and about 2” right at 300 yards. Shot a three shot 1 1/4” group. Was pleased with this group at 300 yards. The OCW loads used brand new Nosler brass (2nds). The impact of the 68.0 grain charge with Nosler brass was three inches higher than the identical rounds with Remington brass and the groups stayed high over the course of the test. I don't think I will shoot >1,000 yards. I believe that anything >3,000 fps will get me to 1,000 yards supersonic. So a node in the 68-69 grain range may do what I want. I also want to save the 300 WM barrel. I looked at the center to center measurement of each group and also at the elevation spread within each group. I understand the change in elevation is a good indication of the robustness of the rifle and its loads with regard to locating its sweet spot. The target photos and the data follow.

This group center to center was 2.3 inches. The elevation was 0.1 MOA.

This group center to center was 2.5 inches. The elevation was 0.2 MOA.

This group center to center was 4.3 inches. The elevation was 0.4 MOA.

This group center to center was 3.8 inches. The elevation was 0.8 MOA.

This group center to center was 2.8 inches and the elevation was 0.2 MOA. The group beside it was center to center was 3.8 inches. The elevation was 0.3 MOA.

This group center to center was 3.1 inches. The elevation was 0.6 MOA.

This group center to center was 2.4 inches. The elevation was 0.5 MOA.

This group center to center was 2.3 inches. The elevation was 0.4 MOA.

This group center to center was 3.5 inches. The elevation was 0.6 MOA.

This is the data.

Looks like I need to start refining the load around 68.3 grains. Looks like the old girl is carrying them pretty good.

Would appreciate any comments.

Finally got around to doing an OCW. This is my first OCW. The rifle is a Mauser action with a 26" Douglas SS target barrel. It has a wood stock which is now fully glass bedded.

The OCW was shot with 168 grain Nosler HPBT and IMR 4350. The range was 300 yards with some wind from 140 degrees. There are 10 groups, with 0.3 grain increases, starting at the upper left with 68.0 grains. The shot group is always above the 1” red square. This was my first surprise. I had previously loaded some identical rounds with 68.0 grains of IMR4350 to use to get on the paper and establish where I wanted the groups to be on the target. I was using old Remington brass for these loads. The POI was zero elevation and about 2” right at 300 yards. Shot a three shot 1 1/4” group. Was pleased with this group at 300 yards. The OCW loads used brand new Nosler brass (2nds). The impact of the 68.0 grain charge with Nosler brass was three inches higher than the identical rounds with Remington brass and the groups stayed high over the course of the test. I don't think I will shoot >1,000 yards. I believe that anything >3,000 fps will get me to 1,000 yards supersonic. So a node in the 68-69 grain range may do what I want. I also want to save the 300 WM barrel. I looked at the center to center measurement of each group and also at the elevation spread within each group. I understand the change in elevation is a good indication of the robustness of the rifle and its loads with regard to locating its sweet spot. The target photos and the data follow.

This group center to center was 2.3 inches. The elevation was 0.1 MOA.

This group center to center was 2.5 inches. The elevation was 0.2 MOA.

This group center to center was 4.3 inches. The elevation was 0.4 MOA.

This group center to center was 3.8 inches. The elevation was 0.8 MOA.

This group center to center was 2.8 inches and the elevation was 0.2 MOA. The group beside it was center to center was 3.8 inches. The elevation was 0.3 MOA.

This group center to center was 3.1 inches. The elevation was 0.6 MOA.

This group center to center was 2.4 inches. The elevation was 0.5 MOA.

This group center to center was 2.3 inches. The elevation was 0.4 MOA.

This group center to center was 3.5 inches. The elevation was 0.6 MOA.

This is the data.

Looks like I need to start refining the load around 68.3 grains. Looks like the old girl is carrying them pretty good.

Would appreciate any comments.

Similar threads

- Replies

- 27

- Views

- 894