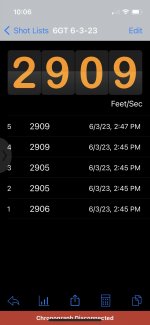

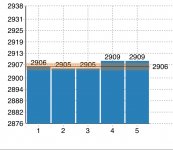

Great results. Hard to argue. Extreme spread of 4 fps is amazing.

Stupid questions follow. I hope you will be patient with me for asking so many.

(1) Will both the resizing die and the seating die work with my RCBS Rock Chucker press?

(2) I saw your recommendation for an .241 expander mandrel (with a link to the part for retaining it, thanks!) above.

(3) chamfer inside of the necks - what tool do you use on the 6GT Alpha brass to chamfer the inside of the necks?

(4) Match Burners - hmmm . . . interesting. Do you sort them or anything? That sort of consistency is not being reported by others here.

(5) I read your order of operations. When do you remove the old primers? Are you lubing and resizing dirty brass?

Thank you in advance for your patience with my questions.

Oh, one more thing - what is that screen shot from? I haven't bought a chronograph yet, and I am trying to decide where best to spend my money.

…5 shots isn’t much of a sample size, but when the numbers look like that, then it’s enough lol.

1. Yes

2. The part I linked above is so you can still decap with the Hornady die without using their expander ball. The mandrel die body and mandrel I use (actually called a “turning mandrel”) can be found here:

Our Generation II Expander Dies completely capture the mandrel within the die so the mandrel cannot pull out. An O-ring in the die cap allows the mandrel to float a bit and find its own center within the case neck. All three Generation II dies are...

www.brownells.com

Check out the SINCLAIR INTERNATIONAL 6mm (0.241") TiN Turning Mandrel SKU: 749019014 available Online at Brownells Today and many more Case Neck Turning products are available in our Reloading Department.

www.brownells.com

3. I use a Hornady Case Prep Duo tool but I change the stock chamfer tool to a VLD specific type (an RCBS one IIRC). I only deburr the outside of case mouths if it’s virgin brass or if I’ve just trimmed the cases, otherwise it’s chamfer only.

4. The Match Burners are great, lots of guys suck at this and turn their noses up at stuff before they know shit. I’ve out shot a lot of guys shooting A-Tips/Bergers with my plebeian Match Burners, I hope they stay cheap forever… a .300+ G7 for 30 cents or less per pull is a secret I don’t want to necessarily get out there lol. I did weigh/sort 500 of them one time and the tolerances were as good as anything else out there, so I haven’t bothered since and I’ve shot ~5000 of them and counting over 3 different barrels at this point.

5. I decap at the same time I’m FL sizing, and yes, more often than not I just lube the dirty brass (IPA/lanolin mix ~10:1 tossed in a 1 gallon ziplock bag), every now and again I tumble dirty brass first when it gets gnarly, but not usually.

I always tumble my lube off BEFORE running the cases through the mandrel. I use 30-40 grit corn cob blasting media which doesn’t get stuck in flash holes, it’s smaller than the corn cob most are used to and falls out of the cases like water so you don’t have to beat the crap out of them to get all the tumbling media out. Hitting the mandrel post-tumble is more important than most know, it fixes the case mouths which most guys have no idea get pretty fucked up while being tumbled. No wet tumbling ever for precision cases. This stuff is great:

Blast Media, Corn Cob, 20 to 40 Grit

For a chronograph, I had a Labradar and sold it, too much of a PITA to me, I switched to a Pro Chrono DLX and $20 Amazon tripod and I dig it for my needs, their Bluetooth/App integration is great and currently beats their more expensive competitors by a mile.

Cheers.