Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bighorn Origin barrel to a TL3

- Thread starter Ranger188

- Start date

Yes, but you need one of these:

I wouldn’t be a fan of a washer to fill the gap.

An Origin SA barrel will not work on a TL3 SA. You’ll have a unsupported case and excessive headspace.

Origin SA, MA, LA share the same tendons as TL3 LA and SR3 LA. TL3 SA and SR3 SA are different.

An Origin SA barrel will not work on a TL3 SA. You’ll have a unsupported case and excessive headspace.

Origin SA, MA, LA share the same tendons as TL3 LA and SR3 LA. TL3 SA and SR3 SA are different.

Correct. This is what you’re thinking of, lets you use a TL3 barrel with an Origin (the reverse of what you want to achieve):I thought I'd read where the recoil lugs were slightly different thickness.

That washer would be the difference.

HLR Origin 0.150 Thick Recoil lug | Hunt's Long Range

Here it is! Do you have a Big Horn TL3 and a Big Horn Origin? Do want to be able to swap the barrels between your actions? HLR has your answer! This precision ground 0.150" thick recoil lug will take the place of the 0.250" thick standard lug that comes with the Big Horn Origin.This

I will add that some smiths will include a boss section before the shoulder for the Origin's recoil to mate too. This will prevent an Origin barrel installing correctly as the TLS has thread all the way up to the shoulder.

www.snipershide.com

www.snipershide.com

Where to get Origin or t3 prefits

I have checked with a few places with no luck, but am wondering if anyone knows places who may have a 300 win mag proof carbon barrel. I would like to keep it to people who frequent or support the hide if possible. Just like everything, they seem pretty hard to come by these days!

And for those who don't know what that means (like me), after some Googlage it became clear that what's being described is: they cut the shank OD on the Origin prefits, then thread a portion of it but not all of it. The last little bit of it that doesn't get threaded won't screw into the TL3/SL3 LA as described in the linked post, which will throw off headspace and prevent the barrel shoulder from mating up with the action face.I will add that some smiths will include a boss section before the shoulder for the Origin's recoil to mate too. This will prevent an Origin barrel installing correctly as the TLS has thread all the way up to the shoulder.

Where to get Origin or t3 prefits

I have checked with a few places with no luck, but am wondering if anyone knows places who may have a 300 win mag proof carbon barrel. I would like to keep it to people who frequent or support the hide if possible. Just like everything, they seem pretty hard to come by these days!www.snipershide.com

@drwood96 Thanks for the link.

I wouldn’t be a fan of a washer to fill the gap.

I can't speak with first hand experience to the exact situation the OP is talking about, but I use the same type of ring (same dimensions, actually) to put TL-3 barrels (.790" tennon) on my American Rifle Co (.690" tennon) actions and provided the ring is ground/machined flat it's a non-issue. The Origin tennon is .890" so I don't see why it wouldn't work the same way going to TL-3.

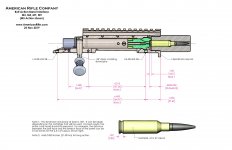

Where are you able to see that ARC actions utilize a 0.690” tenon? This is the only print I found that called out that dimension (through some arithmetic), and it seems to indicate that it’s 0.675” but can be more (up to 0.695”) or potentially even less, based on Note 1:I can't speak with first hand experience to the exact situation the OP is talking about, but I use the same type of ring (same dimensions, actually) to put TL-3 barrels (.790" tennon) on my American Rifle Co (.690" tennon) actions and provided the ring is ground/machined flat it's a non-issue. The Origin tennon is .890" so I don't see why it wouldn't work the same way going to TL-3.

Attachments

The tennon works in conjunction with the exposed case. You can make it work at .690 with .135 exposed case. Ideally there'd be a bit more case sticking out for the ARC extractors, but it works and lets me buy commonly available prefits and/or interchange them with TL-3's and Origins (friends, work guns, etc..).

Cool, got it. That's exactly what I've been trying to figure out, for ARC actions specifically, glad to hear someone's doing it successfully already. I've been figuring I pick up one of the PVA headspace conversion rings to run TL3 prefits on the ARC, and either stack another for Origin prefits (not preferred) or have someone with a lathe cut me a 0.200" stainless ring; what do you do to run Origin prefits?The tennon works in conjunction with the exposed case. You can make it work at .690 with .135 exposed case. Ideally there'd be a bit more case sticking out for the ARC extractors, but it works and lets me buy commonly available prefits and/or interchange them with TL-3's and Origins (friends, work guns, etc..).

Bumping this thread with the announcement of Zermatt's new Ti action with TL3 threads.

How difficult would it be for a smith to recut for a TL3 (if even possible)? If not, is the PVA collar the next best option? Have 2 CF origin prefits that I would love to save 10oz on the action weight with.

How difficult would it be for a smith to recut for a TL3 (if even possible)? If not, is the PVA collar the next best option? Have 2 CF origin prefits that I would love to save 10oz on the action weight with.

If I’m thinking about your question correctly, it’s a full rechamber job to convert an Origin prefit to TL3. You need the breech and chamber to move towards the shoulder interface; the only way to do that other than a spacer ring or thicker recoil lug (not generally an option on an integral lug action) is to rechamber to move the breech face and chamber towards the existing shoulder. Might be able to save a bit on the tenon thread work, but a chamber + thread job will typically run you $250-300 from solid smiths.

I’d just run the $25 spacer that is designed for exactly this purpose.

I’d just run the $25 spacer that is designed for exactly this purpose.

That was essentially my question / what I thought the answer would be. As long as the unsupported brass isn't too much of an issue, sounds like the collar is the perfect solution.If I’m thinking about your question correctly, it’s a full rechamber job to convert an Origin prefit to TL3. You need the breech and chamber to move towards the shoulder interface; the only way to do that other than a spacer ring or thicker recoil lug (not generally an option on an integral lug action) is to rechamber to move the breech face and chamber towards the existing shoulder. Might be able to save a bit on the tenon thread work, but a chamber + thread job will typically run you $250-300 from solid smiths.

I’d just run the $25 spacer that is designed for exactly this purpose.

We made 100 collars about 4 years ago.

The last of them sold out maybe 2 months back and I wasn't planning to make more simply because there was so little call for them though I suppose I can revisit that decision if people here want enough of them to make it worthwhile (25pc).

However, out of the 100 of them that went out the door nobody returned one or made even so much as an email to say they were having problems. They work fine.

The last of them sold out maybe 2 months back and I wasn't planning to make more simply because there was so little call for them though I suppose I can revisit that decision if people here want enough of them to make it worthwhile (25pc).

However, out of the 100 of them that went out the door nobody returned one or made even so much as an email to say they were having problems. They work fine.

I mean I’m game for one, just need 24 more people to hop on boardWe made 100 collars about 4 years ago.

The last of them sold out maybe 2 months back and I wasn't planning to make more simply because there was so little call for them though I suppose I can revisit that decision if people here want enough of them to make it worthwhile (25pc).

However, out of the 100 of them that went out the door nobody returned one or made even so much as an email to say they were having problems. They work fine.

I'm gameWe made 100 collars about 4 years ago.

The last of them sold out maybe 2 months back and I wasn't planning to make more simply because there was so little call for them though I suppose I can revisit that decision if people here want enough of them to make it worthwhile (25pc).

However, out of the 100 of them that went out the door nobody returned one or made even so much as an email to say they were having problems. They work fine.

I'd be in for the normal one, and a double-thick one; it'd let me run an Origin prefit on my Archimedes

I'd also pick up one (or two different) that allowed additional options to put on an Archimedes. Fisher T&C had me a prefit in amazing time but having options is always a good thing IMO.

Maybe. The protrusion is different between the two actions by quite a bit. Enough that the extractor on an Archimedes drags on the face of the Origin barrel. In fact it drags so badly that it can bind up the extractor and has a tendency to make accuracy go to shit as well as cause improper headspace under certain conditions. I looked into it and decided not to do it because there was enough room for problems that I didn't want the liability.I'd be in for the normal one, and a double-thick one; it'd let me run an Origin prefit on my Archimedes

We have a 1 week time available on prefits...I'd also pick up one (or two different) that allowed additional options to put on an Archimedes. Fisher T&C had me a prefit in amazing time but having options is always a good thing IMO.

Well crap, I tried to call once but I guess I should have tried harder. I've heard horror stories of 8 month to 1 yr waits. 6- 10 weeks I was used to but that seemed crazy. Small market with few to serve I guess. At least there are plenty options for consumers. Thank you for your time sir.Maybe. The protrusion is different between the two actions by quite a bit. Enough that the extractor on an Archimedes drags on the face of the Origin barrel. In fact it drags so badly that it can bind up the extractor and has a tendency to make accuracy go to shit as well as cause improper headspace under certain conditions. I looked into it and decided not to do it because there was enough room for problems that I didn't want the liability.

We have a 1 week time available on prefits...

Years ago that was the problem. We've since vertically integrated a lot of stuff that brings lead times down, changed staffing, changed how we handle parts ordering (aka we don't order your parts so we can't be blamed for taking so long to build something with parts we didn't receive). The VM for the shop says that if you don't get us on the phone to email. This is so that phone distractions don't cause screwups on machines and we answer emails every day, I was here til 0100 this morning doing holiday weekend emails and paperwork.Well crap, I tried to call once but I guess I should have tried harder. I've heard horror stories of 8 month to 1 yr waits. 6- 10 weeks I was used to but that seemed crazy. Small market with few to serve I guess. At least there are plenty options for consumers. Thank you for your time sir.

Yeah I ain’t forgot either, I need to give Josh a call and have him explain this issue with Origin barrels in dumb people terms. Even just being able to take TL3 barrels would be awesome.Have a buddy who needs an origin to tl3 spacer. He bought an origin barrel thinking his new medium action was origin. Today he spun it together, and yup, didn't shoulder up, as its a tl3. @bohem hook us up and make a run of these please Josh!

Hey Josh I would be in for 4 . Just to help get the count up. I do have a few actions and all can be used if needed.We made 100 collars about 4 years ago.

The last of them sold out maybe 2 months back and I wasn't planning to make more simply because there was so little call for them though I suppose I can revisit that decision if people here want enough of them to make it worthwhile (25pc).

However, out of the 100 of them that went out the door nobody returned one or made even so much as an email to say they were having problems. They work fine.

I'd be in for one or two.@bohem Is there any chance you'd consider another run of these collars? I can get one spun up custom if you aren't interested, and would be willing to share the dimensions, but it sounds like there might be enough interest to justify another batch?

I'd take one as well.@bohem Is there any chance you'd consider another run of these collars? I can get one spun up custom if you aren't interested, and would be willing to share the dimensions, but it sounds like there might be enough interest to justify another batch?

My understanding is that these used to only be required for the TL3/SR3 short actions in order to run barrels cut for the origins and long action TL3/SR3 (which had the same tenon lengths). Do the medium actions have the same tenon length as the long actions and origins as well?

I know the medium origin uses short action origin tenon. That's all I know of for sure as I have a short action origin barrel on a medium origin, headspaced properly.My understanding is that these used to only be required for the TL3/SR3 short actions in order to run barrels cut for the origins and long action TL3/SR3 (which had the same tenon lengths). Do the medium actions have the same tenon length as the long actions and origins as well?

I'm pretty sure the tenon is the same for all Origins. Its discussed in the Origin build thread.

ETA- all 3 action lengths are called out on their tenon print.

ETA- all 3 action lengths are called out on their tenon print.

Last edited:

I mean I’m game for one, just need 24 more people to hop on board

I would buy one...

I'm game

I'd be in for the normal one, and a double-thick one; it'd let me run an Origin prefit on my Archimedes

I'd also pick up one (or two different) that allowed additional options to put on an Archimedes. Fisher T&C had me a prefit in amazing time but having options is always a good thing IMO.

Have a buddy who needs an origin to tl3 spacer. He bought an origin barrel thinking his new medium action was origin. Today he spun it together, and yup, didn't shoulder up, as its a tl3. @bohem hook us up and make a run of these please Josh!

Hey Josh I would be in for 4 . Just to help get the count up. I do have a few actions and all can be used if needed.

@bohem was sufficient demand ever solidified for these? I’m in for 2, but looks like the 12 accounted for in this thread may not meet your minimum.I'd be in for one or two.

I spoke with my smith, who's actually a badass machinist by trade, he's going to make a small run of these this winter for us that want one. They'll be 1.25od to run on either 1.25 or 1.20 Shank barrels. 0.100 thick and machined flat on both sides. I'll test his prototype on my rig for headspace verification, and then he'll make a large run and send them to nitride before sale.

For those in my situation, with an ARC action, whoever it was who warned about the breech length on a TL3 was correct. Ended up obtaining one of these spacers and had to have my smith take 0.025” off the breech face to allow the bolt to close. Headspace was good to go.

I’m totally game for oneI spoke with my smith, who's actually a badass machinist by trade, he's going to make a small run of these this winter for us that want one. They'll be 1.25od to run on either 1.25 or 1.20 Shank barrels. 0.100 thick and machined flat on both sides. I'll test his prototype on my rig for headspace verification, and then he'll make a large run and send them to nitride before sale.

I just wanted to amplify this comment here. I had a machinist friend make a washer (you need .1000 thick, 1.20-1.250 OD and an ID greater than large major thread/boss section, I ended up needing a 1.0625 to slide on.

However, both proof barrels have an enlarged unmilled boss section while my x-caliber barrel has the tenon cut farther. Need to verify with proof for their tenon print, but will likely also need to either rethread the tenon or have the boss undercut to minor thread dia to allow TL3 to screw all the way in.

However, both proof barrels have an enlarged unmilled boss section while my x-caliber barrel has the tenon cut farther. Need to verify with proof for their tenon print, but will likely also need to either rethread the tenon or have the boss undercut to minor thread dia to allow TL3 to screw all the way in.

I will add that some smiths will include a boss section before the shoulder for the Origin's recoil to mate too. This will prevent an Origin barrel installing correctly as the TLS has thread all the way up to the shoulder.

to

Where to get Origin or t3 prefits

I have checked with a few places with no luck, but am wondering if anyone knows places who may have a 300 win mag proof carbon barrel. I would like to keep it to people who frequent or support the hide if possible. Just like everything, they seem pretty hard to come by these days!www.snipershide.com

Attachments

Leave it to proof to be fn lazy and not put the relief cut in the tenon. They're cut to pint, zermatt tl3 and origin show no relief on their spec sheet, but I know my smith put a relief cut that's smaller diameter than major thread od all the way to shoulder.

@THEWAKLER, can you measure the major diameter of that boss that's between the threads and shoulder?

@THEWAKLER, can you measure the major diameter of that boss that's between the threads and shoulder?

Last edited:

PROOF does that to better locate the recoil lug on the barrel for Origin pre-fits.Leave it to proof to be fn lazy and not put the relief cut in the tenon. They're cut to pint, zermatt tl3 and origin show no relief on their spec sheet, but I know my smith put a relief cut that's smaller diameter than major thread od all the way to shoulder.

@THEWAKLER, can you measure the major diameter of that boss that's between the threads and shoulder?

It's not necessary for function, but it's definitely not laziness on their end to cut it the way they do.

1.0610Leave it to proof to be fn lazy and not put the relief cut in the tenon. They're cut to pint, zermatt tl3 and origin show no relief on their spec sheet, but I know my smith put a relief cut that's smaller diameter than major thread od all the way to shoulder.

@THEWAKLER, can you measure the major diameter of that boss that's between the threads and shoulder?

I confirmed with proof, all of their origin prefits are cut like this.

Will be sending to have a smith undercut to probably .080 off the shoulder.

Last edited:

Similar threads

- Replies

- 2

- Views

- 133

- Replies

- 12

- Views

- 603